Abstract

This study analyzed the characteristics of nanoparticle emissions from a light-duty diesel vehicle in NIER-06 and NIER-09 test cycles, which include acceleration, deceleration, and idling phases without cruise driving phase and thus simulate urban driving patterns during rush hour in South Korea. In general, the tested diesel vehicle emitted more particles as acceleration increased. Since NIER-06 test cycle showed a higher average acceleration than NIER-09 test cycle, the tested diesel vehicle emitted more particles, by 17–31%, per unit distance traveled in NIER-06 test cycle than in NIER-09. When the acceleration phases of NIER-06 and NIER-09 test cycles were categorized into two groups by considering gear shift change, the tested diesel vehicle emitted more particles, by approximately 60%, per unit distance traveled at the acceleration phases with the speed change of lower than 20 km/h, i.e., where it was assumed that gear shift change did not occur during acceleration, than at the acceleration phases with the speed change of higher than 20 km/h, i.e., where it was assumed that gear shift change occurred more than once. Achieving a high average velocity of traffic flow or minimizing sudden acceleration for smooth urban traffic will be of great help in reducing particle emissions from light-duty diesel vehicles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of the automotive industry has drastically increased the portion of on-road mobile source for air pollution sources. Many countries around the world have endeavored to reduce automobile emissions. Emission standards are one of the products of such an attempt. South Korea, Europe, Japan, and the USA initially applied regulations based on mass-based emission (MBE) from diesel vehicles. However, since the implementation of EURO 5b standard in 2011, number-based emission (NBE) regulation has been enforced along with MBE regulation. In South Korea, particulate matter (PM) emission from road mobile source accounts for as much as about 10% of total PM emission (National air pollutants emissions 2015, NIER). Also, in foreign countries, vehicle emissions have been identified as a major source of urban air pollution (Ross et al. 2011). PM emissions from automobiles are harmful to the human body and may cause a respiratory or cardiopulmonary disease and cancers (Sydbom et al. 2001; Ristovski et al. 2012; Ema et al. 2013; Chio et al. 2014; Oravisjärvi et al. 2014).

To solve this problem, various researches are on the way not only to improve fuel quality but also to develop post processing devices. PM in diesel emissions is usually controlled by a diesel particulate filter (DPF) which is a post processing device. Since the first commercialization in 2000 (Salvat et al. 2000), the number of diesel vehicles with DPF increased drastically and regulatory authorities worldwide came to an agreement on vehicle PM limits (US EPA 2001). According to Bergmann et al. (2009) and Tente et al. (2011), the use of DPF can reduce PM in exhaust gas by about 90%.

For this reason, many studies have been conducted to investigate characteristics of PM emissions from diesel vehicles (van Gulijk et al. 2001; Park et al. 2003; Sharma et al. 2005; Fujitani et al. 2006; Giechaskiel et al. 2007; Kamimoto et al. 2007; Biswas et al. 2008; Karavalakis et al. 2009; Oanh et al. 2010; Ushakov et al. 2013; May et al. 2014; Quiros et al. 2014). However, most of those studies focused on the number concentration distribution or total mass concentration measured from PM holder installed in the rear end of a constant volume sampler (CVS) tunnel. In other words, mass concentration of PM emissions from a diesel vehicle has not been directly measured but indirectly estimated through a measuring instrument for size and number concentration such as engine exhaust particle sizer (EEPS), electrical low-pressure impactor (ELPI), scanning mobility particle sizer (SMPS), DustTrak, and Dekati mass monitor (DMM). In the most of the existing studies, mass concentration was converted from number concentration. On the contrary, there have been relatively much fewer cases where mass concentration was directly measured (Fujitani et al. 2006; Lu et al. 2013). Fujitani et al. (2006) used a Dekati low-pressure impactor (DLPI) and a Nano-MOUDI which are instruments for measuring real mass concentration. However, even in this case, real mass concentration from a diesel vehicle was compared under only one cruise driving condition and one acceleration condition.

