Abstract

The current study evaluated the performance parameters and drying characteristics of muskmelon slices in the indirect forced convection solar dryer (IFCSD) without thermal energy storage (TES) device (case-A) and with a TES device (case-B). The average collector and drying efficiencies (ηSAC and ηdr) were 66.37 and 11.37% in case-A and 67.82 and 16.93% in case-B, respectively. The ηSAC of both setups was not affected by the TES as it was installed in the drying cabinet, whereas ηdr of case-B setup was improved because the stored and released heat was more, also, the drying completed within a day compared to case-A. The six sunshine hours were saved, and a 53.98% average drying rate was improved by case-B. The specific moisture extraction rate was improved by 74.19%, and the specific energy consumption was decreased by 42.56% compared to case-A due to the higher quantity of moisture removal per input solar radiation in case-B. Two-term exponential and Page models were appropriately suited for drying muskmelon slabs in case-A and case-B, respectively. The values of effective moisture diffusivity, heat and mass transfer coefficients (averages) were improved slightly by TES device in case-B. The temperature of the drying cabinet could be continued 4.5 to 8.9 °C greater than the atmospheric temperature in case-B after the sunset. The performance of IFCSD was better in case-B compared to case-A, and the final moisture content was achieved within a day in case-B.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Drying is a preservation method to store the food items for a long tenure to decrease post-harvest losses. Solar drying of agricultural foods become popular and economic due to increased fossil fuel prices and the non-availability of continuous electricity in rural areas. The conventional open sun drying (OSD) method produces low quality food products due to exposure to dust, rain and insects. These shortcomings are overcome by an indirect solar dryer (ISD) where the food items are dried by heated air that comes from a solar air collector (SAC) [1]. There are two modes of air flow in ISDs such as natural and forced convection mode. The indirect forced convection solar dryer (IFCSD) dries the food products at a faster rate within less time because of the enhanced mass flow rate of air by fans or blowers compared to the indirect natural convection solar dryer (INCSD) [2].

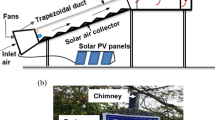

In the present study, an IFCSD was designed by integrating a trapezoidal tunnel consisting of DC fans controlled using solar PV panels at the entry of SAC. The thermal energy storage (TES) unit was integrated with IFCSD enabling continuous drying after sunset and reducing the drying time. The muskmelon is a tropical fruit containing dietary fibre, potassium, vitamin C, β-carotene and folic acid [3]. The higher moisture content (MC) in muskmelon (more than 90%) increases the post-harvest losses in seasonal time and decreases the quality of muskmelon due to attacks of pathogens. The drying of muskmelon slices in IFCSD with a TES device produces quality fruits within less time. The dried muskmelon is used for infusing water, snacking, garnishing cocktails, baking and making smoothies. Dried muskmelon has a lot of health benefits since it has higher quantities of antioxidants, vitamins and minerals per unit volume than fresh fruit [3].

Gopinath et al. [4] explored the drying of grapes in a direct type solar dryer (DTSD) with and without TES utilizing paraffin wax as a phase change material (PCM). The PCM was packed inside and below the meshes of the drying cabinet. It is noticed that the drying duration for grapes was 52, 34, 22 and 10 h in OSD, solar dryer without a storage unit, with 100 and 200 g of PCM, respectively. They also reported that air temperature in the drying cabinet (Ta,dc) was maintained above 50 °C for a duration of 4 h. Nimnuan and Nabnean [5] conducted experiments on DTSD with concrete as storage material during drying ginger from 9 kg per kg of dry basis (db) to 0.11 db. The Ta,dc was in the range of 30–55 °C. The quality of ginger slices was found to be better compared to OSD and 67% of the drying period was saved in the DTSD.

Cetina-Quinones et al. [6] conducted drying experiments of tomatoes on an INCSD with two sensible heat storage (SHS) materials such as limestone and beach sand at three possible locations: under the collector, top and bottom of the drying section. The drying efficiency (ηdr) was found to be 12.57 and 11.02% in INCSD with limestone and beach sand, respectively. The drying duration to achieve the final MC of tomato was observed to be 25, 22 and 23 in INCSD without storage, with limestone and with coastal sand, respectively. Similarly, Sain et al. [7] developed an INCSD with paraffin in the drying section while drying ginger. The average collector efficiency (ηSAC) and ηdr were noticed to be 50% and 12.4%, respectively.

Kesavan et al. [8] made energy, exergy and environmental analysis in an IFCSD affixed with sand as an SHS substance under the collector while drying potato slices. The final MC of potato slabs reached 0.149 db from an initial MC of 3.167 db. It took 4.5 h. The mean ηSAC was determined to be 45%. The best drying model was found to be Midilli and Kucuk model. Similarly, Mohanraj and Chandrasekhar [9] developed an IFCSD with sand as SHS under the collector for drying copra and the average ηSAC was observed to be 24%.

