Abstract

The effect of the molecular layering at liquid–solid interface on the thermal conductivity of the nanofluid is investigated by an equilibrium molecular dynamics simulation. By tracking the position of the nanoparticle and the liquid atoms around the spherical nanoparticle, it was found that a thin layer of liquid is formed at the interface between the nanoparticle and liquid; this thin layer will move with the Brownian motion of the nanoparticle. Through the analysis of the density distribution of the liquid near the nanoparticle, it is found that more argon atoms are attracted to form the layer around the nanoparticle when the diameter of the nanoparticle is larger, and therefore lead to the more significant enhancement of the thermal conductivity of the nanofluid.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanofluid connotes a colloidal suspension with dispersed nanometer-sized metallic or non-metallic particles or nanotubes. Compared to ordinary fluids containing micro-sized particles, nanofluids are more stable, and do not clog micro and nano channels during flow. It has long been recognized that the thermophysical properties of nanofluid are enhanced to a very large degree, compared to the base fluid in which nanoparticle suspensions are made. They are expected to be one of the most promising heat transfer media in the future. Xie et al. (2002) observed an enhancement of thermal conductivity up to 38% in the study for pump oil-based suspensions containing alumina particles with specific surface areas of 25 m2/g and at a volume fraction of 0.05. Das et al. (2003) reported a 2–4-fold increase in thermal conductivity for water-based nanofluids containing Al2O3 or CuO nanoparticles over a small temperature range. Assael et al. (2004) investigated the enhancement of the thermal conductivity of water in the presence of carbon-multiwall nanotubes. The thermal conductivity was measured with a transient hot-wire instrument built for this purpose, and operated with a standard uncertainty better than 2%. The maximum thermal conductivity enhancement obtained was 38%. However, scientists have been perplexed by this thermal phenomenon, and because it cannot be explained by existing theories, numerous research studies have been done to investigate the mechanisms of the heat flow in nanofluid. Das et al. (2006) thoroughly reviewed the heat transfer mechanism and the applications of nanofluids. Keblinksi et al. (2002) proposed four possible factors influencing the heat transport capability of nanofluids: transport of thermal energy by Brownian motion of nanoparticles, formation of liquid layers around the particles, the nature of heat transport in nanoparticle, and the effects of nanoparticles clustering.

Koo and Kleinstreuer (2004) suggested that nanoparticles move randomly and thereby carry relatively large volumes of surrounding liquid with them. This microscale interaction may occur between hot and cold regions, resulting in a lower local temperature gradient for a given heat flux compared with the pure liquid case. Thus, as a result of Brownian motion, the effective thermal conductivity, which is composed of the particles’ conventional static part and the Brownian motion part, increases to result in a lower temperature gradient for a given heat flux. Through an order-of-magnitude analysis of various possible mechanisms, Prasher et al. (2005, 2006) showed that the enhancement in the effective thermal conductivity of nanofluids is due mainly to the localized convection caused by the Brownian motion of the nanoparticles. They also introduced a convective conductive model which accurately captures the effects of particle size, choice of the base liquid, interfacial thermal resistance between the particles and liquid, and temperature. Jang and Choi (2006) have devised a theoretical model that accounts for the fundamental role of dynamic nanoparticles in nanofluids and have found that the Brownian motion of nanoparticles at the molecular and nanoscale level is a key mechanism governing the thermal behavior of nanofluids. On the contrary to the above researches that are favorable to the role of Brownian motion, Evans et al. (2006) reported a kinetic theory-based analysis of heat flow in fluid suspensions of solid nanoparticles. They demonstrated that the hydrodynamics effects associated with Brownian motion have only a minor effect on the thermal conductivity of the nanofluid. It seems that whether the Brownian motion is the main factor affecting the thermal property of the nanofluid still need more research work.

