Abstract

The fabrication and characterization of one-dimensional photonic crystals (1D-PC) in the form of quarter-wavelength multilayered stack (Bragg stack) are presented. The 1D-PC comprises alternatively deposited spin-coated polymer PMMA (Poly(methyl methacrylate)) films as low-refractive index material that change thickness upon exposure to chloroform vapors, and both dense and porous V2O5 films providing both high optical contrast. The possibility of using PMMA–V2O5 structure as an omnidirectional reflector in both cases is confirmed experimentally. Besides, the prospect of utilizing the studied structures as optical indicators of chloroform vapors is demonstrated and discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One-dimensional photonic crystals (1D-PC) are quarter-wavelength multilayered stacks (i.e. Bragg stacks) that satisfy additional conditions for refractive index (Kim and Hwangbo 2002): (1) the optical contrast (difference in refractive indices of both materials) has to be higher than 0.75, and (2) the value of the high refractive index material to be greater than 2.264. In this case an omnidirectional reflectance (ODR) band opens up that means the stacks exhibit high reflectance for all angles of incidence and for both p- and s-polarization. Since the photonic band is sensitive to changes in both refractive index and thickness of the films, PC can be successfully utilized for vapor or liquid sensors with optical detection. The transparent metal oxides TiO2 and SiO2 are the most often used materials for building blocks of porous Bragg stacks. They have been produced in the form of mesoporous films (Choi et al. 2006; Fuertes et al. 2007; Ghazzal et al. 2012) or assemblies of nanoparticles (Calvo and Míguez 2010; Kobler et al. 2009; Pavlichenko et al. 2012). Commercially available SnO2 and Sb:SnO2 particles (Puzzo et al. 2009; Bonifacio et al. 2009), pairs of ZnO/Fe2O3 and WO3 (Redel et al. 2011), TiO2 nanoparticles at different aggregation states (Calvo et al. 2008) and combinations of organic and inorganic materials (Lova et al. 2015) have also been utilized for Bragg stacks. The recent progress of nanozeolite synthesis (Mintova et al. 2015) and their unique properties widened the variety of materials used for porous Bragg stacks fabrication (Lotsch et al. 2010; Hinterholzinger et al. 2012; Babeva et al. 2012a; Gospodinov et al. 2012). Further, MOF’s (metal organic frameworks) are also used for fabrication of all-MOF stacks (Ranft et al. 2015a) or as “defect” layer incorporated into SiO2/TiO2 multilayers in order to combine the high optical quality of a Bragg stack with the characteristic sorption properties of the MOF’s (Ranft et al. 2015b).

The main problem when using a Bragg stack as a color indicator is the change of color when the angle of observation changes. Thus it is not easy to distinguish the vapor concentration change from the viewing angle variation. A possible approach for overcoming the problem is to use an omnidirectional Bragg stacks, i.e. 1D-PC. In this case the color does not depend on incident angle or slightly changes with its variation. However, the fabrication of porous Bragg stack that exhibits omnidirectional reflectance is not a trivial task because it is still a challenge to prepare porous film with high refractive index. Generally, Bragg stacks with insufficient optical contrast are used for color sensing.

Recently we have prepared 1D-PC in the form of 19 layered stack comprising spin coated PMMA (Poly(methyl methacrylate)) and vacuum evaporated As2S3 films and shown their possible application for optical vapor detection (Babeva et al. 2012b). PMMA is one of the most studied polymers owing to its long-term stability, low-cost, low optical loss in the visible spectrum and high scratch hardness (Li et al. 2007). Besides, it has been demonstrated that thin films of PMMA polymer can be used for optical detection of halohydrocarbons (Çapan et al. 2009). The main drawbacks faced were the low porosity of As2S3 and the complicated method of production involving both spin coating and vacuum evaporation. It will be a real advantage if both layers can be deposited by one and the same method of preparation. Recently a sol–gel route for preparing of high refractive index metal oxides films at low temperature was reported (Oubaha et al. 2012). Among them V2O5 films exhibited the highest refractive index. It is obvious that the higher is the refractive index the stronger the artificially induced porosity can be, keeping in the same time the optical contrast at sufficient level. Moreover, both PMMA and V2O5 can be deposited in thin film form by the simple method of spin-coating.