According to Faiz et al. (1996), air pollutant emissions from a vehicle running on roads depend on weight of the vehicle, engine performance, types of fuel, driving pattern, environmental factor (e.g., weather), road gradient, and post processing system. Therefore, it is necessary to develop driving test cycles that reflect dominant driving styles and patterns in each country. In 2005, the South Korean government made it compulsory to install DPF on a diesel vehicle. However, this regulation only applies to large cities. For this reason, there are two groups of diesel vehicles running on roads depending on whether DPF is installed or not. National Institute of Environmental Research (NIER) test cycle has been prepared by the NIER to reflect driving patterns and habits currently widespread in South Korea. A few studies have been conducted to analyze the NIER test cycle, but all of them focused on number concentration distribution and total mass concentration (Myung et al. 2014; Jang et al. 2015). Unfortunately, few studies have been made on real mass concentration distribution. The NIER test cycles addressed in the present study were NIER-06 and NIER-09. These test cycles do not include any cruising phase but consist mainly of acceleration, deceleration, and idling phases. Besides, the test cycles have low average and maximum velocities. For these reasons, the test cycles are suitable for predicting particle emissions from vehicles running on roads during rush hour, unlike the Federal Test Procedure (FTP-75) and the New European Diving Cycle (NEDC).

Many studies have reported that diesel emission particles are harmful to the human body (Sagai et al. 1993; Ichinose et al. 1995; Steerenberg et al. 1998; Singh et al. 2004; Brito et al. 2010). Especially, nanometer-sized diesel emission particles are known to be more toxic to the human lung (Nemmar et al. 2003; Block et al. 2004). Therefore, it is of great importance to investigate the characteristics of nanoparticle emission from a light-duty diesel vehicle during test cycles simulating urban rush-hour driving patterns. Diesel emission has been regulated in terms of not only particle mass but also particle number since the implementation of EURO 5b, but total mass concentration and total number of particles emitted per unit distance traveled have been regulated without considering particle size. It is thus needed to investigate the size distribution of particles emitted from a light-duty diesel vehicle and also the effect of the use of a DPF in removing diesel emission particles, especially nanometer-sized particles. This study evaluated the characteristics of nanoparticle emission from a diesel vehicle mounted on a chassis dynamometer in terms of number concentration and mass concentration. These evaluations were conducted with or without installing a DPF, while the vehicle was being simulated to be running on roads according to the NIER-06 and NIER-09 test cycles simulating urban rush-hour driving patterns in South Korea.

Experimental setup

For this experiment, a diesel vehicle with common rail engine was selected. Table 1 presents the specifications of the vehicle. Figure 1 shows the experimental setup for measuring particle emission from the diesel vehicle. The experimental setup was composed of a chassis dynamometer (ROADSIM 48” MIM CAR, AVL Ltd., Graz, Austria), a constant volume sampler (CVS-ONE, Horiba Ltd., Kyoto, Japan), a solid particle counting system (SPCS, MEXA-2000, Horiba Ltd., Kyoto, Japan), an engine exhaust particle sizer (EEPS 3090, TSI Ltd., MN, USA), a Dekati low-pressure impactor (DLPI, Dekati Ltd., Kangasala, Finland), and a PM holder.

In the case of NBE measurement, the particle number concentration emitted from the diesel vehicle was diluted through CVS tunnel, and then it passed particle number diluters (PND1 and PND2) and heated tubes. Finally, SPCS measured the particle number concentration according to the Particulate Measurement Program of the UNECE-GRPE working group. In the same way, NBE was also measured using EEPS according to particle size.

