Abstract

Wild blueberry fields have a significant proportion of bare spots/weed patches, scattered throughout the field, emphasizing the need for targeted fertilizer applications. The existing prescription map-based variable rate (VR) spreader cannot take account of the presence of small, irregularly shaped bare spots/weed patches during fertilization as only each half of the boom (3.66 m; 6 nozzles) is controlled—not each individual nozzle. The objective of this study was to modify the existing VR spreader for spot-application (SA) of fertilizer only in plant areas. The sensing and control system developed was capable of discriminating bare spots/weeds from plants, and shifting the independent control from 6 nozzles (3.66 m) to each pair of nozzles (1.22 m). The modified VR granular (MVRG) fertilizer spreader was able to use a prescription map and the sensing and control systems simultaneously within a field, to avoid fertilization in variable sized bare spots/weed patches. The performance of the MVRG fertilizer spreader was evaluated under two different lighting conditions and three ground speeds. Twelve bare spots/weed patches and plant areas were randomly selected in the wild blueberry field and weighed sticky collectors were placed to collect clay filler which was used as an analogue of fertilizer. The MVRG fertilizer spreader was operated on SA (application only in plant areas) and uniform (application in plants and bare spots/weed patches) modes alternately and the collectors were collected and re-weighed. Results of this study suggested that the MVRG spreader was capable of detecting plants/bare spots/weeds for SA of fertilizer. Spot application of fertilizer can help to reduce excessive fertilizer usage in bare spots/weeds, which will increase farm profitability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The wild blueberry is an important horticultural crop of Maine, Quebec and the Atlantic Canadian provinces with over 93 000 ha under management, with annual fruit production of 117 000 tons valued at $491 million (Yarborough 2013). Wild blueberry plants spread by underground rhizomes which can grow up to 0.3 m during the growing season (Hall et al. 1979). The wild blueberry production is restrained to a 2-year crop cycle by pruning the plants near to ground level. Pruning is performed either by burning or flail mowing to trigger new shoot production in the vegetative year, which sets the basis for fruit production during the fruit year (Jensen and Yarborough 2004). The forests naturally containing patches of wild blueberry were developed into commercial fields (Jamieson 2008). Bare spots/weed patches may cover significant proportions of the total field area in recently developed wild blueberry fields (Zaman et al. 2010a). Unnecessary fertilization in bare spots and weed patches can result in the degradation of subsurface water quality and stimulation of weed growth, as well as a significant increase in the cost of production. The peculiar features of the wild blueberry cropping system emphasize the need for the development of a real-time sensing and control system to vary fertilizer application rate based on the substantial variability in soil/crop characteristics and presence of bare spots/weed patches.

The need for precise application of agro-chemicals and the introduction of global navigation satellite systems (GNSS) and geographic information systems (GIS) has driven researchers to develop and evaluate variable rate technologies (VRTs) (Dammer et al. 2008; Michaud et al. 2008; Saleem et al. 2013). However, the VRTs developed were based on the mapping and the development of prescription maps in GIS software for fertilizer applications. The unevenly-distributed, small-sized and irregularly-shaped bare spots/weed patches in wild blueberry fields cannot be included in prescription maps for no fertilizer application. The reason is the limited control of the fertilizer boom of the existing spreader which can turn ON/OFF not less than 6 nozzles at a time, thus limiting the size (>3.66 m in width) of bare spots/weed patches to be included in a prescription map. Therefore, design modifications are required in the existing spreader to give independent control of each pair of nozzles and an automated sensing and control system for real-time precise fertilizer application only in plant areas of the field.

