Abstract

Huge advancements in the understanding of photovoltaic (PV) physics have been made, but still, PV has not overtaken conventional energy sources due to PV materials cost, toxicity, and stability concerns. In the pursuit of discovering a new solar energy harvester which satisfies criteria such as low cost, earth-abundance, non-toxicity, high efficiency and long-term stability, extensive research has been conducted on the potential of copper iron oxide (CuFeO2), also known as delafossite oxide. CuFeO2 possesses optimal bandgap (1.5 eV), with a high absorption coefficient and carrier mobility, suitable for potentially cost-effective solar cells. Theoretical modelling based on the optical and electrical characteristics of the CuFeO2 system is performed here on delafossite CuFeO2 to examine its photovoltaic performance. We explored various buffer counterparts for CuFeO2 absorber, and a stack of p–n+–n++ is simulated for device optimization. ZnO showed zero conduction band offset with CuFeO2 and a corresponding efficiency of 28% for CuFeO2/ZnO/ITO (p–n+–n++) device. The optimal range of crucial design parameters, such as doping profile, absorber thickness, surface recombination velocity, back contact work function, resistances, and bulk defects, that allow CuFeO2 solar cells to reach power conversion efficiencies above 25% are quantified. The spectrum loss (thermalization and non-absorption loss) stands at 59.6%, extrinsic recombination loss at 12.3%, and the performance ceiling of CuFeO2 at 28.1%. Theoretical analysis shows that the maximum achievable efficiency of 28% is close to the Shockley–Queisser (S–Q) limit and comparable to contemporary inorganic solar cells. The findings presented in this study are anticipated to stimulate experimentalists to fabricate stable, high-efficiency CuFeO2-based thin film solar cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The cuprous delafossite oxides, composed of Cu1+M3+O2 (where M represents a trivalent transition-metal cation like Fe, Cr, Al, etc.), possess tuneable optoelectrical properties (Xu et al. 2021; Ferri et al. 2020). Consequently, their exceptional properties make them highly sought after for their ability to absorb light in thin-film solar cells. The delafossite oxides (ABO2) are named after the French scientist Gabriel Deloffose, where A is a transition, alkali, or alkaline metal, B is the transition metal, and O is the oxygen (Crespo 2018). Among the cuprous delafossites, CuFeO2 has an ideal bandgap for absorbing the terrestrial AM1.5G spectrum (with Eg approximately 1.5 eV) (Jiang et al. 2019a). It consists of elements abundant in the earth's crust, (Ferri et al. 2020) environmentally friendly, thermally, and chemically stable, (Deng et al. 2023; Prévot et al. 2015) and can be produced using various scalable and cost-effective deposition methods (Deng et al. 2023; Prévot et al. 2015; Jin and Chumanov 2016; Singh et al. 2019; Song et al. 2016; Gonzaga and Mercado 2022; Zhu et al. 2016). The fabrication of CuFeO2 is reported by techniques such as sputtering, pulsed laser deposition, and cost-effective non-vacuum methods like sol–gel-based spin coating, hydrothermal method, spray pyrolysis and electrodeposition (Prévot et al. 2017; Li et al. 2023; Shaili et al. 2021; Son 2022a). Due to its properties, delafossite compounds have found various optoelectronic applications, including hole transport material (HTM) in perovskite, (Akin et al. 2019) in dye-sensitized solar cells, (Zhu et al. 2016) PEC water splitting, (Prévot et al. 2015) CO2 splitting, (Gonzaga and Mercado 2022) transparent conducting oxide semiconductor (Xu et al. 2021) and solar energy harvester (Crespo 2018).

The efficiency of photovoltaic systems is a complex function of material properties, such as their ability to absorb light, bandgap, carrier's lifetime, tendency to undergo non-radiative recombination, etc. There is a significant quest to identify materials that can effectively convert sunlight into energy in a reliable, cost-effective, and efficient manner, and this is a significant hurdle in our journey toward sustainable green energy sources. In this regard, CuFeO2 presents bright prospects as a sustainable, environmentally friendly, nontoxic, and economical absorber for solar cells. Vojkovic et al. (2019) reported pulsed laser deposition of CuFeO2 films. The obtained films showed photoconductivity with light-dependent resistivity. Liu et al. synthesized single-phase, high-purity and highly crystalline CuFeO2 using an optimized hydrothermal process (Liu et al. 2020a, 2020b). They showed a stable solar energy conversion using CuFeO2 as a photocatalyst in an aqueous and reductive environment, demonstrating the exception stability of CuFeO2 and absorption property. Karmakar et al. fabricated heterojunction by electrodeposition of p-type CuFeO2 over n-type ZnO substrate, effectively making a p–n junction (Karmakar et al. 2017). The heterojunction showed high visible light absorption, effective charge carrier (electron–hole) separation and long stability. Akin et al. fabricated a n–i–p perovskite solar cell and utilized CuFeO2 as a p-type layer in this device configuration (Akin et al. 2019). CuFeO2 hole transport layer-based non-encapsulated perovskite solar cells exhibited superior self-stability and retained over 90% of their initial PCE even at 80% relative humidity. Son et al. (2022b) fabricated CuFeO2 film by the galvanostatic electrodeposition followed by annealing in inert gas. Fugate et al. (2019) electrodeposited CuFeO2 and summarised Cu vacancies O interstitials defects causing its p-type nature. Alkallas et al. (2022) demonstrated direct combustion of Cu foil coated with Fe2O3 nanomaterials, leading to the formation of CuFeO2. This freestanding CuFeO2/CuO foil showed optoelectronic application with high photoresponsivity and detectivity in the visible region. Jiang et al. (2019b) prepared CuFeO2 by spin coating and showed heterojunction could effectively separate photogenerated electron–hole pair and their recombination. Shaili et al. (2021) deposited CuFeO2 thin film via spray-coated, revealing p-type conductivity with tunable resistivity. Similar optoelectronic applications are widely reported, demonstrating CuFeO2's advantageous visible light absorption property.