In the case of MBE measurement, the particle emissions from the diesel vehicle were captured directly from the tailpipe by DLPI, or the PM holder installed at the rear end captured the particles which had passed the CVS tunnel. Two diffusion-dryers containing silica gels were connected in series and used to remove moisture emitted from the tailpipe. Each of 13 stages of DLPI was equipped with Teflon-coated filters (TX40HI20WW 25 mm, Pall Ltd., New York, USA). The cut-off sizes of the DLPI stages were 10, 6.8, 4.4, 2.5, 1.6, 1.0, 0.65, 0.4, 0.26, 0.17, 0.108, 0.06, and 0.03 μm. A larger-sized Teflon-coated filter (TX40HI20WW 47 mm, Pall Ltd., New York, USA) was installed to capture particles finally passing out of DLPI, i.e., particles smaller than 0.03 μm. In order to measure total mass concentration of particles that had passed through CVS tunnel, a PM holder was used. A 2.5-μm-cut cyclone separator was installed at the fore-end of the PM holder. The Teflon-coated filter (TX40HI20WW 47 mm, Pall Ltd., New York, USA) was also installed at the PM holder. The filters used in DLPI and PM holder were weighed using an ultra-micro balance (MSA2.7S-000-DF, Sartorius Ltd., Göettingen, Germany). The amount of captured PM was determined by the mass difference before and after each experiment.

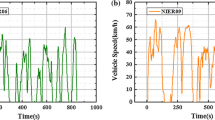

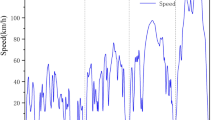

In this study, the number and mass concentrations were measured for the particle emissions from the diesel vehicle in NIER-06 and NIER-09 test cycles. In NIER-06 test cycle, the average velocity is 19.5 km/h, the maximum velocity is 60.1 km/h, the driving time is 846 s, the driving distance is 4.51 km, the ratio of acceleration phase to total driving time is 37.3%, that of deceleration phase is 37.1%, and that of idling phase is 25.6%. In NIER-09 test cycle, the average velocity is 34.1 km/h, the maximum velocity is 70.9 km/h, the driving time is 926 s, the driving distance is 8.74 km, the ratio of acceleration phase to total driving time is 43.4%, that of deceleration phase is 44.9%, and that of idling phase is 11.7%. In compliance with EU regulation test method, each experiment was conducted after parking the diesel vehicle for more than 6 h in a room which was maintained at the temperature of 20–30 °C with the humidity of 50%. NBE and MBE were measured for NIER-06 and NIER-09 test cycles respectively with or without installing a DPF.

Results

Figure 2 shows cases where DPF was removed. The figure shows variation of vehicle speed over driving time of NIER-06 and NIER-09 test cycles respectively (line) and also presents temporal variation of number concentration of particles (symbol), which were emitted from the diesel vehicle running in NIER-06 and NIER-09 test cycles and measured by EEPS and SPCS. EEPS seemed to measure number concentration of particles better than SPCS. It may be because EEPS could detect particles of smaller sizes than SPCS could. During the acceleration/deceleration phases of NIER-06 and NIER-09 test cycles, both EEPS and SPCS could clearly identify the tendency of number concentration of particles emitted from the diesel vehicle, which increased or decreased in correspondence to the acceleration/deceleration phases. During the idling phase, both driving cycles emitted particles with the similar levels of number concentration.

Figure 3 compares total number of particles emitted per unit distance traveled between EEPS and SPCS measurement data for the diesel vehicle without a DPF, running in NIER-06 and NIER-09 test cycles. Since EEPS measured particle size distribution, for the EEPS measurement data, two histogram bars were used to display total number of particles smaller than 100 nm and those larger than 100 nm. It was found that the number of emitted particles smaller than 100 nm was higher than the number of emitted particles larger than 100 nm. In addition, EEPS showed a higher value of total number of particles per kilometer than SPCS. It is because EEPS can measure particles as small as 5.6 nm in diameter, while the measuring range of SPCS is 50% ± 12% in 23 nm and 90% in 41 nm. However, EEPS and SPCS showed the same tendency. It turned out that NIER-06 test cycle generated a higher level of total particle number per unit distance traveled than NIER-09 test cycle.

