Abstract

Offshore oil and gas reservoirs comprise a significant portion of the world’s reserve base, and their development is expected to help close a potential gap in the supply of hydrocarbons in the near future. Continuous advances in technology have helped the oil and gas industry to extend the exploration and production activities to deep and ultra-deep waters in harsher environments. Field development in the offshore environment is associated with numerous significant challenges in different phases including exploration, reservoir description and characterization, development planning, drilling, production, improved oil recovery (IOR) and enhanced oil recovery (EOR), transportation, and decommissioning. These challenges are further complicated by economic restrictions, especially in periods when low or unstable oil prices weaken the incentives of investments due to the high risks and uncertainties involved. Environmental concerns including the adverse effects of seismic surveys, drilling activities, discharge of waste material and produced water, and accidental spills and blowouts add another level of complexity to the design and implementation of offshore projects. Safe, reliable, and efficient development of offshore hydrocarbon reservoirs can be achieved through the proper identification of the challenges and use of modern technologies and innovative methods. This work is an effort to provide a comprehensive review of the history, global distribution, production share, classification, characteristics, and characterization methods of offshore reservoirs, and some of the main aspects and challenges of the experimental and modeling works as well as IOR/EOR planning and implementations from the reservoir engineering and production standpoint. These challenges are categorized based on their area of impact, i.e., characterization and recovery (production) phases. Furthermore, economic and environmental challenges are reviewed. After the recent downturn that caused a decline in offshore investments, current investment trends and the forecasts show that the offshore industry is booming again with more focus on cost saving and operational efficiency. The key technologies that can expedite the growth of the offshore petroleum industry have also been discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Earliest offshore operations started in 1896 by drilling wells in Summerland oilfield in Santa Barbara County, California, USA, using cable-tool rigs installed on wooden piers that extended about 100 m out into the shallow waters of the Pacific (Silcox et al. 1987). Oil production from these wells started in 1897. However, the real birth of the modern offshore industry is believed to have occurred in 1947, upon completion of the first successful well in the Gulf of Mexico that was drilled in ~ 16 km off the shore at a water depth of only ~ 6 m (Chakrabarti 2005). The technological advances in offshore drilling, production, storage, and transportation of oil and gas resulted in searching and drilling for hydrocarbons at increasingly greater water depths, which, today, have exceeded 3500 m.

Safe and reliable development of offshore reservoirs is a challenging task, and the challenges aggravate in deeper waters where about 30% of the new conventional discoveries are expected to be located (Total 2018a, b). Offshore exploration and production frontiers are moved to deeper and harsher environments with increasingly more isolated reserves characterized by more complex rock and fluid systems due to faulting, salt domes, and reservoir discontinuity and burial at greater depths (> 3000 m) from the seabed (Clarkston et al. 2001; Rahman and Fuad 2018). Field development under these circumstances is associated with higher costs and elevated risks due to uncertainties (Rahman and Fuad 2018), and new technologies and advanced business models are required in the current product price environment which adds more complexities and challenges to the offshore industry (Batra et al. 2017). Capital and operational costs need severe compression in the lower-oil-price periods where development strategies are focused on optimum placement of a limited number of wells that can produce the maximum possible amount of the recoverable oil and gas from the offshore reservoirs, while accepting uncertainties is increasingly less viable in these cases (Lavenson et al. 2017; Zirczy et al. 2018).

Water depth, reservoir uncertainty and compartmentalization, recovery factor, costs of drilling, completion, and transportation, operational logistics, operational regulations and restrictions, and environmental issues are some of the principal concerns in the development of offshore resources. Therefore, project economics may be marginal to non-commercial unless emerging and more innovative technologies and more efficient workflows are utilized to achieve acceptable financial metrics (Clarkston et al. 2001). Some of the main areas where continual progress in technologies is needed include flow assurance, subsea processing, floating structures, flowline and pipeline, and risers and umbilicals (Bell et al. 2005).

To achieve successful field development in the offshore environment, early and fast integration of all the relevant data is required to build a reservoir model and assess different production scenarios along with economic evaluation and risk analysis (Zirczy et al. 2018). However, at early development stages, there is generally minimal data available for reservoir characterization, while forecasting the reservoir performance is vital for making further decisions (Rahman and Fuad 2018). Therefore, it is essential to take advantage of the state-of-the-art methods and technologies that help maximize the value of the available data through integration, prediction, and analysis. Reservoir characterization is meant to be used ultimately in construction of a detailed reservoir model, which enables numerical simulation for prediction, and evaluation of reservoir performance under various development scenarios and injection-production strategies.

Once a reservoir model is built based on seismic and geological data and interpretations, this model needs to be populated with properties of the reservoir rock and rock–fluid interaction parameters. A reservoir fluid model is also required for assessment of the phase behavior and changes of the reservoir fluids and EOR injectants. It is worth mentioning that, upon the availability of new production data during the life the reservoir, the reservoir model needs to be updated regularly through production history matching to minimize uncertainties and ensure robust and reliable production forecasting, which is the ultimate goal of reservoir modeling (Hutahaean et al. 2015).

The ideal approach is to determine the reservoir rock and fluid properties using direct laboratory tests and measurements. For reservoir fluids, the main laboratory tests include conventional pressure–volume–temperature (PVT) tests and process-specific (EOR) PVT tests. The main laboratory tests and measurements for determination of reservoir rock properties and rock–fluid interactions are routine core analysis (RCAL) and special core analysis (SCAL). All these reservoir fluid and rock laboratory tests and measurements require samples from reservoir rock and fluids, which, for several different reasons, may not always be available. Therefore, other tools and methods are needed for the prediction of reservoir fluid and rock properties of interest. These predictive techniques include empirical correlations and theoretical relationships as well as more advanced methods based on artificial intelligence (AI), molecular simulations, digital core analysis, and seismic reservoir characterization.

The experimental works in the context of offshore reservoir development face several challenges. During the characterization phase, the main challenges encompass areas such as reservoir fluid sampling, fluid characterization experiments, flow assurance, reservoir rock characterization, coring and core recovery, SCAL (coreflood) uncertainties, whole core analysis, and incorporation of offshore high-pressure high-temperature (HPHT) effects in core analysis. In recovery/production phase, uncertainties in fluid phase behavior kinetics and EOR-related testing protocols constitute challenges. In characterization phase, modeling works are also associated with a number of issues and challenges such as limitations of empirical correlations, equation of state (EOS) limitations, characterization of heavy fraction (C7+) of reservoir fluids, property predictions using AI, molecular dynamics (MD) simulation limitations, and flow assurance. In recovery/production phase, issues in modeling of complex recovery mechanisms, upscaling of coreflood experiments results for use in simulation, and modeling of different phenomena in single and multiphase flow for flow assurance purposes pose challenges to the modeling/simulation approaches.

Some of the main factors causing complexities in offshore field developments from a practical point of view include large well spacing (which is a characteristic feature of offshore reservoirs and is the root of many other challenges as it results in limitations on gathering subsurface data and samples as well as difficulties in implementation of some injection-production schemes), complex rock and fluid systems, platform weight and space constraints, limited window of opportunity for production and implementation of EOR methods, drilling problems in deep and ultra-deep waters, as well as issues in production and flow assurance. The application of IOR and EOR methods is a vital element of any offshore field development plan to maximize the recovery factors during the typically shorter life cycle of offshore facilities compared to their onshore counterparts. However, experience in offshore EOR is much limited compared to onshore, and significantly fewer projects have been conducted in offshore petroleum reserves as the recovery methods face several challenges in terms of projects economics, availability of EOR injectants, space and weight restrictions of offshore platforms for installation of injection, mixing, and processing facilities and storage of injectants (Alvarado and Manrique 2013). The choice of IOR/EOR methods such as water-flooding, gas-based EOR including thermal injections, polymer flooding, and subsea processing may significantly affect the design of the offshore platform and the required surface and subsea facilities. Therefore, such decisions should be made as early as possible during the planning phases given the complexities and high costs of later platform modifications (Jayasekera and Goodyear 2002; Bondor et al. 2005).

