A solution of the problem of increasing the accuracy of a data-measuring system for the nondestructive testing of the thermal properties of materials is proposed. An algorithm for correcting the technical imperfection of the structural components of the system, based on the use of a mathematical model of the measurement procedure and information on influencing destabilizing factors, is developed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

An investigation of the possibilities and ways of improving data-measuring systems when investigating the thermal properties of solids, and improving their technical characteristics, is important and urgent in order to increase the productivity and accuracy of nondestructive testing [1] .

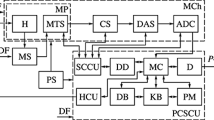

The purpose of this paper is to investigate the destabilizing factors, to construct a mathematical model of the data-measuring system, and to develop an algorithm for correcting the results of measurements of the thermal parameters of materials. A block diagram of the system is shown in Fig. 1. The intelligent sensor IS includes a system of measuring transducers SMT and a microcontroller, which selects measurement transducers depending on the problem of determining the qualitative characteristics of the materials being investigated MI. A portable computer unit PCU records the data on the acting destabilizing factors, synthesizes an algorithm for the measurement and structure of the data-measuring system, depending on the situation, and carries out a sequence of measuring procedures and controls. Experimental data are processed and stored in the computer C, decisions are taken based on the information of the experiments carried out and the database when synthesizing the measurement procedures, and also the output data on the parameters of the thermal properties of the materials are presented in a form convenient for the user. The system also contains a unit for taking decisions, a knowlege base KB, and an intelligent user interface to provide communication between the user and an expert.

Block diagram of the data-measuring system for the nondestructive testing of the thermal properties of materials: MI are the materials being investigated; SMT is a system of measuring transducers; IS is an intelligent sensor; PCU is a portable computer unit; DU is a decision unit; C is a computer; KB is a knowlege base; IUI is an intelligent user interface.

By analyzing the structure and technical characteristics of the existing data-measuring systems, we developed an information and mathematical model of the system, and also an algorithm for correcting the results of measurements. When solving these problems, we used methods of the theory of measuring systems, mathematical and physical modeling, and the classical theory of thermal conduction.

The Mathematical Model of the Measurement Procedure in the Data-Measuring System. An analysis of the architecture of the data-measuring system, taking into account the components of its structural units and the data exchange, enables us to represent the generalized model of the system in the form:

where S is the set of structural components participating in the process by which the measurement data are formed from the primary measuring transducers, the gain of the measured signal in the normalizing amplifier (NA), in the process of analog-to-digital conversion, and processing of the measurement data in the microcontroller; C c is the set of communications of data exchange between the structural components of the system; and F is the set of generated measurement data in the corresponding components, taking into account the action of destabilizing factors [2].

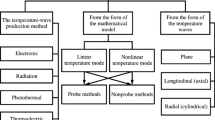

Using the generalized model (1), we developed a mathematical model of the data-measuring system, taking into account the system functioning algorithm, and the input and output signals of the main structural components and the relations between them when they are affected by destabilizing factors [3, 4]. To set up the mathematical model, we analyzed both known relations for the mathematical description of the system of measuring transducers and the normalizing amplifier, and the analog-to-digital converter (ADC), and also those obtained experimentally. In Fig. 2, we show a block diagram of the measurement process in the system with an indication of the structural components of the system showing the main influence on the measurement accuracy, the input actions, the parameters and the destabilizing factors. Heat pulses of specified frequency and power were applied during the measurements from a heat source (TAS) to the material investigated (MI). After this, we recorded the temperature T n of the material at certain instants of monitoring n, which is used in the microcontroller to obtain information E TP on the thermal parameters of the materials: the thermal conductivity and thermal diffusivity (λ and α, respectively), taking into account the approximation error E a of the output relations of the structural components of the system when it is acted upon by destabilizing factors. We can represent the system as follows:

Block diagram of the measurement process in the data-measuring system: TAS is the thermal action source acting on the materials being investigated; T n is its temperature at the instant of monitoring; P i , P N , and P d are the destabilizing factors acting on the system of measuring transducers, the normalizing amplifier, and the analog-to-digital converter, respectively; E TP (T n ) is information on the parameters of the thermal properties of the materials of the relations λ(T) and α(T); E a is the approximation error.