In Fig. 4, NBE was measured by EEPS during the acceleration phases of NIER-06 and NIER-09 test cycles, when DPF was removed. According to gear shift schedule shown in Blagojević et al. (2017) and Parmar et al. (2017), the gear shift change occurred when a vehicle’s speed-change exceeded roughly 15–20 km/h. Therefore, in the present study, the acceleration phases were categorized into two groups, i.e., one group with vehicle-speed-change of less than 20 km/h as listed in Table 2, and the other group with vehicle-speed-change of greater than 20 km/h as enumerated in Table 3. Not only acceleration but also velocities at the beginning and end of each acceleration phase are listed in these tables. Figure 4a plots the data in Table 2, and Fig. 4b displays the data in Table 3. In this study, it was assumed that the gear shift change did not occur in the acceleration phases shown in Fig. 4a, whereas it occurred more than once in the acceleration phases depicted in Fig. 4b. Generally, a large acceleration, in other words, sudden acceleration tended to cause more particles. This is because the increase of acceleration also increases engine load. The trends of NIER-06 and NIER-09 test cycles appeared to overlap, making it possible to obtain linear regression lines. From the comparison of linear regression lines, the acceleration phases with vehicle speed change of less than 20 km/h were found to generate more particles per unit distance traveled than those with vehicle speed change of larger than 20 km/h.

Figure 5 shows average number concentration distribution which was measured by EEPS for NIER-06 and NIER-09 test cycles during total driving time, while DPF was removed. The peak of the number concentration distribution of each test cycle appeared around 0.07 μm, and NIER-06 test cycle had a higher level of number concentration than NIER-09 test cycle, like in Fig. 3. Especially, NIER-06 test cycle generated more particles of > 0.04 μm than NIER-09 test cycle.

Figure 6 presents the mass concentration distribution which was converted from the number concentration distribution of Fig. 5. The particle mass was calculated by Eq. 1, which used effective density by assuming spherical particles.

Mass concentration distribution converted from the average number concentration distribution of Fig. 5 (without a DPF)

Here, dp is the mobility particle size measured by EEPS, ρe is the effective density determined by Eq. 2 (Maricq and Xu 2004).

Here, ρ0 is the density of primary particles, d0e is the size of primary particles, and d f is the fractal dimension. As for the values of Eq. 2, ρ0 = 2 g/cm3, d0e = 0.02 μm, and d f = 2.3 were used, as proposed by Maricq and Xu (2004). It turned out that the converted mass concentration distributions of NIER-06 and NIER-09 test cycles had their peaks around 0.1 μm. In general, NIER-06 test cycle generated more mass of particles than NIER-09 test cycle.

Figure 7 shows actual mass concentration distribution of particles sampled directly by the filter of each stage of DLPI from the tailpipe of the diesel vehicle. The geometric mean particle size of the graph was obtained from the cut-off sizes of neighboring impactor stages. The geometric mean particle size of 0.136 μm, which corresponds to 0.107-μm cut-off size of impactor stage, showed the peak, and this result matches almost the peak of the mass concentration distribution converted from the number concentration distribution which was measured by EEPS in Fig. 6. However, the actual mass concentration distribution shown in Fig. 7 appeared to be much broader than the converted mass concentration distribution displayed in Fig. 6. From the comparison between Figs. 6 and 7, many particles of > 0.2 μm, in reality, were emitted from the diesel vehicle, and this might be because diesel soot particles of primary size grew by agglomeration before being exhausted.

Table 4 presents PM fraction of particles emitted from the diesel vehicle running in NIER-06 and NIER-09 test cycles, i.e., the fractions PM1/PM10, PM1/PM2.5, and PM2.5/PM10, while the DPF was removed. The total mass of particles was larger for NIER-09 than that for NIER-06. However, NIER-06 test cycle showed higher mass of particles emitted per unit distance traveled than NIER-09 test cycle. In addition, NIER-06 test cycle generated relatively smaller particles compared to NIER-09.