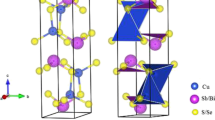

The optoelectronic properties of CuFeO2 arise from its crystal structure. The structure of CuFeO2 consists of alternating layers of Cu and Fe (Xu et al. 2021). Every oxygen atom is coordinated by one Cu+ cation and three M3+ cations. Delafossite oxides crystalize into two rhombohedral structures with space group R3m and hexagonal structures with space group P63 (Jiang et al. 2019a). The slope of VB maxima and CB minima determine the effective masses of charge carriers (thus controlling the mobility) and the dynamics of photoexcited carriers (low exciton binding). It determines the nature of band gap and optoelectronic properties. The maxima of valence band states are contributed by the Cu 3d orbitals along with the hybridization from O 2p states, whereas nonbonding Fe 3d orbitals contribute to the conduction band minima states (Gonzaga and Mercado 2022). The excitation of an electron from O 2p states in the valence band to conduction band Fe 3d states characterizes the primary optical transition in CuFeO2 (CFO). This transition is promptly followed by a thermalization process within the valence band, which involves the holes generated from O 2p states transfer to Cu 3d valence band states. This transfer can be visualized as an electron movement from Cu 3d states to fill the holes in the deeper O 2p states. The thermalization of holes is advantageous and plays a crucial role in facilitating the separation of charges within the lattice and effectively reducing electron–hole recombination. This effect is attributed to the absence of covalent bonding between the Cu and Fe atoms. Consequently, the hole thermalization process is believed to be accountable for the longer carrier lifetime, durability, and excellent photoactivity exhibited by CuFeO2 compared to its parent binary oxide, Cu2O (Jin and Chumanov 2016). CuFeO2 exhibits p-type conductivity, resulting from native Cu vacancies and O interstitials in its structure (Gonzaga and Mercado 2022), and transition metal cation controls the bandgap in the copper delafossites. The well-known copper-based p-type oxide semiconductor, CuO (solar cell absorber), undergoes photo-corrosion and degradation, whereas the CuFeO2 (CFO) exhibits enhanced stability (Ferri et al. 2020). In particular, CFO demonstrates greater chemical stability when exposed to illumination and aqueous environments compared to binary copper oxide compounds (Deng et al. 2023). The CMO2 oxides are nontoxic, abundant (exclusively made of atoms abundant in the earth’s crust), and stable up to 800 °C (Gottesman et al. 2021). CFO possesses several favourable characteristics, including higher absorption coefficients (> 105 cm−1), an appropriate bandgap (~ 1.5 eV), long carrier lifetime (~ 200 ns), (Prévot et al. 2017) good carrier mobility (0.2 cm2/Vs) and high conductivity (Li et al. 2023). These properties result in smaller absorption depths, which, in turn, promote efficient carrier extraction while minimizing carrier recombination (Jin and Chumanov 2016).

Surprisingly, despite its potential as a promising light absorber, no studies have investigated using CuFeO2 as a material for solar cell absorbers. Consequently, we have pioneeringly utilized stable and cost-effective CuFeO2 as a highly efficient inorganic absorber for solar cell application. CFO material holds the potential to offer long-term stability and cost-effective photovoltaic performance owing to its earth abundance. Section 2 describe the device configuration/architecture and simulation methodology utilized for designing CFO-based solar cell. Section 3 describe the theoretically achievable efficiency of CFO-based solar cell under various recombination regimes.

2 Device architecture and simulation approach

Empirically photovoltaic efficiency (\(\eta\)) is given as

where \(V_{OC}\) is the open circuit voltage, FF is the fill factor, \(J_{SC}\) is the short circuit current, and \(P_{in}\) is the incident solar power, which is a function of terrestrial solar spectrum S(E). The VOC depends on the absorber and is given by Kar et al. (2021)

where VLoss is the voltage loss due to recombination, EG is the absorber bandgap. Under instantaneous illumination, a significant quantity of photogenerated electrons accumulates in the conduction band, while many holes gather in the valence band. As a result, separate Fermi levels for electrons and holes are formed. The extent of separation between electrons and holes at the Fermi level is the net conversion of solar heat into chemical potential, leading to the generation of VOC in the device. The JSC is primarily the function of the absorber bandgap. The JSC is empirically given by

The variables q, E, and S(E) represent the electronic charge, the energy of the incoming photons, and the spectral power per unit area of the incident light, respectively. Incident photons with energy lower than the bandgap are transmitted and considered non-absorption losses. Photons with energy greater than the bandgap energy are absorbed; among these photons, only energy equal to EG will contribute to the current, while any excess energy will be lost as thermalization. The fill factor (FF) is influenced by the quality of the device interface and resistance values, and it ideally has a value of 1. FF follows the VOC trend under various recombination regimes.

In this numerical study, we utilized a one-dimensional Poisson solver SCAPS (Burgelman et al. 2000) version 4.02 (solar cell capacitance simulator), which solves Poisson and continuity equations under illumination (generation) and recombination (bulk and interfacial recombination) (Gomathi et al. 2023a, 2023b; Kumar et al. 2022, 2021; Prabu et al. 2023; Livingston et al. 2023; Reddy et al. 2022).

