Abstract

In this present work, a novel structure of octagonal cladding with two elliptical air holes based on photonic crystal fiber (O-PCF) has been presented for the application of different types of communication areas within the terahertz (THz) wave propagation. There are five layers of octagonal design shape of circular air holes in cladding region with elliptical design shape of two air holes in core area has been reported in this research work. This O-PCF fiber has been investigated by the perfectly matched layers with the finite element method. After the simulation process, our proposed O-PCF fiber shows a low effective material loss of 0.0162 cm−1, the larger effective area of 5.88 × 10–8 m2, the core power fraction of 80%, the scattering loss of 1.22 × 10–10 dB/km, and the confinement loss of 3.33 × 10–14 dB/m at the controlling region of 1 terahertz (THz). Due to its excellent characteristics, this proposed O-PCF fiber gives proficient transmission of broadband terahertz waves of signals. Moreover, for different kinds of optical communication applications and biomedical signals, our suggested O-PCF fiber will be highly perfect in the terahertz (THz) regions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In present times, Terahertz (THz) radiation which varying from 0.1 to 10 THz has gained considerable interest due to its numerous functional uses related to electromagnetic radiation. The range of THz frequency deceits the region between the microwave and infrared radiation (IR) in the electromagnetic spectrum (ES). In wavelength, this range corresponds to 0.1 mm to infrared to 1 mm microwave. The THz frequency spectrum shows interesting development in the field of sensors (Vigneswaran et al. 2021; Devika and Mani Rajan 2020; Kabir et al. 2020), pharmaceutical medical testing (Nair et al. 2019), restorative spectrometry (Mohit Sharma et al. 2019), biomedical imaging (Vera et al. 2018), therapeutic diagnostics (Ho et al. 2008; Rana et al. 2018a), DNA hybridization (Vera et al. 2018), communications (Hossain et al. 2020), etc. The radiation of terahertz (THz) ranges has been also utilized within the areas of diagnostics such as skin cancer, basal cell carcinoma, and dysplastic skin nevi, etc. (Zhou and Zheng 2019). On the other hand, colon cancer and breast cancer can be carried out to prevent these diseases by utilizing high-frequency THz radiation.

Besides, hollow-core photonic crystal fiber and polymer fibers can be connected for THz communication since of their outstanding waveguide perspectives (Hossain et al. 2020; Zhou and Zheng 2019). Recently, porous core PCFs have gained considerable interest because of their adaptability in structural nature and required optical controlling possessions such as high core power fraction, lower effective material loss, lower dispersion, lower bending loss, high nonlinearity (Lee et al. 2002; Devi 2018; Shuvo et al. 2020; Hossain and Sen 2020; Islam et al. 2018; Kaijage et al. 2013). Modified Total internal refection (MTIR) and photonic band gap (PGB) are two basic optical guiding properties are found in PCF. Total internal reflection (TIR) and photonic bandgap (PGB) are two basic optical guiding properties are found in PCF. If the light is confined in a higher region of the refractive index in solid-core PCF then the total internal reflection can be optimized. Various polymer is used as background materials in microstructure core PCF to control the optical guiding properties such as TOPAS, Tellurite, Zeonex, Graphene, Teflon, etc. (Ahmen et al. 2017; Hasanuzzaman et al. 2015; Rahman et al. 2019).

Many researchers have been examined the performance of PCF structures previously using the terahertz (THz) waveguides (Hossain et al. 2020; Rahman et al. 2019; Gangwar and Singh 2016; Hasan et al. 2017; Lee et al. 2016). Islam et al. (2015a) proposed a porous-core spiral shape photonic crystal fiber (PCF). Their proposed model obtained the EML and effective area of 0.1 cm−1 and 1.82 × 10−7 m2 accordingly at 1 THz frequency. Nonetheless, their proposed model showed higher EML. Hasan et al. (2016a) explored hexagonal PCFs which gained EML of 0.089 cm−1 at 1 THz frequency. But some of the essential parameters were not listed in his article. At the same time, Saiful et al. (2016a) suggested a rotated hexagonal porous core with circular shape cladding and found the EML of 0.053 cm−1 with a dispersion of 0.25 ps/THz/cm. Rana et al. (2018b) proposed a hexagonal-shaped hole incorporated within the core of a Kagome lattice PCF. Their proposed model shows an EML of 0.029 cm−1 and a core power fraction of 33% at 1.3 THz frequency. In the same year, Sultana et al. (2018a) designed a hexagonal shape cladding with elliptical core PCF to obtain an EML of 0.05 cm−1 and a very high birefringence of 0.086. Besides their suggested model obtained comparably higher EML and some important elements like power fraction and bending loss stayed unexplored.

