Abstract

A near infrared sensitive liquid crystal light valve, based on Ru-doped Bi12TiO20 (BTO:Ru) inorganic crystal and liquid crystal is proposed. The two-beam mixing experiments at Raman–Nath regime show promising gain value at 1064 nm. An image evolution through the proposed device is demonstrated supporting all optical switching property.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, the emergent need for compact, efficient, fast and broadband optoelectronic modules requires development of new generation light modulation devices. Optically addressed spatial light modulators (OASLM) are special class among the light modulators and play essential role as a key devices in optical processing and display technologies.

In particular, OASLM consists of photoconductor and electro-optic material (usually highly birefringent liquid crystal layer) and often has been considered as light valves (LVs) since the read-out process can provide an optical gain. In a past, the light valves usually work in a reflection mode that requires more complicated optical isolation between the input and read-out beams (Yeh 1993). Sillenite type inorganic crystals as Bi12SiO20 (BSO) and Bi12TiO20 (BTO), owing to their excellent photoconductivity and high dark resistivity are well known as perfect components of OASLM devices. For a first time, Aubourg at el. (1982) assembled non-doped BSO crystal with a liquid crystal (LC) layer into a liquid crystal light valve (LCLV) working at transmissive mode. Later on, several non-linear applications have been demonstrated based on non-doped BSO and LC layer, operating at visible spectral range (Huignard 1987; Bortolozzo et al. 2006, 2013).

Despite of the material’s enhanced photosensitivity, currently only limited number of optically addressed light modulators operating at near infrared range has been proposed, mainly based on semiconductor crystals as GaAs doped with Cr (Garcia and Rodriguez 2012; Peigne et al. 2015) or CdTe (Gvozdovskyy et al. 2011). Recently, we found that by doping sillenite crystals with transition metal elements like Ru and Rh, the response time and photosensitivity at near infrared spectral range can be significantly improved. These open further opportunities to match the improved properties of sillenite crystals with organic materials into a single compact device with enhanced functionality (Marinova et al. 2011, 2013).

In this work, a novel light valve device based on near infrared photosensitive BTO:Ru crystal and liquid crystal (in nematic phase) is presented, in which the high photoconductivity comes from the inorganic material and the strong birefringence from the LC layer. The light intensity dependence on the applied voltage and the phase retardation changes are measured. An example of image propagation through the BTO:Ru/LCVL device is demonstrated.

2 Experimental details

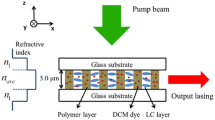

The proposed LCLV device consist of a BTO:Ru crystal as photoreceptor substrate, glass substrate and liquid crystal (MLC-2070 type, Merck). Ru-doped BTO crystal plate with a dimensions of 12 × 15 mm2 lateral size and 0.8 mm thickness was cut from bulk crystal grown by top seeded solution growth method (Sveshtarov and Gospodinov 1991). Ruthenium was introduced into the melt solution as RuO2 and its concentration of 5.1 × 1018 × cm−3 has been determined by atomic absorption spectroscopy analysis. One side of the BTO:Ru plate was preliminary coated with indium tin oxide (ITO) conductive layer and the other side (contacting with the LC) was coated with polyvinyl alcohol (PVA) in order to obtain a planar alignment of the LC molecules. Finally, the liquid crystal layer with the thickness of 12 μm was sandwiched between the BTO:Ru plate and the glass substrate, using Teflon spacers. The schematic structure of the device is presented at Fig. 1.

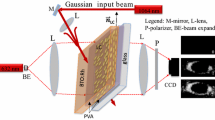

To measure the Freedericksz transition threshold voltage and modulation characteristics, the device was placed between a pair of crossed polarizers with a liquid crystal director (nLC) making an angle of 45° with respect to the transmission axis of the polarizer. A diode-pumped laser operating at 1064 nm was used to pump the BTO:Ru/LC device and a weak laser beam at 790 nm to monitor the intensity changes.