The aim of the present paper is to design, prepare and characterize one-dimensional hybrid photonic crystals comprising alternatively spin-coated PMMA and V2O5 thin films with quarter-wavelength optical thickness and explore further their potential as color indicators for chloroform vapors.

2 Experimental details

V2O5 films were fabricated by spin-coating (3000 rpm, 30 s) of 0.3 ml vanadium sol prepared using 1.5 ml of Vanadium (V) oxytriisopropoxide (Sigma Aldrich) dissolved in a mixture of 17.5 ml acetone and 17.5 ml isopropanol for the dense films or 17.5 ml acetone and 17.5 ml 0.6 % v/v solution of Pluronic PE6100 (BASF) in isopropanol for porous films, stirred for 2 h at room temperature. Both types of films are annealed at 180 °C for 30 min at 5 °C/min acceleration rate. PMMA thin films were deposited by spin coating (3000 rpm, 30 s) of 0.3 ml of 1.62 % w/v solution of PMMA in 1,2-dichloroethane. The polymer films were subjected to the same annealing as the oxide films.

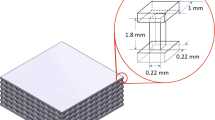

1D-PC with operating wavelength of 500 nm were fabricated in the form of quarter-wavelength Bragg stacks through layer-by-layer deposition of PMMA and dense or porous V2O5 films with targeted thicknesses of 84, 58 and 63 nm, respectively. The surface morphology and structure of the films were studied by Transmission Electron Microscopy (TEM) and Selected Area Electron Diffraction (SAED) using HRTEM JEOL JEM 2100 (Japan) microscope.

The optical properties (refractive index (n) and extinction coefficient (k)) along with the thickness (d) of V2O5 films were determined simultaneously from transmittance (T) and reflectance (R) spectra (Cary 05E (Varian, Australia)) of films deposited on optical glass BK-7 and silicon wafers (Babeva et al. 2001). Optical characterization of PMMA films is based on non-linear curve fitting of measured reflectance of the films deposited on silicon wafers (Lazarova et al. 2014a). For sensing experiments reflectance spectra of the samples were measured before and after exposure to the vapors of chloroform at relative pressure p/p 0 = 1 (p 0 is the pressure of saturated vapors at 20 °C) (Lazarova et al. 2014b).

3 Results and discussion

Typical TEM images of PMMA, dense and porous V2O5 films are shown in Fig. 1. It is seen that Pluronic template induces additional porosity. Generally, the porosity is in the nanosize range and the pores are non-periodically arranged. The SAED diffraction patterns show that all samples have amorphous structure (a representative example is shown in Fig. 1b as an inset).

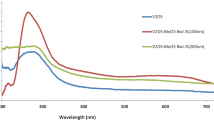

Figure 2a presents the calculated dispersion curves of refractive index and extinction coefficient of dense and porous films. All curves exhibit normal dispersion, i.e. n and k decreases with wavelength being lower for porous film as compared to the dense one. The annealing of films prepared with Pluronic templates results in removing of organic templates and generation of voids in the films thus leading to reduction of film density. Considering that the refractive index is proportional to the density of the sample, it is expected n to decrease for porous films due to the drop of its density. Besides, the smaller values of extinction coefficient observed for the porous film (Fig. 2a) are due to the presence of voids filled with air thus leading to the reduction of volume fraction of the absorbing phase in the total volume of the film. The volume fraction of voids in the porous films, calculated by Bruggeman effective medium approximation, was 14 % (Georgiev et al. 2015).

a Dispersion curves of refractive index (n) and extinction coefficient (k) with respective errors for dense (solid circles) and porous (opened squares) films with thicknesses of 52 and 69 nm, respectively; b Reflectance (R) and calculated refractive index (n) of PMMA films with thickness of 90 nm deposited on silicon wafer