In this article, the newly designed Zeonex based octagonal shape of the cladding region with two elliptical shapes in the core area has been introduced in the THz regime. The proposed model shows an extremely low effective material loss (EML) of 0.0162 cm−1 with 80% core power fraction and larger effective area (EA) of 5.88 × 10–8 m2 at 1 THz optical frequency than the previously published articles (Sultana et al. 2018a; Hossain et al. 2021; Mou et al. 2019, 2020; Islam et al. 2015b; Hasan et al. 2016b, c; Paul and Ahmed 2020).

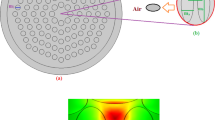

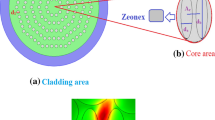

2 Design methodology of the single mode PCF

The geometry view of O-PCF has been provided in Fig. 1 that has two elliptical shape air holes in the core region with five layers octagonal shape circular air holes of cladding region along with the mode field distribution. The number of 1st, 2nd, 3rd, 4th, and 5th layer of air holes are 8, 16, 32, 64, and 128 within the cladding region correspondingly. Here, the pitch and diameter of the air holes are marked by parameters of P1 and m1 respectively at the cladding region. The parameters ratio of m1/P1 is called the air filling ratio and these m1/P1 ratio try to reduce the fabrication complexity between the two air holes at the cladding region. On the other hand, the parameters of pc, ma, and mb are denoted with the pitch and diameters of the two elliptical air holes at the core area. Here, Zeonex is used as background material to reduce the effective material loss, confinement loss and the scattering loss for various communication application areas. Besides, the optimum parameters are diameter of cladding m1 = 244 μm, m2 = m3 = m4 = m5 = 272 μm, pitch of cladding P1 = 325 μm, P2 = P3 = P4 = P5 = 365 μm, diameter of core ma = 74 μm, mb = 195 μm and core pitch Pc = 90 μm and the thickness of PML (boundary condition) is calculated by the 8% of the maximum fiber diameter. Consequently, this O-PCF structure is designed by the FEM method with the PML layers based COMSOL Multiphysics software tool and helps to achieve the better optical features such as scattering loss, effective area, power fraction, the ultra-low effective material loss (U-EML), V-parameter, confinement loss from 0.80 to 3 THz with the terahertz frequency wave pulse ranges.

3 Analysis of optical properties

To plan and reconstruct the highlights of the current O-PCF, the finite element method (FEM) is available in COMSOL Multiphysics 4.2b software. Between the final ring of the cladding region and the core region, the boundary condition perfectly matched layers (PML) are used. The FEM with PML technique, which uses the COMSOL Multiphysics software tool, includes all optical angles and parameters. We know that a larger effective area-based PCF fiber shows better communication in many sectors. Here, the effective area is expressed by Gangwar and Singh (2016), Hasan et al. (2017):

where, I(e) = |Ee|2 is the intensity electric field and effective area = Aea.

One more important property of optical fiber is the power fraction that is determined with the total amount of power through the PCF fiber. Here, the power fraction is calculated by the following equations (Hossain et al. 2020; Lee et al. 2016):

where, the integration of nominator is defined by the region of interest such as the cladding, core or air hole and the whole cross-section area is indicated by the integration of denominator.

Mode propagation of O-PCF is mentioned by V-parameter. Here, V-parameter is analyzed by Islam et al. (2015a):

where, ncoe and ncle is determined by the core and cladding area based on effective refractive index and the radius of the core is e.