where U SMT and U NA are the output voltages of the system of measuring transducers and the normalizing amplifier, respectively; T 1, T 2, …, T n are the temperatures of the operating layers of the thermocouple; P with the subscripts 1, …, i, 1, …, N, and 1, …, d are the destabilizing factors – the temperature of the surroundings, the roughness of the surface of the object being investigated, the humidity, the contact resistance, instability of the supply voltage, the change in the load resistance, the interference and the noise, respectively, acting on the measuring system, the normalizing amplifier and the analog-to-digital converter; B with the subscripts 1, …, m i , 1, …, b, 1, …, c are the parameters of the thermocouples, the normalizing amplifier and the analog-to-digital converter, representing the sensitivity, linearity characteristics, class of accuracy, limit of permissible temperature deviations, the gain, the input and output resistances, the interference and the noise, respectively; t is the time; K ADC is the output code of the ADC, proportional to the signals applied from the output of the normalizing amplifier; E TP are the output parameters of the thermal properties of the materials being investigated, i.e., λ and α are the thermal conductivity and thermal diffusivity, respectively; T m1, T m2, …, T mn are the temperatures at the points where the material is being monitored by the measuring sensor; E 1, E 2, …, E a are the errors in approximating the temperature dependences of λ and α at points of the object being monitored; and B 1, B 2, …, B T are constants determined when calibrating the measuring system.

The mathematical model of the procedure for measuring the temperature with the system of measuring transducers (SMT) in model (2) has the form [5]:

where n is the number of temperature sensors of the measuring system, and H i are the coefficients of the approximating function.

We will represent the mathematical model of the process of converting the data by the amplifier by the relation

where K NA is the gain of the normalizing amplifier, and ΔU NA is the error of the amplifier when acted upon by destabilizing factors.

We will write the mathematical model of the process of converting the measurement data in the analog-to-digital converter as [6]:

where θ is the sampling period of the input analog signal, u is the number of periods, and δ K ADC is the relative error of the analog-digital converter.

Hence, when using (3)–(5) in the mathematical model of measurement process (2), the accuracy with which the thermal parameters of the materials is determined is increased.

The output parameters of the measuring system for the nondestructive testing of the thermal properties of materials are determined using a linear instantaneous heat source (an electric heater, made of nichrome wire with a high electrical resistance) in the contact plane of two semibounded bodies. The heat propagation process on the insulated surface is then described by the relation [7]:

where x is the distance from the linear heat source to the points where the temperature is being monitored, Q is the power of the heating action, and τ is the time.

In the case of pulse-frequency action on the material being investigated, the temperature when the nth pulse is applied, based on (6), can be found from the formula

where F is the frequency at which the heat pulses are applied to the linear heater.

By using two measured values of the temperature T(x, n) and T(x, m), respectively, at the specified instants of time τ1 and τ2, from (7) we obtain the following formulas for calculating the thermal conductivity and the thermal diffusivity:

where K1, …, K4 are calibration coefficients.

An Estimate of the Accuracy of the Data-Measuring System. The error characteristics of the results of measurements of the thermal parameters of solid materials were analyzed using (2). The following structures of the errors of the measurement results were determined:

of the temperature:

where ΔSMT T, ΔNA T i , and ΔADC T i are the conversion errors of the system of measuring transducers, the normalizing amplifier and the analog-to-digital converter; ΔΨ Ti, Δ W Ti, ΔS Ti, and ΔR T Ti are the errors due to the roughness of the material being investigated, the changes in its moisture content, the action of the temperature of the surroundings, and the change in the contact resistance, respectively;

of the thermal diffusivity and thermal conductivity:

where \( {\varDelta}_{K_1},\kern0.62em \dots, \kern0.5em {\varDelta}_{K_4} \) are the errors in determining the calibration coefficients K 1, …, K 4; and ΔT n , ΔT m , Δaλ i are the errors in determining the temperatures T n , T m , and the thermal diffusivity α, respectively.