The one-dimensional Poisson-Schrodinger solver solves a set of interconnected equations, including Poisson's equation, continuity equation, drift–diffusion equation, and generation-recombination profiles. It utilizes Gummel iteration coupled with Newton–Raphson substeps along the p–n+ stack length to model the device working. The solver is applied at the bulk and interface of the device, considering various illumination and biasing conditions. By applying appropriate boundary conditions at the interfaces and contacts, the solver solves the interconnected differential equations as shown,

In the given Eqs. 4–7, variables n and p refer to the carrier density, Ψ represents the electrostatic potential, ρdef is defect density, variables Jn and Jp correspond to the electron and hole current density, symbol µp/e represents the hole/electron mobility, EFn and EFp represent the electron and hole Fermi level, G signifies the generation rate, U is the recombination rate while ε0 and εr denote the permittivity of vacuum and semiconductor, respectively. The \(N_{D}^{ + }\) and \(N_{A}^{ - }\) represent the density of donors and acceptors. Equations 1 and 2 pertain to charge carrier transport, whereas Eqs. 3–4 relate to the continuity of electrons and holes; Eq. 5 represents the Poisson equation. To simulate tunnelling and conduction band offset at junctions and interfaces, SCAPS employs the WKB approximation, a semi-classical approach. The electrostatic potential, generation, and quasi-Fermi levels are calculated using the AM1.5G illumination. The simulation considers the ideal Shockley–Read–Hall (SRH) recombination lifetime due to considerable advancement in fabrication technologies, which enable devices to avoid non-radiative losses. In the simulation, a uniform optical absorption constant α(λ) is utilized, as per the bandgap of the absorber.

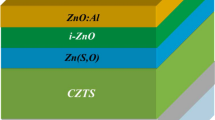

The device configuration under investigation is p/n+/n++. The CuFeO2 is a p-type absorber, and various n+ buffer layers such as ZnO, SnO2, CdO, and MoO3 are examined for their compatibility for heterojunction with CFO. The simulations are performed by taking the material parameters from the literature and are comprehensively summarized in Table 1. Our device and results can be reproduced by using the parameters from Table 1 (Deng et al. 2023; Zhu et al. 2016).

3 Results and discussion

3.1 CuFeO2 device and buffer layer selection

The proposed configuration of the CuFeO2/ZnO/ITO-based solar cell device is shown schematically in Fig. 1. The device p–n+–n++ configuration of CuFeO2/ZnO/ITO shows the device's initial parameters, i.e. the stack arrangement thickness of each layer, is schematically illustrated. The crystal structure of CuFeO2, as shown in Fig. 1a, was plotted using cif file in Diamond software. Figure 1c shows the simulated emission spectrum of the CFO absorber layer using AFORS-HET software (Stangl et al. 2006). Most incident photons with wavelength (λ ≤ 825) are absorbed within the CFO absorber (Forslund 2016). The reported CFO bandgap is 1.5 eV (Liu et al. 2020a). This bandgap value is near ideal for optimal solar spectrum absorption. The theoretical Shockley-Quizzer (SQ) efficiency limit for bandgap 1.5 eV is 32% (Hemalatha et al. 2023). CFO's simulated photoluminescence (PL) shows the PL emission peak at 900 nm. The emission peaks occur near the bandgap of CFO. The PL spectra for CFO highlights its potential prospects as an excellent visible spectrum absorber and applicability as an absorber in solar cell device.

We explored various compatible buffer counterparts for CFO absorbers to make an efficient p-n+ heterojunction. The prospective buffer layer requires a wide bandgap with high electron density higher than the majority carrier concentration in CFO. Table 2 summarizes the oxides n-type materials. Most oxide materials reported here are n+ type with electron density higher than 1018 cm−3, except V2O5 and MoO3. The bandgap of n-type oxides ranges from 2 to 6 eV. Fe2O3 and CdO have a bandgap in the lower range of ~ 2 eV, whereas Al2O3 have a bandgap of ~ 6 eV. Electron affinity of the buffer layer enables it to make a suitable energy level matching; this is one of the crucial parameters for controlling interfacial phenomena such as recombination and carrier collection and is an optimal design consideration. These strict material properties requirements provide guidelines to filter out unsuitable and prospective n-type oxides for the buffer layer. Figure 2 presents the energy level matching (the conduction band and valence band levels) with that of the CFO. Due to their optimal material parameters, we have explored ZnO, CdO and MoO3 as buffer layers for CFO-based devices. The MoO3 makes a spike-type alignment, the CdO makes a cliff-type alignment, and the CFO/ZnO have a matching alignment at the interface (Table 2).

The simulated band diagram of CFO based device with different buffers is shown in Fig. 3. The simulated band diagram plot shows the device stack, the thickness of each layer, their respective band gaps, each layer's electron affinity, and the band bending regions in the device. The CuFeO2/MoO3/ITO, CuFeO2/CdO/ITO and CuFeO2/ZnO/ITO devices are plotted, showing their respective energy levels matching at the interface. The high carrier (electron) density in the n-type buffer window layer causes band bending in the p-type region. This is a desirable condition which is purposely incorporated by choosing a doping profile. The carrier collection at the heterojunction of CFO/buffer is optimal in p–n+–n++ configuration. The EC (conduction band level) in CFO and buffers (MoO3, CdO, ZnO) is different, and they make a different band alignment, as shown in Fig. 3a–c. The corresponding electron affinities cause this spike and cliff band alignment.

