Abstract

Purpose

In transdermal drug delivery system (TDDS), chemical enhancers and crystallization inhibitors added into the adhesive matrixes to improve drug permeation and formulation stability often result in some negative effect on adhesive properties and dressing performance. The aim of this paper is to develop a hydrophilic pressure sensitive adhesive (PSA) for TDDS without using additional chemical enhancers and crystallization inhibitors.

Methods

A quaternary blend (PDGW) composed of polyvinyl pyrrolidone, D,L-lactic acid oligomers, glycerol and water was prepared. The adhesive strength, drug loading capacity, drug state and stability of PDGW were characterized by using ibuprofen (IBU) and salicylic acid (SA) as model drugs. Moreover, In vitro and in vivo drug permeation through rat skin from PDGW patch in comparison to acrylate adhesive (ACA) and nature rubber adhesive (NRA) was investigated.

Results

PDGW performs excellent drug loading and crystallization inhibition capacity. Furthermore, the accumulative amount for 24 h in vitro from PDGW patch is far higher than that from ACA and NRA patch. And the plasma concentration of drugs in vivo from PDGW patch is bigger than that from ACA patch.

Conclusions

PDGW possesses excellent PSA properties and self-enhancement for drug percutaneous permeation, which can be used to develop new formulation of TDDS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Recently, there has been an increasing interest in transdermal drug delivery system (TDDS). TDDS offers many advantages compared with conventional pharmaceutical dosage forms. The TDDS patches include various types, such as microreservoir, reservoir, monolithic matrix and membrane-matrix hybrid, among which monolithic matrix patches remain the most popular because of simplicity of manufacture. Several polymers and their mixtures, as skin adhesives, drug reservoir and membrane, have been used for the matrix of TDDS (1,2). The improvement in pressure sensitive adhesive (PSA) for TDDS application has been done on developing new polymers or modifying the properties of the traditional PSA, such as polyisobutylenes, silicones and polyacrylates, by physical or chemical methods in order to improve the efficiency of TDDS (3,4). Moreover, in order to overcome the excellent barrier function of the stratum corneum, penetration enhancers are introduced and combined with PSA to form matrix devices (5,6). However, the miscibility of adhesive matrix and penetration enhancers is an important factor for TDDS efficiency, because the penetration enhancers usually affect the mechanical strength and adhesive properties of adhesive matrix (7,8). In addition, TDDS containing a high concentration of drug also can be used to promote drug fluxes. However, the system is thermodynamically unstable and the drug might re-crystallize during storage (9). Therefore, crystallization inhibitors, such as silicon dioxide, cholesterol and surfactants or macromolecules, also are added into PSA matrix to control drug crystallization and keep formulation stability (10). Therefore, it would be helpful if the adhesive matrix itself can enhance drug permeation and inhibit drug crystallization.

In order to develop a new type pressure sensitive adhesive for TDDS, a quaternary blend (PDGW) composed of poly (N-vinyl pyrrolidone) (PVP), D,L-lactic acid oligomer (DLLAO), glycerol and water was prepared. Many studies have identified that PVP, as a kind of water soluble polymer with excellent biocompatibility and capacity of hydrogen-bond formation, performs excellent drug compatibility and delivery property as support matrixes for controlled drug release (11–13). The hydrophilicity and high molecular weight of PVP can provide good biocompatibility, mechanical strength and viscosity as adhesive matrix materials, but small molecular plasticizers are needed because of the high T g of PVP (T g ≈176°C). In this work, besides glycerol and water were chosen as the plasticizers, DLLAO as the middle molecular composition was introduced into the PVP matrix, which can improve the mechanical and peel strength of the patches by bridging a hydrogen-bond network between high molecular weight PVP and small molecules of glycerol and water. In our previous work (14), we have reported that the PDGW exhibits excellent adhesion and adhesive transfer on removal without pain when the number average molecular weight of DLLAO is in the range of about 230–400 and the content of DLLAO is in the range of 5–20 wt.% (see supporting information Table S-1 and Figure S-1). The mainly aim of this study is to evaluate the compatibility of PDGW matrix with drugs and the self-enhancement effect of PDGW matrix on drug permeation through rat skin by using ibuprofen (IBU) and salicylic acid (SA) as model drugs.