Analytical relations for all the components of the overall error as a function of the acting factors were obtained, for example, the approximating dependence of the thermal conductivity of perspex on the temperature of the surroundings [9]: λ = F(T) = 3.35·10–8 T 3 + 1.203·10–6 T 2 + 2.28·10–4 T + 0.19. We also determined the similar relations for a number of heat insulating materials (λ = 0.03–0.2 W/mK), polymer materials (0.2–0.4 W/mK), and structural materials (0.3–0.9 W/mK). The contribution of each component to the error characteristic was estimated. We set up and experimentally verified an algorithm for correcting the technical imperfections of the structural components of the measurement system taking destabilizing factors into account, as shown in Fig. 3.

Measurements were made at a thermal power level from the linear heat source of 10 W at a monitoring point situated a distance L = 0.002 m from the heater at instants of time 5 and 120 sec. The table shows the results of a determination of the errors in measuring λ of standard measures of perspex and ripor: estimates of the mathematical expectations of the absolute and relative errors – M[Δλ i ], M[δΔλ i ]; the root mean square values of the absolute and relative errors – σ[Δλ i ] and σ[δΔλ i ]; and the limit absolute and relative errors – Δlimλ i and δlimλ i .

It follows from an analysis of the table that the maximum values of the systematic error M[δΔλ i ] = 2.35% and the random component of the error σ[δΔλ i ] = 1.67% correspond to the requirements imposed on the accuracy of the thermal measurements; the systematic and random components of the measurement error are considerably reduced when using the algorithm for correcting the technical imperfection of the structural components of the data-measuring system when it is acted upon by destabilizing factors.

The results confirm the adequacy of the proposed mathematical model for processing the thermal measurements of materials using the data-measuring system.

Conclusions. We have set up a mathematical model of the process of measuring the parameters of the thermal properties of materials, namely, the thermal conductivity and thermal diffusivity, taking into account the measurement errors of the structural components of the data-measuring system when it is acted upon by destabilizing factors. We have developed an algorithm for correcting the technical imperfection of the structural components of the measuring system using the approximating temperature dependences of the parameters of the thermal properties obtained. The use of the proposed algorithm increases the accuracy with which the measuring system functions.

The results obtained are recommended for use when designing and using data-measuring systems under practical conditions, for the nondestructive testing of the thermal properties of solid materials.

References

Z. M. Selivanova and A. A. Samokhvalov, “An intelligent data-measuring system for determining the thermal properties of materials and articles,” Izmer. Tekhn., No. 9, 38–42 (2012).

D. Yu. Muromtsev, S. V. Artemova, and A. N. Gribkov, “Prediction and compensation of perturbations in optimal control systems,” Vestn. Tambov. Gos. Tekh. Univ., 9, No. 4, 632–637 (2003).

V. I. Pavlov, V. V. Aksenov, and T. V. Belova, “Optimization of the functioning of measurement systems,” Izv. Tomsk. Politekh. Univ., No. 11, 65–68 (2010).

B. Ya. Sovetov and S. A. Yakovlev, Systems Modeling: Textbook. Vysshaya Shkola, Moscow (2005).

GOST R 8.585–2001, Thermocouples. Nominal Static Conversion Characteristics.

Yu. F. Opadchii, O. P. Gludkin, and A. I. Gurov, Analog and Digital Electronics: Textbook, Radio i Svyaz, Moscow (2002).

A. V. Lykov, Theory of Heat- and Mass-Transfer, Gosenergoizdat, Moscow (1963).

Yu. L. Muromtsev and Z. M. Selivanova, Patent No. 2301996 RF, “A method for the nondestructive testing of the thermal properties of materials and articles,” Izobret. Polezn. Modeli, No. 18 (2007).

GOST 17622–72, Technical Organic Glass. Technical Conditions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 9, pp. 45–48, September, 2015

Rights and permissions

About this article

Cite this article

Selivanova, Z.M., Khoan, T.A. Increasing the Accuracy of Data-Measuring Systems for the Nondestructive Testing of the Thermal Properties of Solids. Meas Tech 58, 1010–1015 (2015). https://doi.org/10.1007/s11018-015-0834-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-015-0834-8