A general description of an algorithm for predicting the silicon content in the iron of a blast furnace is given. It is based on the knowledge of the processes occurring in the furnace and the general laws of transient processes. The algorithm allows real-time and 10 hour prediction of the silicon content. A linearized model of the blast furnace process and a combined full-scale/mathematical approach are used. They allow customize the model to the blast furnace conditions, taking into account changes in the composition and properties of iron ore raw materials and coke and in the blast and smelting parameters. The information/modeling system developed based on the algorithm is integrated into the information system of the MMK blast furnace shop. The architecture of the software is described and its operation is illustrated. The accuracy of predicting the silicon content in iron is assessed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The leading metallurgical companies of Russia declared the implementation of the Industry 4.0 concept. According to this concept, factories change approaches to the design and implementation of information systems. One of the development lines in this concept is the creation of intelligent systems for real-time control of processes. Intelligent systems are intended to improve the decision-making algorithm used in computer-aided process control [1,2,3].

The nonstationarity, complexity, and spatial distribution of the blast-furnace process complicate the realtime prediction of the thermal condition of a blast furnace (BF). One of the major indicators of the thermal condition is the silicon content of iron [4,5,6,7].

The dynamic model for real-time prediction of the silicon content of iron was developed based on the laws of heat and mass transfer, gas dynamics, and slag formation during blast-furnace smelting. The blast-furnace process was controlled using the mathematics, algorithms, and software developed at the Ural Federal University (UrFU) [8,9,10,11,12]. The dynamic problem was solved using the general laws of transient processes formulated by the Scientific-Research Institute of Metallurgical Heat Engineering (VNIIMT). Use was also made of the dynamic and linearized models [13, 14] of the blast-furnace process, the principle of small deviations, and the combined full-scale/mathematical approach developed at the Siberian State Industrial University [15].

The dynamic model helped to analyze the blast-furnace transients is described in [16, 17], where it is shown that the dynamic characteristics of a BF are strongly dependent on the furnace operating conditions and the properties of the raw materials.

The silicon content of iron is predicted using the following algorithm:

- (i)

determine the average indicators of the operation of the BF over the previous 12 hours relative to the current moment of time (base period), assuming that the blast furnace process was stationary before the base period (the choice of this period is determined by the average duration of transients in the blast furnace);

- (ii)

calculate the transfer coefficients for the different channels of influence with the UrFU-MMK algorithm [8,9,10,11,12] using the base period, the furnace dimensions, the specific consumption and properties of the burden constituents, the characteristics of combined blast, the composition of liquid products of smelting, the composition of furnace top gas, etc.;

- (iii)

determine the average hourly values of the ore load, the oxygen content of blast, temperature, moisture content, hot blast rate, and the consumption of natural gas during the base period;

- (iv)

analyze the blast-furnace transients in different channels of influence such as ore load, consumption of flux, consumption of natural gas, blast temperature and moisture, oxygen content of blast [16, 17];

- (v)

calculate, if not measured, the silicon content of iron at tappings in the base period and in each of the subsequent ten hours, beginning from the current moment (look-ahead period). Since the system is considered linear, its reaction to any sum k of input influences can be calculated by the following equation using the superposition principle:

where ΔSi(τ) is the change in the silicon content of iron with time, %; n is the number of prediction intervals; Δxij is the increment of the average hour value of the j th input influence over the i th time interval, units of measurement of the parameter; hj is the transfer function of the system in the j th channel of influence, percentage per unit of measurement of the parameter; Δt is the period of averaging of input influences, h.

The input parameters in the predictable period are assumed constant and equal to their values at the current time. The data on the last three (base) tappings for which the silicon content is known are used in calculations. The length of the intertap period and the mass of tapped iron are taken into account. The predicted silicon content is

where [Si]b is the silicon content of iron in the last tappings of the base period, %;

- (vi)

upon receiving new data on the input and output parameters of the blast-furnace process, define new base and prediction periods.

Thus, the model is customized to the BC operating conditions taking into account the changes in the properties of iron ore raw materials and coke, blast characteristics, and blast-furnace smelting conditions.