MATERIALS AND METHODS

Materials

PVP (K90, M n = 100,000 g/mol, T g ≈ 176°C) was the production of BASF (Germany). D, L-lactic acid (88 wt.% aqueous solution) was obtained from National Starch and Chemical Company (USA). Glycerol was obtained from Beijing Fangcao pharmaceutic Company (China). Ibuprofen (IBU) and salicylic acid (SA) was supplied by Pharmaceutical Factory of Juhua Company (China). Azone was purchased from Fuchen Chemical Reagent Ltd. (China). Methanol and acetonitrile (Merck, Germany) were HPLC grade and the other chemicals were analytical grade and used as received.

Natural rubber adhesive (NRA) and acrylate adhesive (ACA) were supplied from Tianjin Tongrentang pharmaceutic Company and Tianjin Zhongbao pharmaceutic Company (China)) for preparation of TDDS, respectively.

Adult male Kunming rats, weight 180–220 g, were obtained from Tianjin Institute of Pharmaceutical Research. The rats were housed in plexiglas cages, five animals in each cage with free access to water and food. The cages were placed in a room under a controlled environmental condition (temperature 25°C, humidity 40–60%). All animal experiments were performed in accordance with the Guidelines for Animal Experimentation of Tianjin Institute of Pharmaceutical Research, Tianjin, China.

Synthesis and Characterization of DLLAO

DLLAO were prepared by the condensation polymerization of D, L-lactic acid under vacuum in the absence of catalysts at 160°C and the number average molecular weight (M n) was determined by titrating the oligomer solution with 0.1 mol/L KOCH3 by using phenolphthalein as the indicator according to a reported method (15). Without special mention, the M n of DLLAO used in this study was 309 ± 7.

Preparation of PDGW Patches

A certain amounts of PVP, DLLAO and glycerol were gradually added into water with stirring continuously until a homogenous solution formed and the bubbles were removed by vacuum. Without special mention, the PDGW matrix used in this study was named as PDGW-6 and the weight ratio of PVP/DLLAO/Glycerol/Water was 45/6/24/25. The PDGW-6 possesses the excellent PSA properties for TDDS, whose tack force, static shear resistance and 180° peel strength is 18, 16.99 ± 1.31 h and 14.87 ± 0.53 N/25 mm, respectively (14).

The drug-loaded PDGW patches were prepared by adequately mixing appropriate amount of PDGW, drug (IBU or SA), or azone in ethanol. The drug-loaded PDGW adhesives were coated on a backing film and the patches were obtained after dried for 20–30 min at 60°C in the oven. Subsequently, the PDGW patches were allowed to evaporate at ambient conditions for a predetermined time (16), as a result, almost all ethanol was evaporated but drug and penetration enhancer were remained in the drug-loaded patches. The thickness of the patches was measured by a vernier caliper. The mass was evaluated by weighing, and the content of water in the patches was determined and controlled by the gravimetric method using an analytical balance in the evaporating process (17,18). The characteristics of the PDGW patches used in this paper were shown in Table I. The drug-loaded ACA or NRA patches were prepared by mixing appropriate amount of IBU or SA into ACA or NRA adhesives in ethanol, and then coating on backing film and evaporating the solvent. All prepared patches were sealed in tinfoil film and stored at ambient environment until analysis.

Adhesive Performance of PDGW Patches

The tack force of PDGW patches (25 × 200 mm) was measured by J. Dow boll rolling test method and was indicated by the ball number by using the CZY-G tack force testing Machine (Labthink Company, China). According to the test methods for pressure sensitive tapes (PSTC-1), the 180° peel strength of PDGW sheet (25 × 200 mm) was measured by Testometric AX M350-10KN Materials Testing Machine (Testometric Company, Germany) at a peel rate of 300 mm/min at 25°C. Four or five specimens were tested for each sample.

Characterizations of PDGW Patches

Differential scanning calorimetry (DSC) was carried out using TA Instrument’s DSC 2920 (TA Instrument, USA). A certain amount of sample (10–15 mg) was placed in a sealed aluminum pan and heated at a heating rate of 5°C/min under nitrogen atmosphere at a flow rate of 80 ml/min.

The crystal states of drugs in PDGW patches were observed by wide-angle X-ray diffraction (XRD) with graphite-filtered Co Kα radiation produced using an X-diffractometer (X’ Pert, Holland). All the samples were measured at 20 mA and 45 KV with the scan range of 3–60° and the scan interval of 0.02°.