Environmental concerns are among the most critical aspects of offshore field developments (Camero 2000). Oil and gas operations in offshore environments may modify various ecological parameters for deep-sea species, assemblages, and ecosystems. These species and assemblages have a set of biological and ecological attributes that make them have low resilience and recovery potential from disturbances caused by human activities including those that occur during oil and gas operations (Schlacher et al. 2013; Cordes et al. 2016; Clark et al. 2016). Different phases of offshore field developments including exploration, production, and decommissioning involve environmental challenges caused by exploration seismic surveys, infrastructure installations, drilling waste and produced water disposal, and accidental discharges. Effective management strategies through international collaborations are required to minimize the adverse environmental effects of offshore oil and gas operations.

In this review, an attempt has been made to provide a comprehensive picture of the offshore reservoirs and their development aspects and challenges with more emphasis on reservoir engineering and production methods. First, offshore reservoirs, their development history, global distribution and share of production (historical and forecasted), classification criteria, characteristics, and main characterization methods are reviewed. The next three sections deal with the different challenges faced in experimental works and modeling approaches as well as the main practical challenges of offshore developments in both characterization and recovery (production) phases. Then, the main recovery methods (i.e., IOR/EOR) and their associated challenges are briefly described, followed by discussions on economic and environmental aspects of offshore operations. Finally, an account is given on prospects of the offshore industry from the economic point of view as well as some of the enabling technologies that hold promise for contribution to the safe, reliable, and efficient development of offshore resources.

Offshore Petroleum Reservoirs

Global Distribution and Contribution

Offshore oil and gas are found in reservoirs located beneath the seabed under various water depths. Earliest offshore field developments date back to the 1890s in California, USA, where the first offshore wells were drilled from wooden piers on extensions of onshore reservoirs under shallow waters (Silcox et al. 1987). Since then, technological advances have gradually made increasingly deeper waters accessible to exploration and production activities. Figure 1 shows the global oil production by water depth from 2005 to 2015 (EIA 2016a). During this decade, around two-thirds of the offshore production has been from continental shelf areas with water depths up to 125 m where exploration and production are less technically challenging. There has also been a 25% increase in deepwater production (water depths of 125–1500 m). The gradual depletion of the reservoirs in shallower waters pushed the boundaries of oil and gas exploration and production further away from the shores to ultra-deepwater environments with water depths beyond 1500 m. The global share of ultra-deepwater production has been increasing during recent years (see Fig. 1).

Modified after (EIA 2016a)

Global offshore production by water depth from 2005 to 2015.

According to the US Energy Information Administration (EIA), around 30% of the global oil production in the period of 2005 to 2015 has been from offshore reservoirs (see Fig. 2) (EIA 2016b). Low oil prices during the recent few years resulted in more strict sanctioning of new offshore development projects with less than 40 projects sanctioned in 2016 (Martinsen and Weiss 2018). However, streamlining of operations and cost reduction measures taken by the offshore industry during the low-oil-price period have resulted in significantly lower breakeven prices, which, together with the recent increase in the oil price, have gradually facilitated sanctioning more offshore projects: 60 projects in 2017 and 100 projects in 2018 (Martinsen and Weiss 2018; Ravi and Reiersen 2018). It is estimated that around 30% of the world’s new conventional resource discoveries will be made in deep and ultra-deep offshore. Around 15% of the global oil production forecast in 2019 is from deep and ultra-deep offshore, and the projections show increasing production from these resources in the future (Total 2018a, b). Global offshore deep and ultra-deep oil and gas production since 2000 to the present as well as projections for up to 2035 are depicted in Figure 3.

Modified after (EIA 2016b)

Global crude oil production from 2005 to 2015.

Considering the geological and tectonic settings, passive margins comprise an important target for offshore petroleum exploration (Pettingill and Weimer 2002). Figure 4 illustrates a typical passive margin, which is a transition between oceanic and continental crust where the plate margin is not active. This type of plate margin is formed as a result of sedimentation above a previously active continental rifting zone pushed away by the new mid-oceanic ridge. A characteristic feature of the passive margins is thick sediment accumulation with the thickest section of the sediments deposited adjacent to the continent.

Modified after (Wikimedia Commons-Public Domain 2007)

Passive plate margins are formed by sedimentation above previously active continental drifting zones, which have been pushed away toward the continental crust by the newly formed oceanic crust.

Global distribution of passive margins is shown in Figure 5. These plate margins are found in the regions around the Atlantic Ocean, the Arctic Ocean, and the western Indian Ocean, as well as the entire coasts of Africa, Greenland, India, and Australia. Other regions with passive margins include the east coast of North America and South America, in western Europe and most of Antarctica as well as East Asia. Although during the 1990s most of the deep offshore investment was either in the US Gulf of Mexico or in Brazil, offshore activities were soon extended to other geographical locations (Latham 2002). The major offshore producing countries in 2017 were Saudi Arabia, Norway, Qatar, Iran, Brazil, USA, Mexico, UAE, UK, and Angola (Ivanova 2017).

Modified after (Pinto 2007)

Global distribution of passive margins.

Classification

From the standpoint of reservoir engineering, there is no basic difference between offshore and onshore reservoirs. In fact, the same classifications considered for onshore reservoirs apply to offshore reservoirs as well, and the production phenomena, mechanisms, and methods are the same for both onshore and offshore reservoirs. Here, we present three criteria for classification of the offshore reservoirs: (1) natural flow properties of reservoir rock; (2) depth of water under which the reservoir is buried; and (3) geological setting of the basin. These classification criteria are explained in this section and summarized in Figure 6.

In the broadest sense, offshore (and onshore) reservoirs are either conventional or unconventional based on natural flow properties of reservoir rocks. Conventional resources are found in sufficiently porous and permeable reservoir formations, where hydrocarbons are kept in place below a cap rock by buoyant forces and where they can flow readily into drilled wells for sufficiently long periods of time (commercial production). Good reservoir qualities in terms of favorable combinations of porosity and permeability are usually encountered in sandstones and carbonates. Porosity and permeability in sandstones depend mainly on grain size and cement properties, while carbonates typically need natural fractures and/or vuggy porosity to exhibit commercial production.

Unconventional resources are, however, those that cannot be produced using the production methods applied to conventional reservoirs. Commercially viable production from unconventional reservoirs requires the application of more advanced recovery solutions such as hydraulic fracturing and horizontal drilling. Therefore, the types of hydrocarbon reservoirs that fall under the category of unconventional resources can change with time due to advances in exploration and production technologies, economic factors, and production duration and scale of these reservoirs. At present, gas and oil shales, tight sands, coalbed methane (CBM), heavy oil and tar sands, and gas hydrates are considered the main unconventional reservoirs whose porosities, permeabilities, mechanisms of fluid trapping, and other characteristics are different from conventional sandstone and carbonate reservoirs.

Development of reservoirs in offshore environments is largely affected by limiting factors which are mainly dictated by the water depth. Although some unconventional plays have been produced, mainly using the hydraulic fracturing technique (Clayton and Gordon 1990; Martins et al. 1992; Rylance et al. 1996; Haidar et al. 1996; Schrama et al. 2011; Shaoul et al. 2013; Langford et al. 2013; Carpenter 2015), currently, most of the offshore oil and gas fluids are being produced from conventional reservoirs. Current technological gaps and relative immaturity of exploitation methods for unconventional reservoirs add to the development complexities of these resources in offshore environments. However, with further research and experimentation in this area, development of unconventional offshore reservoirs can be a future trend to boost production levels once oil and gas prices provide enough incentives.

