Abstract

Monochlorosilane/argon/hydrogen (SiH3Cl-Ar-H2) mixture of different ratios was investigated from the point of PECVD application. RF capacitive plasma discharge of 40.68 MHz frequency was used. The process of deposition was studied by optical emission spectroscopy. The silicon thin films of different phase composition were obtained. The thin films were characterized by Raman-spectroscopy, atomic force microscopy, and secondary ion mass spectrometry. The exhaust gas mixture was analyzed by IR-spectroscopy in outlet of the reactor during PECVD process. The chemical mechanism for the deposition process was also proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The plasma chemical methods for production of silicon layers from silane, especially, the amorphous hydrogenated ones, are well known over 50 years. In early 1970s it was demonstrated that substitution of SiH4 on SiF4 or SiCl4 apparently increases the share of crystalline phase and, thus, substantially improves the parameters of layers. The generation of halogen-containing radicals in plasma stimulates the «crystallization» of layers due to deactivation of the broken Si–H bonds and by selective etching of the amorphous phase of silicon. However, systematic works in this area were mainly initiated in the middle of 1990s when it was shown that poly- and microcrystalline silicon layers much better convert light energy into electrical energy in comparison with amorphous layers. Quite a lot of papers are devoted to production of silicon layers from tetrafluorosilane in its mixture with hydrogen [1, 2]. At the same time, there are substantially less investigations with the focus on usage of more available and cheaper chlorosilanes as precursors. In the mid of 1980s the first set of investigations describing the mechanisms of deposition of silicon thin films via reduction of silicon tetrachloride by hydrogen in plasma was published [3]. Then, the possibility to form the fast-growing layers of amorphous silicon in plasma by reduction of dichlorosilane was also demonstrated [4]. Later it was shown that the gradual addition of dichlorosilane to monosilane leads to formation of micro-crystalline silicon layers. The dark conductivity and activation energy of the films were measured as well [5]. Not so long ago, microcrystalline silicon films were formed from Dichlorosilane SiH2Cl2 with less density of defects in comparison with traditional microcrystalline thin silicon films μc-Si:H produced from silane SiH4. Additionally, the record-breaking growth rate of 40 Å/s was attained for the crystalline films which the authors referred to appearance of high active H and Cl particles formed in the process of plasma chemical deposition and their ability to terminate the surface growing without defects [6]. Moreover, [7, 8] the fast-growing micro-crystalline films were obtained by usage of low-temperature microwave plasma of high density from the mixture of the precursors SiH4-H2 and SiH2Cl2-H2. The shares of the amorphous phase of silicon (20–30 %) and crystalline phase (75–85 %) were estimated. The authors the same way as the one mentioned above pointed out the importance of presence of the particles of active hydrogen and chlorine to provide high quality of the growing surface μc-Si:H:Cl. Despite such deep investigations mentioned above, we could not find any piece, devoted to the usage of monochlorosilane as the initial substance for PECVD production of silicon layers. Monochlorosilane seems to be the cheapest precursor due to it is a bypass product of silane technology production. Additionally, it has only one atom of chlorine and more “soft” etching may be expected in terms of improvement of the thin film surface.

The aim of this work is to study some aspects of monochlorsilane behavior in the non-equilibrium low temperature capacitive plasma discharge, as well as the formation of silicon thin films of different phase consistent.

Experimental

Monochlorosilane of 95.9 vol.% purity and high-pure hydrogen (99.9999 vol.%) were used as the initial substances. The process of plasma chemical deposition was carried out in the setup with the principal scheme given in Fig. 1.

It embraces the system for input of the initial gas mixture, the stainless steel reactor, the trap system, the RF generator, and the pumping system. The setup also includes the reagent gas lines and precision electronic controllers of the gas flows. Additionally, the heated substrate for deposition of reaction products was placed inside the reactor on the ground electrode. The temperature of the substrate was 200 °C. The distance between the electrodes was constantly 30 mm. Power of the RF generator was constant maintained 200 W with frequency 40.68 MHz. During the experimental process the pressure was constant 0.2 Torr. The volume ratio of the raw substances SiH3Cl-Ar-H2 varied from (SiH3Cl/Ar/H2)—20/20/5 (ml) to 20/20/15 (ml). The initial gas mixture was provided through one of the electrodes supplied by the showerhead to spread the reagents directly into the plasma discharge. The outlet of the reactor was fixed with the IR-cuvette. The reaction products were condensed in the trap cooled with liquid nitrogen.