The –COOH values of PDGW and drug-loaded PDGW patches were measured by titration method (19). PDGW and the drug-loaded PDGW patches were sealed into glass bottle and stored into an oven at 40°C with related humidity 50%. After predetermined time, a certain number of PDGW or drug-loaded adhesives were dissolved into the mixed-solvent of ethanol and dichloromethane (1:1 by volume), then titrated with KOH solution in ethanol (0.05 mol/L). A mean value of three titrations was taken.

In Vitro Skin Permeation Experiments

The skin samples were obtained from the abdominal area of Kunming rats. After careful removal of the hair on the abdominal area of the sacrificed rat using an electric clipper, the full-thickness skin was cut and the adherent fat and other debris were carefully removed.

The in vitro permeability of drug through hairless rat skin was measured with a Franz diffusion cell system (1.65 cm2 in area and 17 mL in receptor cell volume, Shishin Technology Co. LTD, China) at 37°C. The receptor compartments were filled with phosphate buffered saline (PBS, pH 7.4), containing 0.02% w/v of sodium azide to retard microbial growth. The solution in the receptor compartment was stirred with small magnetic beads. The skin pieces were mounted over diffusion cells with the dermal-side in contact with the receptor side, equilibrated for 2 h, and then air bubbles were removed. The drug-loaded patches of area 1.65 cm2 to be tested were placed on the skin. Samples (2 mL) were withdrawn from the receptor compartment at predetermined time intervals, and the receptor compartment was replenished to its marked volumes with fresh buffer solution. Addition of solution to the receptor compartment was performed with great care to avoid trapping air beneath the dermis samples.

The amounts of IBU and SA in the receptor solution were measured by HPLC (Agillent1100, USA) using Krcmafsis (250 × 4 mm, 5 μm) C18 column. The IBU was detected at 225 nm. The mobile phase for IBU assay composed of acetonitrile and 50 mM acetate buffer in the ratio of 55:45 (v/v) was performed at a flow rate of 1.5 mL/min and the volume injected was 50 μL. The column temperature was set at 40°C according to reference (20). SA was detected with flow rate at 1.5 mL/min at 295 nm at 25°C. The mobile phase for SA assay was prepared by adding 15 mL acetic acid and 0.25 g ammonium acetate to 300 mL acetonitrile. The volume was completed to 1,000 mL using distilled water (21).

In Vivo Permeation Study

Kunming rats were anaesthetized and the hair on the dorsal side was removed with an electric hair clipper, taking care to prevent damage to the surface of the skin. The IBU-loaded and SA-loaded PDGW matrix patches with a surface area of 4 cm2 (2 × 2 cm) were pasted on the dorsal side of rats. The blood samples (250 μL) were collected from retro-orbital plexus into dry heparinized tubes before and 4, 8, 24, 32, 48 h after drug administration. Intraperitoneal injections of dextrose (250 μL) were given to rats after collection of each blood sample to minimize changes in volume of the central compartment. The plasma was separated after centrifugation of blood at 10,000 rpm for 15 min and frozen until analyzed.

Frozen plasma samples were thawed at room temperature. 20 μL of benzoic acid solution (50 μg/mL of internal standard) and 200 μL acetonitrile were added into 200 μL plasma, then the plasma was vortexed for 2 min, followed by centrifugation for 10 min at 4,500 rpm. Subsequently, 20 μL of supernatant was collected for HPLC measurement at the same chromatographic conditions as that for the in vitro permeation experiment samples.

Data Analysis

The cumulative amounts of drugs (μg/cm2) at each collection time was plotted against time (h) and linear regression of the steady state portion of the curve was used to estimate drug flux (μg/cm2/h) through rat skin. All percutaneous permeation data are mean ± S.D. Statistical significance was checked by Student’s t-test and considered to be granted at P < 0.05, unless otherwise indicated.

RESULTS

Drug Dispersion State and Stability of PDGW Patches

Because IBU and SA are often used as model drugs in the evaluation of the TDDS efficiency, they are used to evaluate the properties of PDGW patches (20–22). In TDDS, the control of the drug dispersion state in the matrix is of particular interest in developing efficient TDDS, because the crystallization of drug in the matrix may significantly affect the percutaneous permeation, the drug-loaded amount and the dressing properties of the patches (23). The drug dispersion state in PDGW matrixes was investigated by XRD and DSC, and the results are shown in Fig. 1. No crystalline peaks are observed in the IBU-loaded and SA-loaded PDGW patches from the XRD and DSC curves when the drug-loaded amount reaches to 10 wt.%. After 12 months storage, no drug crystal is observed from the DSC curves (Fig. 1B, 2* and 4*). It suggests that PDGW matrix can inhibit the drug crystallization when the drug-loaded amount is 10 wt.%, which provides sufficient performance for TDDS applications, because the drug content is normally lower than 5 wt.% for TDDS patches. These results indicate that the PDGW matrix has a good compatibility with IBU and SA, and can inhibit the drug crystallization.