Low confinement loss based O-PCF structure shows better performance in the communication areas. Here, confinement loss \({\text{L}}_{{\text{c}}}\) is calaulted by Hasan et al. (2016a):

where, \({\text{K}}_{0}\) =\(\left( {\frac{{\text{f}}}{{\text{c}}}} \right)\) is the free wave number with the speed of photon c and f is frequency, \({\text{Im }}\left[ {{\text{n}}_{{{\text{ea}}}} } \right]\) is well-defined by the imaginary part of effective refractive index (ERI).

The total amount of loss can be calculated by the scattering of the O-PCF fiber. Here, the scattering loss is totaled by Islam et al. (2016a):

where, \({\text{C}}_{{\text{S}}}\) is denoted by the scattering coefficient with f is frequency and c is the speed of photon.

TOPAS is the background material of O-PCF fiber and supports to reduce the effective material loss (EML) with the wide band frequency range. So, effective material loss (EML) is determined by Hossain et al. (2021), Mou et al. (2019), Mou et al. (2020):

where, ε0 = relative permittivity and \({\upmu }_{0}\) = the permeability of free space, \({\text{n}}_{{{\text{mat}}}} =\) Refractive index of the material and \({\upalpha }_{{\text{mat }}}\) = bulk material absorption loss, Pointing vector Szt = \(\frac{1}{2}\) (E \(\times\) \({\text{H}}^{*}\)). The component of electric field (E) and magnetic field (\({\text{ H}}^{*}\)) which are the complex parameters.

4 Simulated results analysis and discussions

We have found the complete graphical results from the PML layers and the FEM method based COMSOL Multiphysics software tool of this single mode photonic crystal fiber. From Figs. 2, 3, 4, 5, 6, 7, 8 and 9, it is clearly seen that the total amount of lights transmits within the core area. As a result, this O-PCF fiber shows better graphical results about of optical properties like as low effective material loss (EML), scattering loss, larger effective area, high core power fraction (CPF), V-parameter, confinement loss with the frequency ranges from 0.08 to 3 terahertz (THz).

The effective area along with different frequency as well as functional porosity for instance 63%, 73%, and 83% have been given by the Fig. 2. The effective area is decreased with the increasing frequency ranges that has been shown in Fig. 2. Here, the effective area is calculated as 5.88 × 10–8 m2, 6.20 × 10–8 m2, and 6.05 × 10–8 m2 for 83%, 73%, and 63% porosities respectively at 1 terahertz (THz) frequency.

In Fig. 3 shows the better numerical results of effective area along with the core diameter for different porosities such as 63%, 73%, and 83%. Successful effective area decreases with the rise of the core diameter. Moreover, it is seen that the effective area stays flat from Dcore = 196 μm to Dcore = 390 μm. For optimum core diameter Dcore = 376 μm, the effective area is expected as 5.55 × 10–8 m2, 6.50 × 10–8 m2, and 7.20 × 10–8 m2 for 83%, 73%, and 63% porosities for 1 terahartz (THz) frequency correspondingly.

The effective material loss of the anticipated O-PCF has been given by frequency modification in Fig. 4 and the effective material loss reduces with the rising of frequency. This O-PCF fiber shows better effective material losses such as 0.0348 cm−1, 0.0236 cm−1 and 0.0162 cm−1 for 63%, 73% and 83% porosities correspondingly at 1 terahertz (THz) for optimum parameters.

The effect of various core diameters and the effective material loss for 83%, 73% and 63% porosities has been shown in Fig. 5. Here, the effective material losses is increased with the increasing of core diameters. On the other hand, for Dcore = 376 μm, porosity = 83%, 73% and 63% at 1 terahertz (THz) frequency, the effective material loss shows 0.0162 cm−1, 0.0187 cm−1, 0.0137 cm−1 at optimal design parameters.

Figure 6 shows the distribution of power across the core, cladding and materials with respect to frequency at a fixed Dcore = 376 um. As the light generated within the fiber, some of the power is absorbed by air holes and core materials in the fiber. The experimental frequency ranges within 0.08 THz–3 THz in electromagnetic band. As it was found that, 80% optical power generated through the fiber core at 1 terahertz (THz) which means maximum light contact with analytes in the core region. Moreover, the air holes in cladding region induced light waves to pass within the core and provide maximum core power fraction. The observed power fraction is considerably higher than the previously stated article. The power fractions of core, cladding and materials are 80%, 2% and 28% respectively which operated at 1 THz ranges.