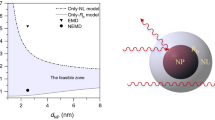

Some researchers believed that liquid molecules can form layers around the nanoparticles because of the strong force from the nanoparticle, and the atomic structure of liquid layer is more orderly than that of the bulk liquid. Since phonon transfers in crystalline solid is very effective, such ordered layer in the liquid would have higher thermal conductivity and therefore contribute to the enhancement of the thermal conductivity of the nanofluids. Yu and Choi (2003) developed a renovated Maxwell model for effective conductivity of nanofluids. They determined that the presence of a very thin nanolayer, even though only a few nanometers thick, can measurably increase effective volume fraction and subsequently the thermal conductivity of nanofluids, particularly when nanoparticle diameter is less than 10 nm. Leong et al. (2006) proposed a model for predicting the effective thermal conductivity of nanofluids. They believed that the interfacial layer at the solid (nanoparticle)–liquid interface and nanoparticle size are the major mechanisms for enhancing the thermal conductivity of nanofluids—the thickness of the layer of 1 nm was used in their article. Xie et al. (2005) investigated the impact of this interfacial nanolayer on the effective thermal conductivity of nanofluid. Effects of nanolayer thickness, nanoparticle size, volume fraction, and thermal conductivity ratio of nanoparticle to fluid were discussed.

The shortcoming with the above models is that the liquid-layering thickness cannot be determined by these models and must be obtained by fitting the experimental data. The liquid layer thicknesses required to match with the experimental data are about 2–3 nm, which is significantly larger than the liquid thickness suggested by experiments (Yu et al. 2000) and molecular dynamics (MD) simulation (Xue et al. 2004) (three to five times of the liquid molecular diameters). There are large discrepancies on the thickness of the liquid layer on the surface of the nanoparticles. Xue et al. (2004) performed a non-equilibrium MD simulation to study how the ordering of the liquid at the liquid–solid interface affects the interfacial thermal resistance. They suggested that the experimentally observed large enhancement of thermal conductivity in suspensions of solid nanosized nanoparticles could not be explained by altered thermal transport properties of the layered liquid. The role of liquid layering at the nanoparticle surface on the heat transfer enhancement is still being debated and, hence, needs further intensive studies.

Since theMD simulation allows the direct simulation of the motion and interaction of particles (atoms or molecules), it has increasingly been used to study various thermal transport problems in the recent years (Poulikakos et al. 2003). In this article, effect of the ordered liquid layer between the liquid and nanoparticle on enhancement of the thermal conductivity will be investigated using MD simulation. The movement of the nanoparticle and the liquid atoms around the spherical nanoparticle will be tracked to investigate the existence of the layer and then estimate the thickness of the liquid layer through the analysis of the density distribution of the liquid atoms near the nanoparticle. The relationship between the layer and the enhancement of the thermal conductivity of the nanofluid will also be discussed.

Methodology

The simulation in this study is done with the nanofluid system with solid copper nanoparticles dispersed into the liquid argon. The reason that argon and copper are selected is that the interatomic potentials of both substances can be described by the widely accepted Lennard-Jones (LJ) 12-6 potential,

where ε and σ are the energy values of interaction and equilibrium distance, respectively, and both of them depend on the type of the molecules. The intermolecular distance between atoms i and j is represented by r ij . For argon, the LJ parameters are ε = 1.67 × 10−21 J and σ = 0.3405 nm, respectively. For copper, the LJ parameters are ε = 65.625 × 10−21 J and σ = 0.23377 nm, respectively. For parameters between argon and copper atoms, the following Berthlot mixing rule (Sarkar and Selvam 2007; Allen and Tildesley 1987) was used:

Therefore, ε and σ between copper and argon are 10.4153 × 10−21 J and 0.2872 nm, respectively. The temperature is 86 K and density of argon is 1,401 kg/m3. The density of copper is 8,960 kg/m3. The difference between the densities of the two is taken into account during MD simulation.