Methods have been developed in the past to detect and differentiate weeds from bare spots and/or crop for precise herbicide applications in different cropping systems (Beck 1998; Hanks and Beck 1998). Sui et al. (1989) used ultrasonic sensors to measure plant characteristics of bush-type plants. Tall weeds and height difference between plants and bare spots (completely bare of vegetation) indicated the potential for weeds and bare spots detection using ultrasonic sensors in wild blueberry fields. Swain et al. (2009) developed and tested an ultrasonic system for weeds (taller than plants) and bare spots (completely bare of vegetation) detection and mapping within wild blueberry fields. However, the variations in wild blueberry plant height from 0.1 m to 0.4 m (Farooque et al. 2014) and plant density from 870 to 1230 stems m−2 (Eaton 1994) limits the use of ultrasonic sensors to detect short weeds and bare spots in wild blueberry fields. Therefore, the researchers sought an automated ground measurement method using a digital photography technique to differentiate plants from weeds and bare spots. Zhang et al. (2010) introduced a machine vision system to detect bare spots in wild blueberry fields using a digital photography technique. Esau et al. (2014) used digital color cameras, custom image processing software, fast controllers and processors to differentiate bare spots from wild blueberry plants in real-time. Chattha et al. (2014) developed a modified variable rate granular fertilizer spreader (MVRG) and evaluated its software and hardware components for spot-application (SA) of clay filler only in green grass areas of the field. The clay filler was used to avoid repeated fertilizer deposition as it can adversely affect the field soil conditions and environment (Chattha et al. 2014). The MVRG fertilizer spreader made use of normalized green-ratio (G-ratio) image processing software to differentiate between the artificial bare spots and green foliage. Chang et al. (2012) developed a color co-occurrence matrix (CCM)-based algorithm to identify the blueberry plants, weeds and bare spots on the basis of texture analysis in real-time for SA of agrochemicals in wild blueberry fields.

The machine vision sensing research has largely been done under controlled lighting conditions. However, one of the major concerns regarding the use of machine vision in outdoor conditions is variable illumination (Tian and Slaughter 1998; Steward and Tian 1999; Chandler 2003). Marchant and Onyango (2002) developed a method for calculating invariant spectra of light reflected from surfaces under variable daylight illumination conditions. They reported some variations in results due to difference in local daylight conditions and the standards set by the International Commission on Illumination (CIE Central Bureau, Vienna, Austria), and the rest by measurement and modeling errors. Uncontrolled outdoor working conditions differ significantly from controlled indoor facilities. Therefore, machine vision systems designed for the agricultural sector must be capable of operating in these unstructured environments (Tian et al. 1997).

The objective of this study was to evaluate the software and hardware components of the MVRG fertilizer spreader for SA of fertilizer only in blueberry plant areas under variable lighting conditions and at different ground speeds of the fertilizer spreader.

Materials and methods

Modified variable rate granular fertilizer spreader

The unevenly distributed and irregularly shaped bare spots/weed patches in wild blueberry fields require an automated sensing and control system for real-time detection and avoidance during fertilization. A 7.32-m wide boom Valmar 1255 pull-type variable rate granular fertilizer spreader (Valmar Airflo Inc., Elie, MB, Canada) with 12 nozzles spaced at 0.61 m and independent control on each half of the fertilizer boom was modified. The MVRG fertilizer spreader was able to control each pair of nozzles (1.22 m spacing; 2 nozzles) independently rather than operating a half boom section at a time (3.66 m; 6 nozzles) (Chattha et al. 2014). A diverting valve bank with 12 solenoid valves (Model: V3221-08T, E.MC®, Yinzhou, Ningbo, China), single acting pneumatic cylinders (Model: E.MC®, Yinzhou, Ningbo, China) and an air compressor (Model: CBHRFP209400RB, Campbell Hausfeld/Scott Fetzer Co., OH, USA) were incorporated into the commercial Valmar 1255 granular fertilizer spreader. Each pneumatic cylinder was connected to a gate at one side and with solenoid valve at the top. The position of the custom-made valve bank in the MVRG fertilizer spreader was above Venturi cups and air manifold. The solenoid valve operates the pneumatic cylinder to close the Venturi opening of the nozzle, which is directly above the bare spot/weed patch, by shutting the gate off. The return auger system guides any unused fertilizer into the hopper.