To compare the measured and predicted silicon contents, the following statistics were used:

the root-mean-square deviation of the predicted value of silicon content from the measured value:

\( \upsigma =\sqrt{\frac{1}{n-1}\sum \limits_{i=1}^n{\left({\left[\mathrm{Si}\right]}_i^{\mathrm{m}}-{\left[\mathrm{Si}\right]}_i^{\mathrm{pr}}\right)}^2}, \)

where n is the number of tappings; \( {\left[\mathrm{Si}\right]}_i^{\mathrm{m}} \) is the measured silicon content in the i th tapping, %; \( {\left[\mathrm{Si}\right]}_i^{\mathrm{pr}} \) is the predicted silicon content in the i th tapping, %;

the reliability of prediction defined as the ratio of the number of predictions with an absolute error of no more than 0.05% to the total number of predictions.

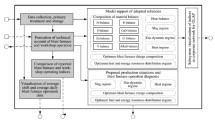

These parameters allow estimating the accuracy and reliability of prediction. The algorithm of predicting the silicon content of iron is schematized in Fig. 1. The architecture of the information/modeling system for predicting the silicon content of iron is presented in Fig. 2.

The software is a C#-language web application developed in the ASP.NET MVC framework using .NET Framework and .NET Core. It consists of three modules: data processing, computation, and data reporting. Such an approach makes the modules independent, which considerably facilitates the testing process and allows independent development of such modules. The data processing module allows avoiding the dependence of the computation modules on the source of data when it is changed. Therefore, the data reporting modules can be completely redesigned to meet the new convenience requirements to the graphical user interface.

The computation modules employ the UrFU-MMK model of the blast-furnace smelting process taking into account its dynamics. The modules are intended to calculate the indicators and condition of the BF and to model dynamics, which, in combination, allows us to dynamically simulate the influence of the controlled parameters on the silicon content of iron.

The data reporting modules are the graphical user interface intended to visualize the calculated results.

The graphical interface consists of four modules (webpages): prediction of the silicon content of iron, presentation of transients, presentation of real-time smelting data, and references.

The Prediction of Silicon Content of Iron Webpage (Fig. 3) displays the data on the measured and predicted silicon content of iron in graphical and tabulated forms and the predicted silicon content in the 10-hour period starting at the current time.

The Transient Representation Module models the change of the silicon content of iron in different channels of influence. Figure 4 shows, as an example, a webpage with curves of transients occurring upon an increase in the blast temperature by 10°C, the consumption of natural gas by 20 m3 /min, the oxygen content of blast by 0.5%, the ore load by 0.1 ton/ton, the blast moisture by 1 g/m3 for each parameter and their total influence on the silicon content of iron.

The data processing module is intended to obtain values of controlled parameters needed for calculations from the MICS database of the blast-furnace shop.

The Real-Time Smelting Data Representation module is intended to visualize data on the average parameters of the blast-furnace smelting process in the chosen period.

We will consider, as an example, how the silicon content of iron in MMK DP-6 is predicted. A period of 15 tappings (31 h of continuous operation of the furnace) is chosen for this purpose. Figure 5 shows the dynamics of the basic input parameters. Figure 6 compares the measured and predicted silicon contents of iron in this period.

The root-mean-square deviation of the predicted silicon content of iron from the measured value at tappings is 0.09%. The reliability of prediction is 46%, which is indicative of satisfactory agreement between the predicted and actual values.

The root-mean-square deviation of the silicon content of iron between subsequent tappings is 0.17%, the root-mean-square deviation of the predicted silicon content of iron from the measured value being 0.09%. The reliability of prediction is 46%, and the maximum error of the predicted values does not exceed 0.22%.

The fraction of prediction errors that fall into the range 0–0.1% is 73%, and the fraction of errors in the range 0.11–0.2% is 20%. The results obtained are indicative of satisfactory agreement between the predicted and actual values of the silicon content of iron.

Thus, the information/modeling system allows real-time prediction of the silicon content of iron and promotes making scientifically justified decisions on control of the thermal condition of the blast-furnace process.

Conclusions

-

1.

The information/modeling system for real-time prediction of the silicon content of iron has been developed using modern technologies.

-

2.

The prediction algorithm accounts for change in the basic parameters (ore load, consumption of natural gas, oxygen content of blast, blast temperature and moisture, consumption of flux). The algorithm is based on fundamental knowledge on the modern blast-furnace smelting theory and practice, laws of heat and mass transfer, gas dynamics, and slag formation.

-

3.

Application of the linearized blast-furnace smelting model and the combined full-scale/mathematical approach allows customizing the model to a specific BF, allowing for changes in the composition and properties of iron ore raw materials and coke, and the blast and blast-furnace conditions.