Research of Raman scattering (RS) of the samples was carried out on the scheme of reflection. The excitation was done by the usage of a semiconductor laser with a wavelength of 473 nm. The radiation was focused by 100× lens with the aperture of NA = 0.95. Power of unfocused laser radiation was measured by a silicon photodetector 11PD100-Si (Standa Ltd), varied by means of a variable optical density filter in the range from 0.01 mW to 5 mW. All spectra were obtained at the room temperature. The study was carried out in the range of 150–1000 cm−1, with the pace 0.7 cm−1. The samples of thin films were investigated by the atom force microscope (NT-MDT, Russia). The morphology of the surfaces was studied in the contact regime using of HA-C probes (NT-MDT, Russia). The secondary ion mass spectrometry (SIMS) was used for determination of certain impurities in the silicon films. The element composition was analyzed using SIMS with a TOF.SIMS-5 instrument (IONTOF). For the layer-by-layer analysis, we used an ion gun of O2+ ions with the energy of 2 keV, a beam current of 500 nA, and a beam diameter of 100 μm or Cs+ ions (2 keV, 300 nA, and 50 μm). These beams were scanned in the 120 × 120 μm raster pattern. IR-spectroscopy of outlet gas mixture was done by Tensor FTIR- spectrometer (Bruker).

Results and Discussion

The Gas Phase Process

The emission spectra of SiH3Cl-Ar-H2 mixture at different additions of hydrogen are shown in the Fig. 2. Existence of various reactive species in plasma was indicated. The argon lines were especially deducted due to their strong intensity and close location to the chloride ones. The main observed emission lines and bands, which have been assigned to some electronic excited states of H, H2, SH, Cl are summarized in Table 1.

The main distinguish of the spectra represented from the same ones for the other chlorosilanes are the presence of the SH species, which is the feature for the silane spectrum.

The process of dissociation of monochlorosilane molecules caused by electron impact seems to be one of the mechanisms of the plasma reactions:

The apparent lines of SH and Cl species of the emission spectrum at minimum hydrogen dilution (curve 1) proof this point and the statement correlates with the data of the research literature [3]. However, the following addition of hydrogen (curves 2, 3) suppresses this process due to decreasing of the electron concentration. It leads to the sequence of reactions:

The diminishing of the concentration of Cl species and, at that time, keeping concentration of SH species at about the same level supports this scheme.

Because of the lack of information about the spectral range of 280–350 nm the conclusion about the existence of SiCl2, SiCl, and HSiCl species, which are traditionally observed in the spectra of the other chlorosilanes couldn’t be drawn. In order to complete the information about gas phase processes the IR-spectrum in the range of 300–5000 cm−1 of the exhausted gas mixture were studied. The results of the graphs address to the mixture with the minimum hydrogen content. Firstly, the IR-spectrum of the initial gas mixture was measured without plasma discharge. Due to liability of monochlorosilane to disproportion just at the room temperature [9] the visible traces of silane (3800 cm−1), dichlorosilane (1700 cm−1), and hydrogen chloride (3000 cm−1) are observed Fig. 3.

After igniting of the plasma discharge the concentration of the components wassubstantially altered. Silane and dichlorosilane prevail; the concentration of monochlorosilane sharply dropped down and the concentration of tetrachlorosilane remained approximately the same. Additionally, the apparent quantity of trichlorosilane (1100 cm−1) is observed. It allows to make an assumption that reaction of disproportional occurs to be one of the stages of silane formation.

Besides, the reaction (6) may be the origin of trichlorosilane appearance.

Thus, the plasma process engages at least three possible reactions of silane formation (SH species) electron impact of monochlorosilane molecule (1), the monochlorosilane interaction with active hydrogen (3) and intermolecular interaction of two molecules monochlorosilane (5) with following disproportion. All the assumptions are in agood correlation with the emission data and IR spectrum.

The Solid Phase Process

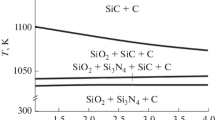

The samples of silicon thin films of the different ratios of (SiH3Cl-Ar-H2) mixture were obtained. The Corning Glass substrates were used. The data of the Raman spectra point out on the formation of both microcrystalline and amorphous phases in all samples (Fig. 4).

It is shown that the share of the crystalline phase decreases with the increasing of hydrogen dilution of the initial gas mixture. The chlorine active species use up on the reactions (3) and (4) with the excess of hydrogen and etching of amorphous phase declines.

Figure 5 shows the comparison between surfaces of three thin films: conventional μc-Si (a) [8], and μc-Si:H,Cl prepared from SiH2Cl2 (b) [8] and SiH3Cl (c) measured by atomic force microscopy. The RMS (root mean square) roughness of the conventional μc-Si film deposited from SiH4/H2 mixture was 1.7 nm, and that of the μc-Si:H,Cl films deposited from SiH2Cl2 and SiH3Cl was 1.9 and 2.1 nm, respectively. Although the RMS roughness is approximately the same between the three samples, the surface morphology is quite different; the surface morphology of the μc-Si:H,Cl samples is much rougher than the conventional μc-Si. The surface diffusion coefficient of the precursor seems to be enhanced by the hydrogen coverage in conventional μc-Si film growth. However, in μc-Si:H,Cl growth the hydrogen coverage on the growing surface appears to be much reduced because of the formation of HCl. The Cl radicals can etch weak Si–Si bonds like H radicals in the growth of μc-Si. Thus Cl radicals promote the growth of μc-Si when Cl radicals exist at the growth surface. But, the addition of a large amount of chlorosilanes (SiH3Cl or SiH2Cl2) deteriorates the film properties because of the change in film structure from microcrystalline to amorphous [8].

