Results of a study of the fine structure and phase composition in single-crystal refractory nickel alloy VZhM4-VI [001] tested for long-tern strength at a temperature of 1000°C and a stress of 300 MPa are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rotor blades of high-pressure turbines (HPT) of modern high-heat gas turbine engines (GTE) are produced from refractory nickel alloys (RNA) with special alloying by the method of single-crystal casting with 5° accuracy of the principal orientation.

The use of single-crystal refractory nickel alloys for HPT has made it possible to raise substantially their strength and thus to prolong the service life. Every new generation of RNA raises the temperature operating capacity of the alloys by 25°C [1], which results in growth of the temperature of the gas at the inlet to the turbine, decrease in consumption of fuel, and increase in their efficiency [2].

In this connection, it is expedient to use carbonless single-crystal alloys with additives of Re and Ru for HPT blades of modern GTE. Rhenium dissolves chiefly in the nickel fcc-solid solution (γ-phase), decelerates the diffusion processes in it, and hence raises the creep resistance of the alloys under the action of high temperatures and stresses. To stabilize the phase composition and reduce the probability of precipitation of tcp phases rhenium-containing RNA are alloyed with ruthenium [3, 4].

The aim of the present work was to study the structural and phase transformations in a single-crystal nickel alloy containing rhenium and ruthenium in tests for long-term strength.

Methods of Study

We studied single-crystal nickel alloy VZhM4-VI with an average chemical composition (in wt.% [3, 5]) 6.0 Al, 2.5 Cr, 6.0 Co, 4 Mo, 4.0 W, 4.5 Ta, 6.0 Re, 4.0 Ru, the remainder Ni.

Nickel-base alloy VZhM4-VI belongs to the class carbonless refractory alloys with rhenium and ruthenium and is used for fabricating single-crystal rotor blades of advanced GTE engines.

Specimens for the study were cast in an UVNK-8P device with liquid-metal coolant and had crystallographic direction [001]. To form an optimum microstructure with uniform distribution of particles of γ′-phase in the γ-matrix, cast preforms 14 mm in diameter were subjected to a complete heat treatment that included stage heating to 1320 ± 5°C with a hold of 20 h and two-stage aging at 1130 ± 5°C and 870 ± 10°C [3, 5, 6].

The tests for long-term strength were performed at a tress of 300°C and a temperature of 1000°C in the air atmosphere of the furnace with the help of a VPK-11 machine under uniaxial loading of cylindrical specimens with functional part 5 mm in diameter and 25 mm long. The specimens were cut from cast preforms with ∅ 14 mm after heat treatment. The average time before failure was determined after testing three specimens.

The metallographic study and the analysis of the chemical composition of the phases were conducted by the method of scanning electron microscopy (SEM) with the help of a “Jeol JSM-6490 LV” device with an “Oxford Inca Drycool” attachment for x-ray spectrum microanalysis.

The electron microscope studies of the fine structure of the alloy were conducted by the method of transmission electron microscopy (TEM) of thin foils in an “ÉMV-100L” device.

Results and Discussion

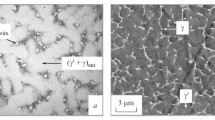

The single crystals obtained from alloy VZhM4-VI had a well manifested dendritic cellular structure typical for cast single crystals of RNA with orientation [001]. The microstructure of alloy VZhM4-VI after a complete cycle of heat treatment is presented in Fig. 1. Two processes develop under high-temperature homogenization of the alloy, i.e., dissolution of the nonequilibrium (γ + γ′) eutectic and then diffusion leveling of the chemical composition within dendritic cells. Micropores 2.0 – 4.0 μm in size form due to the dissolution of the (γ + γ′) eutectic in the dendrite spacing [3–5].

After the complete heat treatment the distribution of the particles of the γ′-phase acquires a pseudo-regular pattern and their size ranges within 0.4 – 0.5 μm. The electron diffraction and microdiffraction analyses show that the particles of the γ′-phase are arranged over directions [100]γ of the single crystal.

The heat treatment does not remove fully the segregation inhomogeneity of alloy VZhM4-VI, especially with respect to rhenium [3].

The tests for long-term strength of specimens of alloy VZhM4-VI at σ = 300 MPa and T = 1000°C show that the mean time before failure is 86.4 h.

Analysis of fracture surfaces of the failed specimens shows the presence of pores in the fractures (Fig. 2), which are of homogenization and deformation natures.

Under the action of high temperature and stresses particles of the γ′-phase intergrow and form a raft structure in the initial and steady creep stages (Fig. 3 a), which is typical for carbonless single-crystal RNA [6, 7]. The driving force of this change in the morphology of the initial (γ + γ′) structure of VZhM4-VI under the influence of temperature and stresses is mismatch between the lattice parameters and the moduli of elasticity of the γ- and γ′-phases [7]. The size of the initial γ′-phase grows considerably, and it is enriched with Al and Ta (Fig. 3 b ). The thickness of the layers of the γ-solid solution increases, and they are enriched substantially with the refractory elements of the alloy (Cr, Mo, Ru, W, Re).

A detailed study of the two-phase structural component (γ + γ′) in alloy VZhM4-VI has shown that the layers of the γ-phase have a complex structure (Fig. 4), i.e., the fine particles of the γ′-phase in layers with a size of 30 – 60 nm may be classified as nanolevel γ′n -particles. The layers of phase γn between the particles of γ′n have a thickness of about 10 nm and also belong to the nanosize group. This occurs upon cooling of the specimens from the test temperature due to decomposition of the γ-phase by the scheme γ→γn +γ′n. Particles of γ′n-phase also form on the boundaries of a coarse γ′-phase and a (γn + γ′n) mixture [8].