An automated sensing and control system comprising of six μEye color cameras, a ruggedized laptop computer, 8-channel VR controller, programmable logic controller, pocket PC using wireless Bluetooth® radio with Windows Mobile®, solenoid valves, pneumatic cylinders and custom software was developed and incorporated into the MVRG fertilizer spreader. Detailed hardware functioning of the MVRG fertilizer spreader was described in Chattha et al. (2014).

Software development

The CCM algorithm (Chang et al. 2012) and G-ratio algorithm (Chang et al. 2014; Chattha et al. 2014) were fused together in a C++ program using Visual Studio 2010 (Microsoft®, Redmond, WA, USA). The software fusion developed was used for real-time detection of bare spot and green foliage within wild blueberry fields. The digital color images taken by six µEye color cameras (Model: UI-1220SE/C, IDS Imaging Development System Inc., Woburn, MA, USA) mounted on the front camera boom were transferred to a ruggedized laptop computer (Model: Latitude E6400 XFR, Dell Inc., Round Rock, TX, USA). The image processing software installed in the ruggedized laptop acquired a 640 × 128 pixel image consisting of five 128 × 128 pixel 24-bit red–green–blue (RGB) sub-images, corresponding to 1.22 m × 0.31 m area of interest from each camera for processing in real-time. The CCM algorithm was customized to discriminate bare spot areas from non-bare spot areas (anything other than bare spots) based on each 128 × 128 pixel sub-image (different size from Chang et al. (2012)) and then a decision routine will send 0 VDC (OFF signal) to an 8-channel variable rate controller (VRC) if a bare spot was detected. Secondly the G-ratio, (G × 255)/(R + G + B), algorithm differentiated the plant areas from green weeds. The noise causing hot and dark spots were removed using comparison (R > 200 and G > 200 and B > 200) or (R + G + B < 50). The threshold value (>85) was used for segmentation to find the apparent foliage green pixels from the remaining pixels. A de-noise process using a 2 × 2 erosion filter was applied to remove small clusters of noise resulting from specular reflection. In the next step, the program calculated the number of over-threshold green pixels. The software sends the 0 VDC (OFF signal) to the VRC if the percentage of green pixels calculated by G-ratio algorithm is greater than 10 % (weeds) and 5 VDC (ON signal) if the percentage is less than 10 % (mowed plants) (Fig. 1). The VRC conveys the signal to a programmable logic controller (PLC; Model: Omron ZEN-20C1DR-D-V2, Santa Clara Systems Inc., CA, USA) for fertilization in the specific section of the boom where the targets had been detected with time adjustment considering image acquisition/processing time and solenoid response time and speed variation. The PLC adjusts another time difference among the nozzles (200–780 ms) which could occur with a pneumatic spreading system.

Field tests

Test 1

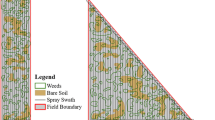

The fertilizer normally used in wild blueberry fields contains 16.5 % of N, 34.5 % of P, 4.5 % of K and 44.5 % of clay filler (Saleem et al. 2013). The clay filler has the same physical appearance as granules of fertilizer. Therefore, clay filler was used in lieu of actual fertilizer for the first evaluation test as the repeated use of fertilizer can adversely affect the field soil conditions and environment. A wild blueberry field was selected near Debert (45°26′28″N and 63°27′02″W) in central Nova Scotia. The performance of the software and hardware components of the MVRG fertilizer spreader for SA of fertilizer was evaluated in the selected field. A test track, 7.3 m in width and 100 m in length was made (Fig. 2). The track boundary and bare spots/weed patches were mapped with a real-time kinematic GPS (RTK-GPS). Equal number (12) of bare spots/weed patches and plant areas were randomly selected in the field. Pre-weighed sticky collectors (Model: Catch Master, AP&G Co., Inc., Brooklyn, NY, USA) were placed on the selected bare spots/weed patches and plant areas to collect the applied clay filler (Fig. 2). The MVRG fertilizer spreader was operated at three different ground speeds (1.6, 3.2 and 4.8 km h−1) and two different lighting conditions (mainly cloudy and mainly sunny), to test the software and hardware components of the MVRG fertilizer spreader for SA. The spreader was operated at SA and uniform (UN) modes for each combination of ground speed and lighting condition. The clay filler collected by each sticky collector was weighed and recorded.