Nabnean et al. [10] constructed an IFCSD integrated with a heat exchanger between the water storage tank and drying cabinet. The warmed water from SAC was filled in a tank and was utilized to heat the air via a heat exchanger. The sample object considered was tomato slabs. The ranges of ηSAC and Ta,dc were 21 to 69% and 30 to 65 °C, respectively. A similar mode of work was dealt by Amer et al. [11] during drying chamomiles. The drying time was diminished by 50% compared to OSD. The Midilli model was identified to be a fitting drying model for chamomiles.

Lakshmi et al. [12] performed experiments with black pepper on the mixed-mode solar dryer (MSD) with a paraffin wax storage tank and two SACs. The drying time for black pepper to reach final MC in MSD and OSD was 14 and 59 h, respectively. The ηdr was observed to be 51%. The specific energy consumption (SC) was concluded to be 2.2 kWh kg−1. Similarly, Arun et al. [13] dried banana slices in MSD with paraffin wax capsules on SAC. The optimized distance between trays of 0.15 m and slice thickness of 2 mm was found during the drying of banana slices. The ηdr and SC ranged from 33.9–42.52% and 4.32–5.19 kWh kg−1, respectively.

Deeto et al. [14] constructed a hybrid type solar dryer (HTSD) consisting of a solar greenhouse dryer and water storage tank integrated with SAC for drying coffee beans. The hot water was used after the sunset to dry the coffee beans. The coffee beans were reduced to 0.136 from 1.22 db in a period of 12 h. The drying behaviour of coffee beans could be matched with Midilli et al. model. The value of effective moisture diffusivity (De) was found to be 9.754 × 10−11 m2 s−1. Similarly, Reyes et al. [15] fabricated an HTSD that consists of a SAC with paraffin wax under the absorber plate and electric heaters in the drying cabinet for drying mushrooms. The De was in between 2.5 and 8.4 × 10−10 m2 s−1.

Chaatouf et al. [16] designed a CFD model to investigate the dynamic and thermal characters of ISD integrated with PCM-filled copper tubes that were located on the side of the drying cabinet. At night, the ηdr increased by 3.12% when compared to an arrangement without a TES system. The performance of Paraffin RT58 is better than RT24 and Gallium and it increased the temperature difference by 11 °C at night. Similarly, Yadav and Chandramohan [17] concluded that finned copper tubes gained maximum heat compared to those without fins in a TES device in a drying cabinet. The temperature difference of the air in concentric tubes was found to be 9.1 and 5.47 °C for with and without fins on copper tubes, respectively.

The literature survey conjectured that various SHS and latent heat storage (LHS) substances were used at various places such as at the bottom of the collector [6, 8, 9, 15], using a detached heat exchanger [10,11,12,13] and in the drying cabinet [4, 6, 7] in different solar dryers including DTSD [4, 5], INCSD [6, 7], IFCSD [8,9,10,11], MSD [12, 13] and HTSD [14, 15]. The SHS materials included sand [6, 8, 9], concrete [5], limestone [6] and water [10, 11, 14] were used in solar dryers. Mostly, the paraffin wax [7, 12, 13, 15] was used for LHS in different solar dryers. The drying characteristics of different food materials including grapes [4], ginger [5, 7], tomato [6, 10], potato [8], copra [9], black pepper [12], banana [13] and mushrooms [15] were analysed in various solar dryers. There are limited studies available on using TES in drying cabinets of ISD [6, 7]. Few studies are available on numerical analysis of storage materials in solar dryers [16, 17]. The finned inner tubes in concentric tubes increased the heat transfer and gave a higher air temperature in the drying cabinet [17]. The drying period was diminished due to the usage of TES devices in solar dryers [5, 6, 11, 18].

The important parameters for analysing the drying process such as De, activation energy (Eae) and surface transfer coefficients (hht and hmt) were not studied in ISD with a TES device. The SC and specific moisture extraction rate (SR) were not evaluated in ISD without and with a TES device. There is no study found on IFCSD integrated with trapezoidal tunnel consisting of DC fans governed using solar PV panels with TES device. The detailed performance analysis of IFCSD with storage and drying characteristics of muskmelon slices was not studied. There is no comparison study found on IFCSD without (case-A) and with TES device (case-B). An attempt was made in this study to fulfil the above research gaps.

The objectives of the current study are: (i) to execute experiments of muskmelon slices on an IFCSD dryer without (case-A) and with a TES device (case-B), (ii) to compare the temperature of the air at various places of IFCSD in case-A and Case-B, (iii) to evaluate performance parameters such as ηSAC, ηdr, SC and SR in both cases (iv) to illustrate moisture ratio of muskmelon slices with drying time and evaluation of drying models in both cases (v) to analyse parameters such as De, Ea, hht and hmt in both cases and appraise the IFCSD without and with TES device.