The equilibrium MD relates the equilibrium heat current autocorrelation function to the thermal conductivity, k, through the Green Kubo method (Rapaport 2001)

where k B is the Boltzmann constant, T is the temperature, V is the volume, J q is the instantaneous microscopic heat current vector, and the angular brackets denote the ensemble average, or, in the case of a MD simulation, the average over time.

The heat current vector was calculated as

where E i denotes the excess energy and r i is the position vector of the atom i. For a two-component system, the heat current can be expressed as the constitution of the kinetic part, the potential part, and the collision part. Then, an extended form of Eq. 4 is used to calculate the heat current vector (Vogelsang et al. 1987; Xue et al. 2004):

where α and β denote copper and argon, and i, j are the number of particles. N α and N β are the number of particles of kinds α and β. \( {\mathbf{v}}_{i}^{k} \) is the velocity of a particle i of kind α, h α stands for the mean partial enthalpy which is calculated as the sum of the average kinetic energy, potential energy, and average virial terms per particle of each species (Sarkar and Selvam 2007). I is the unit tensor.

During the calculation the heat current at each MD, time step Δt is computed and saved. Since the simulation is performed for discrete time steps, Eq. 3 is in fact a summation. Including the time averaging, what we actually compute is

where N is the number of MD time steps after equilibration, M is the number of steps over which the time average is calculated, and J(m + n) is the heat current at MD time step m + n. In order to ensure good statistical averaging, M should be considerably smaller than the number of MD steps.

Results and discussions

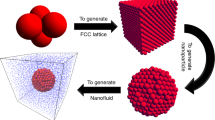

A MD simulation code is developed based on the Verlet algorithm (Allen and Tildesley 1987). In order to validate our computer code, the thermal conductivity of pure argon is calculated first using the Green Kubo method (Rapaport 2001). Sarkar and Selvam (2007) studied the influence of the number of atoms on the simulation result. They suggested that the results are in good agreement with the experimental value for pure argon when the number of atom is larger than 500, and for nanofluid when the number of atoms is larger than 1,372. The aim of this article is to study the formation of the interfacial layer at the surface of the nanoparticle and its effect on the thermal conductivity of the nanofluid. In order to get a more proper calculation, a large domain is used. The number of argon atoms used in the simulation is 4,000. The initial positions of all the atoms are arranged in a regular fcc lattice. The time step used in the simulation is 4 fs. The calculated thermal conductivity of the pure liquid argon is 0.126 W/m-K, which is in good agreement with the value of 0.127 W/m-K reported in Sarkar and Selvam (2007).

Then, the thermal conductivity properties of nanofluid with volume fractions of 1.0, 1.5, and 2.0% are studied. The computational domain is in cubic shape with length of each side being equal to 5.72 nm. A single nanoparticle was considered in base fluid atoms, and the shape of the nanoparticle is spherical. The model nanofluid system, consisting of solid copper nanoparticle in argon base fluid, is developed by replacing the same fraction of argon atoms with copper atoms. Since the density of copper is different from that of the argon, the number of argon atoms and copper atoms are different even with the same volume. For the abovesaid three different volume fractions of nanofluids, 55, 79, and 87 of the argon atoms are replaced by 79, 141, and 201 copper atoms, respectively. Therefore, the number of the total atoms within the computational domain is 4,024, 4,062, and 4,114, which correspond to one nanoparticle with a diameter of 1.528, 1.750, and 1.926 nm, respectively.

Molecular dynamics simulations were performed in the NEV ensemble with periodic boundary conditions. A typical MD simulation requires 500,000 MD steps. The initial 100,000 steps were ignored in the calculation of thermal conductivity to allow the system to reach the equilibrium. After 100,000 time steps, the results are used to calculate the thermal conductivity. Through the simulation, it was found that the typical normalized heat autocorrelation functions of the different nanofluids decay to zero in 3–4 ps. Therefore, the statistical averaging M in Eq. 6 is given as 15,000, which is sufficient to obtain good results. Through the calculation, the thermal conductivity of the three different volume fraction nanofluids are 0.144, 0.150, and 0.152 W/m-K, respectively. Compared to the thermal conductivity of pure argon (0.126 W/m K), these values of thermal conductivity for nanofluid represent increases of 14, 19, and 21, respectively.