Test 2

After testing the hardware and software components of the MVRG fertilizer spreader at Debert site using the clay filler, another wild blueberry field was selected in Kemptown (45°31′50″ N and 63°07′45″W), Nova Scotia to evaluate the performance accuracy of the MVRG spreader using actual fertilizer. The selected field was in vegetative sprout year in 2012.

Slope variability of the selected field was measured and mapped with a slope measurement and mapping system at the start of the experiment (Zaman et al. 2010b). Geostatistical analysis was performed using GS+Geostatistics for the Environmental Sciences Version 9 software (Gamma Design Software, LLC, Woodhams St, Plainwell, MI, USA) to characterize the spatial variability in slope within the selected site. The semivariogram was produced and modeled using several authorized models that can be fitted to the data and the one with minimum nugget was selected (Oliver, 1987). The best fitted semivariogram model for the Kemptown site was spherical. The geostatistical analysis suggested large spatial variability in slope with the range of influence (15 m; R 2 = 0.88) within the selected field (Fig. 3). The substantial variation in slope and presence of bare spots/weeds within blueberry fields emphasize the need for site-specific fertilization to increase the fruit yield, farm profitability and mitigate environmental risks. The partial sill and ranges of influence from the semivariogram were utilized in kriging interpolation to produce a detailed slope map (Fig. 4). The field boundary and bare spots/weed patches of the selected field were mapped using RTK-GPS. The field was divided into three slope categories, i.e., low slope (Zone 3, 0 ≤ slope ≤ 12°), moderate slope (Zone 2, 12 < slope ≤ 24°) and steep slope (Zone 1, slope > 24°) (Fig. 4).

The selected field was approximately divided into three equal sections for fertilizer application, first section received UN fertilization (UN section), second received variable rate (VR) fertilization using prescription map only (VRPM section), and the third section received VR fertilization using prescription map and real-time detection system (VRPRD section) of the MVRG fertilizer spreader. The fertilizer (N, P, K: 16.6, 34.5, 4.5) was applied in the 3rd week of May during sprout year. The fertilizer application rates of 200, 150 and 100 kg ha−1 were allocated according to the prescription map in steep, moderate and low slope areas of VRPM and VRPRD sections, respectively (Saleem et al. 2013). Big (>3.66 m) and symmetrical bare spots/weed patches were defined as a separate class in the VRPM section and zero fertilizer rate was allocated to them. Bare spots/weed patches in the VRPRD section were not included in the prescription map as the real-time sensing and control system of the MVRG spreader was expected to detect and avoid fertilization in bare spots/weed patches of the VRPRD section during fertilization. Prior to the fertilizer application, six small and asymmetrical bare spots/weed patches and the same number of plant areas were selected in each management zone of the VRPM and VRPRD sections to place the sticky collectors for the evaluation of the MVRG fertilizer spreader (Fig. 4).

Statistical analysis

The weights of the clay filler collected by the sticky collectors placed on the plant areas in SA and UN treatments during the test at Debert site were compared using a paired t test. Paired t test was also performed to compare both SA and UN treatments for the collected clay filler by the sticky collectors placed on bare spots/weed patches. The level of significance used for both tests was 5 %. The analysis was performed using Minitab 16 (Minitab Inc., NY, USA) statistical software.

Two sample t test at 5 % level of significance was used to compare the fertilizer weights collected from the plant areas of the VRPRD and VRPM sections during actual fertilization at the Kemptown site. Similarly, the weights collected from the bare spots/weed patches of both sections (VRPRD and VRPM) were also compared using two sample t test in Minitab 16 statistical software.

Results and discussion

Evaluation at Debert site

Mainly sunny conditions

The experiment under mainly sunny conditions (Table 1) was conducted on May 08, 2012 at the Debert site. The temperature ranged from −2 to 18 °C, average humidity was 58.5 %, and wind speed was 10.5 km h−1 from the West (National Climate Data and Information Archive 2012).