Another classification for offshore hydrocarbon resources is based on water depth under which the reservoir is buried: shallow, deep, and ultra-deep. In the last 3 decades, deepwater has been defined differently in terms of depth range. However, generally, the depth interval of 400–1500 m has been considered as deepwater (Fang and Duan 2014). Of ~ 80% of the Earth’s surface which is covered by the oceans, only 7.5% are continental shelves with water depths up to 200 m. More than 40% of the currently proven hydrocarbon reserves are buried in deepwater and ultra-deepwater environments with water depths greater than 500 m (Fang and Duan 2014). Therefore, it seems logical to assume that increasingly deeper offshore areas will be important targets in future exploration and production activities. In fact, following a peak of exploration success rates in deepwater areas in the early 2000s, most offshore exploration leading companies opted to search for new oil and gas resources in ultra-deepwater, making the ultra-deepwater exploration business a fast-growing trend in the petroleum industry (Latham 2002).

Deepwater offshore resources can also be classified based on the basin settings where the main categories are confined and unconfined basins (Pettingill and Weimer 2002). Confined basins are the dominant type and include both extensional and contractional systems with mobile substrates such as salt and shale, which provide structural elements for trapping and control the reservoir distribution. Confinement and partitioning of the basins into sub-basins may also occur due to structural movements in the absence of mobile substrates. The remaining deepwater resources are in unconfined basin floor settings (non-turbidites).

Characteristics

Most deepwater oil and gas reservoirs have been fed by good source rocks of Jurassic, Cretaceous, and Tertiary ages deposited in both continental and deep marine sedimentary environments. The quality of reservoir fluids varies in different deepwater plays, and even local variations of oil properties are expected in some basins. Such variations in reservoir fluid characteristics will add to complexities involved in the development of offshore resources, particularly in ultra-deepwater. High sulfur content, low API gravity, and deposition of solids (asphaltenes, waxes, and hydrates) comprise some of the main reservoir fluid-related issues to deal with in offshore environments (Pettingill and Weimer 2002).

Offshore reservoirs in deep and ultra-deep environments are predominantly found in turbidite sandstones. Turbidites are classic sediments deposited from gravity-driven flows, i.e., turbidity currents, in deep ocean environments (Fig. 7). Graded bedding with coarser sediments at the base fining upwards is a characteristic feature of low-density turbidites, indicating a sudden strong current where larger and heavier sediments deposit upon a slight decrease in the energy of the current, followed by deposition of finer sediments due to further decrease in current energy. Turbidites usually exhibit desirable reservoir qualities with porosity values over 30% and permeabilities beyond 1000 mD; however, reservoir connectivity and continuity may be poor in low net-to-gross channels and levees in some areas. Shallow marine and fluvial sandstones and carbonates are other types of deepwater conventional reservoirs (Pettingill and Weimer 2002).

Turbidites form as deep-sea fans deposited from turbidity currents (Tarbuck et al. 2008)

Field sizes in terms of ultimate recovery can vary significantly in deep and ultra-deepwater environments depending mainly on the trap settings, which usually include a stratigraphic component—if not purely stratigraphic—due to the predominance of turbidites. Trap area and net thickness of pay zones, as well as recovery factors, are the main factors determining the size of the reserves. Different combinations of these factors have resulted in varying reserve sizes in different basins around the world (Pettingill and Weimer 2002).

The vital characteristic feature of offshore reservoirs is the complex nature of field development in terms of economic, technical, and operational challenges. In summary, vast distances between offshore wells and consequently less certain reservoir characterization due to less dense reservoir property maps, platform space and weight limitations, restricted availability, transportation, and storage of EOR injectants, limited downstream fluid disposal opportunities, closer process surveillance and control, and higher capital and operating costs are some of the main reasons that offshore developments are considered challenging (Bondor et al. 2005; Alvarado and Manrique 2013). These factors are discussed in more details in the next sections. The complexities involved in the development of offshore assets necessitate close integration of subsurface and surface disciplines as well as early and upfront commercial and contracting decisions to ensure timely and proper selection and implementation of the most effective solutions in terms of design and execution of different project components (Clarkston et al. 2001).

Characterization Methods

Reservoir characterization is an integrated and multi-disciplinary approach to define the reservoir architecture and geometry, geological facies and lithology, petrophysical and fluid properties and their distributions, and flow units and boundaries (Beucher and Renard 2005). For either onshore or offshore reservoirs, it is essential to gather as much data as possible of the reservoir extent, geology, pressure and flow behavior, rock, and fluids to ensure successful field development planning and design. The ultimate goal of reservoir characterization is the construction of a reservoir model for prediction and evaluation of reservoir performance under various development scenarios and injection-production strategies.

Proper determination and prediction of reservoir fluid and rock properties is the major task in reservoir characterization. As mentioned previously and discussed further in the next sections, the limited number of wells drilled per reservoir area in offshore developments translates into lack of sufficient coverage of the reservoir extent with real data collection points in terms of fluid samples, cores, and well logs. As a result, although laboratory experiments and measurements performed on representative samples of reservoir fluids and rocks (cores) are traditionally considered the most reliable source of data for description and modeling of reservoir fluids and rocks, other prediction methods are also required to:

Compensate data deficiencies, particularly at earlier stages of field development;

Augment experimental results and analyses at later stages when more data and samples are available from the reservoir;

Obtain reliable property predictions in the absence of enough samples to make timely field planning and design decisions;

Model the behaviors and properties that cannot be obtained experimentally; and

Reduce experimental costs.

These additional predictive methods include the application of empirical correlations and theoretical relationships as the traditional method of property calculations as well as the more advanced methods based on computational artificial intelligence (AI) such as connectionist modeling and optimization algorithms, molecular simulations, and digital core analysis.

AI has gained extensive applications in different branches of science and engineering. Since the 1990s, artificial neural networks (ANNs) and various intelligent optimization techniques have been successfully applied in petroleum engineering for recognition of patterns in data and prediction of reservoir fluid and rock properties with higher accuracy, reliability and robustness than empirical correlations that rely on linear or nonlinear multiple regression methods. ANNs are modeled based on the human brain’s data analysis method and are composed of massively parallel distributed processing elements (neurons) which are interconnected in a layered network capable of learning the patterns between input and output data. Through a learning algorithm, the connection weights of the neurons are gradually adjusted based on an objective function. The trained ANN is then capable of predicting outputs from a new set of inputs that the network has never encountered before (Bishop 1995; Haykin 1999). Several authors have used ANNs to predict the properties of reservoir fluids (Gharbi and Elsharkawy 1997; Boukadi et al. 1999; Osman et al. 2001; Al-Marhoun and Osman 2002; Goda et al. 2003; Naseryan-Moghadam et al. 2011; Asadisaghandi and Tahmasebi 2011; Seifi and Abedi 2012; Kazemi et al. 2013; Al-Marhoun et al. 2014) and reservoir rock–fluid interactions (Baldwin et al. 1989, 1990; Wiener et al. 1991; Mohaghegh et al. 1994, 1995; Wong et al. 1995a, b; Huang et al. 1996a, b; Malki et al. 1996; Abedini and Torabi 2013).