Figure 7 indicates the scattering loss analysis for the variations in wavelength in proposed structure. Therefore, light totally absorbed by the core area and reduce scattering loss. Scattering loss is an important parameter because it contributes the total losses of the fiber. Scattering loss is increasing with the increases of frequency within 0.08–3 THz range appeared in Fig. 7, where’s the Dcore = 376 um. The attained scattering loss (SL) of this O-PCF is 1.22 × 10–10 dB/km at optical wavelength 1 terahertz (THz) which is negligible.

Figure 8 shows the behavior of confinement loss due to the frequency at optimal structure. It can be observed from the figure, confinement loss of proposed model is being reduced due to rising of frequency across 0.08–3 THz at Dcore = 376 um. When light passes through the core with high frequency then it improves the index contrast of core and cladding and thus minimize the confinement loss. It is found that that the confinement loss of proposed O-PCF is 3.33 × 10–14 dB/m.

V-parameter indicates the fiber act as single mode or multimode. V-parameter is calculated as the function of frequency for optimum design parameter at Dcore = 376 μm in Fig. 9. As it evolves that, V-parameter is 1.20 at operating frequency 3 terahertz (THz) which shows the suggested model is single mode fiber (SMF ≤ 2.405). On the other hand, single mode fiber is best suitable for wide band communication applications and others communication related signals. Here, the proposed O-PCF design of optimum elements are diameter of cladding m1 = 244 μm, m2 = m3 = m4 = m5 = 272 μm, pitch of cladding P1 = 325 μm, P2 = P3 = P4 = P5 = 365 μm, diameter of core ma = 74 μm, mb = 195 μm and core pitch Pc = 90 μm.

The designed O-PCF shows the better effective material loss, Confinement loss, Core power fraction, and effective area properties than other designed PCFs at 1 terahertz (THz) functional frequency as providing in Table 1.

From the investigation of Table 1 that the proposed O-PCF will play an essential role in various wideband transmission applications in THz micro-technology. On the other hand, fabrication technique is an important issue of any PCF structure. So, many fabrication techniques are appropriate essentially to fabricate the O-PCF (Islam et al. 2017b, Tang et al. 2013) but sol–gel (Hamzaoui et al. 2012) procedure is more appropriate for fabricate the O-PCF.

5 Conclusion

In this proposed work, Zeonex based two elliptical shape air holes of the core region along with octagonal shape circular air holes of cladding region have been thoroughly examined using the PML boundary structure with the FEM based COMSOL Multiphysics. After the numerical procedure, our reported O-PCF fiber gives an outstanding optical property such as a low effective material loss (EML) of 0.0162 cm−1, the larger effective area of 5.88 × 10–8 m2, the core power fraction (PF) of 80%, the scattering loss (SL) of 1.22 × 10–10 dB/km and the confinement loss of 3.33 × 10–14 dB/m at the operating region of 1 terahertz (THz). Therefore, our proposed O-PCF structure will be used in many communication applications for its excellent optical properties.

References:

Ahasan Habib, M., Shamim Anower, M., Rabiul Hasan, M.: Highly birefringent and low effective material loss microstructure fiber for THz wave guidance. Opt. Commun. 423, 140–144 (2018). https://doi.org/10.1016/j.optcom.2018.04.022

Ahmed, K., Chowdhury, S., Paul, B.K., Islam, M.S., Sen, S., Islam, M.I., et al.: Ultrahigh birefringence, ultralow material loss porous core single-mode fiber for terahertz wave guidance. Appl. Opt. 56(12), 3477–3483 (2017). https://doi.org/10.1364/AO.56.003477

Ahmen, K., Paul, B.K., Chowdhury, S., Sen, S., Islam, M.I., Islam, M.S.: Design of a single mode photonic crystal fiber with ultra-low material loss and large effective mode area in THz regime. IET Optoelectron. 11(6), 265–271 (2017)

Devi, D.: Structural parameters, electronic properties, and band gaps of a single walled carbon nanotube: a pz orbital tight binding study. Superlattices Microstruct. 120, 108–126 (2018). https://doi.org/10.1016/j.spmi.2018.05.023