Figure 8 shows the comparison of actual mass of particles emitted per unit distance traveled, measured by the PM holder installed at the rear end of CVS tunnel, while DPF was removed. Due to the 2.5-μm-cut cyclone that was installed before the PM holder, the diesel soot particles captured by the PM holder had the aerodynamic sizes of < 2.5 μm. These particles showed the same tendency of mass, as shown in Fig. 7. In other words, NIER-06 test cycle generated more particle mass per unit distance traveled than NIER-09 test cycle.

Figure 9 shows the measurements of total number of particles emitted from the diesel vehicle with DPF installed. EEPS and SPCS were used for measurement. The first two histogram bars display total number of particles smaller than 100 nm and those larger than 100 nm, measured by EEPS. These results show the same tendency as those of Fig. 3 where DPF was uninstalled. In comparison with the results of Fig. 3, in regard to the measurements of total particle number, the results of EEPS and SPCS showed the reduction by 1 order and about 3 orders, respectively. The reason for this is as follows. The installation of DOC-DPF system is known to increase non-volatile nanometer-sized particles of nucleation mode (Johnson et al. 2009; Young et al. 2012). The detection size limit of EEPS is lower than that of SPCS. Therefore, more non-volatile nanometer-sized particles could be measured by EEPS. Thus, when DPF was installed, more diesel particle emissions were measured by EEPS. Figure 10 shows actual mass of particles emitted per unit distance traveled, measured by the PM holder installed at the rear end of CVS tunnel, while DPF was installed. The results of Fig. 10 show the same tendency of those of Fig. 8 where DPF was removed. The particle mass emitted by the diesel vehicle was much reduced owing to the use of the DPF.

Table 5 compares NBE and MBE according to particle size range based on aerosol measuring instruments, depending on whether or not the DPF was installed. Since the EEPS can measure size distribution, PM0.1 and PM0.5, that is, particles smaller than 0.1 μm and those smaller than 0.5 μm, were obtained for each test cycle. By considering the NBE without DPF and the NBE with DPF, the collection efficiency of the DPF, from the EEPS measurement data, was estimated to be approximately 93–94% in NIER-06 test cycle and 95–96% in NIER-09 test cycle. Meanwhile, the SPCS can measure particles with the detection efficiency of 50% ± 12% in 23 nm and 90% in 41 nm, and thus it was assumed that most of the particles detected by the SPCS were larger than 40 nm and PM>0.04 denoting particles larger than 0.04 μm was compared. The collection efficiency of the DPF for particles larger than 0.04 μm was estimated to be more than 99.9% from the SPCS measurement data, but it should be noted that a lot of particles in the order of 1010 particles/km were emitted even when the DPF was installed. Similarly, the MBEs without or with DPF were compared. Since a 2.5-μm-cut cyclone was used before the PM holder, the particles collected on the filter placed in the PM holder were assumed to be smaller than 2.5 μm, that is, PM2.5. From the PM holder measurement data, the collection efficiency of the DPF was estimated to be about 95% in NIER-06 test cycle and 93% in NIER-09 test cycle. In case of the DLPI measurement data without DPF, the masses of particles collected on filters placed at some impactor stages were lower than the detection limit of the microbalance used in this study and thus was not available. From the data obtained by the EEPS or PM holder, the DPF used in this study was estimated to have collection efficiency of about 93–96% for particles smaller than 2.5 μm. However, when the SPCS measurement data was considered, the DPF was evaluated to have collection efficiency of more than 99.9% for particles larger than 0.04 μm. As a result, the collection efficiency of the DPF used in this study was assumed to be very low for particles smaller than about 0.04 μm, including primary diesel particles and semi-volatiles. This implies that the DPF needs to be improved to collect even the particles smaller than about 0.04 μm.