Materials and methods

The IFCSD setup consists of a trapezoidal duct, SAC, drying section and a chimney as mentioned in Fig. 1(a) and it is called case-A. The trapezoidal duct has three DC fans (0.25 A, 12 V) taken from waste CPUs and energized by solar panels. Hence, in this setup, no artificial energy is used and only natural energy is utilized for running the setup. The trapezoidal duct is made with galvanized iron sheets. The SAC (2 m × 1.05 m × 0.07 m) is made with window glass, copper plate, mild steel and rock wool insulation. In this case-A setup, the TES device was incorporated in the drying section as shown in Fig. 1 (b) and is called case-B. The rectangular TES device is constructed with polycarbonate sheets, and it consists of 50 TES cells. Each cell has two tubes: an outer polycarbonate tube and an inner aluminium tube with circular fins. The paraffin wax (melting point: 58–60 °C, HIMEDIA, India) melted and poured into the space between the inner and outer tubes. The SAC outlet air flows through aluminium tubes and charges the PCM during the day and after sunset, the PCM discharges the heat into the air. A total of 35 kg of paraffin wax is filled with 50 TES cells. The dimensions of the TES device and TES cells are given in Fig. 2. The drying cabinet (1.05 m × 0.85 m × 0.4 m) is made with aluminium sheets and thermocol insulation. Trays in the drying cabinet were made with plastic mesh and wooden bars. The components and the dimensions of the IFCSD setup and instruments used in the experiments were clearly explained in the earlier study [19]. The TES device is installed below the first tray of the drying chamber without changing the case-A setup’s dimensions.

On the day of the experiments, the fresh muskmelon fruits were brought from the market in the morning, peeled and cut into pieces (thickness: 10 mm, width: 15 mm and length: 20 mm). The four trays of the drying cabinet were filled with 800 g of muskmelon slices (200 g on each tray) and 200 g for the OSD drying. First, the experiments were executed on IFCSD without a TES device (case-A). Next, the experiments were done with a TES device (case-B). The muskmelon slices were weighed for each hour by a weighing balance. The temperatures of air in the atmosphere, SAC entry and exit, five locations of TES cell and four trays of drying cabinet were measured by RTD sensors. The velocity at the SAC outlet, relative humidity at the SAC entry and exit were probed by Testo 635, India. The performance analysis and drying characteristics of muskmelon slices were evaluated for both cases by following equations.

Performance analysis of ISD

The ηSAC was defined as the ratio of useful heat output (Qi,SAC) and input of SAC (Qo,SAC) and these are evaluated [19, 20] using;

The temperature at the SAC inlet and outlet is represented by Ti,SAC and To,SAC, respectively. The solar intensity (W m−1) and area of the collector (m2) are denoted by isr and ASAC, respectively.

The ηdr of ISD [6] was estimated using;

The quantity of water terminated (kg) and latent heat of evaporation (J kg−1) are denoted by mwv and LHwv, respectively.

The parameters SR and SC [6, 8] are given by;

Drying characteristics

A hot air oven was utilized to determine the initial MC (MCi). The initial (mi) and final masses (md) of the samples were measured by weighing balance. The MCi on db [19] is determined by;

The moisture ratio (MR) [8, 21] was evaluated by;

In the literature, various mathematical models were proposed for various food products. The frequently used twelve models [8, 11, 22] were analysed for MR vs time during drying of muskmelon slices and reported in Table 1.

The best mathematical models to represent the drying behaviour of muskmelon slices were estimated by finding the reduced Chi-square (χ2) and coefficient of determination (R2) of each model [23]. These are determined by;

where N and n are denoted as the number of experimental values and coefficient number of the model, respectively.

The difference in two successive MCs was given by the drying rate (DR) [11] and it is estimated as;

The De, hht and hmt [19, 24] were estimated using;

where B, V and As are thickness, volume and surface area of the muskmelon sample, respectively. The Lewis number and diffusivity constant of water–air are denoted by Le and Dwa, respectively. αda and kda are denoted as thermal diffusivity and conductivity of drying air, respectively.

The Eae which depends on De and absolute temperature is given by Arrhenius equation [25] and is estimated using;

where Dapf and Run are denoted as pre-exponential factor and the universal gas constant, respectively.

Uncertainty of parameters

In the analysis of results, two types of terminologies such as independent (b1, b2…bn) and dependent terminologies can be found. The uncertainty of independent terminologies was found by the least count of measuring instruments and their uncertainty values (u1, u2…un). The uncertainty of the dependent property (UR) is determined by Eq. (18) [26]. The uncertainties of solar radiation, temperature, velocity, relative humidity and mass are given as ± 10 W m−2, ± 1 °C, ± 0.03 m s−1, ± 2% and ± 0.0002 g, respectively. The uncertainties of dependent parameters found in the present study are given in Table 2.