Results indicated no significant difference between SA and UN treatments in applying clay filler in plant areas at the ground speed of 1.6 km h−1 (Table 2). The weight of the clay filler collected by the sticky collectors at SA and UN modes of operation ranged from 13.0 to 21.3 g m−2 and from 12.7 to 20.0 g m−2, respectively. Similar results were obtained at the ground speeds of 3.2 and 4.8 km h−1, indicating no significant difference between SA and UN treatments in applying clay filler in plant areas of the wild blueberry field (Table 2).

The tests were repeated to compare both SA and UN treatments for the collected clay filler by the sticky collectors placed on the bare spots/weed patches. The MVRG fertilizer spreader was operated at a ground speed of 1.6 km h−1 and the applied clay filler was collected. Results indicated a significant difference between SA and UN treatments (Table 2), suggesting that the bare spots/weed patches received much less clay filler during SA treatment. Similar results were obtained at the ground speed of 3.2 km h−1 using SA treatment (Table 2). The test was repeated at a ground speed of 4.8 km h−1 and the weights of the clay filler collected by the sticky collectors at SA and UN modes of operation ranged from 0.0 to 25.3 g m−2 and from 12.3 to 29.3 g m−2, respectively. Despite the significant difference between SA and UN treatments, few bare spots received clay filler using SA treatment at 4.8 km h−1 (Table 2). The bare spots which received clay filler were very close to highly undulating ground surfaces. The higher ground speed (4.8 km h−1) and steep slope surface induced intensive movement in the front camera boom which might have caused the cameras to take blurred images. Therefore, the developed CCM algorithm could not differentiate these bare spots from plants at the ground speed of 4.8 km h−1.

Mainly cloudy conditions

The experiment under mainly cloudy conditions (Table 1) was conducted at Debert site, on May 07, 2012. The temperature ranged from 1 to 11 °C, average humidity was 78 % and wind speed was 16 km h−1 from the South (National Climate Data and Information Archive 2012).

The experiment was designed for the paired comparison of the weights of the clay filler collected by the sticky collectors placed on plant areas using SA and UN treatments. Results indicated non-significant difference between SA and UN treatments in applying clay filler in plant areas at a ground speed of 1.6 km h−1 (Table 3). The weight of the clay filler collected by the sticky collectors at SA and UN modes of operation ranged from 13.0 to 22.3 g m−2 and from 12.0 to 22.3 g m−2, respectively. Similar results were obtained at ground speeds of 3.2 and 4.8 km h−1, suggesting no significant difference between SA and UN treatments in applying clay filler in plant areas of the wild blueberry field (Table 3). Paired t-test was used to compare the SA and UN treatments for the collected clay filler by the sticky collectors placed on the bare spots/weed patches. Results indicated significant difference between SA and UN treatments at 1.6 and 3.2 km h−1 ground speeds with no clay filler application in bare spots/weed patches during SA treatment (Table 3). Results obtained at a ground speed of 4.8 km h−1 under mainly cloudy conditions reinforced the results obtained under mainly sunny conditions at the same settings of the MVRG fertilizer spreader, suggesting failure to detect and skip few bare spots/weed patches during SA treatment (Table 3).

The potential reason for limited accuracy for SA while moving at a ground speed of 4.8 km h−1 could be the intensive movements experienced by the front camera boom on undulating ground surface causing the cameras to take blurred images. Therefore, the CCM algorithm developed could not differentiate some of the bare spots from plants at a ground speed of 4.8 km h−1. Moreover, non-significant difference between SA and UN treatments under cloudy conditions and at a ground speed of 4.8 km h−1 using sticky collectors could be due to blurred images and cloudy conditions with sunny breaks (Table 3). Further research and experimentation for the development of more flexible software and hardware is needed to make MVRG fertilizer spreader rigorous to apply fertilizer at higher speeds in commercial wild blueberry fields.