It is seen from Fig. 2b that the dispersion of n for PMMA films (calculated from reflectance spectra, also shown in Fig. 2b) is weaker as compared to V2O5 films: n varies from 1.495 to 1.472 in 400–900 nm spectral range while n for V2O5 changes from 2.374 to 1.983 and from 2.071 to 1.879 for dense and porous case, respectively. The reason is that PMMA is transparent in the studied range with values of extinction coefficient in the range 0.007–0.005. These values are significantly lower as compared to k values for dense film (0.298–0.133) or even to those for the porous one (0.155–0.089).

The development of R-band at normal light incidence of Bragg stacks consisting of 2, 3, 5 and 7 alternating layers of PMMA and V2O5 films is illustrated in Fig. 3 for the case of dense and porous films. The reflectance maximum increases with number of the layers in the stacks and reaches values of 69.3 and 47.8 % for 7-layered stack consisting of dense and porous V2O5 films, respectively. The smaller optical contrast between PMMA and porous V2O5 leads to lower values of R in the case of porous stack. The optical contrast of 0.66 and 0.47 in the case of dense and porous films, respectively is not sufficient for omnidirectional band to open up (Kim and Hwangbo 2002). However, a quazi-omnidirectional reflectance band (q-ODR) could be expected.

The measured spectra R ang = (R p + R s)/2, (R p and R s being reflectance for p- and s-polarized light, respectively) of 7-layered stacks at oblique incidence of light are depicted in Fig. 4. In both cases a blue shift of reflectance band is observed with increasing of incident angle from 0° to 70°. Simultaneously, a decrease in R max takes place. A q-ODR band appears for both stacks centered at wavelengths of 433 nm and 492 nm with peak reflectance of 50 and 37.8 % for the dense and porous stacks, respectively.

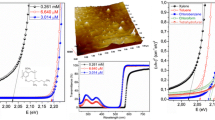

Figure 5 demonstrates the possible application of 1D stack as an optical indicator for chloroform vapors. Upon exposure to chloroform vapors the reflectance band of the stack gradually shifts towards longer wavelength with time of exposure (Fig. 5a). By measuring the reflectance spectra of single films deposited on Si-substrate prior to and after exposure to chloroform vapor we have determined a thickness change of 5 % for PMMA film (85 nm thick) and no change in reflectance for V2O5 film in both dense and porous cases. Thus we have concluded that the observed red shift of R-band and consequent change of color of the stack (Fig. 5b, c) is due to the PMMA thickness change.

a Reflectance band shifts of 7-layered hPC due to exposure to chloroform vapors at denoted durations; Pictures of 7 layered hPC consisting of dense (b) and porous (c) V2O5 with a spot being exposed to chloroform vapor; d reflectance variation at fixed wavelength as a function of number of the layers in the stacks

The reflectance variation at fixed wavelength (ΔR) increases both with duration of exposure (Fig. 5a) and number of the layers in the stack (Fig. 5d). For porous stacks the change is more than twice stronger as compared to the dense case (Fig. 5d).

In order to study the selectivity, the response of the stack towards different vapors was examined. The reflectance changes for acetone and chloroform vapors are shown in Fig. 6 as a function of the number of the layers in the stack. The response to chloroform is almost 4 times higher as compared to acetone. There is no response for ethanol, methanol and water.

We should stress here that by optimizing optical and sensing properties we have found a compromise between the porosity level and omnidirectional reflectivity in order the optical indicator to be more sensitive.

4 Conclusions

PMMA and V2O5 thin films are successfully utilized as building blocks for one-dimensional photonic crystals. An optical contrast of 0.66 and 0.47 was achieved in the case of dense and porous V2O5 films, respectively, fabricated without and with addition of Pluronic PE6100 template. Wide quazi-omnidirectional reflectance band was developed for angles of incidence from 0° to 70° being stronger and wider in the case of dense V2O5 films.