The increasing of H2 in gas phase indicates that the effect of Cl radicals on the growth of μc-Si:H,Cl diminishes, when hydrogen radical density is very high, since Cl density at the growing surface will be much lower because of the formation of HCl with abundant H radicals. It is expected that the incorporation of Cl on the growing surface could be controlled by the addition of H2. The hydrogen content in the μc-Si:H,Cl film was found to decrease with increasing H2 in gas phase, as in the cases of μc-Si films deposited by using of SiF4/H2 plasma and μc-Si:H,Cl obtained from SiH2Cl2 [1, 8]. Secondary ion mass-spectrometry measurement was used for tentative determination of the presence of impurities in the microcrystalline silicon thin film. Figure 6 shows a depth profile distribution of silicon and some impurities obtained using Cs+ ions.

The film thickness was estimated as 600–650 nm by a known rate of sputtering of Cs + gun. The silicon thin films include substantial content of oxygen because of special precautions were not taken concerning the state of the reactor such as prebaking to reduce outgassing of the walls. Although, there are proofs [5] that the presence of even small amounts of SiH2Cl2 the (SiH4–H2) mixture may strongly reduce the oxygen incorporation and improve the degree of crystallinity of film due to additional etching, but in this case the etching process was suppressed by the addition of hydrogen. There is no chlorine distribution through the depth of the film except for the surface layer.

Conclusions

The mixture (SiH3Cl + Ar + H2) with different hydrogen content was investigated. The plasma process engages at least three possible reactions of silane (SH-species) formation electron impact of monochlorosilane molecule, the monochlorosilane interaction with active hydrogen and intermolecular interaction of two molecules monochlorosilane with the following disproportion. The share of the crystalline phase decreases with the increasing of hydrogen dilution of the initial gas mixture. Due to the absence of special precautions the films deposited include substantial amounts of oxygen. There is no chlorine distribution inside the whole film except for the surface.

References

Mansfeld DA, Vodopyanov AV, Golubev SV, Sennikov PG, Mochalov LA, Andreev BA, Drozdov Yu N, Drozdov MN, Shashkin VI, Bulkin P, Roca i Cabarrocas P (2014) Deposition of microcrystalline silicon in ECR discharge (24 GHz) plasma from silicon tetrafluotide precursor. Thin Solid Films 562:114–117

Sennikov PG, Golubev SV, Kornev RA, Mochalov LA, Shilaev AA (2014) Study of silicon tetrafluoride reduction with hydrogen in RF discharge. High Energy Chem 48(1):49–53

Bruno G, Capezzuto P, Cicala G, Cramarossa F (1986) Mechanism of silicon film deposition in the RF plasma reduction of silicon tetrachloride. Plasma Chem Plasma Process 6(2):109–125

Nakata M, Wagner S (1994) Fast growth of hydrogenated amorphous silicon from dichlorsilane. Appl Phys Lett 65(15):1940–1942

Platz R, Wagner S (1998) Intrinsic microcrystalline silicon by plasma enhanced chemical vapor deposition from dichlorsilane. Appl Phys Lett 73:1236–1238

Ohse N, Hamada K, Kumar Saha J, Kobayashi T, Takemura Y, Shirai H (2008) High density microwave plasma-enhanced chemical vapor deposition of microcrystalline silicon from dichlorsilane. Thin Solid Films 516:6585–6591

Kumar Saha J et al (2010) Fast deposition of microcrystalline Si films from SiH2Cl2 using a high-density microwave plasma source for Si thin film solar sell. Sol Energy Mater 94:524–526

Kim SK, Moon BY, Byun JS, Jeon HB, Jang J (1996) Preparation of wide band gap microcrystalline silicon film by using SiH2Cl2. Appl Phys Lett 69(8):1131–1133

Walch S, Dateo C (2001) Thermal decomposition pathways and rates for silane, chlorosilane, dichlorosilane, and trichlorosilane. J Phys Chem 105(10):2015–2022

Acknowledgments

This work was financially supported by the Ministry of Education and Science of the Russian Federation (in part of the gas phase characterization), project part of State tasks, No. 10.695.2014/K and by the Russian Foundation of Basic Research, Project No. 15-48-02184, solid phase characterization was supported by Russian Scientific Foundation Grant No. 16-12-00038.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mochalov, L.A., Kornev, R.A., Nezhdanov, A.V. et al. Preparation of Silicon Thin Films of Different Phase Composition from Monochlorosilane as a Precursor by RF Capacitive Plasma Discharge. Plasma Chem Plasma Process 36, 849–856 (2016). https://doi.org/10.1007/s11090-016-9703-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-016-9703-8