XRD (A) and DSC (B) curves of drugs and drug-loaded PDGW patches, 1 IBU; 2 10 wt.% IBU-loaded PDGW patch; 2* 10 wt.% IBU-loaded PDGW patch after sealed store for 12 months at ambient environment; 3 SA; 4 10 wt.% SA-loaded PDGW patch; 4* 10 wt.% SA-loaded PDGW patch after sealed store for 12 months at ambient environment.

The mixing of drug into PSA matrix often affects the adhesive properties and dressing performances (24–27). For example, Ho and Dodou reported that the addition of the nortriptyline HCl or paracetamol into the adhesive caused a concentration-dependent increase in its cohesive strength (27). The 180° peel strength and tack force are two important mechanical parameters to estimate adhesive properties of PSA. It can be seen from Table II that 10 wt.% drug-loading hardly affects the adhesive properties of PDGW patches. After 12 months storage under sealed condition, both the tack force and 180° peel strength of PDGW patches with or without drug are unchanged. These results indicate that the degradation of DLLAO during storage can be neglected because the 180° peel strength of the patches will decrease largely if DLLAO degraded. For example, the 180° peel strength of PDGW-6* with lower molecular weight DLLAO in Table II is lower than that of PDGW-6 with a higher molecular weight DLLAO. If DLLAO was degraded to lower molecular weight during storage, the 180° peel strength of the patches will decrease obviously, but no decrease in 180° peel strength was observed during 12 months storage. Furthermore, The titration results of –COOH in Table III indicate that the –COOH values of PDGW and the drug-loaded PDGW do not change during 3 months sealed storage at ambient environment, which further demonstrate the stability of the PDGW patches. If DLLAO was degraded to lower molecular weight during storage, the –COOH values of the patch will increase, but the results in Table III show that the –COOH values did not change during storage. Thus, it can be concluded that DLLAO is stable in the matrix, and the influence of DLLAO degradation on properties of PDGW patches can be ignored even though the degradability of poly(lactic acid) is well known.

In Vitro Skin Permeation

Effect of Compositions of PDGW Patches

The influence of the compositions of PDGW patches on IBU permeation through rat skin from PDGW matrix was investigated. As shown in Fig. 2, the skin penetration amount of IBU from PVP/Glycerol/Water = 45/30/25 is much higher than that from PVP/Water = 45/55 and the IBU flux increases with increasing glycerol content, which indicates that glycerol acts more important role on enhancing the penetration of IBU through skin than water. However, without adding DLLAO, the blends of PVP, water and glycerol can not provide good mechanical and adhesive properties for TDDS application. As mentioned above, 5–20 wt.% DLLAO in PDGW matrix is necessary to provide good strength and adhesive properties, as a result, the PDGW matrix with an optimal composition of PVP/DLLAO/Glycerol/Water = 45/6/24/25 will be used in the below study.

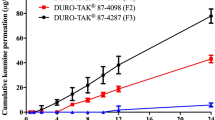

Effect of Different Adhesive Matrices

The in vitro skin permeation of IBU and SA from PDGW matrix was evaluated by comparing with two common adhesive patches, i.e., ACA and NRA patch. It can be seen from Fig. 3A that accumulative amount of IBU for 24 h from the PDGW patch is much higher than that from ACA patch, and also higher than that from ACA with 4 wt.% azone. The accumulative amount of IBU for 24 h from PDGW patch is about 1,900 μg/cm2, which is four times higher than that from ACA patch. The in vitro skin permeation studies of SA from the three kinds of matrixes give the similar results as shown in Fig. 3B.

The effect of drug-loaded amount on the flux of IBU and SA are shown in Fig. 4. For the three matrixes, the drug flux increases with the increase of drug-loaded amount. The PDGW patch presents the significantly highest drug flux among the three kinds of patches at different drug content. These results further confirm PDGW patch possesses self-enhancement for drug percutaneous permeation through rat skin and indicate that PDGW matrix more benefits for transdermal delivery patches with high drug-loaded amount.