Results and analyses

Analysis of performance parameters

The drying experiments were conducted on IFCSD without a thermal energy storage (TES) device (case-A) and with a TES device (case-B). The experiments started at morning 8.00 a.m. and ended at 5.00 p.m. with 9 h duration in a day for case-A. These are denoted using 0.00 and 9.00 in the X-axis of Fig. 3 for the first day and the same were denoted using 10.00 and 19.00 h in the X-axis for the second day, respectively. For case-B, in the X-axis, 0.00 represents 8.00 a.m. and 16.00 h represents 12.00 h at midnight. Since there is no isr in non-sunshine hours (5.00 p.m. to midnight) hence isr of one day time is only used in case-B. Therefore, the values of isr are shown for one day in case-B and two days in case-A in Fig. 3. Since the experiments were performed on consecutive days, the average solar radiation (isr) was found to be almost the same in both cases. The average value of isr in case-A and case-B is 666.05 and 673.8 W m−2, respectively.

The Tamb, Ti,SAC, To,SAC, Ta1, Ta2, Ta3 and Ta4 represents the air temperature in the atmosphere, entry of SAC, exit of SAC, trays-1,2,3 and 4, respectively. The mean values of Tamb, Ti,SAC, To,SAC, Ta1, Ta2, Ta3 and Ta4 were 36.64, 37.05, 51.2, 46, 43.75, 41.85 and 40.15 °C, respectively, in case-A. The temperature of air diminished while flowing from tray-1 to 4 due to the absorption of moisture from muskmelon slices. The maximum values of Tamb, Ti,SAC, To,SAC, Ta1, Ta2, Ta3 and Ta4 were 41.5, 42, 64, 55, 52, 50 and 48 °C, respectively (Fig. 4). The temperature drop within trays in day-1 is lower than day-2 since the maximum amount of moisture was lost in day-1 itself.

Similarly in case-B, the mean values of Tamb, Ti,SAC, To,SAC, Ta1, Ta2, Ta3 and Ta4 were 37.07, 37.24, 45.75, 44.35, 42.76, 41.41 and 40.12 °C, respectively (Fig. 5). The maximum values of the same were 43.1, 43.5, 65.4, 52, 49, 47 and 45 °C, respectively. Since PCM energizes from the hot air, the temperature in trays was lower in case-B compared to A. The air temperature in the drying cabinet (Ta,dc) was in the range of 40–54 °C and 45–52 °C from 01.00 p.m. to 4.00 p.m., in case-A and B, respectively. The PCM stores and releases the heat during this period and maintains the range of Ta,dc lower in case-B. The TES device releases the heat after 5.00 p.m. and it increases the To,SAC by 3 to 9.5 °C till midnight. The present results were found to be better compared to the studies in the literature, where in the published literature, the Ta,dc was maintained to be 6 °C [27] and 2.5–7.5 °C [28] higher than Tamb after the sunset due to TES in the drying chamber.

Figure 6 illustrates the change in ηSAC of IFCSD for both cases. Since ηSAC is inversely proportional to solar radiation and the value of ηSAC cannot be evaluated in non-sunshine hours for case-B, the change in ηSAC is drawn for one day in case-B and two days in case-A. The heat output of the collector was from 208.04 to 1733.63 W and 221.90 to 1678.15 W, in case-A and B, respectively. In case-A, the average and maximum ηSAC were noticed to be 66.37 and 89.09%, respectively, and in case-B, the same were 67.82 and 85.70%, respectively. The similar conditions of weather on successive days resulted in almost the same ηSAC in both cases and the effect of the TES device is not there on the value of ηSAC. A similar range of ηSAC was reported in the ISDs by Nabnean et al. [10] (21 to 69%) and Arun et al. [13] (53.9 to 65.5%) while drying tomatoes and bananas, respectively.

The change in ηdr with time for both cases is shown in Fig. 7. Similar to ηSAC, ηdr also cannot be evaluated in non-sunshine hours for case-B. So, a change in ηdr is drawn for one day in case-B and two days in case-A. The ηdr was from 0 to 24.61% and 0 to 21.66% in case-A and B, respectively. The average value of ηdr in case-A and B was found to be 11.37 and 16.93%, respectively. The average ηdr is increased by 48.90% in case-B since the Ta,dc was maintained constantly even after sunset due to the TES device. Also, the drying was completed within a day. In the literature, a similar range of values was estimated by Cetina-Quiñones et al. [6] (8.32 to 12.57%) in ISD with TES during drying tomato slices and Bena and Fuller [29] (9 to 22%) in DSD while drying pineapple slices. The improvement in ηdr is compared with results obtained by Abubakar et al. [30] (18.80%) and Chaatouf et al. [16] (3.12%). Both studies used TES units in their ISDs. As a result of the comparison, it is concluded that present ISD with TES is more effective than other models in the literature.

The value of SR in case-A and case-B was 0.620 and 1.080 kg kWh−1, respectively. The SC for the same was 1.612 and 0.926 kWh kg−1, respectively. It is noticed that SR is improved by 74.19% and SC is decreased by 42.56% in case-B compared to A. The energy input to the dryer in case-B is lower than case-A since the final MC was achieved in a day in case-B. The present setups gave lower SC values compared to the existing studies done by Cetina-Quinones et al. [6] (5.11 kWh kg−1 for tomato slices) and Kesavan et al. [8] (5.58 kWh kg−1 for potato slabs). Also, the muskmelon pieces can be dried in case-B within one day using the TES unit, whereas, case-A takes two days as it needs sunshine.