The simulated device efficiency of the CFO device with MoO3, ZnO and CdO buffer is shown in Fig. 4a. The MoO3 have lower efficiency than the CFO/CdO and CFO/ZnO device. The MoO3 have a positive conduction band offset, the spike-type alignment. The conduction band offset (CBO) is given by electron affinity different from heterojunction counterparts and empirically given as CBO = EACFO − EABuffer. The efficiency is best for the CFO/ZnO heterojunction as they have zero conduction band offset. The high CBO barrier in positive (spike) and negative (cliff) damages device performance. The inset image shows the schematic of the band alignment of the spike and cliff type at the interface. The high cliff-type alignment will increase the probability of interfacial recombination, as shown in the inset of Fig. 4b. The high spike barrier hinders carrier transport, thus decreasing device performance. It is observed that zero CBO and a slight spike barrier are optimal for device performance.

The probability of occupation of interface states by electrons and holes controls overall interfacial recombination. The conduction band offset at absorber/buffer, with cliff and spike type alignment, is schematically shown in Fig. 5. The interface recombination pathway for the cliff is marked in Fig. 5a, and the spike is marked in Fig. 5b. Spike alignment has a wide interface as compared to cliff alignment. Wide interfaces in spike alignment have a lower probability of recombination than cliff alignment. The wide front bandgap of absorber alters the conduction band offset (CBO) in device. CBO is given by

where EA is the electron affinity. CBO (ECBO) is negative for cliff-type alignment and positive for spike-type alignment. Ideally, CBO should have zero or slightly positive spike alignment to lower interfacial recombination. Even though spike alignment creates a barrier for charge transport, small positive barriers up to 0.1 eV are benign. As seen in the schematic, the interface is wider for spike alignment, which decreases the recombination probability of electrons from the conduction band of the buffer and holes from the valence band of the absorber. Similar physical reasoning of small positive spike-type band alignment are reported in the literature for lowering interfacial recombination (Kumar and Ajay 2018; Minemoto and Murata 2015). On the other hand, cliff-type alignment lowers the interfacial gap, increasing the recombination probability of electrons from the conduction band of the buffer and holes from the valence band of the absorber.

3.2 Optimization of carrier density

The efficiency of CFO/ZnO/ITO is plotted for the carrier density of the absorber and the buffer layer. The background doping profile of the absorber and buffer controls the recombination profile and charge separation at the absorber/buffer interface. Higher hole density in the absorber layer makes a p+n configuration, whereas the high electron density in the buffer will make the device a p-n+ configuration. The p-n+ configuration is advantageous as the depletion region is shifted in the absorber region, drifting the photogenerated carrier toward the buffer side and expediting carrier collection. The p+n configuration will have a depletion region in the buffer region, a suboptimal condition for carrier separation. The simulation plot in Fig. 6 shows the efficiency dependence on the absorber and buffer respective carrier density. The efficiency is highest for CFO hole density of 1016 cm−3 and buffer electron density of 1018 cm−3, which correspond to the p-n+ configuration. The carrier doping ratio (electron density in buffer/hole density in CFO absorber) of 100 is observed to be the optimal condition.

The efficiency of the CFO device increases with decreasing defect density, as shown in the simulated plot in Fig. 7a. At low absorber bulk defect density, the performance is better for higher absorber thickness. It is observed that lower absorber thickness performs better than high absorber thickness under high defect density, as shown in the inset plot of Fig. 7a. Efficiency exhibits an inverse relationship with defect density and a direct relationship with thickness. As a result, there is a trade-off between these two design parameters. A low thickness is preferred when dealing with high defect density, while a higher thickness is the optimal design rule for a lower defect density in the device. The device performance is simulated under the impact of varied carrier lifetime and the thickness of the CFO absorber layer. Figure 7b shows the performance parameters, viz. efficiency, for τ variation from 1 to 1000 ns. The non-radiative Shockley–Read–Hall (SRH) recombination is directly proportional to the defect density (NT) and inversely proportional to the carrier lifetime as given by Chowdhury et al. (2020)

The vth is electron thermal velocity, σn and σp capture cross-sections for electrons and holes, NT defect density, ni intrinsic density, n and p concentrations of electrons and holes at equilibrium, and n1 and p1 concentrations of electrons and holes in trap defects and valence band, respectively. When the defect density exceeds a certain threshold (beyond 1016 cm−3), bulk recombination becomes dominant, leading to the annihilation of charge carriers. This significantly affects the efficiency, causing a sharp decline, as observed in Fig. 7. Reducing the absorber layer's thickness can effectively mitigate the impact of such high defect density. The reduced thickness of the absorber could minimize recombination but result in reduced JSC. An optimized thickness is required for maximized performance by trade-off between JSC and recombination.

The doping profile in the absorber and buffer layer controls the position of the Fermi energy levels, bend bending and drift field at the junction (Klenk 2001; Kumar and Thakur 1953). Different doping profiles (p–n+ and p+–n) and their comparative energy band diagram are shown in Fig. 8. It is observed that the majority of energy bending occurred in the doped layer. The corresponding doping profile of p–n+ is a hole density of 1015 cm−3 in the p-layer and an electron density of 1018 cm−3 in the n+-layer. Similarly, the p+–n junction has a doping profile of hole density of 1018 cm−3 in the p+–layer and electron density of 1015 cm−3 in n-layer. This asymmetric doping profile could manoeuvre the device's band bending profile and drift field and tune interfacial recombination. Energy band bending provides drift to photogenerated carriers and is advantageous for their collection. Under illumination, the photogenerated electrons in the p absorber of the p–n+ device go through this additional drift field and are efficiently collected in the buffer layer. This increases collection efficiency and reduces the interfacial recombination probability. This bending becomes crucial for charge extraction as it aids carrier diffusion length and active absorption region. The p+n configuration causes band bending in n-region. This bending in the wide band gap buffer region significantly lowers the n-layer conduction band level, creating a probable recombination channel for the valence band hole in the p+ layer and the conduction band electron in the n-layer.