Effect of Azone on Drug Penetration

The results in Fig. 5 show the enhancement of azone on IBU permeation and the effect of azone on the 180° peel strength of the matrixes. Azone, as a common penetration enhancer, has been widely studied in TDDS (28), while the effect of azone on the adhesive properties of the patches was seldom studied. The results in Fig. 5 show that azone has no obvious enhancement effect for IBU in PDGW patch but induces fast decrease in 180° peel strength of PDGW patch. Although, azone presents significant enhancement for IBU permeation through rat skin from ACA and NRA patches, the IBU flux from ACA or NRA patches containing azone are still much lower than that from PDGW patch without azone. Furthermore, the addition of azone also induces the obvious decrease in 180° peel strength of ACA and NRA matrixes. Therefore, the self-enhancement matrix is significant to avoid the negative effect of enhancers on adhesive properties.

In Vivo Skin Permeation

The in vivo skin permeation efficiency of the IBU and SA-loaded PDGW patches are investigated by using Kunming rats as the experimental animals. As shown in Fig. 6A, the IBU concentration in blood rapidly increases when the IBU-loaded PDGW patches were applied on the Kunming rat skins for 16 h, and then maintains a stable level about 20 μg/mL for more than 24 h. As an enhancer, azone in the PDGW patches induces a slight increase of plasma concentration of drug than that without azone. Similar results for SA in vivo percutaneous permeation were also obtained as shown in Fig. 6B. The plasma concentration of drugs from PDGW patch without enhancer is far higher than that from ACA patches with 4 wt.% azone, and the highest plasma concentration from PDGW patch is about four times higher than that from ACA patch. These results indicate that, from the PDGW patch without any enhancer, IBU and SA can be permeated into the blood through skin and maintain a stable plasma concentration for a long time. It further confirms that PDGW matrix has a function of self-enhancement for the drug percutaneous permeation.

DISCUSSION

All above results indicate that, besides possessing excellent adhesive properties, drug compatibility and storage stability, the quaternary blend of PVP/DLLAO/Glycerol/Water with suitable composition presents self-enhancement for drug percutaneous permeation.

In TDDS applications, drug crystallization within a PSA matrix may cause a reduction in skin permeation and the dressing performance of TDDS. Therefore, the control of drug crystallization is of particular interest for the efficiency and quality of TDDS application (23). In our work, without additional crystallization inhibitor, PDGW adhesives can inhibit the crystallization of IBU and SA during storage at high drug content (10 wt.%). It can be attributed to PVP macromolecules, which was found to be the most effective crystallization inhibitor in transdermal matrix (29). Moreover, many researchers suggest that the inhibition of PVP is due to the interaction between the drug and PVP (30–32). As the framework component in PDGW, PVP containing tertiary amide groups possesses strong ability of hydrogen-bond formation and can interact with IBU and SA strongly by hydrogen-bond and subsequently inhibit the drug crystallization (33). Therefore, the crystallization inhibition of PVP can maintain the stability of drug distribution at molecular level in the matrix during long time storage, which affords good compatibility between the drug and the matrix. Moreover, the drugs in PDGW matrix may exist in the glycerol/water domains and interface of PVP/DLLAO network without destroying the PVP/DLLAO network structure. As a result, the loaded drugs hardly affect the adhesive properties of PDGW even when the drug-loaded amount is up to 10 wt.%. PDGW matrixes can keep good storage stability for long term in the physical and chemical properties, and the effect of degradation of DLLAO on adhesive properties of PDGW patches can be ignorable. It can be attributed to that the degradation of DLLAO dispersed in PVP is comparatively difficult and the strong hydrogen-bond network in PDGW matrix can hinder the degradation of DLLAO, which have been confirmed by FT-IR and TGA (14).

The miscibility and interdiffusion of PVP, DLLAO, glycerol and water may construct an interpenetration hydrogen-bond network. In addition, owing to the appreciable length and flexibility of the DLLAO chains, they may create a space within this network and provide the coupling of the high cohesive strength of a hydrogen-bond complex and a large free volume (34). The network imparts to the blend a rubber-like elasticity, whereas the free volume leads to increasing molecular mobility and segmental relaxation of the blend (35). As a result, the PDGW matrix provides not only excellent adhesive performance and drug loading capacity, but also free interspace for drug diffusion. In addition, the PVP in PDGW matrix also can improve the drug flux because the anti-nucleating effect of PVP can convert the crystalline drug into amorphous state, which generally possesses a high thermodynamic activity that facilitates the permeation rate of drug through the skin (36). Moreover, the glycerol also acts as an enhancer in PDGW matrix because of its considerable role in changing the properties of the skin, which induces consequent swelling of corneocytes and enhances the drug penetration across the rat skin (37,38). In addition, the water in the PDGW matrix may promote the hydration of the skin, which will improve the penetrability of the skin. However, the hydration of water on the skin may not benefit the permeation of the hydrophobic drug through skin, such as ibuprofen (logK octanol/water = 3.5) and salicylic acid (logK octanol/water = 2.26). The results obtained are consistent with several previous studies which have reported that the increased water content in lipids of skin may inhibit the penetration of hydrophobic molecules (39–41). Therefore, PDGW matrix presents excellent self-enhancement on drug penetration across rat skin by combining the crystallization inhibition function of PVP, the effect of hydrogen-bond network and the penetration enhancement of glycerol. However, the enhancement effect of glycerol should be further studied in the future.