Conclusions

This study examined the characteristics of fine particle emissions from a light-duty diesel vehicle in NIER-06 and NIER-09 test cycles, which are certification test cycles in South Korea. NIER-06 and NIER-09 test cycles are composed mainly of acceleration, deceleration, and idling phases without a cruise driving phase. Therefore, these test cycles can simulate urban rush-hour driving patterns in South Korea. NBE was measured by EEPS and SPCS, while MBE was measured by DLPI and PM holder. Especially, DLPI measured actual mass concentration of particles emitted from the tailpipe of a diesel vehicle.

By considering gear shift change, the acceleration phases of NIER-06 and NIER-09 test cycles were categorized into two groups, i.e., one group with vehicle speed change of less than 20 km/h and the other group with vehicle speed change of more than 20 km/h. Without regard to test cycle, more particles were emitted, by approximately 60%, per unit distance traveled when the diesel vehicle was accelerated with the speed change of less than 20 km/h, i.e., where it was assumed that gear shift change did not occur during acceleration. For both groups of acceleration phases with and without gear shift change, particle emission per unit distance traveled generally increased with increasing vehicle acceleration. Since the average acceleration of NIER-06 test cycle was 0.49 m/s2 and that of NIER-09 was 0.41 m/s2, NIER-06 test cycle had 17–31% higher values of NBE and MBE per unit distance traveled than NIER-09 test cycle, and both test cycles showed the same tendency with or without DPF. In addition, as for the actual emission of PM1, PM2.5, and PM10, NIER-06 test cycle generated a higher portion of PM1, which indicated that during low-velocity driving or heavy road traffic, ultrafine particles are more likely to be generated. Accordingly, the driving pattern needs to avoid sudden and drastic acceleration as much as possible, and the driving habit needs to be formed such that NBE and MBE from light-duty diesel vehicles are minimized. In other words, achieving a high average velocity of traffic flow or minimizing sudden acceleration for smooth urban traffic will be of great help in reducing particle emissions from light-duty diesel vehicles. In addition, the DPF needs to be developed to more efficiently collect nanoparticles, e.g., smaller than 0.04 μm.

References

Bergmann M, Kirchner U, Vogt R, Benter T (2009) On-road and laboratory investigation of low-level PM emissions of a modern diesel particulate filter equipped diesel passenger car. Atmos Environ 43:1908–1916

Biswas S, Hu S, Verma V, Herner JD, Robertson WH, Ayala A, Sioutas C (2008) Physical properties of particulate matter (PM) from late model heavy-duty diesel vehicles operating with advanced PM and NOx emission control technologies. Atmos Environ 42:5622–5634

Blagojević IA, Vorotović GS, Stamenković DD, Petrović NB, Rakićević BB (2017) The effects of gear shift indicator usage on fuel efficiency of a motor vehicle. Therm Sci 21:707–713

Block ML, Wu X, Pei Z, Li G, Wang T, Qin L, Wilson B, Yang J, Hong JS, Veronesi B (2004) Nanometer size diesel exhaust particles are selectively toxic to dopaminergic neurons: the role of microglia, phagocytosis, and NADPH oxidase. FASEB J 18:1618–1620

Brito JM, Belotti L, Toledo AC, Antonangelo L, Silva FS, Alvim DS, Andre PA, Saldiva PH, Rivero DH (2010) Acute cardiovascular and inflammatory toxicity induced by inhalation of diesel and biodiesel exhaust particles. Toxicol Sci 116:67–78

Chio CP, Liao CM, Tsai YI, Cheng MT, Chou WC (2014) Health risk assessment for residents exposed to atmospheric diesel exhaust particles in southern region of Taiwan. Atmos Environ 85:64–72

Ema M, Naya M, Horimoto M, Kato H (2013) Developmental toxicity of diesel exhaust: a review of studies in experimental animals. Reprod Toxicol 42:1–17

Faiz A, Weaver CS, Walsh MP (1996) Air pollution from motor vehicles: standards and technologies for controlling emissions. World Bank Publications, Washington

Fujitani Y, Hasegawa S, Fushimi A, Kondo Y, Tanabe K, Kobayashi S, Kobayashi T (2006) Collection characteristics of low-pressure impactors with various impaction substrate materials. Atmos Environ 40:3221–3229