Evaluation at Kemptown site

Results of evaluation under sunny and cloudy conditions suggested that the MVRG fertilizer spreader can be used for the SA of fertilizer in wild blueberry fields. A test was conducted to assess the performance of the MVRG fertilizer spreader in a wild blueberry field at the Kemptown site. The MVRG fertilizer spreader was operated at the ground speed of 3.2 km h−1. A two sample t-test was performed to compare VRPRD and VRPM treatments. The weights collected by the sticky collectors placed in the steep slope plant areas (fertilizer application rate of 200 kg ha−1) of the VRPRD and VRPM sections were compared. Results indicated no significant difference between VRPRD and VRPM treatments (Table 4). Results also suggested that both treatments were identical in applying fertilizer in plant areas. Similar results were obtained when the weights collected from the moderate slope (fertilizer application rate of 150 kg ha−1) and the low slope plant areas (fertilizer application rate of 100 kg ha−1) of VRPRD and VRPM sections were compared (Table 4).

The weights of the fertilizer collected by the sticky collectors placed on the bare spots/weed patches of VRPRD and VRPM treatment sections were also compared using a two sample t-test. Results indicated significant difference between VRPRD and VRPM treatments (Table 4), suggesting that the MVRG fertilizer spreader performed efficiently in applying fertilizer only in plant areas using the VRPRD treatment.

Conclusions

The MVRG fertilizer spreader was tested for SA of clay filler (applying clay filler only in plant areas) under two different lighting conditions at different ground speeds. The ground speeds of 1.6 and 3.2 km h−1 were found to be suitable for real-time detection and fertilizer application under sunny and cloudy conditions. Poor performance of the MVRG fertilizer spreader was observed at a ground speed of 4.8 km h−1 under both lighting conditions. The combination of higher ground speed (4.8 km h−1) and undulating topography of the wild blueberry field induced movement in the front camera boom, which might have resulted in the detection failure of bare spots by the CCM algorithm due to blurred images. The MVRG fertilizer spreader was successfully operated for SA at a ground speed of 3.2 km h−1 for actual fertilization in wild blueberry fields.

References

Beck, J. L., & Kinter, M. L. (1998). Agricultural implement having multiple agents for mapping fields. U.S. Patent No. 5,793,035 A.

Chandler, R. C. (2003). Autonomous agent navigation based on textural analysis (Doctoral dissertation, University of Florida, 2003).

Chang, Y. K., Zaman, Q. U., Esau, T. J., & Schumann, A. W. (2014). Sensing system using digital photography technique for spot-application of herbicide in pruned wild blueberry fields. Applied Engineering in Agriculture, 30(2), 143–152.

Chang, Y. K., Zaman, Q. U., Schumann, A. W., Esau, T. J., & Aylew, G. (2012). Development of color co-occurrence matrix based machine vision algorithms for wild blueberry fields. Applied Engineering in Agriculture, 28(3), 315–323.

Chattha, H. S., Zaman, Q. U., Chang, Y. K., Read, S., Schumann, A. W., Brewster, G. R., et al. (2014). Variable rate spreader for real-time spot-application of granular fertilizer in wild blueberry. Computers and Electronics in Agriculture, 100, 70–78.

Dammer, K. H., Wollny, J., & Giebel, A. (2008). Estimation of the leaf area index in cereal crops for variable rate fungicide. European Journal of Agronomy, 28, 351–360.

Eaton, L. J. (1994). Long-term effects of herbicides and fertilizers on lowbush blueberry growth and production. Canadian Journal of Plant Science, 74, 341–345.

Esau, T. J., Zaman, Q. U., Chang, Y. K., Schumann, A. W., Percival, D. C., & Farooque, A. A. (2014). Spot-application of fungicide for wild blueberry using an automated prototype variable rate sprayer. Precision Agriculture, 15, 147–161.

Farooque, A. A., Zaman, Q. U., Groulx, D., Schumann, A. W., Yarborough, D., & Quang, T. (2014). Effect of ground speed and head revolutions on the picking efficiency of commercial wild blueberry harvester. Applied Engineering in Agriculture, 30(4), 535–546.