CONCLUSION

From the results of this investigation, it is concluded that the PDGW matrix composed of PVP/DLLAO/Glycerol/Water combines the advantages of the high loading capacity of the matrix, the crystallization inhibition function of PVP on loaded drug and the effect of hydrogen-bond network structure, as well as the improvement of the drug permeation through hairless mouse skin. As a result, PDGW matrix, besides providing suitable adhesive strength, can maintain the TDDS stability for long time storage and effectively enhance the drugs permeation through the rat skin. Therefore, as a self-enhancement matrix, PDGW can be used to develop new formulation of TDDS without addition of enhancers and crystallization inhibitors, which can avoid the negative effect of small molecular additives on the mechanical strength and adhesive properties. However, it is well known that human skin is much different from hairless mouse skin, and PDGW matrix may have different behavior in different skin models. Therefore, further studies are needed in order to assess the performance of PDGW matrix in a more authentic model such as human skin.

References

A. M. Wokovich, S. Prodduturi, W. H. Doub, A. S. Hussain, and L. F. Buhse. Transdermal drug delivery system (TDDS) adhesion as a critical safety, efficacy and quality attribute. Eur. J. Pharm. Biopharm. 64:1–8 (2006). doi:10.1016/j.ejpb.2006.03.009.

C. Valenta, and B.G. Auner. The use of polymers for dermal and transdermal delivery. Eur. J. Pharm. Biopharm. 58:279–289 (2004). doi:10.1016/j.ejpb.2004.02.017.

S. Venkatraman, and R. Gale. Skin adhesives and skin adhesion: 1. Transdermal drug delivery systems. Biomaterials. 19:1119–1136 (1998). doi:10.1016/S0142-9612(98)00020-9.

H. S. Tan, and W.R. Pfister. Pressure-sensitive adhesives for transdermal drug delivery systems. PSTT. 2:60–69 (1999).

S. Mitragotri. Synergistic effect of enhancers for transdermal drug delivery. Pharm. Res. 17:1354–1359 (2000). doi:10.1023/A:1007522114438.

A. C. Williams, and B. W. Barry. Penetration enhancers. Adv. Drug. Deli. Rev. 56:603–618 (2004). doi:10.1016/j.addr.2003.10.025.

S. M. Taghizadeh, and F. Lahootifard. Effect of different skin permeation enhancers on peel strength of an acrylic PSA. J. Appl. Polym. Sci. 90:2987–2991 (2003). doi:10.1002/app.12931.

S. R. Trenor, A.E. Suggs, and B.J. Love. Influence of penetration enhancers on the thermomechanical properties and peel strength of a poly(isobutylene) pressure sensitive adhesive. J. Mater. Sci. Lett. 21:1321–1323 (2002). doi:10.1023/A:1019748112291.

P. N. Kotiyan, and P.R. Vavia. Eudragits: role as crystallization inhibitors in drug in adhesive transdermal systems of estradiol. Eur. J. Pharm. Biopharm. 52:173–180 (2001). doi:10.1016/S0939-6411(01)00174-6.

F. Cilurzo, P. Minghetti, A. Casiraghi, L. Tosi, S. Pagani, and L. Montanari. Polymethacrylates as crystallization inhibitors in monolayer transdermal patches containing Ibuprofen. Eur. J. Pharm. Biopharm. 60:61–66 (2005). doi:10.1016/j.ejpb.2005.02.001.

M. M. Feldstein, V. N. Tohmakhchi, L.B. Malkhazov, A.E. Vasiliev, and N.A. Platé. Hydrophilic polymeric matrixes for enhanced transdermal drug delivery. Int. J. Pharm. 131:229–242 (1996). doi:10.1016/0378-5173(95)04351-9.