The two-wave mixing experiments were performed using 1064 nm diode laser with linear polarization oriented parallel to the LC director. To check the gain (amplification) value the ratio between the pump beam IP (high intensity) and signal IS beam (weak intensity) has been fixed to Ip/Is = 70.

Finally, based on the phase modulation ability, an image evolution illuminated on BSO:Ru/LCLV device was demonstrated.

3 Results and discussions

Figure 2 shows the probe beam intensity transmitted through the device as a function of the applied voltage (at frequency f = 1 kHz). Obviously, the LC molecules show the tendency to reorient along the direction of the applied voltage, which follows the typical behavior of conventional liquid crystal devices (few volts are enough to modulate the light intensity several times). The intensity dependence of the voltage amplitude allows determining the Fredericksz transition voltage value.

Next, the phase shift is measured by sending the pump and probe beams together to the LCLV at a fixed voltage (4.2 V according to Fig. 2a). When the pump light illuminates the BTO:Ru crystal side, due to its high photoconductivity and resistivity [low dark conductivity ~10−15 (1/Ω cm) Marinova et al. 2003], the crystal behaves as a light-controlled resistor which reduces its impedance. Consequently the voltage is transferred to the LC layer, which supports the LC molecules reorientation and due to the LC birefringence the beam experience a phase retardation Φ for the e-wave and o-wave components at the exit of the light valve.

The induced phase retardation ∆Φ is a function of the applied voltage (V0) and the pump beam intensity (Ip) and is calculated by the formula (Yeh and Gu 2009):

where T = (Iprobe/Iprobe max), d—the LC thickness and Δn = (ne (Ip, V0) − n0).

In consequence, the phase shift of the light valve varies for several π with the applied voltage (V0) and intensity of pump light Ip. Figure 2b shows the phase retardation at the beginning of the modulation process up to 200 mW/cm2.

Further, to check the two-wave mixing behavior, an interference set-up has been arranged using 1064 nm. The two-beam interference creates an intensity fringe pattern which induces a local re-orientation of the LC molecules and formation of refractive index grating inside the LC layer with a fringe space \(\Lambda = \frac{\lambda }{{2\sin \left( {\frac{\theta }{2}} \right)}}\), where θ is the intersection angle between the two beams and λ is the wavelength. Since the LC thickness (d) is much less than the fringe space d ≪ Λ, the grating recorded in the LC layer acts as a thin hologram. Therefore the light-valve device operates at Raman–Nath regime with several diffracted beams (0, ±1, ±2,…) at the output. Figure 1b supports the Raman–Nath diffraction orders detected on infrared viewing card.

Two-wave mixing gain G is measured experimentally as G = I0/Is, where Is is the input signal intensity (without pump light) and I0 is the amplified signal after the device (signal beam plus pump beam). At an interaction angle of 2.5° (12 μm grating period) the measured gain value is G = 4.1. Consequently, the exponential gain of Γ ~ 1180 cm−1 is calculated by the \(I(0) = I(s)e^{\Gamma d}\). This value is among the highest reported until now for such kind of hybrid light valve devices, operating at near infrared spectral range (Bortolozzo et al. 2006, 2013; Garcia and Rodriguez 2012; Peigne et al. 2015).

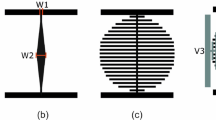

Finally, we demonstrate an image (letter A) addressed on BTO:Ru/LCLV device and its time evolution. Figure 3a shows the begining of the process and its evolution at (b) 50 ms and (c) 100 ms.

The response time of our device is limited by either the rotational response of the LC molecules or the capacitance of LC cell although the response time of BTO:Ru crystal is much faster (about 50–60 ms at 1064 nm) (Marinova et al. 2011, 2013).

The reported experimental results support the idea that Ru addition in BTO crystal structure significantly improves the concentration of efficient charge carriers leading to enhanced photosensitivity and photoconductivity at near infrared spectral range, where only limited number of OASLM operates. This opens further opportunity for new hybrid device design, operating at near infrared.