Analysis of drying characteristics

The value of the initial MC of muskmelon slices was estimated to be 12.4156 db. The final MC reached in case-A and case-B was 0.1604 and 0.2108 db, respectively, and it is achieved in 15 and 9 sunshine hours, respectively. Figure 8 shows the change in MR of muskmelon slices for both cases. More amount of moisture is lost after 3.00 p.m. in case-B compared to case-A since higher Ta,dc is maintained due to the TES device.

Figure 9 illustrates the variation of DR for both dryers. The maximum and average values of DR were noticed to be 2.119 and 0.817 kg h−1 and 1.898 and 1.258 kg h−1, in case-A and case-B, respectively. The value of DR increased till noon and decreased after. The higher DR values were observed in case-B in the afternoon since a higher amount of MC was removed because of maintaining constant Ta,dc till evening. There is an improvement of 53.98% in average DR in case-B compared to case-A.

The experimental values of change in MR were fitted to various correlations which are from the literature and the best fit was examined by finding the correct one with higher R2 and lower χ2. The 12 models (mentioned in Table 1) were added to Origin 2018 software by mentioning dependent and independent variables and constants. A nonlinear curve fitting was done for experimental values of MR vs time in four trays and OSD. It generated a fitting curve and constants of a model, with R2 and χ2 values. Out of 12 mathematical models, the fitting results of the best four models for case-A and B were given in Table 3. The Two-term exponential model was recognized to be the appropriate model for estimating the drying pattern of muskmelon slabs with R2 = 0.99544 and χ2 = 0.00052 in case-A. The Page and modified Page were the satisfactory models for case-B with the same R2 = 0.99809 and χ2 = 0.00023, respectively. The next best two models were: Verma and Page models in case-A and Verma and Two-term exponential models in case-B, respectively. The fitting of the best model in case-A and B is shown in Fig. 10.

The change in De for case-A and B was shown in Fig. 11. The range of De was from 9.14 × 10−9 to 5.82 × 10−8 m2 s−1 in case-A, and in B, it was from 9.14 × 10−9 to 5.51 × 10−8 m2 s−1, respectively. The average De was 3.04 × 10−8 and 3.13 × 10−8 m2 s−1 in case-A and B, respectively. The increment in average De was 2.96% in case-B in comparison with case-A. Higher De values were observed in case-B in comparison with case-A after 4.00 p.m., since a greater amount of MC is eliminated after the sunset due to heated air from the TES device. The range of De is comparable with 1.68 × 10−9 to 1.18 × 10−8 m2 s−1 for mint leaves [31] and 1.07 to 1.31 × 10−9 m2 s−1 for tomato slices [32].

The nature of variation in hht and hmt with time is similar to the change of De and these are estimated for case-A and B, respectively (Fig. 12). The values of hht were in the range of 0–11.57 and 0–10.85 W m−2 K−1, respectively, in case-A and B, respectively. The hmt values were in the range of 0–0.010 and 0–0.0094 m2 s−1 in case-A and B, respectively. The increment in average hht was 4.28% in case-B compared to case-A with values of 5.026 and 5.241 W m−2 K−1 in case-A and B, respectively. The average hmt was 4.36 × 10−3 m s−1 in case-A and in case-B, it was 4.55 × 10−3 m s−1 with an improvement of 4.36%. The estimated hht values were within the range reported by Ndukwu et al. [33] (0.64–10.5 W m−2 K−1 for plantain slices). The range of hmt reported by Lingayat et al. [25] was 0.82 × 10−4–2.85 × 10−3 m s−1 for tomato slices. The values of De, hht and hmt are increased with drying time as moisture is removed continuously till the end of the drying process. In case-A and B, the total drying duration was noted to be 15 h (sunshine) and 16 h (9 sunshine and 7 non-sunshine), respectively. Since the difference in drying duration was low between the two cases and drying duration in case-B is higher, the minimum improvement in De, hht and hmt values was observed in case-B (with TES) compared to case-A (without TES). But the advantage is that case-B dried the product within a day but case-A took two consecutive days.

The Eae was found by Eq. (17) by a linear fit of the ln(De) and 1/T (K). The Eae was found to be 28.61 and 21.49 kJ mol−1 in case-A and B, respectively. The decrement of 24.89% is noticed in Eae in case-B compared to case-A due to constant Ta,dc in case-B. The Eae values reported for various food products from the literature were: ginger slices (35.68 kJ mol−1) [34] and ivy gourd (21.23 to 27.79 kJ mol−1) [35].

Table 4 summarises the performance analysis of IFCSD and drying characteristics of muskmelon slices in both cases. It is observed that ƞdr, DR, SR, hht, hmt and De are increased and Eae and SC are decreased in case-B compared to case-A. This infers that the TES device improved the efficiency and performance of the IFCSD setup since the TES device maintained almost a constant drying cabinet temperature in the afternoon session. Also, the drying duration is lower in case-B. Therefore, it is suggested that the TES can be used in any solar dryer to improve the drying efficiency and reduce the drying duration. Also, the estimated thermal properties in the present analysis will not change in other large or small-scale solar dryers until then the same solar flux and temperatures inside the setup are changed.