A significant shift of reflectance band towards longer wavelengths and consequent change of color of the PC are observed when photonic crystals are exposed to chloroform vapors. The increase of thickness of PMMA films mostly pronounced for porous structures is the discussed reason for the change. The response gradually increases both with number of the layers in the stacks and duration of chloroform vapor exposure being more than twice higher in the case of porous films. The selectivity studies show fourfold increase in PC response toward chloroform as compared to acetone. There is no response for ethanol, methanol and water. A compromise between the porosity level and omnidirectional reflectivity is found in order the optical indicator to be more sensitive.

References

Babeva, T., Kitova, S., Konstantinov, I.: Photometric methods of determination of the optical constants and the thickness of thin absorbing films: Selection of a combination of photometric quantities on the base of error analysis. Appl. Opt. 40, 2675–2681 (2001)

Babeva, T., Todorov, R., Gospodinov, B., Malinowski, N., El Fallah, J., Mintova, S.: Nanosized MEL zeolite and GeSe2 chalcogenide layers as functional building blocks of tunable Bragg stacks. J. Mater. Chem. 22, 18136–18138 (2012a)

Babeva, T., Marinov, G., Tasseva, J., Lalova, A., Todorov, R.: One dimensional photonic crystals from As2S3 and PMMA films for photonic and sensor applications. J. Phys. Conf. Ser. 398, 012025 (2012b)

Bonifacio, L., Lotsch, B., Puzzo, D., Scotognella, F., Ozin, G.: Stacking the nanochemistry deck: structural and compositional diversity in one-dimensional photonic crystals. Adv. Mater. 21, 1641–1646 (2009)

Calvo, M., Míguez H.: Flexible and transferable one dimensional photonic crystals based on polymer infiltrated nanoparticle multilayers. In: Proceedings of SPIE Vol. 7713, 771318, 6 pages (2010)

Calvo, M.E., Colodrero, S., Rojas, T.C., Ocana, M., Anta, J.A., Mıguez, H.: Photoconducting Bragg mirrors based on TiO2 nanoparticle multilayers. Adv. Funct. Mater. 18, 2708–2715 (2008)

Çapan, İ., Tarımcı, Ç., Hassan, A.K., Tanrısever, T.: Characterisation and optical vapour sensing properties of PMMA thin films. Mater. Sci. Eng. C 29, 140–143 (2009)

Choi, S.Y., Mamak, M., von Freymann, G., Chopra, N., Ozin, G.: Mesoporous Bragg stack color tunable sensors. Am. Chem. Soc. 6, 2456–2461 (2006)

Fuertes, M., López-Alcaraz, F., Marchi, M., Troiani, H., Luca, V., Míguez, H., Soler-Illia, G.: Photonic crystals from ordered mesoporous thin-film functional building blocks. Adv. Funct. Mater. 17, 1247–1254 (2007)

Georgiev, R., Georgieva, B., Vasileva, M., Ivanov, P. and Babeva, T.: Optical properties of sol-gel Nb2O5 films with tunable porosity for sensing applications. Adv. Condens. Matter Phys. 2015, 403196 (2015)

Ghazzal, M., Deparis, O., Errachid, A., Kebaili, H., Simonis, P., Eloy, P., Vigneron, J., De Coninck, J., Gaigneaux, E.: Porosity control and surface sensitivity of titania/silica mesoporous multilayer coatings: applications to optical Bragg resonance tuning and molecular sensing. J. Mater. Chem. 22, 25302–25310 (2012)

Gospodinov, B., Dikova, J., Mintova, S., Babeva, T.: Tunable Bragg stacks from sol-gel derived Ta2O5 and MEL zeolite films. J. Phys. Conf. Ser. 398, 012026 (2012)

Hinterholzinger, F., Ranft, A., Feckl, J., Ruhle, B., Bein, T., Lotsch, B.: One-dimensional metal–organic framework photonic crystals used as platforms for vapor sorption. J. Mater. Chem. 22, 10356–10362 (2012)