References

A. A. Eremin, Magnitka 4.0: (Magnitogorsk Iron and Steel Works) Interviewed about What Has Been Digitized at the MMK and How to Make Steel Without Human Intervention [in Russian]; http://www.mashportal.ru/interview-49200.aspx (access date: 4/29/2019).

The NLMK Group Combines Digital Transformation and Information Technology [in Russian]; http://www.metalinfo.ru/ru/news/108069 (access date: 4/29/2019).

The Metalloinvest Has Transformed Business Processes Based on the Industry 4.0 Principles [in Russian]; http://www.metalinfo.ru/ru/news/103230 (access date: 4/29/2019).

I. G. Tovarovskii, Blast-Furnace Smelting [in Ukrainian], Porogi, Dnepropetrovsk (2009).

M. Geerdes, R. Chaigneau, I. Kurunov, O. Lingiardi, and J. Ricketts, Modern Blast Furnace Ironmaking. An Introduction, IOS Press, Amsterdam (2015).

S. Taguchi, H. Kubo, N. Tsuchiya, et al., “Development of a mathematical model of silicon transfer via SiO in the blast furnace,” Tetsu-To-Hagane. J. of the Iron and Steel Institute of Japan,68, No. 15, 2303–2310 (1982).

Xu Jian, Sheng-li Wu, Xin-ying Guo, and Kai-ping Du, “Numerical simulation on dynamic and static holdups of powder inside prereduction shaft furnace,” in: Proc. 6th Int. Congr. on the Science and Technology of Ironmaking, Rio de Janeiro, RJ, Brazil, October 14-18 (2012), pp. 414-424.

N. A. Spirin (ed.), V. V. Lavrov, V. Yu. Rybolovlev, et al., Mathematical Simulation of Metallurgical Processes in a Process Automation System [in Russian], OOO “UIPTs,” Ekaterinburg (2014).

O. P. Onorin, N. A. Spirin (ed.), V. L. Terent’ev, et al., Computer-Based Methods for the Simulation of the Blast-Furnace Process [in Russian], UGTU-UPI, Ekaterinburg (2005).

N. A. Spirin, V. V. Lavrov, I. E. Kosachenko, et al., “Software for the raw-materials management system in blast-furnace smelting,” Metallurgist,59, No. 1–2, 104–112 (2015).

N. A. Spirin, V. V. Lavrov, V. Y. Rybolovlev, et al., “Use of contemporary information technology for analyzing the blast furnace process,” Metallurgist,60, No. 5-6, 471–477 (2016).

A. V. Pavlov, A. A. Polinov, N. А. Spirin, et al., “Use of model systems for solving new technological problems in blast-furnace production,” Metallurgist,61, No. 5–6, 448–454 (2017).

V. I. Moikin, N. M. Babushkin, and B. A. Bokovikov, “Dynamic characteristics of a blast furnace found by mathematical simulation,” in: Issues of Iron Making in Blast Furnaces [in Russian], Metallurgiya, Moscow (1984), pp. 46–52.

Yu. N. Ovchinnikov, V. I. Moikin, N. A. Spirin, and B. A. Bokovikov, Nonstationary Processes and Improvement of the Effectiveness of Blast-Furnace Smelting [in Russian], Metallurgiya, Chelyabinsk (1989).

S. V. Emel’yanov, S. K. Korovin, L. P. Myshlyaev, et al., Theory and Practice of Prediction in Control Systems [in Russian], Rossiiskie Universitety, Kuzbassvuzizdat-ASTSh, Kemerovo–Moscow (2008).

O. P. Onorin, N. A. Spirin, A. S. Istomin, et al., “Features of blast furnace transient processes,” Metallurgist,61, No. 1-2, 121–126 (2017).

N. A. Spirin, O. P. Onorin, A. S. Istomin, et al., “Study of transition processes of blast-furnace smelting by the mathematical model method,” IOP Conf. Series: Mater. Sci. and Eng.,411, No. 1, 012–073 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 9, pp. 22–28, September, 2019.

Rights and permissions

About this article

Cite this article

Spirin, N.A., Polinov, A.A., Gurin, I.A. et al. Information System for Real-Time Prediction of the Silicon Content of Iron in a Blast Furnace. Metallurgist 63, 898–905 (2020). https://doi.org/10.1007/s11015-020-00907-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00907-y