Many other artificial intelligence models including support vector machine (SVM) (Vapnik 1995, 1999; Vapnik et al. 1997), least square support vector machine (LSSVM) (Suykens and Vandewalle 1999; Suykens et al. 2000, 2002), gene expression programming (GEP) (Ferreira 2001), reference vector-guided evolutionary algorithm (RVEA) (Cheng et al. 2016), particle swarm optimization (PSO) (Kennedy and Eberhart 1995), coupled simulated annealing (CSA) (Xavier-de-Souza et al. 2010), imperialist competitive algorithm (ICA) (Atashpaz-Gargari and Lucas 2007), and hybrids of these methods have also been used in petroleum engineering data processing to predict the properties of reservoir fluids (El-Sebakhy et al. 2007; El-Sebakhy 2009; Dutta and Gupta 2010; Khoukhi 2012; Farasat et al. 2013; Rafiee-Taghanaki et al. 2013; Karimnezhad et al. 2014; Ahmadi et al. 2014a, 2015a; Afshar et al. 2014) and reservoir rock–fluid interactions (Huang et al. 1996a, b, 2001; Lim 2005; Saemi et al. 2007; Helmy et al. 2010; Irani and Nasimi 2011; Olatunji et al. 2012; Ahmadi et al. 2014b, 2016; Aïfa et al. 2014; Gholami et al. 2014; Torabi et al. 2015) as well as other applications such as reservoir production history matching (Hutahaean et al. 2016, 2017). Compared to conventional statistical methods, AI provides the capacity of extracting nonlinear correlations between input–output sets of data, omits statistical input data distribution, and is not severely impacted by noise in data (Sambo et al. 2018).

Recently, molecular dynamics (MD) simulations have gained considerable attention in petroleum and process engineering for a wide range of studies on the properties of reservoir fluid and rock and their related phenomena at an atomic level (Seyyedattar et al. 2019). MD simulation is a deterministic method in which motions of all the atoms in the system are tracked by solving Newtonian equations of motion. Properties of interest are then extracted from the analysis of atomic trajectories and velocities during the time evolution of the system (Meller 2001; Springer 2006). Although early MD simulations of reservoir rock and fluids were conducted on rather simple representations of porous media and one-component natural gases, advances in computational power and efficiency have facilitated modeling of more complex rock structures and multi-component reservoir fluids. A particularly important research area accelerated by MD simulation is flow and phase behavior of reservoir fluids under nano-confinement (Wu et al. 2012; Gouth et al. 2013; Dhanapal et al. 2014; Welch and Piri 2015).

Seismic data and interpretation are also among the essential tools for reservoir characterization. Among many other crucial applications of seismic data in the oil and gas industry, primary reservoir characterization data such as porosity and saturation can be obtained from seismic studies (Spikes 2017). Seismic imaging techniques and quantitative interpretation of seismic data are continually being improved to help calibrate important parameters of reservoir models (Zirczy et al. 2018). Rock properties can be extracted from seismic data using deterministic or geostatistical (stochastic) inversion methods to generate reservoir maps and volumes in which property distributions can be predicted by numerical models or neural networks. Advanced 4D seismic technologies can be integrated into the reservoir model to monitor changes in reservoir properties such as fluid saturation changes within the reservoir. While well log-based methods generally provide good vertical resolution, seismic data can offer better lateral estimations of rock properties (Sambo et al. 2018).

Reservoir Fluid Characterization

Fluid properties and phase behaviors are among the most vital information required in the early stages of offshore developments (Lavenson et al. 2017). Fluid sampling, laboratory experiments and equation of state (EOS) modeling, characterization of heavy fraction (C7+), and flow assurance studies are the main constituents of reservoir fluid characterization. Determination of fluid properties is key to successful reserve estimation, numerical reservoir simulation, production planning, flow assurance, and design of surface facilities (Gharbi and Elsharkawy 1999; El-Sebakhy 2009; Dutta and Gupta 2010). Reservoir fluid laboratory experiments include conventional pressure–volume–temperature (PVT) tests and process-specific (EOR) PVT tests.

Conventional PVT evaluation encompasses a primary set of tests and measurements aimed at providing volumetric information about the liquid and gas phases with changes of thermodynamic variables to understand fluid phase behavior during natural depletion pressure reductions, from inside the reservoir all the way to the surface facilities (Danesh 2003). A summary of the conventional PVT tests and the main fluid properties and parameters obtained from these experiments is provided in Table 1.

Process-specific (EOR) PVT tests are additional experiments conducted to evaluate specific fluid properties and phase behavior associated with mechanisms involved in production methods beyond primary pressure depletion, i.e., IOR and EOR methods. A summary of the main process-specific PVT tests and the main parameters obtained is given in Table 2.

Once enough experimental data on reservoir fluid properties and phase behavior are obtained from PVT tests, these data are used to tune an EOS and build the reservoir fluid model for use in reservoir simulation to predict the outcome of different possible production scenarios. Commercial EOS-based software programs provide an efficient and convenient way for calculation of a broad range of reservoir fluid properties.

Since the 1940s, numerous empirical black oil and natural gas correlations have been developed for estimation of reservoir fluid properties such as bubble point pressure, solution gas/oil ratio, oil and gas formation volume factors, compressibility, density, and viscosity among others. These correlations are different from each other in terms of the number of data points, the range of properties, and geographical location (Danesh 2003; Amadei 2005). Some correlations have gained more popularity due to their higher level of generalization and prediction accuracy for wider ranges of fluids.

Application of AI has also been the subject of many research activities in the prediction of fluid properties. Due to their numerous degrees of freedom or fitting parameters, connectionist models are able to capture the nonlinear trends of reservoir fluid data in a superior manner, giving more robust and reliable predictions than the traditional correlations (Gharbi and Elsharkawy 1999). Different ANNs have been used to forecast properties such as oil formation volume factor, solution gas–oil ratio, oil viscosity, saturated oil density, undersaturated oil compressibility, and evolved gas gravity (Gharbi and Elsharkawy 1997; Elsharkawy 1998; Varotsis et al. 1999; Elsharkwy and Gharbi 2001; Osman et al. 2001; Al-Marhoun and Osman 2002; Asadisaghandi and Tahmasebi 2011). Similar properties have been obtained using other intelligent methods such as SVM, GEP, and LSSVM (Malallah et al. 2006; El-Sebakhy et al. 2007; El-Sebakhy 2009; Ahmadi et al. 2014a; Ahmadi and Ebadi 2014; Ahmadi and Elsharkawy 2017). Different hybridizations of AI methods have also been applied to predict properties such as gas compressibility factor, asphaltene precipitation and deposition, bubble point pressure, minimum miscibility pressure (MMP), and gas–oil interfacial tension (Chamkalani et al. 2013a, b; Zendehboudi et al. 2014; Chamkalani et al. 2014; Ahmadi et al. 2015a, b; Ahmadi and Mahmoudi 2016).

Various equilibrium and transport properties of reservoir fluids can be studied using MD simulations (Ungerer et al. 2006, 2007). Different fluid properties and fluid-related phenomena including thermal properties of natural gases, hydrocarbon phase behavior and volumetric properties, gas solubility, shear and bulk velocities, diffusion heat and mass transfer coefficients, and compositional grading as well as EOR-related aspects of fluid injections such as determination of MMP and interfacial phenomena at water–oil, CO2–water, and CO2–oil interfaces have been investigated in some recent MD simulation works (Campos et al. 2009; Galliero and Montel 2009; Makimura et al. 2013; Herdes et al. 2015; Bao et al. 2016; Yang et al. 2016). This simulation technique provides unique opportunities to study aspects of reservoir fluids, which cannot be adequately addressed by laboratory procedures, particularly under extremely high-temperature and high-pressure conditions encountered in some deep offshore environments.

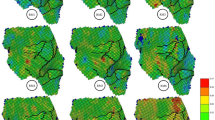

The principal methods of reservoir fluid characterization are summarized in Figure 8.

Reservoir Rock Characterization and Rock–Fluid Interactions

Fluid storage, distribution, and flow properties are controlled by the complex nature of the reservoir rocks at macroscopic and microscopic scales (Gaafar et al. 2015). Experimental characterization of reservoir rocks is typically performed through routine core analysis (RCAL), geological core analysis, and special core analysis (SCAL), the latter being preceded by SCAL pre-study (sample selection and design) and imaging. The objectives of these experiments include assessment of reservoir quality (e.g., pore geometry, mineralogy, cements, clays, and depositional environments), determination of petrophysical properties (e.g., porosity, permeability, effects of stress, and effective porosity), water saturation (e.g., electrical properties, and capillary pressure), saturation change (e.g., relative permeability, gas or water injection, and recoverable hydrocarbon), and rock mechanics (e.g., compressibility, sanding, fracture design, and stimulation).