Devika, V., Mani Rajan, M.S.: Hexagonal PCF of honeycomb lattice with high birefringence and high nonlinearity. Int. J. Mod. Phys. B 33, 2050094 (2020). https://doi.org/10.1142/S0217979220500940. (World Scientific)

El Hamzaoui, H., Ouerdane, Y., Bigot, L., Bouwmans, G., Capoen, B., Boukenter, A., Girard, S., Bouazaoui, M.: Sol-gel derived ionic copper-doped microstructure optical fiber: a potential selective ultraviolet radiation dosimeter. Opt. Express 20(28), 29751–29760 (2012)

Gangwar, R.K., Singh, V.K.: Study of highly birefringence dispersion shifted photonic crystal fiber with asymmetrical cladding. Optic 127(24), 11854–11859 (2016)

Hasan, M.R., Islam, M.A., Anower, M.S., Razzak, S.M.A.: Low-loss and bend-insensitive terahertz fiber using a rhombic-shaped core. Appl. Opt. 55, 8441–8447 (2016a)

Hasan, M.R., Islam, M.A., Anower, M.S., Razzak, S.M.: Low-loss and bend-insensitive terahertz fiber using a rhombic-shaped core. Appl. Opt. 55(30), 8441–8447 (2016b). https://doi.org/10.1364/AO.55.008441

Hasan, M.R., Islam, M.A., Rifat, A.A.: A single mode porous-core square lattice photonic crystal fiber for THz wave propagation. Eur. Opt. Soc. Rapid Publ. 12(1), 15 (2016c). https://doi.org/10.1186/s41476-016-0017-5

Hasan, M.R., Akter, S., Khatun, T., Rifat, A.A., Anower, M.S.: Dual-hole unit-based kagome lattice microstructure fiber for low-loss and highly birefringent terahertz guidance. Opt. Eng. 56(4), 043108 (2017). https://doi.org/10.1117/1.OE.56.4.043108

Hasanuzzaman, G.K.M., Habib, M.S., Razzak, S.A., Hossain, M.A., Namihira, Y.: Low loss single-mode porous-core kagome photonic crystal fiber for THz wave guidance. J. Lightwave Technol. 33(19), 4027–4031 (2015)

Ho, L., Pepper, M., Taday, P.: Terahertz spectroscopy: signatures and fingerprints. Nat. Photonics 2(9), 541–543 (2008)

Hossain, M.S., Shuvo, S., Hossain, M.M.: Design of a chemical sensing circular photonic crystal fiber with high relative sensitivity and low confinement loss for terahertz (THz) regime. Optik Int. J. Light Electron Opt. 222, 165359 (2020). https://doi.org/10.1016/j.ijleo.2020.165359

Hossain, M.S., Sen, S.: Design and performance improvement of optical chemical sensor based photonic crystal fiber (PCF) in the terahertz (THz) wave propagation. Silicon. 1–9 (2020). https://doi.org/10.1007/s12633-020-00696-8

Hossain, M.S., Hasan, M.M., Sen, S., Mollah, M.S.H., Azad, M.M.: Simulation and analysis of ultra-low material loss of single-mode photonic crystal fiber in terahertz (THz) spectrum for communication applications. J. Opt. Commun. 4873 (2021). doi: https://doi.org/10.1515/joc-2020-0224

Islam, R., Rana, S., Ahmad, R., Kaijage, S.F.: Bend-insensitive and low-loss porous core spiral terahertz fiber. IEEE Photonics Technol. Lett. 27(21), 2242–2245 (2015). https://doi.org/10.1109/LPT.2015.2457941

Islam, R., Rana, S., Ahmad, R., Kaijage, S.F.: Bend-insensitive and low-loss porous core spiral terahertz fiber. IEEE Photon Technol. Lett. 27(21), 2242–2245 (2015b). https://doi.org/10.1109/LPT.2015.2457941

Islam, M.S., Rana, S., Islam, M.R., Faisal, M., Rahman, H., Sultana, J.: Porous core photonic crystal fiber for ultra-low material loss in THz regime. IET Commun. 10(16), 2179–2183 (2016a)