During the simulation, it was found that due to the Brownian motion the nanoparticle moves and rotates, but the motion is not very significant. Since the attractive force between the copper atoms is much stronger than that between the argon atoms and between the argon atoms and copper atoms, the copper atoms in the solid nanoparticle will attract each other, and the nanoparticle retains the spherical shape when it moves randomly. Figure 1 shows the position of the atoms in the nanofluid with a volume fraction of 1.5% at the different times, where 1 is the position of nanoparticle atoms at t 1 = 400 ps, and 2 denotes the position of the nanoparticle atoms at t 2 = 1,500 ps. In order to reveal the movement of the nanoparticle more clearly, only the movements of nanoparticle atoms are shown while the positions of liquid atoms are at time t 1. It can be seen that the nanoparticle atoms move due to Brownian motion. During the motion, all the nanoparticle atoms move together, and the shape of the particle still remains spherical.

Through the analysis on the movement of the atoms, it was observed that some argon atoms near the nanoparticle stick to the surface and move with the Brownian motion of the nanoparticle. In order to analyze the relative movement of the liquid atoms and nanoparticle atoms, the tracks of the liquid argon atoms are recorded. When the equilibrium state is reached, the positions of the nanoparticle atoms and the liquid atoms within a given distance from the nanoparticle surface are recorded at one time. Then, only the movements of these selected atoms are tracked. For the nanofluid with volume fraction of 1.0%, when the tracking distance from the nanoparticle surface is three times of the argon atom diameter and the positions of the selected atoms are recorded at time of 100,000th time step, it was found that all the selected argon atoms always remain in the tracking area during the next 100,000 time steps. Even though the nanoparticle will move randomly, these selected argon atoms will also move with the nanoparticle. If the tracking distance is increased to 3.5 times of the argon atom diameter, then about 70% of the selected argon atoms remain in the tracking area during the next 100,000 time steps. If the tracking distance is increased to four times of the argon atom diameter, then about 60% of the selected atoms remain in the tracking area. Figures 2, 3, and 4, respectively, show the positions of the nanoparticle atoms and the selected liquid atoms within 3.0, 3.5, and 4.0 times of the argon atom diameter from the nanoparticle surface at three different times: t 1 = 1,100 ps, t 2 = 1,200 ps, and t 3 = 1,300 ps, respectively.

Through the observation of the position changes of the selected atoms in Figs. 2, 3, and 4, it can be seen that most liquid atoms near the nanoparticle surface always move with the nanoparticle, even though some atoms may move away from the nanoparticle surface. Because the interactive force between copper atoms is much stronger than that between the argon atoms, the atoms of the copper nanoparticle stick together during their movements. Some argon atoms are attracted to and stick to the nanoparticle surface and move with the nanoparticle because the interactive force between the copper and argon atoms is also stronger than that between the argon atoms. These parts of liquid atoms seem to form a thin layer at the interface of copper nanoparticle and liquid argon.