RCAL tests are aimed at providing basic parameters for reservoir engineering studies such as reserve estimation. Rock–fluid interactions in RCAL tests can theoretically be neglected. These tests include determination of porosity, grain density, and permeability as well as natural gamma radiation for depth matching and shale typing, core and sample photography for visual inspection, and measurement of as-received fluid saturations to calibrate logs and evaluate the performance of different production mechanisms. The main RCAL purposes or properties obtained along with the methods and the equipment required are summarized in Table 3.

SCAL tests are performed to understand the interactions between the rock and fluids and their effects on flow in the reservoir. Compared to RCAL, SCAL tests are generally more difficult, more complex, and costlier, and take longer times. SCAL includes relative permeability and capillary pressure measurements, mercury injection for pore structure characterization, measurement of under-stress petrophysical properties, determination of electrical characteristics and shale effects, and wettability and interfacial tension measurements. A summary of the key SCAL properties or tests and their measurement purposes is provided in Table 4.

Numerous theoretical models and empirical relationships have been developed for estimation of reservoir rock properties and flow-related rock–fluid interaction parameters including porosity, permeability, capillary pressure, and two-phase and three-phase relative permeabilities.

AI has also been used extensively by researchers in reservoir rock characterization and prediction of flow-related parameters. Primarily, estimation of permeability (mainly from well log data) triggered numerous studies on the application of AI in reservoir rock characterization. However, prediction of other properties such as porosity, fluid saturation, and relative permeabilities has also been the subject of many studies. ANNs have been used for lithofacies identification as well as determination of porosity, fluid saturations, permeability, and capillary pressure (Baldwin et al. 1989, 1990; Wiener et al. 1991; Mohaghegh et al. 1994, 1995; Wong et al. 1995a, b; Huang et al. 1996a, b; Malki et al. 1996; Abedini and Torabi 2013). Many authors have applied hybridization of AI models to estimate permeability, porosity, and oil–water relative permeability (Huang et al. 1996a, b, 2001; Lim 2005; Saemi et al. 2007; Helmy et al. 2010; Irani and Nasimi 2011; Olatunji et al. 2012; Ahmadi et al. 2014b, 2016; Aïfa et al. 2014). Several other intelligent methods have been implemented to estimate permeability and three-phase relative permeability (Karimpouli et al. 2012; Tahmasebi and Hezarkhani 2012; Kaydani et al. 2014; Gholami et al. 2014; Torabi et al. 2015).

MD simulations of rock–fluid interactions have recently made significant contributions to reservoir characterization. A particularly important research area accelerated by MD simulation is flow and phase behavior of reservoir fluids under nano-confinement. Examples of such research activities include investigation of flow behavior of oil–water mixtures in confined nano-channels of clays, effect of pore size on the pressure-driven flow of oil–water mixtures, effects of pressure and pore size on transport properties of single components and binary mixtures of natural gases through clay pores, and effects of pressure, pore size, and pore connection on methane adsorption, and retrograde condensation for fluids under confinement to nano-pores of shale rocks, to mention a few (Wu et al. 2012; Gouth et al. 2013; Didar and Akkutlu 2013; Dhanapal et al. 2014; Welch and Piri 2015).

Another recent advance in reservoir characterization is the digital core analysis that is used to obtain valuable information on rock–fluid interactions and flow-related phenomena. In this method, a digital model of the core, which is made using advanced imaging and image analysis technologies, is employed to simulate different rock characterization and flow tests with unlimited repeatability to test various conditions of flow rate, initial saturation, and wettability (Hazlett 1995; McDougall and Sorbie 1995; Bakke and Øren 1997; Dixit 1999; Patzek 2001; Blunt et al. 2002; Nguyen et al. 2006; Demianov et al. 2010; Idowu and Blunt 2010). Even damaged cores and drill cuttings can be used in the construction of the core model. In the case of tight formations, digital core models allow performing measurements and tests that are very challenging to perform on real cores due to their extremely low permeabilities (Sondergeld et al. 2010; Lemmens et al. 2011; Walls and Sinclair 2011; Silin and Kneafsey 2011; Curtis et al. 2012; Loucks et al. 2012; Kuila et al. 2012; Milliken et al. 2013). Pore-scale reservoir mechanisms such as recovery, compaction, flooding, and formation damage can be studied using this technique (Van der Zwaag et al. 1997; Youssef et al. 2010; Iglauer et al. 2011; Saadatfara et al. 2012; Saadatfar et al. 2012; Blunt et al. 2013; Berg et al. 2013; Nadeev et al. 2013). Furthermore, particular rock–fluid studies such as evaluation of trapped oil distribution in EOR and IOR injections and three-phase flow modeling, which are currently not possible to study experimentally, can be addressed using the digital core analysis method (Vinegar and Wellington 1987; Piri and Blunt 2005; Kumar et al. 2009; Youssef et al. 2010; Iglauer et al. 2010; Knackstedt et al. 2011).

The main methods of characterization of reservoir rock and rock–fluid interactions are depicted in Figure 9.

Research and Engineering Aspects/Challenges of Experimental Works/Tests

Characterization Phase

Reservoir Fluid Sampling

Given the operational difficulties and high costs of offshore reservoir fluid sampling, collection of sufficient reservoir-representative volumes of fluids, particularly in the case of downhole (bottomhole) sampling, is required to ensure proper and timely fluid testing schemes (Danesh 2003; Lawrence et al. 2008; Pedersen et al. 2015). Sample contamination (change of composition) by oil-based muds should be avoided or corrected mathematically (Lawrence et al. 2008; Sah et al. 2012; Pedersen et al. 2015). If asphaltene tests are planned for the reservoir fluid, sample pressure should be adequately controlled to avoid irreversible precipitation of asphaltenes (Pedersen et al. 2015). In the case of surface sampling, the major challenges include correct determination of the producing GOR for recombination, ensuring the steady flow rate of the well and collection of both liquid and gas samples at their saturation pressures. In addition, great operational skill is required to run the separators at optimal conditions with no liquid entrainment in separator gas and no gas or foaming, solids, or emulsions in the separator liquid. Other challenges are the correct design of the sampling program in reservoirs with compositional grading and proper sample handling, transfer, and shipping practices (Lawrence et al. 2008).

Fluid Characterization Experiments

Special test designs and equipment might be required for near-critical samples and gas injection tests where longer equilibrium times and higher-accuracy measurements are necessary to account for complex phase behavior and steep phase changes due to small changes in thermodynamic conditions (Nagarajan et al. 2007). In the case of extra-heavy oils, the sample needs to reach equilibrium at each stage of the test, requiring longer times and speedup measures (Satik et al. 2004). Removal of free and emulsified water from the samples and the use of special PVT cells capable of handling three phases might be necessary for some samples (Nagarajan et al. 2007). Gas chromatography–mass spectrometry (GC–MS) technique is a traditional industry-standard method for compositional characterization of reservoir fluids (Varotsis and Guieze 1996). However, this method faces limitations in characterization of the high-polarity fractions and molecular weights greater than 400 g/gmol (Kim et al. 2016), while detailed description of these fractions is essential for the proper definition of the C7+ fraction for different purposes. A solution to this shortcoming is to augment GC–MS results with more advanced methods (Rodgers et al. 2005; Cho et al. 2015; Liu et al. 2016) which, indeed, may not be available in many laboratories.

Flow Assurance

Formation of solids such as gas hydrates, asphaltenes, waxes, and scales and their consequent deposition in reservoirs, wells, facilities, and pipelines as well as corrosion, foaming, and emulsion constitute one of the most critical problems faced during the development of offshore resources (Bell et al. 2005; Bomba et al. 2018). Understanding the operations and design of production and transportation facilities in multiphase systems is addressed by flow assurance technologies. From being traditionally considered as a branch of process or production engineering, flow assurance has evolved into an essential engineering discipline in the petroleum industry (Bomba et al. 2018).