Islam, R., Habib, M.S., Hasanuzzaman, G.K.M., Rana, S., Sadath, M.A., Markos, C.: A novel low-loss diamond-core porous fiber for polarization maintaining terahertz transmission. IEEE Photon Technol. Lett. 28(14), 1537–1540 (2016b)

Islam, M.S., Sultana, J., Rana, S., Islam, M.R., Faisal, M., Kaijage, S.F., Abbott, D.: Extremely low material loss and dispersion flattened TOPAS based circular porous fiber for long distance terahertz wave transmission. Opt. Fiber Technol. 34, 6–11 (2017a). https://doi.org/10.1016/j.yofte.2016.11.014

Islam, M.S., Sultana, J., Atai, J., Abbott, D., Rana, S., Islam, M.R.: Ultra low loss hybrid core porous fiber for broadband applications. Appl. Opt. 56(9), 1232–1237 (2017b)

Islam, M.S., Sultana, J., Dorraki, M., Atai, J., Islam, M.R., Dinovitser, A., Abbott, D.: Low loss and low dispersion hybrid core photonic crystal fiber for terahertz propagation. Photon Netw. Commun. 35(3), 364–373 (2018)

Kabir, M.A., Hassan, M.M., Ahmed, K., Mani Rajan, M.S., Aly, A.H., Hossain, M.N., Paul, B.K.: Novel spider web photonic crystal fiber for robust mode transmission applications with supporting orbital angular momentum transmission property. Opt. Quantum Electron. 52, 331 (2020). https://doi.org/10.1007/s11082-020-02447-w

Kaijage, S.F., Ouyang, Z., Jin, X.: Porous-core photonic crystal fiber for low loss terahertz wave guiding. IEEE Photonics Technol. Lett. 25(15), 1454–1457 (2013)

Lee, J.H., Teh, P.C., Yusoff, Z., Ibsen, M., Belardi, W., Monro, T.M., Richardson, D.J.: A holey fiber-based nonlinear thresholding device for optical CDMA receiver performance enhancement. IEEE Photonics Technol. Lett. 14(6), 876–878 (2002)

Lee, Y.S., Lee, C.G., Jung, Y., Oh, M.K., Kim, S.: Highly Birefringent and dispersion compensating photonic crystal fiber based on double line defect core. J. Opt. Soc. Korea 20(5), 567–574 (2016)

Mou, F.A., Rahman, M.M., Mahmud, A.A., Bhuiyan, M.I.H., Islam, M.R.: Design and characterization of a low loss polarization maintaining photonic crystal fiber for THz regime. In: IEEE International Conference on Telecommunications and Photonics (2019)

Mou, F.A., Rahman, M.M., Islam, M.R., Bhuiyan, M.I.H.: Development of a photonic crystal fiber for THz wave guidance and environmental pollutants detection. Sens. Bio-Sens. Res. 29, 100346 (2020). https://doi.org/10.1016/j.sbsr.2020.100346

Nair, A.A., Boopathi, C.S., Jayaraju, M., Mani Rajan, M.S.: Numerical investigation and analysis of flattened dispersion for supercontinuum generation at very low power using hexagonal shaped photonic crystal fiber (H-PCF). Optik 179, 718–725 (2019)

Paul, B.K., Ahmed, K.: Analysis of terahertz waveguide properties of Q-PCF based on FEM scheme. Opt. Mater. 100, 109634 (2020). https://doi.org/10.1016/j.optmat.2019.109634

Paul, B.K., Bhuiyan, T., Abdulrazak, L.F., Sarker, K., Hassan, M.M., Shariful, S., Ahmed, K.: Extremely low loss optical waveguide for terahertz pulse guidance. Results Phys. 15, 102666 (2019). https://doi.org/10.1016/j.rinp.2019.102666

Rahman, M.M., Mou, F.A., Bhuiyan, M.I.H., Islam M.R.: Extremely low effective material loss of air core photonic crystal fiber for THz guidance. In: IEEE Region 10 Symposium (TENSYMP), Kolkata, India, pp. 716–720 (2019), doi: https://doi.org/10.1109/TENSYMP46218.2019.8971297