The endurance of the alloy is determined by the duration of the steady stage controlled by the rate of plastic deformation (sliding of dislocations in plates of the γ-phase accompanied by formation of dislocation nets on the γ/γ′ boundaries and cutting of plates of the γ′-phase). The mechanisms of accumulation of strain and fracture under tests of single-crystal alloys for long-term strength have been studied in detail in [7, 9, 10]. It is shown there that the main part of the elongation (about 99%) in creep of single-crystal alloys falls to dislocation creep, which is classical for alloys with (γ + γ′) structure. Dislocations slide and climb both in regions of the γ-phase and in particles of the γ′-phase of different sizes. In the places of formation of necks the concentration of pores is elevated, especially in the zone of failure. Microcracks nucleate on micropores in the end of the stationary stage and in the stage of accelerated creep, which causes failure of the specimen (Fig. 5). The microporosity controls the duration of only the accelerated stage of creep, the contribution of which into the total endurance is low [10]. Under the action of tensile stresses at 1000°C diffusion pores form in the γ′-phase in the region of fracture of the specimen (see Fig. 2 b). The diffusion pores formed in the coarse γ′-phase have an octahedral facing over planes {111} of the close packing of the Ni3Al intermetallic [11] and become sources of nucleation of microcracks in the alloy.

In the tests for long-term strength (T = 1000°C) alloy VZhM4-VI oxidizes intensely (Fig. 5 b and c). The oxidation produces a mixture of complex metal oxides based on nickel and refractory elements of the alloy. This shows that modern single-crystal RNA possessing a high long-term strength are oxidized intensely at a high temperature, which means that their surface should be protected with refractory protective coatings.

Conclusions

-

1.

Testing of alloy VZhM4-VI [001] for long-term strength produces a raft structure in the former. Particles of the γ′-phase intergrow, and the phase is enriched with Al and Ta. The thickness of the layers of γ′-phase increases, and they are enriched with refractory elements Cr, Mo, Ru,W, and Re.

-

2.

The layers of the γ-phase have a complex structure represented by fine particles of γ′-phase 30 – 60 nm in size in the layers, which may be classified as nanolevel particles of phase γ′n. The layers of the γn-phase between the γ′n-particles have a thickness of about 10 nm and also belong to the nanolevel.

-

3.

The changes in the chemical composition of the γ′- and γ-phases of alloy VZhM4-VI give rise to stresses on the interphase boundaries, the relaxation of which produces dislocations on the γ/γ′ interfaces and paired dislocations.

-

4.

The fractures of the specimens after the tests contain micropores of homogenization and deformation nature. The microcracks nucleated on them cause failure of the specimens.

References

E. N. Kablov, N. V. Petrushin, I. L. Svetlov e al., “Castable refractory nickel alloys for promising aircraft GTE,” Tekhnol. Legk. Splavov, No. 2, 6 – 16 (2007).

E. N. Kablov, Cast Blades of Gas Turbine Engines: Alloys, Technologies, Coatings [in Russian], MISiS, Moscow (2001), 632 p.

N. V. Petrushin, I. L. Svetlov, A. I. Samoilov, et al., “High-temperature phase and structural transformations in single crystals of a refractory nickel alloy containing rhenium and ruthenium,” Materialovedenie, No. 10, 13 – 18 (2008).

E. N. Kablov, N. V. Petrushin, I. P. Svetlov, and I. M. Demonis, “New-generation castable refractory alloys,” in: 75 Years. Aircraft Materials, Selected Work of “VIAM” in 1932 – 2007 [in Russian], VIAM, Moscow (2007), pp. 27 – 44.

V. P. Kuznetsov, V. P. Lesnikov, I. P. Konakova, et al., “Structure and phase composition of single-crystal alloy VZhM-4 with gas-circulation protective coating,” Metalloved. Term. Obrab. Met., No. 3, 28 – 32 (2011).

I. L. Svetlov, I. V. Iskhodzhanova, A. G. Evgenov, et al., “A study of high-temperature creep and structural flaws in singlecrystal nickel refractory alloy after hot isostatic pressing,” Deform. Razrush. Mater., No. 3, 28 – 32 (2011).

P. E. Shalin, I. L. Svetlov, E. B. Kachanov, et al., Single Crystals of Nickel Refractory Alloys [in Russian], Mashinostroenie, Moscow (1997), 336 p.

V. P. Kuznetsov, V. P. Lesnikov,M. S. Khadyev, et al., “Structure and phase transformations in single-crystal alloy ZhS36-VI [001] after holding in the temperature range of 1050 – 1300°C,” Metalloved. Term. Obrab. Met., No. 2, 38 – 44 (2012).

Yu. R. Kolobov, E. N. Kablov, É. V. Kozlov, et al., Structure and Properties of Intermetallic Materials with Nanophase Reinforcement [in Russian], MISiS, Moscow (2008), 328 p.

A. I. Epishin, I. L. Svetlov, and W. Brükner, “High-temperature creep of single crystals of nickel refractory alloys with orientation [001],” Materialovedenie, No. 5, 32 – 2 (1999).

M. R. Orlov, “Physicochemical features of formation of thermal-origin pores and operating capacity of single-crystal turbine blades,” Deform. Razrush. Mater., No. 6, 43 – 48 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 55 – 59, August, 2015.

Rights and permissions

About this article

Cite this article

Kuznetsov, V.P., Lesnikov, V.P., Konakova, I.P. et al. Structural and Phase Transformations in Single-Crystal Rhenium- and Ruthenium-Alloyed Nickel Alloy Under Testing For Long-Term Strength. Met Sci Heat Treat 57, 503–506 (2015). https://doi.org/10.1007/s11041-015-9912-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-015-9912-4