Abstract

Organic dye lasers are widely used in science and technology. Impregnation of dyes into polymers demonstrates many technical advantages, especially in the case when the dye monomer solution is filled inside the cavities of nanoporous glasses and then polymerized within the pores (PFNPG-P composite). This allows to create a rigid true solid-state active elements. Peculiarities of luminescence in such compositions are the subject of the work. Luminescence of 12 laser dyes was studied in liquid solutions (ethanol, MMA) and solid matrixes such as PMMA and PFNPG-P composite. Concentration dependences were measured for pyrromethenes, phenalemines, xanthenes and other types of dyes to define the quenching threshold of luminescence.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Organic dyes are applied widely in laser equipment, such as: dye lasers, Q-switches, optical decoupling elements, power limiters, up converters and so on. Mainly dyes are used in liquid solvents. However, liquids possess a number of obvious drawbacks such as poor thermooptical parameters, toxicity of some solutions, etc. For this reason, many efforts have been directed to create the solid-state host materials for laser optics (Dyumaev et al. 1991). The advantages of solid host materials for organic dyes lasers are: reliability, safety, compactness, easy operation.

In our earlier studies we have investigated: polymers, sol–gel glass, ormosil glass, composite polymer-filled nanoporous glasses (PFNPG-P) (Aldag et al. 2000a).

PFNPG-P sample preparation procedure was as follows:

Nanoporous plates, which are the base of a composite material, were made of an alkali-borosilicate glass by the method of acid leaching (Aldag et al. 2000a). The characteristic pore radius was 2–7 nm. To form a polymer composite component, we prepared a mixture of a methylmetacrylate (MMA) monomer and a low-molecular modifying additive, in which a dye was dissolved. But first, a monomer was distilled, and then the mixture was filtered through a 0.1-µm porous filter. Because nanoporous glass (NPG) is a strong adsorbent, to remove the adsorbed substances, NPG sample was annealed at 550 °C. After annealing the NPG sample was impregnated with monomer mixture prepared and free-radical polymerization was carried out at temperature of 30–100 °C, followed by annealing. After polymerization, the polymer sample was removed and subjected to optical block processing. The resulting laser elements have high hardness, strength and uniformity, low scattering. Detailed studies have also shown that the polymer fills the nanopores without microvoids. The resulting material has high laser damage resistance and thermooptical properties (Aldag et al. 2000a).

Numerous studies have proven the exceptional mechanical, optical and laser properties of the composite PFNPG-P and showed its promising use in laser technology (Aldag et al. 2000a, b; Dolotov et al. 2002). The problem of solid-sate elements for laser optics activated by organic dyes was solved to a great extent.

However, dyes behavioral studies in different environments are still remain actual. The concentration quenching of fluorescence—is one of the limitations of the conversion efficiency of laser elements. This was the subject of many articles. Most often studied Rhodamine 6G (Setiawan et al. 2010; Zehentbauer et al. 2014), however, in Green and Buckley (2015) a study of concentration quenching of other dyes is presented.

Peculiarities of laser dyes impregnation and fluorescence in PFNPG-P composite are the subject of the work. Fluorescence of 12 laser dyes was studied in liquid solution (ethanol, MMA) and solid matrixes such as PMMA and polymer-filled nanoporous glasses (PFNPG-P) composite. Concentration dependencies were measured for some pyrromethenes, phenalemines, xanthenes and other types of dyes to define the concentration quenching thresholds of fluorescence.

2 Experimental setup

The luminescence spectra and intensity was measured by Perkin-Elmer 650-40 fluorimeter using the front excitation geometry (Levshin and Saletsky 1994), in the same conditions for all the samples. This scheme allows to correctly identify the change in the luminescence intensity with increasing concentration of the dye.

The excitation wavelength always corresponded to the absorption maximum of the particular dye. To obtain the wavelength of maximum of fluorescence spectra of dyes we used the low concentration solutions of 5 × 10−5 mol/l. Optical scheme of investigations of the fluorescence spectra is shown in Fig. 1.

Optical scheme of investigations of the fluorescence spectra and intensity by Perkin-Elmer 650-40 fluorimeter using the front excitation geometry (Levshin and Saletsky 1994): 1 excitation radiation, 2 studied cell with a dye or a sample of the PFNPG-P composite, 3 fluorescence radiation, 4 reflected pump radiation, 5 diaphragm, 6 detection unit of fluorimeter

The intensity of fluorescence was measured at wavelength corresponding to maximum of fluorescence spectrum of particular sample.

3 Results and discussion

The measurement results of the luminescence intensity depending on the concentration of the dyes are shown in Table 1.

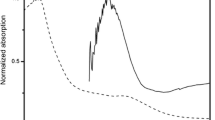

A typical dependence of fluorescence intensity on dye concentration is shown in Fig. 2.