Rana, S., Hasanuzzaman, G.K., Habib, S., Kaijage, S.F., Islam, R.: Proposal for a low loss porous core octagonal photonic crystal fiber for T-ray wave guiding. Opt. Eng. 53(11), 115107–115107 (2014). https://doi.org/10.1117/1.OE.53.11.115107

Rana, S., Rakin, A.S., Hasan, M.R., Reza, M.S., Leonhardt, R.: Low loss and flat dispersion kagome photonic crystal fiber in the terahertz regime. Opt. Commun. 410, 452–456 (2018a)

Rana, S., Rakin, A.S., Hasan, M.R., Reza, M.S., Leonhardt, R., Abbott, D., Subbaraman, H.: Low loss and flat dispersion Kagome photonic crystal fiber in the terahertz regime. Opt. Commun. 410, 452–456 (2018b)

Sharma, M., Vigneswaran, D., Skibina, J.S., Mani Rajan, M.S., Konar, S., Hoang, T.T., Ngo, Q.M.: Giant nonlinear AlGaAs-doped glass photonic crystal fibers for efficient soliton generation at femtojoule energy. IEEE Photonics 11, 7102411 (2019)

Shuvo, S., Shafi, M.A., Sikder, A.S., Hossain, M.S., Azad, M.M.: Zeonex based decagonal photonic crystal fiber (D-PCF) in the terahertz (THz) band for chemical sensing applications. Sens. Bio-Sens. Res. 31, 100393 (2020). https://doi.org/10.1016/j.sbsr.2020.100393

Sultana, J., Islam, M.S., Faisal, M., Islam, M.R., Ng, B.W.H., Ebendorf-Heidepriem, H., Abbott, D.: Highly birefringent elliptical core photonic crystal fber for terahertz application. Opt. Commun. 407, 92–96 (2018a)

Sultana, J., Islam, M.S., Ahmed, K., Dinovitser, A., Ng, B.W.-H., Abbott, D.: Terahertz detection of alcohol using a photonic crystal fiber sensor. Appl. Opt. 57(10), 2426–2433 (2018b). https://doi.org/10.1364/ao.57.002426

Sultana, J., Islam, M.S., Islam, M.R., Abbott, D.: High numerical aperture, highly birefringent novel photonic crystal fibre for medical imaging applications. Electron. Lett. 54(2), 61–62 (2018c). https://doi.org/10.1049/el.2017.3694

Tang, X., Jiang, Y., Sun, B., Chen, J., Zhu, X., Zhou, P., Wu, D., Shi, Y.: Elliptical hollowfiberwith inner silver coating for linearly polarized terahertz transmission. IEEE Photonics Technol. Lett. 25(4), 331–334 (2013)

Vera, E.R., Restrepo, J.U., Durango, C.J., Cardona, J.M., Cardona, N.G.: Design of low loss and highly birefringent porous core photonic crystal fiber and its application to terahertz polarization beam splitter. IEEE Photonic J. 10(4), 1–13 (2018)

Vigneswaran, D., Mani Rajan, M.S., Biswas, B., Grover, A., Ahmed, K., Paul, B.K.: Numerical investigation of spiral photonic crystal fiber (S-PCF) with supporting higher order OAM modes propagation for space division multiplexing applications. Opt. Quantum Electron. 53, 78 (2021). https://doi.org/10.1007/s11082-021-02733-1

Zhou, J., Zheng, Y.: Fiber refractive index sensor with lateral-offset micro-hole fabricated by femtosecond laser. Optik 185, 1–7 (2019). https://doi.org/10.1016/j.ijleo.2019.03.094. (ISSN 0030-4026)

Acknowledgements

The authors do not receive any funding for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors announce that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Optical and Quantum Sciences in Africa

Guest edited by Salah Obayya, Alex Quandt, Andrew Forbes, Malik Maaza, Abdelmajid Belafhal and Mohamed Farhat.

Rights and permissions

About this article

Cite this article

Hossain, M.S., Kamruzzaman, M.M., Sen, S. et al. Design and analysis of the effect of Zeonex based octagonal photonic crystal fiber for different types of communication applications. Opt Quant Electron 53, 382 (2021). https://doi.org/10.1007/s11082-021-03084-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-021-03084-7