3.3 Performance under various recombination regime

The device's extrinsic losses include the back contact, parasitic resistances, surface recombination velocity, and SRH non recombination (VOC). Impact of various design parameter on CFO device performance is summarised in Table 3 (Kumar and Ranjan 2021; Pan et al. 2006; Kumar and Thakur 2019). Figure 9 shows the efficiency waterfall of the CFO for various extrinsic losses. The CFO/ZnO/ITO configuration has near ohmic front contact due to high carrier concentration in the n-type window layer. The p-type semiconductor has a stringent requirement of high work function (greater than the electron affinity and bandgap of the absorber combined) for near ohmic contact. Thus, very few materials with high work function are suitable to obtain a near ohmic contact with a p-type semiconductor. The back contact work function dependence is summarised as the bar chart in Fig. 9. Simulation results show that device efficiency falls steeply with decreased back contact work function (BCWF). CFO/ZnO device showed efficiency > 28% for electron affinity above 5.5 eV of rear contact. Another parameter of contact quality is surface recombination velocity. Efficiency falls to 11% for electron affinity ~ 5.0 eV of rear contact. Another crucial metric of contact quality is surface recombination velocity (SRV). The efficiency dependence on SRV is summarized in Fig. 9 bar chart. Here, we quantify the range of surface recombination velocities that would allow the CFO solar cell to reach power conversion efficiencies above 25%. SRV less than 100 cm/s enable efficiency above 28%. It is observed that SRV as high as 104 cm/s is acceptable without much degradation on the CFO/ZnO solar cell. Passivated contacts in Si possess SRV below 10 cm/s, perovskite materials showed similar SRV values (Wang et al. 2019). The bar chart plot summarises the electrical loss due to parasitic resistance of series resistance (RS) and shunt resistance (RSH). Series resistance (RS) offers electrical resistance, which limits JSC and FF. Shunt resistance (RSH) signifies the internal recombination in the device. It causes high internal recombination and FF degradation for low (RSH). The performance ceiling of the device under trap-assisted non-radiative SRH recombination is simulated. The increased defect density in the absorber accelerates the SRH recombination such induced recombination causes VLoss, where VLoss= EG/q-VOC. The ideal device will have a VLoss of 0.3 V. The general VLoss in the experimental device is observed to be 0.5 V in perovskite, 0.6 V in CIGS, CdTe and 0.7 V in CZTS solar cell devices. We simulated a loss of 0.5 to 0.7 for the CFO device and observed the corresponding efficiency. With open circuit voltage loss VLoss of 0.4, 0.5, 0.6 and 0.7 V, the simulated efficiency is 28%, 17.8%, 12% and 8.4%, respectively. Table 4 summarizes the VOC, FF and JSC for various VLoss of 0.4–0.7 V. Apart from VOC, FF is severely affected by increased VLoss. The comparative VLoss of 0.5 V and 0.6 V for increased bulk defect density in the absorber have highlighted the importance of controlling defects. Restricting resistance and SRH losses is crucial for achieving high performance in CFO device.

3.4 Optimized performance of CuFeO2 solar cell

The theoretical maximum efficiency corresponding to the absorber with a bandgap of 1.5 eV is 31.7%. CFO final device with a description of incident energy utilization in the conversion process as shown in Fig. 10. The spectrum loss, which consists of thermalization and transmission losses, stands at 59.6% for CFO/ZnO/ITO device with absorber bandgap of 1.5 eV. The extrinsic recombination due to electrical loss of parasitic resistance RS and RSh, non-ideal mobility, SRV, non-ohmic contact, etc., stands at 3.6% in this optimized configuration. The intrinsic radiative recombination is observed to be 8.7%, comprised of intrinsic loss such as radiation dilution, entropy generation, etc. The net useful efficiency, which is the remainder of incident solar energy from all the losses, stands at 28.1%. After selecting a suitable buffer counterpart, the CFO device, absorber thickness, defect density optimization, contact, and SRV optimization showed 28.1% performance. Theoretical analysis shows that optimized device configuration can significantly reduce recombination, resulting in improved performance.

The final current density vs voltage J-V plot is shown in Fig. 11a. The final performance parameter of the CFO/ZnO/ITO device stand at VOC = 1.14 eV, JSC = 27 mA/cm2, FF = 88% and efficiency = 28.06%. The external quantum efficiency EQE is shown in Fig. 11b. The EQE is optimal in the 400–800 nm wavelength range and shows an absorption onset near 825 nm wavelength. Higher wavelengths than this are transmitted and non-absorbed. Wavelength regions from 825 to 400 nm are showing near 100% EQE. The external quantum efficiency refers to how the photovoltaic device reacts to different wavelengths of light, which can be used to determine the net short circuit current density JSC. The net short circuit current could be estimated from the product of quantum efficiency (QE) and the solar spectrum. In the 300–400 nm wavelength range, a decrease in quantum efficiency is noticed because of unwanted absorption occurring in the electron transport layer (ETL) and hole transport layer (HTL).

The detailed balance efficiency limit, or the Schockley-Queisser (SQ) limit, represents the theoretical maximum efficiency achievable and depends on the band gap. The SQ limit of efficiency and 60% of efficiency as a function of the bandgap is plotted in Fig. 12. The experimentally reported efficiency of the contemporary solar cells is compared with the SQ limit values. The predicted efficiency of CFO is 28%, comparable to the leading inorganic photovoltaic technologies of Si, GaAs, and CsPbI3 perovskites. CFO is an inorganic, nontoxic, earth-abundant and stable absorber with promising prospects as solar cells. Theoretical analysis showed that CFO/ZnO/ITO device is achieving 88.5% of the theoretical value (SQ limit) for an absorber corresponding to the bandgap of 1.5 eV.

