The paper presents the results of increasing the strength and modulus of single filaments and yarns of a paraaramid fiber by their processing with an aqueous suspension of carbon nanotubes in the production process

Similar content being viewed by others

Avoid common mistakes on your manuscript.

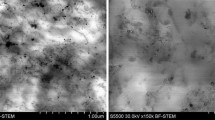

In [1], the prospect of modification of aramids using carbon nanotubes (CNTS) for the development of new composite materials is shown. In [2], the results of increasing the shear strength of a composite based on an aramid fiber fabric and epoxy resin are presented. The surface of finished fabric was first coated with CNTS. The properties of fibers determined in the process of introduction of CNTS before molding were unstable. In [3], the results of tests on paraaramid copolymer fibers [4], treated with an aqueous suspension of CNTS produced by “Nanotechcenter” (Russia, Tambov) [5], at the intermediate stage after molding is shown. The tests were conducted within a month after their manufacture. Test results for the same samples within 10 months of fiber manufacture are presented in this paper, and they coincide with the data given in [4]. Figure 1 shows the distribution histograms of the tensile strength of filaments of the original and CNT-treated samples. Table 1 presents the results of tests on filaments and yarns. The clamping length of filaments during the tests was 20 mm, and the strain rate was 0.0041 s–1. The test of yarns was carried out according to standard methods on the basis of 500 mm at the same strain r ate.

The results obtained showed no increase in the aging rate of the CNT-treated samples during storage. The statistical scatter of their properties during the processing had decreased, and the properties had become more stable. The increase in the strength characteristics of fibers as a result of their processing with the suspension of CNTS was statistically significant.

The theoretical distribution was selected using the Kolmogorov– Smirnov criterion [6].

The adequacy of the normal

lognormal

and Weibull

distributions was checked. It is found that formally experimental data can be adequately approximated by either of them, but, according to the Kolmogorov–Smirnov criterion, there is a preferable one in each particular case.

In Table 1, the parameters of the density distribution function of the tensile strength and modulus of single filaments and yarns of paraaramid copolymer fibers are presented: elastic modulus E (GPa), tensile strength s σus (GPa), the upper and lower bounds, G1 and G2, of the confidence interval, and the number N of parallel experiments; confidence level 95%. The preferred distributions are shown in bold.

References

T. Sainsbury, K. Erickson, D. Okawa, C. S. Zonte, J. M. Fréchet, and A. Zettl, “Kevlar functionalized carbon nanotubes for next-generation composites,” Chemistry of Materials, 22, No. 6, 2164-2171 (2010).

S. M. Shebanov, V. Yu. Chong, I. V. Tikhonov, V. G. Bova, and T. Kaisina, “Strength characteristics of composite materials with a polymeric matrix containing carbon nanotubes,” Oboron. Kompl.–Nauch-Tekhn. Progr. Russia, No. 4, 44-45 (2008).

S. M. Shebanov, V. G. Bova, and I. K. Novikov, “Increasing the strength of Rusar C thread by its processing with a suspension of a carbon nanostructured material “Taunit,” Kompozit. Mir, No. 1, 66-70 (2016)

J. Q. Zheng, K. Masters, and W. W. Chen, “Mechanical behavior of A265 single fibers,” J. Mater. Sci., 45, No. 3, 652-661 (2010).

URL: www.nanotc.ru (date of application 12.12.2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 53, No. 2, pp. 379-382 , March-April, 2017.

Rights and permissions

About this article

Cite this article

Shebanov, S.M., Novikov, I.K., Gumargalieva, K.Z. et al. Increasing the Strength of Single Filaments and Yarns of a Paraaramid Fiber by Their Processing with an Aqueous Suspension of Carbon Nanoparticles. Mech Compos Mater 53, 267–270 (2017). https://doi.org/10.1007/s11029-017-9659-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-017-9659-7