Conclusions

The present study conducted experiments on indirect forced convection solar dryer (IFCSD) without (case-A) and with thermal energy storage (TES) device (case-B). Muskmelon slices were used for the sample object. Performance parameters and drying characteristics were evaluated in both cases and the following conclusions were drawn:

-

The average collector efficiency (ηSAC) in case-A and case-B was 66.37% and 67.82%, respectively. The ηSAC did not affect with TES device as it was installed in the drying cabinet.

-

The average ηdr was increased by 48.90% in case-B compared to case-A since drying continued till midnight and was completed within a day in case-B compared to case-A where the drying had taken two successive days.

-

The final MC reached in case-A and case-B was 0.1604 and 0.2108 db, and it was achieved in 15 and 9 sunshine hours, respectively. The energy stored in TES was consumed in 7 non-sunshine hours to reach the final MC in case-B.

-

An increment of 74.19% in specific moisture extraction rate (SR) was in case-B compared to case-A with the values of 0.620 and 1.080 kg kWh−1 in case-A and B, respectively. It showed a higher quantity of MC was removed in case-B for a given input solar radiation. The decrement in specific energy consumption (SC) was 42.56% in case-B compared to case-A since SC is the reciprocal of SR. It proved that lower energy was required to remove the MC from muskmelon slices in case-B.

-

The mean value of the drying rate was 0.817 and 1.258 kg h−1 in case-A and B, respectively, with an improvement of 53.98% in case-B where drying was completed in one day in case-B.

-

Two-term exponential and Page were determined to be the appropriate models for drying characteristics of muskmelon slices in case-A and case-B, respectively.

-

Minimal improvements were noticed in the average effective moisture diffusivity, heat and mass transfer coefficients (2.96%, 4.28% and 4.36%, respectively) in case-B compared to case-A since the drying duration is only 1 h more in case-B compared to case-A and these values mainly depend on air velocity.

Abbreviations

- db:

-

Dry basis

- DR:

-

Drying rate (kg h−1)

- DTSD:

-

Direct type solar dryer

- HTSD:

-

Hybrid type solar dryer

- INCSD:

-

Indirect natural convection solar dryer

- IFCSD:

-

Indirect forced convection solar dryer

- ISD:

-

Indirect solar dryer

- LHS:

-

Latent heat storage

- MC:

-

Moisture content

- MR:

-

Moisture ratio of the product

- MSD:

-

Mixed mode solar dryer

- OSD:

-

Open sun drying

- PCM:

-

Phase change material

- SAC:

-

Solar air collector

- SHS:

-

Sensible heat storage

- TES:

-

Thermal energy storage

- A :

-

Area (m2)

- c pa :

-

Specific heat (J kg−1 K−1)

- D wa :

-

Diffusivity constant of water–air (m2 s−1)

- D apf :

-

Pre-exponential factor

- D e :

-

Effective moisture diffusivity (m2 s−1)

- E ae :

-

Activation energy (kJ mol−1)

- E i,dr :

-

Input energy to the setup (kWh)

- B :

-

Thickness of the sample (m)

- h ht :

-

Heat transfer coefficient (W m−2 K−1)

- h mt :

-

Mass transfer coefficient (m s−1)

- i sr :

-

Intensity of solar radiation (W m−2)

- k :

-

Thermal conductivity (W m−1 K−1)

- LH :

-

Latent heat of evaporation (J kg−1)

- Le :

-

Lewis number

- \({\dot{m}}_{\rm a}\) :

-

Mass flow rate (kg s−1)

- m wv :

-

Quantity of water removed (kg)

- N :

-

Number of experimental values

- n :

-

Coefficient number

- Q :

-

Rate of heat transfer

- R 2 :

-

Coefficient of determination

- R un :

-

Universal gas constant

- SC :

-

Specific energy consumption (kWh kg−1)

- SR :

-

Specific moisture extraction rate (kg kWh−1)

- T :

-

Temperature of air (°C)

- t :

-

Drying period (h)

- V:

-

Volume of the product (m3)

- b 1, b 2…b n :

-

Independent variables

- u 1, u 2…u n :

-

Uncertainties of independent variables

- η :

-

Efficiency (%)

- χ 2 :

-

Reduced Chi-square

- α :

-

Thermal diffusivity of air (m2 s−1)

- amb:

-

Atmosphere

- i:

-

Inlet

- o:

-

Outlet

- da:

-

Drying air

- dr:

-

Drying

- a,dc:

-

Drying cabinet air temperature

- SAC:

-

Solar air collector

- s:

-

Surface area of the product

- a1, a2, a3, a4:

-

Trays from 1 to 4

- wv:

-

Water vapour

References

Sami S, Etesami N, Rahimi A. Energy and exergy analysis of an indirect solar cabinet dryer based on mathematical modeling results. Energy. 2011;36:2847–55. https://doi.org/10.1016/j.energy.2011.02.027.