The first step in flow assurance engineering and technologies to deal with these issues across the lifecycle of offshore developments starting from the reservoir to wells, flowlines, processing equipment, and platform facilities, is proper reservoir fluid characterization. The reservoir fluid and its behavior during thermodynamic changes resulting from production or contact with injectants need to be thoroughly characterized (Bomba et al. 2018). A pressure–temperature (P–T) diagram, which shows the asphaltene, wax, and hydrate phase envelop for a typical reservoir fluid, is presented in Figure 10. Knowledge of the phase envelops, and several other fluid properties, is initially gained through specific laboratory tests and measurements.

P–T diagram of hydrocarbon solids phase envelopes (Zendehboudi et al. 2014)

The main challenges in flow assurance experimental works and tests are related to obtaining clean samples of reservoir fluids and developing test methods for more accurate determination of fluid compositions. Appropriate fluid sampling and analysis encompass the collection of contamination-free representative samples, their proper handling, preservation, and transportation, as well as planning (or even designing) effective experimental schemes (Bomba et al. 2018).

Determination of asphaltene onset pressure, i.e., the pressure (at the test temperature) at which asphaltene starts to precipitate from the reservoir fluid, is a significant challenge in the case of unstable oils which show variations in asphaltene onset pressure gradients across the field. Failure to identify asphaltene onset pressure gradients within the field may result in misinterpretation of non-homogenous onset pressures as experimental uncertainty. Since many aspects of offshore field development including well placement and completion, pressure maintenance, subsea and surface facilities, and recovery factors can be impacted by variations of asphaltene onset pressure, identification of onset pressure gradients is critically important in the success of field development (Dumont et al. 2017). Regardless of the variations of asphaltene onset pressure gradients within the field, quantification of asphaltene content and establishment of asphaltene phase envelop suffer from test-specific uncertainties. Different laboratory methods have resulted in the determination of asphaltene onset pressures with uncertainties of up to 1000 psi (Yonebayashi et al. 2016). Such huge errors in determination of the asphaltene onset pressure may result in significant financial losses due to total shut down of production, leaving much residual oil in the reservoir (Dumont et al. 2017). Lack of appropriate tests and predictive methods to estimate the formation of paraffins and waxes is also another immediate challenge in experimental methods contributing to flow assurance (Bomba et al. 2018).

Reservoir Rock Characterization

Reliability of the reservoir modeling and simulation depends in no small extent on proper determination of rock and flow properties. However, there are uncertainties in reservoir rock experimental data that can propagate into the reservoir model. Porosity evaluation uncertainties affect volumetric calculations of in-place hydrocarbons. Uncertainties in permeability and relative permeability estimations adversely influence flow rates and the fractional flow prediction reliability. Recovery factor estimations can be very unreliable due to uncertain wettability, endpoint saturation, and relative permeability, as well as permeability contrasts (Honarpour et al. 2006). These uncertainties stem from problems such as core damage, variable data quality, inadequate planning and inappropriate design, method-sensitivity of the results, and poor reporting standards which have rendered about 70% of SCAL data unfit for purpose (McPhee 2015).

Coring and Core Recovery

Acquisition of reservoir-representative cores is challenging in offshore reservoirs. Severe contamination of the cores due to the invasion of drilling fluids, especially oil-based muds (OBMs), reduces the chance of successful rock characterization (Skopec 1992; Honarpour et al. 2006). In deep and ultra-deep offshore drilling, coring is usually performed using synthetic-based muds (SBM) whose filtrate can invade and damage the core and consequently alter the core wettability (Shafer 2007). Once contaminated with OBM or SBM, bringing the core back to its original wettability can be very difficult, and special core cleaning and wettability restoration procedures must be utilized (Honarpour et al. 2006; Shafer 2007). Further challenges of core recovery in offshore environments are related to the mechanical strength of rocks and the tendency of the drilling operators to speed up the coring schedule. These include shear failure in weak rocks during the coring and development of tensile fractures in the cores due to fast removal of the drill string from the wellbore not allowing the dissipation of pore pressure (Shafer 2007; McPhee 2015).

SCAL (Coreflood) Uncertainties

Displacement of hydrocarbons in reservoir rocks is studied using coreflood experiments. Data obtained from these experiments constitute a vital component of the reservoir model for simulation and design of EOR methods. Economic and operational limitations in offshore environments impose restrictions on coring opportunities (Bondor et al. 2005). Therefore, maximizing the value of available core samples relies on the optimum planning of laboratory tests, including corefloods. These tests and measurements are not without challenges. Measurement uncertainties are inevitable due to various testing procedures and equipment setups and resolutions in different laboratories (Moreno et al. 2018). Coreflood experiments should be designed in a way that they closely represent the behaviors/trends that need to be determined through measurements. Otherwise, compromised or incomplete coreflood information can result in misleading characterization and predictions, which may not be physically meaningful. Displacement heterogeneity and capillary end effects should be verified through saturation imaging of the cores. The accuracy of injection and production rates of different phases and agents should be validated using the material balance method. Application of coreflood results in the design of EOR processes needs further precautions to reduce the uncertainties. Interpretation of coreflood tests is influenced by the capillary end effects for which correlations have been proposed to address these issues in special core analyses, but further work is required if these results are to be used in the full-field simulation of EOR schemes. Saturation monitoring along the core plug length, though expensive, can reduce such uncertainties and provide a detailed understanding of the displacement changes. The increased expenses can be justified by the assurance of obtaining valid and reliable coreflood results, which may otherwise result in inaccurate prediction of recoveries and chemical parameters, leading to failures in proper screening of EOR processes (Huang and Honarpour 1998; Guédon et al. 2017; Moreno et al. 2018). Reliability of relative permeability measurements can be improved by proper wettability restoration, in situ monitoring, and coreflood simulation. Use of best practices, careful selection and design of necessary tests, and rigorous quality control (QC) of the rock samples and experimental procedures can improve the quality and reliability of SCAL results (Honarpour et al. 2006; McPhee 2015).

Whole Core Analysis

Many laboratories still do not offer reservoir-pressure whole core analysis services, which can be significantly important for multiphase flow experiments and proper permeability characterization in heterogeneous or fractured rocks where core plugs are not long enough to reflect the reservoir-scale effects of heterogeneity and anisotropy. Other challenges of whole core analysis include lack of appropriate whole core cleaning methods and difficulty of establishing representative water saturations in drainage capillary pressure experiments and directional permeability measurements in SCAL (Honarpour et al. 2005).

Incorporation of Offshore HPHT Effects in Core Analysis

Proper design of core analysis experiments for deep and ultra-deep offshore reservoirs should incorporate the specific HPHT conditions encountered in these environments. Pore pressures as high as 20,000 psi result in an exponential increase in permeability by up to 50%. Therefore, RCAL permeability and porosity should be evaluated at net confining pressures (Shafer 2007). Conventional capillary pressure measurements with laboratory fluids such as mineral oil and air should be corrected to reservoir fluids to build reliable primary drainage capillary pressure curves. However, interfacial tension (IFT) values of reservoir fluids at HPHT conditions are usually unknown, and extrapolation of low-IFT data of live oils to higher pressures can result in uncertainties up to 100%, leading to significant errors in the calculation of in-place fluid volumes (Amin and Smith 1998; Shafer 2007).