Decreasing of fluorescence intensity at low concentrations is because the excitation light is not completely absorbed in the sample of the test substance, so reducing the number of excited molecules. This effect is due to the peculiarities of the measurement circuit, and is not associated with concentration quenching.

It was found that luminescence quenching in pyrromethene and phenalemine dyes in PMMA and liquid solution occurs at 2.5/5 × 10−3 mol/l which is significantly (from 10 to 100 times) higher than quenching concentrations for other types of dyes. Quenching threshold of pyrromethene dyes in the composite PFNPG-P is even more shifted towards higher concentrations, compared to the initial monomer composition, due to incomplete impregnation of dye molecules into PFNPG-P. The quenching threshold of 1/2 × 10−2 mol/l was measured for investigated dyes. Contrary to pyrromethene, phenalemine dyes in PFNPG-P composite revealed quenching shifts towards lower concentrations as compared to the initial monomer solution due to their extremely high impregnation into the porous matrix, demonstrating the quenching threshold at 1/5 × 10−5 mol/l for the reference set of dyes. The observed difference in dye doping for PFNPG-P matrix was also confirmed by absorption spectroscopy of the manufactured active elements.

Dyes impregnation coefficients were calculated in PFNPG-P composite. It is defined as the ratio of the dye concentration in composite and concentration in the initial monomer composition:

where C NPG —concentration measured in NPG-P composite, C in —concentration in the initial monomer solution.

The dye concentration in PFNPG-P composite was determined by the absorption intensity near the shortwave local maximum, as the optical density near the main absorption peak exceeded the limits of spectrophotometer measurements. Dye impregnation coefficient in PFNPG-P composite calculated for a various types of dyes are given in Table 2.

We found that the pyrromethene dyes are impregnated in the composite is significantly worse than phenalemine dyes. It must keep in mind in the preparation of the initial monomer composition intended for the manufacture of PFNPG-P composite.

You can make the assumption that the greater the polarity of the dyes, the higher dye impregnation coefficient of dye in PFNPG-P composite. Apparently, hydroxyl groups are in a large amount in the inner surface of nanoporous glass and they actively interact with polar dyes. Therefore, F-640, having an ionic structure in solvents, has the highest dye impregnation coefficient. For illustration, Fig. 3 shows investigated dyes formulas.

These results allow us to continue the work started by us in Koldunov et al. (2004) to optimize the concentration of the solid state dye lasers, aimed at maximum conversion efficiency and lifetime.

References

Aldag, H.R., et al.: Microporous glass-polymer composite as a new material for solid-state dye lasers: I. Material properties. Quantum Electron. 30(11), 954–958 (2000a)

Aldag, H.R., et al.: A microporous glass-polymer composite as a new material for solid-state dye lasers: II. Lasing properties. Quantum Electron. 30(12), 1055–1059 (2000b)

Dolotov, S.M., et al.: An efficient solid-state laser based on a nanoporous glass—polymer composite doped with phenalemine dyes emitting in the 600–660-nm region. Quantum Electron. 32(8), 669–674 (2002)

Dyumaev, K.M., Manenkov, A.A., Maslyukov, A.P., Matyushin, G.A., Nechitaylo, V.S., Prokhorov, A.M.: Interaction of laser radiation with optical polymers. In: Proceedings of the GPI, vol. 33. Nauka, Moscow, 1991 (in russian)

Green, A.P., Buckley, A.R.: Solid state concentration quenching of organic fluorophores in PMMA. Phys. Chem. Chem. Phys. 17, 1435–1440 (2015)

Koldunov, M.F., et al.: Relation between spectral and lasing properties for dyes of different classes. Quantum Electron. 34(2), 115–119 (2004)

Levshin, L.V., Saletsky, A.M.: Optical Methods for Studying Molecular Systems. M. Ed. Moscow State University, 1994 (in russian)

Setiawan, D., Kazaryan, A., Martoprawiro, M.A., Filatov, M.: A first principles study of fluorescence quenching in rhodamine B dimers: How can quenching occur in dimeric species? Phys. Chem. Chem. Phys. 12, 11238–11244 (2010)

Zehentbauer, F.M., Moretto, C., Stephen, R., Thevar, T., Gilchrist, J.R., Pokrajac, D., Richard, K.L., Kiefer, J.: Fluorescence spectroscopy of Rhodamine 6G: concentration and solvent effects. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 121, 147–151 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Fundamentals of Laser Assisted Micro- and Nanotechnologies.

Guest edited by Eugene Avrutin, Vadim Veiko, Tigran Vartanyan and Andrey Belikov.

Rights and permissions

About this article

Cite this article

Kravchenko, Y.V., Koldunov, M.F. & Petukhov, V.A. Concentration quenching of laser dyes fluorescence in variety of solid matrices and liquid solutions. Opt Quant Electron 49, 143 (2017). https://doi.org/10.1007/s11082-017-0963-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-017-0963-1