Reddy Mugi V, Chandramohan VP. Energy, exergy and economic analysis of an indirect type solar dryer using green chilli: a comparative assessment of forced and natural convection. Therm Sci Eng Prog. 2021;24:100950. https://doi.org/10.1016/j.tsep.2021.100950.

Asokapandian S, Venkatachalam S, Swamy GJ, Kuppusamy K. Optimization of foaming properties and foam mat drying of muskmelon using soy protein. J Food Process Eng. 2016;39:692–701. https://doi.org/10.1111/jfpe.12261.

Gopinath GR, Muthuvel S, Muthukannan M, Sudhakarapandian R, Praveen Kumar B, Santhan Kumar C, et al. Design, development, and performance testing of thermal energy storage based solar dryer system for seeded grapes. Sustain Energy Technol Assess. 2022;51:101923. https://doi.org/10.1016/j.seta.2021.101923.

Nimnuan P, Nabnean S. Experimental and simulated investigations of the performance of the solar greenhouse dryer for drying cassumunar ginger (Zingiber cassumunar Roxb.). Case Stud Therm Eng. 2020;22:100745. https://doi.org/10.1016/j.csite.2020.100745.

Cetina-Quiñones AJ, López López J, Ricalde-Cab L, El Mekaoui A, San-Pedro L, Bassam A. Experimental evaluation of an indirect type solar dryer for agricultural use in rural communities: Relative humidity comparative study under winter season in tropical climate with sensible heat storage material. Sol Energy. 2021;224:58–75. https://doi.org/10.1016/j.solener.2021.05.040.

Sain P, Songara V, Karir R, Balan N. Natural convection type solar dryer with latent heat storage. Int Conf Renew Energy Sustain Energy. 2013;8:9–14. https://doi.org/10.1109/ICRESE.2013.6927808.

Kesavan S, Arjunan TV, Vijayan S. Thermodynamic analysis of a triple-pass solar dryer for drying potato slices. J Therm Anal Calorim. 2019;136:159–71. https://doi.org/10.1007/s10973-018-7747-0.

Mohanraj M, Chandrasekar P. Drying of copra in a forced convection solar drier. Biosyst Eng. 2008;99:604–7. https://doi.org/10.1016/j.biosystemseng.2007.12.004.

Nabnean S, Janjai S, Thepa S, Sudaprasert K, Songprakorp R, Bala BK. Experimental performance of a new design of solar dryer for drying osmotically dehydrated cherry tomatoes. Renew Energy. 2016;94:147–56. https://doi.org/10.1016/j.renene.2016.03.013.

Amer BMA, Gottschalk K, Hossain MA. Integrated hybrid solar drying system and its drying kinetics of chamomile. Renew Energy. 2018;121:539–47. https://doi.org/10.1016/j.renene.2018.01.055.

Lakshmi DVN, Muthukumar P, Nayak PK. Experimental investigations on active solar dryers integrated with thermal storage for drying of black pepper. Renew Energy. 2021;167:728–39. https://doi.org/10.1016/j.renene.2020.11.144.

Arun KR, Srinivas M, Saleel CA, Jayaraj S. Active drying of unripened bananas (Musa Nendra) in a multi-tray mixed-mode solar cabinet dryer with backup energy storage. Sol Energy. 2019;188:1002–12. https://doi.org/10.1016/j.solener.2019.07.001.

Deeto S, Thepa S, Monyakul V, Songprakorp R. The experimental new hybrid solar dryer and hot water storage system of thin layer coffee bean dehumidification. Renew Energy. 2018;115:954–68. https://doi.org/10.1016/j.renene.2017.09.009.

Reyes A, Mahn A, Vásquez F. Mushrooms dehydration in a hybrid-solar dryer, using a phase change material. Energy Convers Manag. 2014;83:241–8. https://doi.org/10.1016/j.enconman.2014.03.077.

Chaatouf D, Salhi M, Raillani B, Amraqui S, Mezrhab A. Assessment of a heat storage system within an indirect solar dryer to improve the efficiency and the dynamic behavior. J Energy Storage. 2021;41:102874. https://doi.org/10.1016/j.est.2021.102874.

Yadav S, Chandramohan VP. Performance comparison of thermal energy storage system for indirect solar dryer with and without finned copper tube. Sustain Energy Technol Assess. 2020;37:100609. https://doi.org/10.1016/j.seta.2019.100609.

Pankaew P, Aumporn O, Janjai S, Pattarapanitchai S, Sangsan M, Bala BK. Performance of a large-scale greenhouse solar dryer integrated with phase change material thermal storage system for drying of chili. Int J Green Energy. 2020;17:632–43. https://doi.org/10.1080/15435075.2020.1779074.

Goud M, Reddy MVV, Chandramohan VP, Suresh S. A novel indirect solar dryer with inlet fans powered by solar PV panels: Drying kinetics of Capsicum annum and Abelmoschus esculentus with dryer performance. Sol Energy. 2019;194:871–85. https://doi.org/10.1016/j.solener.2019.11.031.