Recovery/Production Phase

Uncertainty in Fluid Phase Behavior Kinetics

Different aspects of production in offshore fields are affected by the fluid phase behavior kinetics, which, if not understood well, pose a critical source of uncertainty to field development, operations, and troubleshooting, as the offshore industry focuses more on simplifying the designs and reducing the sizes and costs. Gas evolution from liquid below bubble point pressure and gas dissolution in the liquid above bubble point pressure occur in different zones across the flow of reservoir fluids from within the reservoir to production tubing, separators, downstream of boosting pumps, and through the pipelines (Lavenson et al. 2017). It has been recognized that gas evolution and dissolution are not instantaneous phenomena but occur at rates depending on properties of the fluids and the related systems (Schweitzer and Szebehely 2004). However, the kinetics of fluid phase changes are often overlooked, and there are currently no tools available to estimate or predict gas evolution and dissolution rates which are not measured during standard fluid characterization tests. As a result, engineering design and simulations still resort to assuming near-instantaneous equilibrium conditions for these processes. Nevertheless, this uncertainty becomes increasingly crucial in deeper offshore environments, particularly in design and optimization of artificial lift systems, compact separators, subsea or topsides pumping, design and operation of electrical submersible pumps, subsea processing evaluation, and multiphase flow predictions. A good example of the importance of fluid phase kinetics can be discussed about subsea processing which usually involves an initial step of gas–liquid separation on the seafloor. To reduce the costs of offshore production, compact separation systems have been developed which, compared to conventional separators, often have shorter residence times for the fluids. Considering the changing fluid and system properties such as the degree of supersaturation of the fluid, shear, viscosity, emulsions, and multi-component gas streams, robust prediction of the minimum time required for complete evolution of gas at separator thermodynamic conditions is required to ensure this processing time remains within the residence time limit of the compact separator. Failure to assess and reduce this uncertainty may have consequences such as the over-conservative design of separation systems, operational upsets and downstream liquid handling inefficiencies and downtime due to chronic gas carry-under, and poor performance of downhole pumps. This source of uncertainty can be addressed by conducting additional research and experimental work on the measurement of fluid phase behavior kinetics, which will pave the way for developing predictive methods and modeling techniques (Lavenson et al. 2017).

EOR-Related Testing Protocols

Laboratory tests and measurements constitute an essential component in the design and risk mitigation of EOR deployments. Experimental results are used for characterization of the interactions between the reservoir rock, reservoir fluids, and EOR injectants as well as estimation of the potential recovery. The laboratory tests, however, face challenges regarding uncertainties, experimental design, measurement accuracy, scalability, and differences in testing protocols form laboratory to laboratory. More complexities arise from the fact that parameters related to fluid flow and frontal advancement of EOR processes (e.g., non-wetting phase trapping and IFT) are not measured directly but, instead, are inferred from other laboratory results. A serious challenge in the application of EOR flooding tests is their direct use in numerical models, while the differences of scale and dominant forces may be overlooked (Moreno et al. 2018).

Figure 11 summarizes the research and engineering aspects and challenges of experimental works and tests in the context of offshore reservoirs.

Research and Engineering Aspects/Challenges of Modeling Works

Characterization Phase

Limitations of Empirical Correlations

The primary challenge in property estimation using empirical correlations is that they have been developed based on a specific set of data and their reliability in predicting properties is questionable if the input parameters are not within the range of data based on which the correlation has been established. Moreover, most of the correlations developed for reservoir fluids result from linear regressions on data and lack thermodynamic basis, giving rise to significant errors if extrapolated outside their specific data ranges and conditions (Danesh 2003; Nagarajan et al. 2007; Ahmed 2016). Oversimplifying assumptions made in obtaining the theoretical relationships, and their inability to track local variations of properties, particularly in undrilled locations of the reservoir, are other limitations of this method.

EOS Limitations

Despite the widespread application of the EOS approach in reservoir fluid characterization, EOS modeling faces a number of challenges. Although evaluation of the accuracy of different EOS models has been the focus of several studies so far (Ahmed 1988; Danesh et al. 1991; Wu and Rosenegger 1999), no EOS has been collectively selected as the single most reliable EOS for prediction of all the fluid properties at all conditions. Besides, the accuracy of EOS predictions is significantly affected by the choice of the most suitable mixing rules for EOS parameters (Danesh 2003). Accuracy of compositional analyses, reservoir fluid handling, preservation, transportation, and testing practices and procedures, as well as the level of expertise of the users of EOR-based software in terms of selection of appropriate EOS and tuning parameters, number of components used to define the reservoir fluid, and splitting and lumping criteria are some of the factors that constitute challenges to the EOS approach. Furthermore, to use the EOS approach for prediction of reservoir fluid properties and phase behavior, the detailed fluid composition is required at the minimum.

Characterization of Heavy Fraction (C7+) of Reservoir Fluids

Reservoir engineering still has difficulties in the adequate characterization of the critical properties and acentric factors of heavy C7+ fraction (Ahmed 2016). Various methods have been proposed for reservoir fluid modeling in terms of splitting C7+ into pseudo-components for different purposes. Leaving the entire C7+ fraction as one component may be appropriate in simple depletion studies of black oils. However, for simulation of more complex cases such as near-critical fluids, miscible gas injection, and viscosity behavior of heavy oils as well as their wax and asphaltene formation properties, usually a more detailed description of C7+ with more pseudo-components is required. In such cases, the choice of the most suitable method for defining the distribution of components (or their properties) in the C7+ fraction and the number of pseudo-components is the responsibility of the reservoir engineer and requires good understanding of the process for which the reservoir fluid model is being prepared (Danesh 2003; Nagarajan et al. 2007; Pedersen et al. 2015; Ahmed 2016).

Challenges of Property Predictions Using AI

Recent advances in the application of AI in the oil and gas industry and particularly in the prediction of reservoir fluid and rock properties have shown some promise. However, most of the predictive connectionist models reported in the literature have not been clearly presented in terms of generalized formulations. Since each AI method provides advantages and has drawbacks, successful application of any given AI technique for a specific dataset may not necessarily ensure the same level of accuracy or ease of application for other datasets. This issue has been partially overcome by hybridization of the AI methods and evolutionary algorithms in some more recent studies. Nevertheless, more research is required on the application of optimization-based hybrid intelligence and different possible combinations (Anifowose et al. 2017). In addition, the high level of designer-dependency of the AI models hinders their widespread application, at least currently.

MD Simulation Limitations

MD simulation is a powerful research tool that uniquely complements experiment and theory but still has some limitations. While quantum mechanics provides higher accuracy in terms of describing particle dynamics using Schrödinger’s equation which, accounts for the states of both the atomic nuclei and the electrons, MD simulation is based on classical mechanics, i.e., the calculation of particle trajectories using Newtonian equations of motion for simplicity and computational efficiency (Griebel et al. 2007; Ippoliti 2011). This approach, therefore, cannot model quantum effects such as changes in chemical bonds (e.g., formation or breaking of the covalent bonds), existence of non-covalent intermediates, specific heat drop in crystals below a specific temperature, and thermal expansion coefficient anomalies, especially at low temperatures (Meller 2001; Ippoliti 2011). Another limitation of MD simulation is the imperfection of force fields, which represent interatomic forces. These forces are obtained by taking the gradient of the potential energy function. The reliability of MD simulation results, then, depends on how realistically the interatomic forces are approximated by the potential energy function. Several force fields (i.e., the functional forms and parameter sets used to calculate the potential energy) have been developed for different MD simulation purposes. However, these force fields are merely approximations of the real forces acting on particles as the potential energy functions, and the parameters of these force fields are often obtained empirically by fitting to available experimental data (Meller 2001; Ippoliti 2011). Detailed discussions on some limitations of such approximations are available in the literature (Myers and Pace 1996; Israelachvili 2011). Limitations in computational power and resources also impose restrictions on time and size scales of the MD simulations. The types of problems that can be handled by the MD simulation technique depend on the maximum number of system particles, timestep lengths, and the total duration of the MD simulation, which should be long enough to sample the simulated macroscopic phenomenon and small enough to avoid discretization errors and maintain the numerical stability of the integrations. Current MD simulations span nanoseconds to microseconds, while some phenomena of interest in the oil and gas industry need longer times to occur. The simulation box size limitation to the number of particles in the simulation is also another serious challenge in many MD simulation studies, as the observables and structural properties should be within the nanometer-size scale of the simulation box (Meller 2001; Springer 2006; Ippoliti 2011). Research is active in the area of improving computational power and memory to enable longer timesteps and trajectories for more particles in MD simulations.