Hall, I. V., Aalders, L. E., Nickerson, N. L., & Kloet, S. V. (1979). The biological flora of Canada. I. Vaccinium angustifolium Ait., sweet lowbush blueberry. Canadian Field-Naturalist, 93, 415–430.

Hanks, J. E., & Beck, J. L. (1998). Sensor-controlled hooded sprayer for row crops. Weed Technology, 12, 308–314.

Jamieson, A. R. (2008). Developing seed-propagated lowbush blueberry families. American HortScience, 43, 1686–1689.

Jensen, K. I. N., & Yarborough, D. E. (2004). An overview of the weed management in the wild lowbush blueberry-past and present. Small Fruits Review, 3, 229–255.

Marchant, J. A., & Onyango, C. M. (2002). Spectral invariance under daylight illumination changes. Journal of the Optical Society of America, 19(5), 840–848.

Michaud, M. A., Watts, K. C., Percival, D. C., & Wilkie, K. I. (2008). Precision pesticide delivery based on aerial spectral imaging. Canadian Biosystems Engineering, 50(2), 9–15.

National Climate Data and Information Archive (2012). Environment Canada. http://www.climate.weatheroffice.gc.ca. Accessed 06 May 2015.

Oliver, M. (1987). Geostatistics and its application to soil science. Soil Use and Management, 3(1), 8–20.

Saleem, S. R., Zaman, Q. U., Schumann, A. W., Madani, A., Farooque, A. A., & Percival, D. C. (2013). Impact of variable rate fertilization on sub-surface water contamination in wild blueberry cropping system. Applied Engineering in Agriculture, 29(2), 225–232.

Steward, B. L., & Tian, L. F. (1999). Machine vision weed density estimation for real-time outdoor lighting conditions. Transactions of ASAE, 42(6), 1897–1909.

Sui, R., Wilkerson, J. B., Wilhelm, L. R., & Tompkins, F. D. (1989). A Microcomputer based morphometer for bush-type plants. Computers and Electronics in Agriculture, 4(1), 43–58.

Swain, K. C., Zaman, Q. U., Schumann, A. W., Percival, D. C., Nams, D., & Esau, T. J. (2009). Detecting weed and bare-spot in wild blueberry using ultrasonic sensor technology. St. Joseph, MI, USA.: ASABE Paper, (096879).

Tian, L. F., & Slaughter, D. C. (1998). Environmentally adaptive segmentation algorithm for outdoor image segmentation. Computers and Electronics in Agriculture, 21(3), 153–168.

Tian, L. F., Slaughter, D. C., & Norris, R. F. (1997). Outdoor field machine vision identification of tomato seedlings for automated weed control. Transactions of ASAE, 40(6), 1761–1768.

Yarborough, D. E. (2013). Wild Blueberry. University of Maine Cooperative Extension. Orono, Maine. http://umaine.edu/blueberries/newsletters/wild-blueberry-newsletter-january-2013/. Accessed 06 May 2015.

Zaman, Q. U., Schumann, A. W., & Percival, D. C. (2010a). An automated cost-effective system for real-time slope mapping in commercial wild blueberry fields. HortTechnology, 20(2), 431–437.

Zaman, Q. U., Swain, K. C., Schumann, A. W., & Percival, D. C. (2010b). Automated, low-cost yield mapping of wild blueberry fruit. Applied Engineering in Agriculture, 26(2), 225–232.

Zhang, F., Zaman, Q. U., Schumann, A. W., & Percival, D. C. (2010). Detecting bare spot in wild blueberry fields using digital color photography. Applied Engineering in Agriculture, 26(5), 723–728.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chattha, H.S., Zaman, Q.U., Chang, Y.K. et al. Effect of lighting conditions and ground speed on performance of intelligent fertilizer spreader for spot-application in wild blueberry. Precision Agric 16, 654–667 (2015). https://doi.org/10.1007/s11119-015-9400-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11119-015-9400-2