Same simulations are carried out for the nanofluid with the volume fraction of 1.5 and 2.0%, and the same phenomena are observed. For example, Figs. 5 and 6 show the positions of the nanoparticle atoms and the selected liquid atoms within 4.0 times of the argon atom diameter from the nanoparticle surface for the nanofluid with the volume fractions of 1.5 and 2.0%, respectively. Comparison of the Fig. 4 with Figs. 5 and 6 indicates that more argon atoms in Fig. 4 moved away from the nanoparticle. On the contrary, most argon atoms in Fig. 6 stick to the nanoparticle all the time. These phenomena show that the number of argon atoms that are attracted to the nanoparticle surface is related to the size of the nanoparticle. When the size of the nanoparticle is larger, the number of copper atoms is more and, then, the interactive force on the argon atoms from the copper atoms is also larger. Consequently, more argon atoms are attracted to the particle surface to form the liquid layer. The atomic structure of liquid layer near the nanoparticle is significantly more orderly than that of the bulk liquid. Such liquid layering near the interface would have higher thermal conductivity and could contribute to higher thermal conductivity of the nanofluids. This is also the reason why for the three sizes of nanoparticles, the enhancement of the thermal conductivity of the nanofluid with a larger nanoparticle is more significant than that with a small sized nanoparticle.

More detailed research on the existence of the liquid layer near the surface of the nanoparticle is performed by examining the density distribution of the argon from the center of the nanoparticle. The number of atoms per unit volume—defined as number density—is

where ΔN is number of atoms within the volume ΔV. The computational domain is divided into many spherical shells, and the numbers of atoms within each spherical shell are accounted to obtain the number density.

Through the analysis of the density of argon atoms around the copper nanoparticle, it was found that the density of argon atoms is not uniform in the computational domain. The density of argons is high near the nanoparticle surface and will decrease as the distance from the nanoparticle surface increases. Figures 7, 8, and 9 show the distribution of the density of the argon for nanofluid with three different fractions at different times after the equilibrium state is reached. The independent variable, X, is that distance from the surface of the nanoparticle (the zero point is the surface of the nanoparticle). The dependent variable n/n 0 is the relative number density of argon over the density of pure argon n 0. The three times represented by 1, 2, and 3 correspond to 1,300, 1,400, and 1,500 ps, respectively. It can be seen that when nanoparticle moves, the density of argon fluctuates slightly but the density near the nanoparticle is always higher than that at locations far away from the nanoparticle surface. This means that the nanoparticle atoms move due to Brownian motion, and a layer of argon atoms does stick to the nanoparticle and moves with the nanoparticle.

Keblinksi et al. (2002) had carried out the direct estimation of the effect of Brownian motion on thermal conductivity. They simulated the two slightly different cases of the same system. In the first simulation, all the atoms were allowed to move according to Newton’s second law, whereas in the second simulation, the center of mass of the solid particle was constrained to a fixed position. Their study results showed that the thermal conductivity is not affected by Brownian motion. Applying kinetic theory, Prasher et al. (2005) calculated the enhancement in the thermal conductivity due to the Brownian motion of the particles. They suggested that the thermal conductivity due to Brownian motion can be expressed as

where C N is the heat capacity per unit volume of the nanoparticles, l is the mean free path due to the collision of the nanoparticles with each other and with the liquid molecules, and ν N is the root-mean-square velocity of a Brownian particle, and it can be defined as \( \nu_{N} = \sqrt {3k_{\text{B}} T/m_{N} } , \) where k B is the Boltzmann constant and m N is the particle mass. The enhancements of the thermal conductivity due to the Brownian motion of the particle for the three different volume fractions studied in this article are 0.026, 0.035, and 0.046%, respectively. Consequently, the contribution of the Brownian motion of the particle to the nanofluid thermal conductivity enhancement can be negligible.

The atoms will collide with each other when they move according to Newton’s equations. During the period of the collision, the atoms will exchange the energy between each other. When the density of the substance is larger, the atoms will be more crowded, and then, they will collide more frequently and transfer more energy. Consequently, the thermal conductivity of the substance with higher density will be larger. This is the reason why normally the thermal conductivity of the solid is larger than that of the liquid. There are some theoretical studies (Eapen et al. 2002; Tretiakov and Scandolo 2004) which examined the thermal conductivity of the liquid argon and solid argon with different densities, and the results of those studies showed that the thermal conductivity is larger when the density is larger. From the analysis above, it can be concluded that the liquid layer near the interface would increase the thermal conductivity of the nanofluid. Such solid-like liquid layer has larger density and would have higher thermal conductivity and, therefore, contribute to higher thermal conductivity of the nanofluids.