Giechaskiel B, Munoz-Bueno R, Rubino L, Manfredi U, Dilara P, De Santi G, Andersson J (2007) Particle measurement programme (PMP): particle size and number emissions before, during and after regeneration events of a Euro 4 DPF equipped light-duty diesel vehicle. SAE Technical Paper 2007–01–1944

Ichinose T, Furuyama A, Sagai M (1995) Biological effects of diesel exhaust particles (DEP). II. Acute toxicity of DEP introduced into lung by intratracheal instillation. Toxicology 99:153–167

Jang J, Lee J, Kim J, Park S (2015) Comparisons of the nanoparticle emission characteristics between GDI and PFI vehicles. J Nanopart Res 17:1–14

Johnson KC, Durbin TD, Jung H, Chaudhary A, Cocker DR III, Herner JD, Robertson WH, Huai T, Ayala A, Kittelson D (2009) Evaluation of the European PMP methodologies during on-road and chassis dynamometer testing for DPF equipped heavy-duty diesel vehicles. Aerosol Sci Technol 43:962–969

Kamimoto T, Shimono M, Takahashi A, Minagawa T (2007) Evaluation of transient performance of diesel particulate filters via light extinction and scattering. SAE Technical Paper, Capri

Karavalakis G, Stournas S, Bakeas E (2009) Effects of diesel/biodiesel blends on regulated and unregulated pollutants from a passenger vehicle operated over the European and the Athens driving cycles. Atmos Environ 43:1745–1752

Lu T, Cheung CS, Huang Z (2013) Influence of waste cooking oil biodiesel on the particulate emissions and particle volatility of a DI diesel engine. Aerosol Air Qual Res 13:243–254

Maricq MM, Xu N (2004) The effective density and fractal dimension of soot particles from premixed flames and motor vehicle exhaust. J Aerosol Sci 35:1251–1274

May AA, Nguyen NT, Presto AA, Gordon TD, Lipsky EM, Karve M, Alváro G, Robertson WH, Zhang M, Brandow C, Chang O, Chen S, Cicero-Fernandez P, Dinkins L, Fuentes M, Huang SM, Ling R, Long J, Maddox C, Massetti J, McCauley E, Miguel A, Na K, Ong R, Pang Y, Rieger P, Sax T, Truong T, Vo T, Chattopadhyay S, Maldonado H, Maricq MM, Robinson AL (2014) Gas-and particle-phase primary emissions from in-use, on-road gasoline and diesel vehicles. Atmos Environ 88:247–260

Myung CL, Ko A, Lim Y, Kim S, Lee J, Choi K, Park S (2014) Mobile source air toxic emissions from direct injection spark ignition gasoline and LPG passenger car under various in-use vehicle driving modes in Korea. Fuel Process Technol 119:19–31

Nemmar A, Hoet PH, Dinsdale D, Vermylen J, Hoylaerts MF, Nemery B (2003) Diesel exhaust particles in lung acutely enhance experimental peripheral thrombosis. Circulation 107:1202–1208

NIER 2015) National air pollutants emission. National Institute of Environmental Research, Incheon, Republic of Korea. Available at: http://airemiss.nier.go.kr/mbshome/mbs/airemiss/index.do

Oanh NTK, Thiansathit W, Bond TC, Subramanian R, Winijkul E, Paw-armart I (2010) Compositional characterization of PM 2.5 emitted from in-use diesel vehicles. Atmos Environ 44:15–22

Oravisjärvi K, Pietikäinen M, Ruuskanen J, Niemi S, Laurén M, Voutilainen A, Keiski RL, Rautio A (2014) Diesel particle composition after exhaust after-treatment of an off-road diesel engine and modeling of deposition into the human lung. J Aerosol Sci 69:32–47