Kim, S.H., Hwangbo, C.K.: Design of omnidirectional high reflectors with quarter-wave dielectric stacks for optical telecommunication bands. Appl. Opt. 41, 3187–3192 (2002)

Kobler, J., Lotsch, B., Ozin, G., Bein, T.: Vapor-sensitive Bragg mirrors and optical isotherms from mesoporous nanoparticle suspensions. ACS Nano 3, 1669–1676 (2009)

Lazarova, K., Vasileva, M., Marinov, G., Babeva, T.: Optical characterization of sol-gel derived Nb2O5 thin films. Opt. Laser Technol. 58, 114–118 (2014a)

Lazarova, K., Awala, H., Thomas, S., Vasileva, M., Mintova, S., Babeva, T.: Vapor responsive one-dimensional photonic crystals from zeolite nanoparticles and metal oxide films for optical sensing. Sensors 14, 12207–12218 (2014b)

Li, Y., Wang, H., Yang, M.: n-Type gas sensing characteristics of chemically modified multi-walled carbon nanotubes and PMMA composite. Sens. Actuators B Chem. 121, 496–500 (2007)

Lotsch, B., Scotognella, F., Moeller, K., Bein, T., Ozin, G.: Stimuli-responsive Bragg Stacks for chemo-optical sensing applications. In: Proceedings of SPIE, Vol. 7713, 77130 V, 10 pages (2010)

Lova, P., Manfredi, G., Boarino, L., Comite, A., Laus, M., Patrini, M., Marabelli, F., Soci, C., Comoretto, D.: Polymer distributed bragg reflectors for vapor sensing. ACS Photon. 2, 537–543 (2015)

Mintova, S., Jaber, M., Valtchev, V.: Nanosized microporous crystals: emerging applications. Chem. Soc. Rev. 44, 7207–7233 (2015)

Oubaha, M., Elmaghrum, S., Copperwhite, R., Corcoran, B., McDonagh, C., Gorin, A.: Optical properties of high refractive index thin films processed at low-temperature. Opt. Mater. 34, 1366–1370 (2012)

Pavlichenko, I., Exner, A., Guehl, M., Lugli, P., Scarpa, G., Lotsch, B.: Humidity-enhanced thermally tunable TiO2/SiO2 Bragg stacks. J. Phys. Chem. C 116, 298–305 (2012)

Puzzo, D., Bonifacio, L., Oreopoulos, J., Yip, C., Manners, I., Ozin, G.: Color from colorless nanomaterials: Bragg reflectors made of nanoparticles. J. Mater. Chem. 19, 3500–3506 (2009)

Ranft, A., Niekiel, F., Pavlichenko, I., Stock, N., Lotsch, B.: Tandem MOF-based photonic crystals for enhanced analyte-specific optical detection. Chem. Mater. 27, 1961–1970 (2015a)

Ranft, A., Pavlichenko, I., Szendrei, K., Zehetmaier, P.M., Hu, Y., Mankowski, A., Lotsch, B.: 1D photonic defect structures based on colloidal porous frameworks: reverse pore engineering and vapor sorption. Microporous Mesoporous Mater. 216, 216–224 (2015b)

Redel, E., Mirtchev, P., Huai, Ch., Petrov, S., Ozin, G.: Nanoparticle films and photonic crystal multilayers from colloidally stable, size-controllable zinc and iron oxide nanoparticles. ACS Nano 5, 2861–2869 (2011)

Acknowledgments

The authors acknowledge the financial support of National Science Find—Bulgaria (project DFNI-T02/26).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Advances in the Science of Light.

Guest Edited by Jelena Radovanovic, Milutin Stepic, Mikhail Sumetsky, Mauro Pereira and Dragan Indjin.

Rights and permissions

About this article

Cite this article

Lazarova, K., Georgiev, R., Vasileva, M. et al. One-dimensional PMMA–V2O5 photonic crystals used as color indicators of chloroform vapors. Opt Quant Electron 48, 310 (2016). https://doi.org/10.1007/s11082-016-0577-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0577-z