T. Loftsson, and A.M. Sigurðardóttir. The effect of polyvinylpyrrolidone and hydroxypropyl methylcellulose on HPβCD complexation of hydrocortisone and its permeability through hairless mouse skin. Eur. J. Pharm. Sci. 2:297–301 (1994). doi:10.1016/0928-0987(94)90013-2.

B. Mukherjee, S. Mahapatra, R. Gupta, B. Patra, A. Tiwari, and P. Arora. A comparison between povidone–ethylcellulose and povidone–eudragit transdermal dexamethasone matrix patches based on in vitro skin permeation. Eur. J. Pharm. Biopharm. 59:475–483 (2005). doi:10.1016/j.ejpb.2004.09.009.

J. H. Zhang, L. D. Deng, H. J. Zhao, M. Liu, H. J. Jin, J. Q. Li, and A. J. Dong. Pressure sensitive adhesive properties of poly(N-vinyl pyrrolidone)/D,L-lactic acid oligomer/glycerol/water blends for TDDS. J. Biomater. Sci. Polym. Ed (2009). doi:10.1163/156856209X410111.

N. Wang, and X. S. Wu. Synthesis, characterization, biodegradation and drug delivery application of biodegradable lactic/glycolic acid oligomers: Part II. Biodegradation and drug delivery application. J. Biomater. Sci. Polym. Ed. 9:75–87 (1997). doi:10.1163/156856297X00272.

M. Aqil, and A. Ali. Monolithic matrix type transdermal drug delivery systems of pinacidil monohydrate: in vitro characterization. Eur. J. Pharm. Biopharm. 54:161–164 (2002). doi:10.1016/S0939-6411(02)00059-0.

W. H. Gardner. Water content. In A. Kline (ed.), Methods of Soil Analysis, 2nd ed. American Society of Agronomy, Madison, WI, 1986, pp. 493–544.

A. Gal, and A. Nussinovitch. Plasticizers in the manufacture of novel skin-bioadhesive patches. Int. J. Pharm. doi:10.1016/j.ijpharm. 2008.11.015 (2008).

M. J. Maurice. The determination of carboxyl groups in polycaprolactam. Anal. Chim. Acta. 26:406–409 (1962). doi:10.1016/S0003-2670(00)88406-8.

S. M. Al-Saidan. Transdermal self-permeation enhancement of ibuprofen. J. Control. Release. 100:199–209 (2004). doi:10.1016/j.jconrel.2004.08.011.

N. H. Gabboun, N.M. Najib, H.G. Ibrahim, and S. Assaf. Release of salicylic acid, diclofenac acid and diclofenac acid salts from isotropic and anisotropic nonionic surfactant systems across rat skin. Int. J. Pharm. 212:73–80 (2001). doi:10.1016/S0378-5173(00)00585-8.

L. Simonsen, A. Jørgensen, E. Benfeldt, and L. Groth. Differentiated in vivo skin penetration of salicylic compounds in hairless rats measured by cutaneous microdialysis. Eur. J. Pharm Sci. 21:379–388 (2004). doi:10.1016/j.ejps.2003.11.004.

J. H. Kim, and H.K. Choi. Effect of additives on the crystallization and the permeation of ketoprofen from adhesive matrix. Int. J. Pharm. 236:81–85 (2002). doi:10.1016/s0378-5173(02)00017-0.

S. Y. Lin, C.J. Lee, and Y.Y. Lin. Drug–polymer interaction affecting the mechanical properties, adhesion strength and release kinetics of piroxicam-loaded Eudragit E films plasticized with different plasticizers. J. Control. Release. 33:375–381 (1995). doi:10.1016/0168-3659(94)00109-8.

D. G. Maillard-Salin, Ph. Bécourt, and G. Couarraze. A study of the adhesive–skin interface: correlation between adhesion and passage of a drug. Int. J. Pharm. 200:121–126 (2000). doi:10.1016/S0378-5173(00)00369-0.

T. Kokubo, K. Sugibayashi, and Y. Morimoto. Interaction between drugs and pressure-sensitive adhesives in transdermal therapeutic systems. Pharm. Res. 11:104–107 (1994). doi:10.1023/A:1018906013527.

K. Y. Ho, and K. Dodou. Rheological studies on pressure-sensitive silicone adhesives and drug-in-adhesive layers as a means to characterise adhesive performance. Int. J. Pharm. 333:24–33 (2007). doi:10.1016/j.ijpharm.2006.09.043.