Park K, Cao F, Kittelson DB, McMurry PH (2003) Relationship between particle mass and mobility for diesel exhaust particles. Environ Sci Technol 37:577–583

Parmar C, Tiwari S, Chauhan A, Srivastava S, Gangopadhyay S (2017) Tackle low frequency structural vibration in AMT car using gear shift schedule optimization. SAE Technical Paper 2017–26–0198

Quiros DC, Yoon S, Dwyer HA, Collins JF, Zhu Y, Huai T (2014) Measuring particulate matter emissions during parked active diesel particulate filter regeneration of heavy-duty diesel trucks. J Aerosol Sci 73:48–62

Ristovski ZD, Miljevic B, Surawski NC, Morawska L, Fong KM, Goh F, Yang IA (2012) Respiratory health effects of diesel particulate matter. Respirology 17:201–212

Ross Z, Kheirbek I, Clougherty JE, Ito K, Matte T, Markowitz S, Eisl H (2011) Noise, air pollutants and traffic: continuous measurement and correlation at a high-traffic location in New York City. Environ Res 111:1054–1063

Sagai M, Saito H, Ichinose T, Kodama M, Mori Y (1993) Biological effects of diesel exhaust particles. I. In vitro production of superoxide and in vivo toxicity in mouse. Free Radic Bio Med 14:37–47

Salvat O, Marez P, Belot G (2000) Passenger car serial application of a particulate filter system on a common rail direct injection diesel engine. SAE Technical Paper Series, Detroit

Sharma M, Agarwal AK, Bharathi KVL (2005) Characterization of exhaust particulates from diesel engine. Atmos Environ 39:3023–3028

Singh P, DeMarini DM, Dick CA, Tabor DG, Ryan JV, Linak WP, Kobayashi T, Gilmour MI (2004) Sample characterization of automobile and forklift diesel exhaust particles and comparative pulmonary toxicity in mice. Environ Health Persp 112:820–825

Steerenberg PA, Zonnenberg JA, Dormans JA, Joon PN, Wouters IM, van Bree L, Scheepers PT, van Loveren H (1998) Diesel exhaust particles induced release of interleukin 6 and 8 by (primed) human bronchial epithelial cells (BEAS 2B) in vitro. Exp Lung Res 24:85–100

Sydbom A, Blomberg A, Parnia S, Stenfors N, Sandström T, Dahlen SE (2001) Health effects of diesel exhaust emissions. Eur Respir J 17:733–746

Tente H, Gomes P, Ferreira F, Amorim JH, Cascão P, Miranda AI, Nogueira L, Sousa S (2011) Evaluating the efficiency of diesel particulate filters in high-duty vehicles: field operational testing in Portugal. Atmos Environ 45:2623–2629

US EPA (2001) Control of air pollution from new motor vehicles: heavy-duty engine and vehicle standards and highway diesel fuel sulfur control requirements. Final Rule. Fed Regist 66:5002–5173

Ushakov S, Valland H, Nielsen JB, Hennie E (2013) Particle size distributions from heavy-duty diesel engine operated on low-sulfur marine fuel. Fuel Process Technol 106:350–358

van Gulijk C, Schouten JM, Marijnissen JCM, Makkee M, Moulijn JA (2001) Restriction for the ELPI in diesel particulate measurements. J Aerosol Sci 32:1117–1130

Young LH, Liou YJ, Cheng MT, Lu JH, Yang HH, Tsai YI, Wang LC, Chen CB, Lai JS (2012) Effects of biodiesel, engine load and diesel particulate filter on nonvolatile particle number size distributions in heavy-duty diesel engine exhaust. J Hazard Mater 199:282–289

Funding

This research was funded by the National Institute of Environmental Research (NIER) of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kim, WG., Kim, CK., Lee, JT. et al. Characteristics of nanoparticle emission from a light-duty diesel vehicle during test cycles simulating urban rush-hour driving patterns. J Nanopart Res 20, 94 (2018). https://doi.org/10.1007/s11051-018-4197-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-018-4197-3