Akbulut A, Durmuş A. Energy and exergy analyses of thin layer drying of mulberry in a forced solar dryer. Energy. 2010;35:1754–63. https://doi.org/10.1016/j.energy.2009.12.028.

Tagnamas Z, Kouhila M, Bahammou Y, Lamsyehe H, Moussaoui H, Idlimam A, et al. Drying kinetics and energy analysis of carob seeds (Ceratonia siliqua L.) convective solar drying. J Therm Anal Calorim. 2022;147:2281–91. https://doi.org/10.1007/s10973-021-10632-6.

Çakmak G, Yıldız C. The drying kinetics of seeded grape in solar dryer with PCM-based solar integrated collector. Food Bioprod Process. 2011;89:103–8. https://doi.org/10.1016/j.fbp.2010.04.001.

Akpinar EK. Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Convers Manag. 2010;51:2407–18. https://doi.org/10.1016/j.enconman.2010.05.005.

Wang W, Li M, Hassanien RHE, Wang Y, Yang L. Thermal performance of indirect forced convection solar dryer and kinetics analysis of mango. Appl Therm Eng. 2018;134:310–21. https://doi.org/10.1016/j.applthermaleng.2018.01.115.

Lingayat A, Chandramohan VP, Raju VRK, Suresh S. Drying kinetics of tomato (Solanum lycopersicum) and Brinjal (Solanum melongena) using an indirect type solar dryer and performance parameters of dryer. Heat Mass Transf. 2020. https://doi.org/10.1007/s00231-020-02999-3.

Murugavelh S, Anand B, Midhun Prasad K, Nagarajan R, Azariah Pravin Kumar S. Exergy analysis and kinetic study of tomato waste drying in a mixed mode solar tunnel dryer. Energy Sources Part A Recover Util Environ Eff. 2019;20:1–17. https://doi.org/10.1080/15567036.2019.1679289.

Jain D, Tewari P. Performance of indirect through pass natural convective solar crop dryer with phase change thermal energy storage. Renew Energy. 2015;80:244–50. https://doi.org/10.1016/j.renene.2015.02.012.

Shalaby SM, Bek MA. Experimental investigation of a novel indirect solar dryer implementing PCM as energy storage medium. Energy Convers Manag. 2014;83:1–8. https://doi.org/10.1016/j.enconman.2014.03.043.

Bena B, Fuller RJ. Natural convection solar dryer with biomass back-up heater. Sol Energy. 2002;72:75–83. https://doi.org/10.1016/S0038-092X(01)00095-0.

Abubakar S, Umaru S, Kaisan MU, Umar UA, Ashok B, Nanthagopal K. Development and performance comparison of mixed-mode solar crop dryers with and without thermal storage. Renew Energy. 2018;128:285–98. https://doi.org/10.1016/j.renene.2018.05.049.

Eltawil MA, Azam MM, Alghannam AO. Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). J Clean Prod. 2018;181:352–64. https://doi.org/10.1016/j.jclepro.2018.01.229.

Sacilik K, Keskin R, Elicin AK. Mathematical modelling of solar tunnel drying of thin layer organic tomato. J Food Eng. 2006;73:231–8. https://doi.org/10.1016/j.jfoodeng.2005.01.025.

Ndukwu MC, Diemuodeke EO, Abam FI, Abada UC, Eke-emezie N, Simo-Tagne M. Development and modelling of heat and mass transfer analysis of a low-cost solar dryer integrated with biomass heater: application for West African Region. Sci African. 2020;10:e00615. https://doi.org/10.1016/j.sciaf.2020.e00615.

Thorat ID, Mohapatra D, Sutar RF, Kapdi SS, Jagtap DD. Mathematical modeling and experimental study on thin-layer vacuum drying of ginger (Zingiber officinale R.) Slices. Food Bioprocess Technol. 2012;5:1379–83. https://doi.org/10.1007/s11947-010-0429-y.

Elangovan E, Natarajan SK. Effects of pretreatments on quality attributes, moisture diffusivity, and activation energy of solar dried ivy gourd. J Food Process Eng. 2021;44:1–14. https://doi.org/10.1111/jfpe.13653.

Acknowledgements

The financial support given by Mechanical Engineering Department, NIT Warangal is highly appreciated. The ref no: NITW/MED/Head/2015/408 dated 3 Dec. 2015.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Vishnuvardhan Reddy Mugi, Mulatu C. Gilago and Chandramohan V.P. The first draft of the manuscript was written by Vishnuvardhan Reddy Mugi and Mulatu C. Gilago. The supervision, revision and manuscript correction were done by Chandramohan V.P. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mugi, V.R., Gilago, M.C. & Chandramohan, V.P. Performance studies on indirect forced convection solar dryer without and with thermal energy storage during drying muskmelon slices. J Therm Anal Calorim 148, 9201–9216 (2023). https://doi.org/10.1007/s10973-023-12120-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12120-5