The thickness of this aligned solid-like layer of liquid molecules at the interface is in the order of nanometer (Xie et al. 2005). By analyzing the change of the density of the argon along the radius of the nanoparticle, we can conclude that the thickness of the layer is about 0.5 nm. The ordered liquid layer is a little thicker bigger with a larger nanoparticle under the three sizes considered in this article. The thickness of the layer that we obtained is consistent with the data used in Jang and Choi (2006) and Leong et al. (2006). It was known that the thermal conductivity of the solid is larger than that of liquid. The density of the layer is between that of solid and liquid, and then a thicker layer means larger area behaves more like the solid, and therefore the enhancement of the thermal conductivity is significantly more; this means the thermal conductivity of the layer is larger than that of the pure liquid. Consequently, the effective thermal conductivity of the nanofluid is enhanced, and the enhancement is more significant with a thicker layer.

Yu and Choi (2003) proposed a renovated Maxwell model that takes into account the influence of the nanolayer and the particle size. The thermal conductivity of the nanofluid is obtained using:

where k l is the thermal conductivity of the base fluid, ϕ is the volume fraction, β = h/r is the ratio of the nanolayer thickness to the original particle radius, and k pe is the equivalent thermal conductivity of the equivalent particles, which can be calculated using

where k p is the thermal conductivity of the particle,and γ = k layer/k p is the ratio of nanolayer thermal conductivity to particle thermal conductivity.

Considering the thermal conductivity of the solid argon and that of the copper, we assume that γ equals 0.01. With the help of Eqs. 9 and 10, we can calculate the thermal conductivity of the nanofluids with three different volume fractions as 0.143, 0.148, and 0.153 W/m-K, respectively, which is consistent with the results from MD simulation.

Conclusions

By tracking the movement of the solid nanoparticle and the liquid atoms, it was found that a solid-like thin liquid layer is formed at the interface between the nanoparticle and liquid and that this layer moves with the Brownian motion of the nanoparticle. The number of the atoms in the liquid layer is related to the nanoparticle diameter. More argon atoms will be attracted to form the liquid layer around a larger nanoparticle. This layer contributes to the significant enhancement of the nanofluid thermal conductivity. Through the analysis of the density distribution of the liquid near the nanoparticle, it can be estimated that the thickness of the layering is about 0.5 nm under the parameters used in this article. The thermal conductivity of the layer is larger than that of the liquid, and therefore the thermal conductivity of the nanofluid with a larger nanoparticle will be enhanced more significantly.

Abbreviations

- E :

-

Excess energy

- h :

-

Mean partial enthalpy

- I :

-

Unit vector

- Jq(0):

-

Heat current vector at time zero

- Jq(t):

-

Heat current vector at time t

- k :

-

Thermal conductivity of nanofluids

- k B :

-

Boltzmann constant

- m :

-

Mass or number of time steps

- M :

-

Total number of MD time steps for averaging

- n :

-

Number of time steps or number density

- N :

-

Number of atoms or total number of MD simulation time steps

- r :

-

Position vector

- r ij :

-

Distance between atoms i and j

- t :

-

Time

- T :

-

Temperature

- v :

-

Velocity

- V :

-

Volume

- Δt :

-

Time step

- ϕ:

-

Volume fraction of nanoparticles

- Φ:

-

Lennard Jones potential

- σ:

-

Lennard Jones distance parameter

- ε:

-

Lennard Jones cohesive energy parameter

- ρ:

-

Density

- s:

-

Solid

- l:

-

Liquid

- α, β:

-

Copper or argon

References

Allen MP, Tildesley DJ (1987) Computer simulations of liquids. Clarendon, Oxford

Assael MJ, Chen C-F, Metaxa I, Wakeham WA (2004) Thermal conductivity of suspensions of carbon nanotubes in water. Int J Thermophys 25:971–985