J. Hirvonen, J. H. Rytting, P. Paronen, and A. Urtti. Dodecyl N,N-dimethylamino acetate and azone enhance drug penetration across human, snake, and rabbit skin. Pharm. Res. 8:933–936 (1991). doi:10.1023/A:1015824100788.

X. H. Ma, J. Taw, and C.M. Chinan. Control of drug crystallization in transdermal matrix system. Int. J. Pharm. 142:115–119 (1996). doi:10.1016/0378-5173(96)04647-9.

K. H. Ziller, and H. Rupprecht. Control of crystal growth in drug suspensions. Drug Dev. Ind. Pharm. 14:2341–2370 (1988). doi:10.3109/03639048809152019.

L. S. Taylor, and G. Zografi. Spectroscopic characterization of interaction between PVP and indomethacin in amorphous molecular dispersions. Pharm. Res. 14:1691–1697 (1997). doi:10.1023/A:1012167410376.

M. Yoshioka, B.C. Hancock, and G. Zografi. Inhibition of indomethacin crystallization in poly(vinylpyrrolidone) coprecipitates. J. Pharm. Sci. 84:983–986 (1995). doi:10.1002/jps.2600840814.

N. M. Najib, M. Suleiman, and A. Malakh. Characteristics of the in vitro release of ibuprofen from polyvinylpyrrolidone solid dispersions. Int. J. Pharm. 32:229–236 (1986). doi:10.1016/0378-5173(86)90183-3.

B. Yuan, C. McGlinchey, and E. M. Pearce. Explanation of tackifier effect on the viscoelastic properties of polyolefin-based pressure sensitive adhesives. J. Appl. Polym. Sci. 99:2408–2413 (2006). doi:10.1002/app.22820.

M. B. Novikov, A. Roos, C. Creton, and M. M. Feldstein. Dynamic mechanical and tensile properties of poly(N-vinyl pyrrolidone)–poly(ethylene glycol) blends. Polymer. 44:3561–3578 (2003). doi:10.1016/S0032-3861(03)00132-0.

P. R. Rao, M. N. Reddy, S. Ramakrishna, and P. V. Diwan. Comparative in vivo evaluation of propranolol hydrochloride after oral and transdermal administration in rabbits. Eur. J. Pharm. Biopharm. 56:81–85 (2003). doi:10.1016/S0939-6411(03)00038-9.

J. M. Barichello, N. Yamakawa, M. Kisyuku, H. Handa, T. Shibata, T. Ishida, and H. Kiwada. Combined effect of liposomalization and addition of glycerol on the transdermal delivery of isosorbide 5-nitrate in rat skin. Int. J. Pharm. 357:199–205 (2008). doi:10.1016/j.ijpharm.2008.01.052.

M. Hara, and A.S. Verkman. Glycerol replacement corrects defective skin hydration, elasticity, and barrier function in aquaporin-3-deficient mice. Proc. Natl. Acad. Sci. U.S.A. 100:7360–7365 (2003). doi:10.1073/pnas.1230416100.

O. Diez-Sales, A. C. Watkinson, M. Herráez-Dominguez, C. Javaloyes, and J. Hadgraft. A mechanistic investigation of the in vitro human skin permeation enhancing effect of Azone. Int. J. Pharm. 129:33–40 (1996). doi:10.1016/0378-5173(95)04237-7.

S. C. Chi, E. S. Park, and H. Kim. Effect of penetration enhancers on flurbiprofen permeation through rat skin. Int. J. Pharm. 126:267–274 (1995). doi:10.1016/0378-5173(95)04137-0.

J. Y. Fang, T. L. Hwang, C. L. Fang, and H. C. Chiu. In vitro and in vivo evaluations of the efficacy and safety of skin permeation enhancers using flurbiprofen as a model drug. Int. J. Pharm. 255:153–166 (2003). doi:10.1016/S0378-5173(03)00086-3.

Acknowledgments

This project was supported by the National Natural Science Foundation of China (Number 30672554).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 72.0 kb)

Rights and permissions

About this article

Cite this article

Zhang, J., Liu, Z., Du, H. et al. A Novel Hydrophilic Adhesive Matrix with Self-Enhancement for Drug Percutaneous Permeation Through Rat Skin. Pharm Res 26, 1398–1406 (2009). https://doi.org/10.1007/s11095-009-9850-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-009-9850-1