4 Conclusion

The earth-abundant, nontoxic delafossite CuFeO2 absorber-based solar cell is optimized by SCAPS 1D. We first explored an efficient buffer counterpart from a host of available n-type materials to form an efficient heterojunction with CFO. Wide bandgap ZnO is found to be a compatible heterojunction counterpart based on its suitable bandgap, electron affinity and high electron carrier density. We assessed this CFO-based device under different recombination regimes to identify efficiency limiting factors, theoretical maximum efficiency, and optimal device design. The stack of CuFeO2/ZnO/ITO with p-n+-n++ configuration is optimal and showed an efficiency of 28%. The findings presented in this study are anticipated to inspire researchers to create stable, high-efficiency CFO-based thin film solar cells.

Data availability

Data from the simulation can be assessed upon request to the authors.

References

Akin, S., Sadegh, F., Turan, S., Sonmezoglu, S.: Inorganic CuFeO2 delafossite nanoparticles as effective hole transport material for highly efficient and long-term stable perovskite solar cells. ACS Appl. Mater. Interfaces 11(48), 45142–45149 (2019)

Alkallas, F.H., Ben Gouider Trabelsi, A., Alrebdi, T.A., Ahmed, A.M., Rabia, M.: Development of a highly efficient optoelectronic device based on CuFeO2/CuO/Cu composite nanomaterials. Materials 15, 6857 (2022)

Almora, O., Baran, D., Bazan, G.C., Berger, C., Cabrera, C.I., Catchpole, K.R., Erten-Ela, S., Guo, F., Hauch, J., Ho-Baillie, A.W.Y., Jesper-Jacobsson, T., Janssen, R.A.J., Kirchartz, T., Kopidakis, N., Li, Y., Loi, M.A., Lunt, R.R., Mathew, X., McGehee, M.D., Min, J., Mitzi, D.B., Nazeeruddin, M.K., Nelson, J., Nogueira, A.F., Paetzold, U.W., Park, N.G., Rand, B.P., Rau, U., Snaith, H.J., Unger, E., Vaillant-Roca, L., Yip, H.L., Brabec, C.J.: device performance of emerging photovoltaic materials (Version 2). Adv. Energy Mater. 11, 2102526 (2021)

Burgelman, M., Nollet, P., Degrave, S.: Modelling polycrystalline semiconductor solar cells. Thin Solid Films 361–362, 527–532 (2000)

Chowdhury, M.S., Shahahmadi, S.A., Chelvanathan, P., Tiong, S.K., Amin, N., Techato, K., Nuthammachot, N., Chowdhury, T., Suklueng, M.: Effect of deep-level defect density of the absorber layer and n/i interface in perovskite solar cells by SCAPS-1D. Results Phys. 16, 102839 (2020)

Crespo, C.T.: Potentiality of CuFeO2-delafossite as a solar energy converter. Sol. Energy 163, 162–166 (2018)

Dandogbessi, B.S., Akin-Ojo, O.: First-principles prediction of the electronic structure and carrier mobilities of biaxially strained molybdenum trioxide (MoO3). J. Appl. Phys. 120(5), 055105 (2016)

Deng, Q., Shi, L., Lu, K., Wang, G., Di, T., Shen, Y., Wang, S.: Construction of Ca-CuFeO2/TiO2(B) p–n heterojunctions with efficient visible light-driven photocatalysis. The Journal of Physical Chemistry C 127(9), 4704–4713 (2023). https://doi.org/10.1021/acs.jpcc.2c08064

Egbo, K.O., Shil, S.K., Kwok, C.G., Wang, Y., Liu, C.P., Yu, K.M.: Band alignment of wide bandgap NiO/MoO3 and NiO/WO3 p-n heterojunctions studied by high-resolution X-ray photoelectron spectroscopy. J. Alloy. Compd. 876, 160136 (2021)

Elumalai, N.K., Vijila, C., Jose, R., et al.: Metal oxide semiconducting interfacial layers for photovoltaic and photocatalytic applications. Mater. Renew. Sustain. Energy 4, 11 (2015). https://doi.org/10.1007/s40243-015-0054-9

Ferri, M., Elliott, J., Fabris, S., Piccinin, S.: Establishing best practices to model the electronic structure of CuFeO2 from first principles. Phys. Rev. B 101, 155201 (2020)

Forslund, A.: Synthesis and characterization of delafossite CuFeO2 for solar energy applications, PhD thesis, Uppsala Universitet (2016)

Fugate, E.A., Biswas, S., Clement, M.C., Kim, M., Kim, D., Asthagiri, A., Baker, L.R.: The role of phase impurities and lattice defects on the electron dynamics and photochemistry of CuFeO2 solar photocathodes. Nano Res. 12, 2390–2399 (2019)

Gomathi, S., Sivapriya, J., Kalaiyarasi, M., Sivakumar, J., Jaanaa Rubavathy, S., Kumar, A.: Analyzing the performance ceiling of RbSnGeI3 -based lead-free stable perovskite solar cell. Opt. Quant. Electron. 55, 734 (2023a)

Gomathi, S., Raj, A.G., Mishra, C.S., Kumar, A.: Straddling type sandwiched absorber based solar cell structure. Optik 272, 170354 (2023b)

Gonzaga, I.L.E., Mercado, C.C.: Copper ternary oxides as photocathodes for solar-driven CO2 reduction. Rev. Adv. Mater. Sci. 61(1), 430–457 (2022)

Gottesman, R., Levine, I., Schleuning, M., Irani, R., Abou-Ras, D., Dittrich, T., Friedrich, D., van de Krol, R.: Overcoming phase-purity challenges in complex metal oxide photoelectrodes: a case study of CuBi2O4. Adv. Energy Mater. 11, 2003474 (2021)