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. ASME J Heat Transf 125:567–574

Das SK, Choi SUS, Patel HE (2006) Heat transfer in nanofluids—a review. Heat Transf Eng 27:3–9

Eapen J, Li J, Yip S (2002) Mechanism of thermal transport in dilute nanocolloids. Phys Rev Lett 98:028302

Evans W, Fish J, Keblinski P (2006) Role of Brownian motion hydrodynamics on nanofluid thermal conductivity. Appl Phys Lett 88:093116

Jang SP, Choi SUS (2006) Role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl Phys Lett 84:4316–4318

Keblinksi P, Phillpot SR, Choi SUS, Eastman JA (2002) Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf 45:855–863

Koo J, Kleinstreuer C (2004) A new thermal conductivity model for nanofluids. J Nanopart Res 6:577–588

Leong KC, Yang C, Murshed SMS (2006) A model for the thermal conductivity of nanofluids—the effect of interfacial layer. J Nanopart Res 8:245–254

Poulikakos D, Arcidiacono S, Maruyama S (2003) Molecular dynamics simulations in nanoscale heat transfer: a review. Microscale Thermophys Eng 7:181–206

Prasher R, Bhattacharya P, Phelan PE (2005) Thermal conductivity of nanoscale colloidal solutions (nanofluids). Phys Rev Lett 94:025901

Prasher R, Bhattacharya P, Phelan PE (2006) Brownian-motion-based convective-conductive model for the effective thermal conductivity of nanofluids. J Heat Transf 128:588–595

Rapaport DC (2001) The art of molecular dynamics simulation. Cambridge University Press, Cambridge

Sarkar S, Selvam RP (2007) Molecular dynamics simulation of effective thermal conductivity and study of enhanced thermal transport mechanism in nanofluids. J Appl Phys 102:074302

Tretiakov KV, Scandolo S (2004) Thermal conductivity of solid argon from molecular dynamics simulations. J Chem Phys 120:3765–3769

Vogelsang R, Hoheisel C, Ciccotti G (1987) Thermal conductivity of the Lennard-Jones liquid by molecular dynamics calculations. J Chem Phys 86:6371–6375

Xie H, Wang J, Xi T, Liu Y, Ai F, Wu Q (2002) Thermal conductivity enhancement of suspensions containing alumina particles. J Appl Phys 91:4568–4572

Xie H, Fujii M, Zhang X (2005) Effect of interfacial nanolayer on the effective thermal conductivity of nanoparticle-fluid mixture. Int J Heat Mass Transf 48:2926–2932

Xue L, Keblinski P, Phillpot SR, Choi SUS, Eastman JA (2004) Effect of liquid layering at the liquid-solid interface on thermal transport. Int J Heat Mass Transf 47:4277–4284

Yu W, Choi SUS (2003) The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanopart Res 5:167–171

Yu CJ, Richter AG, Datta A, Durbin MK, Dutta P (2000) Molecular layering in a liquid on a substrate: an X-ray reflective study. Physica B 283:27–31

Acknowledgments

This study was funded by the Office of Naval Research Grant No. N00014-06-1-1119. Ling Li and Mo Yang also acknowledge the supports received from the Key Discipline Construction Foundation of Shanghai Municipality under Grant No. J50501, the Key Project program of the National Natural Science Fund of China under Grant No. 50636050, and the Natural Science Fund of Shanghai under Grant No. 09ZR1422400.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was completed at University of Missouri during the first author’s visiting appointment.

Rights and permissions

About this article

Cite this article

Li, L., Zhang, Y., Ma, H. et al. Molecular dynamics simulation of effect of liquid layering around the nanoparticle on the enhanced thermal conductivity of nanofluids. J Nanopart Res 12, 811–821 (2010). https://doi.org/10.1007/s11051-009-9728-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-009-9728-5