4 Conclusion

In conclusion, we have demonstrated near infrared sensitive LCLV device based on BTO:Ru crystal and LC layer (nematic phase). The two-wave mixing experiments provide promising values of the gain amplification. The proposed LCLV hybrid structure may open possibilities for new infrared nonlinear devices allowing electro-optical control of the phase modulation.

References

Aubourg, P., Huignard, J.P., Hareng, M., Mullen, R.A.: Liquid crystal light valve using bulk monocrystalline Bi12SiO20 as the photoconductive material. Appl. Opt. 21, 3706–3712 (1982)

Bortolozzo, U., Residori, S., Huignard, J.P.: Enhancement of the two-beam coupling gain in a stack of thin nonlinear media by use of the Tabolt effect. Opt. Lett. 31, 2166–2168 (2006)

Bortolozzo, U., Residori, S., Huignard, J.P.: Transmissive liquid crystal light-valve for near-infrared applications. Appl. Opt. 52, E73–E77 (2013)

Garcia, R.R., Rodriguez, C.B.: Enhancement of the coupling gain in GaAs-liquid crystal hybrid devices. Mol. Cryst. Liq. Cryst. 561, 68–73 (2012)

Gvozdovskyy, I., Shcherbin, K., Evans, D.R., Cook, G.: Infrared sensitive liquid crystal photorefractive hybrid cell with semiconductor substrate. Appl. Phys. B 104, 883–886 (2011)

Huignard, J.P.: Spatial light modulators and their applications. J. Opt. 18, 181–186 (1987)

Marinova, V., Lin, S.H., Sainov, V., Gospodinov, M., Hsu, K.Y.: Light-induced properties of Ru-doped Bi12TiO20 crystals. J. Opt. A Pure Appl. Opt. 5(6), S500–S506 (2003)

Marinova, V., Liu, R.C., Lin, S.H., Hsu, K.Y.: Real time holography in ruthenium doped bismuth sillenite crystals at 1064 nm. Opt. Lett. 36, 1981–1983 (2011)

Marinova, V., Liu, R.C., Chen, M.S., Lin, Y.H., Lin, S.H., Hsu, K.Y.: Near infrared properties of Rh-doped Bi12TiO20 crystals for photonic applications. Opt. Lett. 38, 495–497 (2013)

Peigne, A., Bortolozzo, U., Residori, S., Molin, S., Nouchi, P., Dolfi, D., Huigrand, J.-P.: Adaptive holographic interferometer at 1.55 μm based on optically addressed spatial light modulator. Opt. Lett. 40(23), 5482–5485 (2015)

Sveshtarov, P., Gospodinov, M.: The effect of the interface shape on authomatic Czochralski weight diameter control system performance. J. Cryst. Growth 113, 186–208 (1991)

Yeh, P.: Introduction to photorefractive nonlinear optics. Wiley, New York (1993)

Yeh, P., Gu, C.: Optics of liquid crystal display. Wiley, Hoboken (2009)

Acknowledgments

This work was funded by Bulgarian Science Fund under the Project FNI-T-02/26 and Ministry of Science and Technology (MOST), Taiwan under the Contracts: MOST 103-2221-E-009-079; 104-2221-E-009-164; 104-2221-E-009-151 and 103-2911-I-009-516. N. Berberova acknowledged the Elite internship program of NCTU, Taiwan.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Advances in the Science of Light.

Guest Edited by Jelena Radovanovic, Milutin Stepić, Mikhail Sumetsky, Mauro Pereira and Dragan Indjin.

Rights and permissions

About this article

Cite this article

Marinova, V., Chi, C.H., Tong, Z.F. et al. Liquid crystal light valve operating at near infrared spectral range. Opt Quant Electron 48, 270 (2016). https://doi.org/10.1007/s11082-016-0546-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0546-6