Green, M.A., Dunlop, E.D., Yoshita, M., Kopidakis, N., Bothe, K., Siefer, G., Hao, X.: Solar cell efficiency tables (version 62). Prog. Photovolt. Res. Appl. 31(7), 651–663 (2023)

Hemalatha, S., Prabu, R.T., Radhika, R., Kumar, A.: Dual-absorber thin-film solar cell: a high-efficiency design. Phys. Status Solidi A 220, 2200761 (2023)

Jiang, C.M., Reyes-Lillo, S.E., Liang, Y., Liu, Y.S., Liu, G., Toma, F.M., Prendergast, D., Sharp, I.D., Cooper, J.K.: Electronic Structure and Performance Bottlenecks of CuFeO2 Photocathodes. Chem. Mater. 31(7), 2524–2534 (2019a)

Jiang, T., Zhao, Y., Xue, H.: Boosting the performance of delafossite photocathode through constructing a CuFeO2/CuO heterojunction for photoelectrochemical water reduction. J. Mater. Sci. 54, 11951–11958 (2019b)

Jin, Y., Chumanov, G.: Solution synthesis of pure 2H CuFeO2 at low temperatures. RSC Adv. 6, 26392–26397 (2016)

Kang, M., Jung, J., Lee, S.Y., Ryu, J.W., Kim, S.W.: Conductivity, carrier density, mobility, seebeck coefficient, and power factor in V2O5. Thermochim. Acta 576, 71–74 (2014)

Kar, M., Sarkar, R., Pal, S., Sarkar, P.: Lead-free two-dimensional mixed tin and germanium halide perovskites for photovoltaic applications. J. Phys. Chem. C 125, 74–81 (2021)

Karmakar, K., Sarkar, A., Mandal, K., Khan, G.G.: Nano-engineering of p-n CuFeO2-ZnO heterojunction photoanode with improved light absorption and charge collection for photoelectrochemical water oxidation. Nanotechnology 28, 325401 (2017)

Klenk, R.: Characterisation and modelling of chalcopyrite solar cells. Thin Solid Films 387, 135–140 (2001)

Kumar, A., Ajay, D.: Thakur Role of contact work function, back surface field, and conduction band offset in Cu2ZnSnS4 solar cell. Jpn. J. Appl. Phys. 57, 08RC05 (2018)

Kumar, A., Ranjan, P.: Defects signature in VOC characterization of thin-film solar cells. Sol. Energy 220, 35–42 (2021)

Kumar, A., Thakur, A.D.: Design issues for optimum solar cell configuration. AIP Conf. Proc. 1, 050022 (1953)

Kumar, A., Thakur, A.D.: Comprehensive loss modeling in Cu2ZnSnS4 solar cells. Curr. Appl. Phys. 19, 1111–1119 (2019)

Kumar, A., Singh, N.P., Sundaramoorthy, A.: Comparative device performance of CZTS solar cell with alternative back contact. Mater. Lett. X 12, 100092 (2021)

Kumar, A., Prabu, R.T., Das, A.: Configuration analysis of SnS-based solar cells for high-efficiency devices. Opt. Quant. Electron. 54, 521 (2022)

Lee, D., Park, J.W., Cho, N.K., et al.: Verification of charge transfer in metal-insulator-oxide semiconductor diodes via defect engineering of insulator. Sci. Rep. 9, 10323 (2019)

Li, R.P., Shan, B.F., Zhao, Z.Y.: Delafossite CuFeO2 nanosheets with highly exposed 001 crystal facets for enhancing charge separation efficiency. Appl. Surf. Sci. 618, 156594 (2023)

Liu, X., Zheng, H., Zhang, J., Xiao, Y., Wang, Z.: Photoelectric properties and charge dynamics for a set of solid-state solar cells with Cu4Bi4S9 as the absorber layer. J. Mater. Chem. a. 1, 10703–10712 (2013)

Liu, Q.L., Zhao, Z.Y., Zhao, R.D., Yi, J.H.: Fundamental properties of delafossite CuFeO2 as photocatalyst for solar energy conversion. J. Alloy. Compd. 819, 153032 (2020a)

Liu, Q.L., Zhao, Z.Y., Yi, J.H.: Excess oxygen in delafossite CuFeO2+δ: Synthesis, characterization, and applications in solar energy conversion. Chem. Eng. J. 396, 125290 (2020b)

Livingston, L.M.M., Raj, A.G.S., Prabu, R.T., et al.: Computational analysis of FeS2 material for solar cell application. Opt. Quant. Electron. 55, 244 (2023)

Medhi, R., Li, C.H., Lee, S.H., Marquez, M.D., Jacobson, A.J., Lee, T.C., Lee, T.R.: Uniformly spherical and monodisperse antimony- and zinc-doped tin oxide nanoparticles for optical and electronic applications. ACS Appl. Nano Mater. 2(10), 6554–6564 (2019)

Minemoto, T., Murata, M.: Theoretical analysis on effect of band offsets in perovskite solar cells. Sol. Energy Mater. Sol. Cells 133, 8–14 (2015)

Pan, J., Gloeckler, M., Sites, J.R.: Hole current impedance and electron current enhancement by back-contact barriers in CdTe thin film solar cells. J. Appl. Phys. 100, 124505 (2006)

Prabu, R.T., Malathi, S.R., Kumar, A., Al-Asbahi, B.A., Laref, A.: Bandgap assessment of compositional variation for uncovering high-efficiency improved stable all-inorganic lead-free perovskite solar cells. Phys. Status Solidi A 220, 2200791 (2023)