Flow Assurance

The essential component of a successful flow assurance scheme is the characterization of reservoir fluid and production chemistry using various simulation and modeling techniques, which include (Bomba et al. 2018):

PVT tests that simulate depletion and recovery phenomena from the reservoir to the surface

EOS modeling using experimental data from PVT tests to tune a fit-for-purpose EOS for prediction of fluid behavior in different processes and scenarios

Characterization of unconventional fluids and heavy oils

Correction of mud contamination

Prediction of the precipitation and deposition rates of solids such as asphaltenes and waxes

Although flow assurance technologies have improved dramatically in recent years, there are still many challenges that need to be addressed. Despite the significant efforts put into understanding the kinetics of hydrates and their transport, the industry still relies on avoidance measures. There is not enough confidence in asphaltene precipitation and deposition models at the industry level. In flow modeling, slug prediction is not fully understood although much work has been focused on fine-tuning of the current models (Bomba et al. 2018).

Recovery/Production Phase

Modeling Complex Recovery Mechanisms

Offshore EOR projects need careful planning and design to avoid economic and environmental consequences of potential failure. Advanced modeling approaches are required to provide the most realistic picture of the recovery mechanisms involved in each EOR method. Most EOR techniques involve the miscible or near-miscible injection of fluids into the reservoir. Development of miscibility and near-miscible behavior has traditionally been considered as either condensing (i.e., components with intermediate molecular weights transferring from the injected gas to the reservoir oil) or vaporizing (i.e., components with intermediate molecular weights transferring from the reservoir oil to the injected gas) processes, leading to the design of the laboratory testing protocols which are still being used today. However, with the recent evolution of the understanding of the phase behavior of these processes and acknowledgment of the occurrence of combined vaporizing and condensing (where multiple phases exist and flow simultaneously), more advanced laboratory strategies and numerical models are needed to adequately and realistically describe and characterize miscible and near-miscible injections (Moreno et al. 2018).

Upscaling of Coreflood Experiments Results for Use in Simulation

Another important source of data required for the proper design of pilot and full-field EOR implementations using numerical simulation is rock properties obtained from core laboratories. However, to overcome the limitations of numerical reservoir simulation, coreflood data need to be upscaled to much coarser scales. The magnitude of the scale difference between laboratory results and simulation grid blocks dictates the complexity level of the upscaling process, which is dominated by the displacement velocity, force balance, dispersive flow, conformance, and displacement mechanisms. The upscaling strategy should be decided from the start to consider its effect on the calibration of coreflooding. Care must be exercised in relative permeability upscaling because the coarsening process will naturally result in loss of reservoir heterogeneity. Advancement of immiscible fronts is more impacted by heterogeneity. However, EOR processes, such as chemical flooding, are also influenced by heterogeneity effects as well as other upscaling complexities (Moreno et al. 2018). For example, interactions of chemical agents with the reservoir rock, reservoir fluid, and other injectants lead to complex physical phenomena that cannot be easily reflected even on fine grid blocks of the model. Therefore, their upscaling to the coarser grids will be even more challenging (Han et al. 2007; Moreno et al. 2018).

Flow Assurance

Flow modeling, including single and multiphase flow systems, is another essential component of flow assurance modeling works. Thermo-hydraulics and fluid-related phenomena and flow system behaviors are dealt with in multiphase analyses. Rate and location of solids deposition can be investigated through the combined use of fluid and flow modeling approaches (Bell et al. 2005; Bomba et al. 2018).

Various complex physical phenomena such as severe slugging and composition tracking can be quantitatively studied through simulation of transient multiphase flow of oil, water, and gas in wells and pipelines with process equipment. However, there are still many uncertainties that need to be addressed in further research, particularly given the more complex fluids and development processes used in increasingly deeper and harsher offshore environments that are continually being explored and developed (Bell et al. 2005; Total 2018a, b). Such projects should always deal with challenges including flow assurance over longer transport distances, greater line diameters, and unusual temperature and pressure conditions at greater water depths. These challenges, in turn, require new architecture designs with considerations such as fluid processing limitations or even pulsating flows over long distances. Therefore, conducting flow experiments in laboratories is necessary to validate the accuracy of flow models. In addition, the effects of structures and fluid chemistry on flow interactions need to be investigated. Other challenges that require further flow modeling work include corrosion, erosion, and sand deposits in flow lines and facilities (Total 2018a, b).

Advances of offshore field developments to water depths beyond 3000 m would not have been possible without significant collaborations of oil and gas operators with academia and contractors over the last 2 decades on numerous technologies including flow assurance. Validation of flow assurance concepts and flow modeling software through extensive experimental works has resulted in vast improvements in pipeline configurations, insulation materials, and solids deposition control methods (Bomba et al. 2018; Total 2018a, b).

The main reservoir fluid characterization and multiphase flow simulation aspects related to flow assurance are listed in Table 5.

The research and engineering aspects and challenges of modeling works in the context of offshore reservoirs discussed above are summarized in Figure 12.

Practical Aspects/Challenges of Offshore Petroleum Reservoirs

Development of offshore reservoirs is a challenging task, which requires extensive planning and making timely decisions. Here, some of the main factors causing complexities in offshore field developments are discussed in detail.

Characterization Phase

Large Well Spacing

Due to high installation and operational costs of offshore platforms, the number of wells per area that can usually be drilled in offshore reservoirs is typically limited compared to onshore developments. A direct result of this limitation is fewer opportunities for collection of geological and reservoir engineering data through well logging, coring, and collection of reservoir fluid samples, leaving the reservoir models less populated with real data, thus increasing property modeling uncertainties. Another consequence of the restricted number of wells per area in an offshore reservoir is the restriction on IOR and EOR design and implementation which usually require certain well patterns and close spacings (Jayasekera and Goodyear 2002; Bondor et al. 2005; Alvarado and Manrique 2013).

Complex Rock and Fluid Systems

Deep offshore developments may be further challenged by characterization complexities such as thinly bedded reservoirs and reservoir heterogeneity which give rise to uncertainties in terms of lateral and vertical reservoir continuity. Thin beds may show similar characteristics in well logging evaluations, but their production behavior can be drastically different because of the differences in vertical and horizontal permeabilities. In such cases, use of more advanced well logging techniques such as nuclear magnetic resonance (NMR) will be required to gain a better estimation of flow potential and production behaviors (Claverie et al. 2007; Folger et al. 2018). Presence of thinly laminated sands and shales in sandstone reservoirs can be associated with the high potential of oil and gas production without any water-cut due to the high irreducible water saturation (Tyagi et al. 2008). However, these high-resistivity intervals might be interpreted as unproductive zones due to being masked by conductive shales. Such high clay contents together with unknown water salinity can pose challenges to the estimation of reserves and production potentials (Fadjarijanto et al. 2018). Moreover, the chemistry of complex fluids in deep offshore reservoirs results in flow obstacles, which need to be thoroughly addressed by the flow assurance engineering.

Recovery/Production Phase

Platform Weight and Space Constraints

Platform space and weight are always at a premium in offshore developments. On the other hand, all EOR methods involve some material injection from the platform down to the reservoir. Such injection schemes require installation of an array of surface equipment including compression facilities, separation systems, mixing and softening units, as well as facilities for storage of injectants and disposal of produced material. These requirements can be beyond the capacity of the offshore platforms, and tradeoffs should be made to achieve an optimum design considering surface and subsurface facilities (Bondor et al. 2005; Alvarado and Manrique 2013).

Limited Window of Opportunity