Prévot, M.S., Guijarro, N., Sivula, K.: Enhancing the performance of a robust sol–gel-processed p-type delafossite CuFeO2 photocathode for solar water reduction. Chemsuschem 8, 1359–1367 (2015)

Prévot, M.S., Jeanbourquin, X.A., Bourée, W.S., Abdi, F., Friedrich, D., van de Krol, R., Guijarro, N., Le Formal, F., Sivula, K.: Evaluating charge carrier transport and surface states in CuFeO2 photocathodes. Chem. Mater. 29(11), 4952–4962 (2017)

Reddy, Y.K., Manjunath, V., Bimli, S., Devan, R.S.: Futuristic kusachiite solar cells of CuBi2O4 absorber and metal sulfide buffer Layers: theoretical efficiency approaching 28 %. Sol. Energy 244, 75–83 (2022)

Ryu, J.H., You, Y.G., Kim, S.W., Hong, J.H., Na, J.H., Jhang, S.H.: Effect of Al2O3 deposition on carrier mobility and ambient stability of few-layer MoS2 field effect transistors. Curr. Appl. Phys. 20(2), 363–365 (2020)

Scanlon, D., Dunnill, C., Buckeridge, J., et al.: Band alignment of rutile and anatase TiO2. Nat. Mater. 12, 798–801 (2013)

Shaili, H., Salmani, E., Beraich, M., Elhat, A., Rouchdi, M., Taibi, M., Ez-Zahraouy, H., Hassanain, N., Mzerd, A.: Revealing the impact of strontium doping on the optical, electronic and electrical properties of nanostructured 2H-CuFeO2 delafossite thin films. RSC Adv. 11, 25686 (2021)

Shi, J., Zhang, J., Yang, L., Qu, M., Qi, D.C., Zhang, K.H.: Wide bandgap oxide semiconductors: from materials physics to optoelectronic devices. Adv. Mater. 33, 2006230 (2021). https://doi.org/10.1002/adma.202006230

Singh, G., Kaur, T.P., Tangra, A.K.: Novel KFeO2 nanoparticles for dye-sensitized solar cell. Mater. Res. Express 6, 1150f5 (2019)

Singh, A.P., Wang, R.B., Tossi, C., Tittonen, I., Wickman, B., Hellman, A.: Hydrogen induced interface engineering in Fe2O3–TiO2 heterostructures for efficient charge separation for solar-driven water oxidation in photoelectrochemical cells. RSC Adv. 11, 4297–4307 (2021)

Son, M.-K.: Effect of deposition parameters on morphological and compositional characteristics of electrodeposited CuFeO2 film. Coatings 12(12), 1820 (2022a). https://doi.org/10.3390/coatings12121820

Son, M.-K.: Effect of deposition parameters on morphological and compositional characteristics of electrodeposited CuFeO2 Film. Coatings 12, 1820 (2022b). https://doi.org/10.3390/coatings12121820

Song, J.D., Wu, J.C., Rao, X., Li, S.J., Zhao, Z.Y., Liu, X.G., Zhao, X., Sun, X.F.: Single crystal growth of CuFe1−xGaxO2 by the optical floating-zone method. J. Cryst. Growth 446, 79–84 (2016)

Stangl, R., Kriegel, M., Schmidt, M.: AFORS-HET, Version 2.2, a numerical computer program for simulation of heterojunction solar cells and measurements. In: Proc. WCPEC-4, 4th world conference on photovoltaic energy conversion, Hawaii, May (2006). https://doi.org/10.1109/WCPEC.2006.279681

Vojkovic, S., Fernandez, J., Elgueta, S., Vega, F.E., Rojas, S.D., Wheatley, R.A., Seifert, B., Wallentowitz, S., Cabrera, A.L.: Band gap determination in multi-band-gap CuFeO2 delafossite epitaxial thin film by photoconductivity. SN Appl. Sci. 1, 1322 (2019)

Wang, J., Fu, W., Jariwala, S., Sinha, I., Jen, A.K., Ginger, D.S.: Reducing surface recombination velocities at the electrical contacts will improve perovskite photovoltaics. ACS Energy Lett. 4(1), 222–227 (2019)

Xu, H., Wu, R., Zhang, J.Y., Han, W., Chen, L., Liang, X., Haw, C.Y., Mazzolini, P., Bierwagen, O., Qi, D.C., Zhang, K.H.: Revealing the electronic structure and optical properties of CuFeO2 as a p-type oxide semiconductor. ACS Appl. Electron. Mater. 3(4), 1834–1841 (2021)

Zakutayev, A., Major, J.D., Hao, X., Walsh, A., Tang, J., Todorov, T.K., Wong, L.H., Saucedo, E.: Emerging inorganic solar cell efficiency tables (version 2). J. Phys. Energy. 3, 032003 (2021)

Zhu, T., Deng, Z., Fang, X., Huo, Z., Wang, S., Dong, W., Shao, J., Tao, R., Song, C., Wang, L.: High photovoltages of CuFeO2 based p-type dye-sensitized solar cells. J. Alloys Comp. 685, 836–840 (2016)

Acknowledgements

AK acknowledge Prof Marc Burgelmann for the SCAPS software package.

Funding

No funding.

Author information

Authors and Affiliations

Contributions

PD, AG and LM performed simulations and prepared the initial draft, and AK conceptualized and prepared the final draft.

Corresponding author

Ethics declarations

Conflict of interests

Authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prasad, D., Anitha, G., Leo, L.M. et al. Theoretical analysis of earth-abundant solar cell based on green absorber CuFeO2. Opt Quant Electron 55, 1262 (2023). https://doi.org/10.1007/s11082-023-05499-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-023-05499-w