Abstract

In this work, the pyrolysis characteristics and release of sulphur contaminant were studied under different mass percentages (25%, 50% and 75%) of Zhundong coal in the sample mixtures. The results showed that the yields of volatile products during co-pyrolysis were higher than those calculated from linear combination of corresponding yields of pure sludge and Zhundong coal, which mean that a certain synergistic effect occurs in co-pyrolysis process. The yields of H2S, COS and SO2 decreased with the increase in the content of Zhundong coal in the samples. What’s more, when the content of Zhundong coal were 50%, a great significance on the yields of sulphur contaminant occurs in the process of co-pyrolysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The output of sewage sludge has increased with the increase in the process of urbanization. Due to this reason, the resource utilization of sludge has become a research focus and developmental trend as it treats and disposes of the sludge [1]. Sludge usually has relatively low calorific value, performs poorly if combusted independently, sludge pyrolysis technology has attracted much research attention for reasons of harmless treatment while fully reclaiming the energy from sludge effectively [2, 3]. China has abundant coal reserves including the largest integrated coal field, namely the Zhundong coal field, which produces coal having advantages, such as low ignition point and high burnout rate [4, 5]. However, such a coal contains comparatively higher amounts of alkali and alkaline earth metals, including Na, K and Ca [6], which not only tend to sublimate and condense, but may also produce low temperature eutectic mixtures after reacting with Si, and Al that cause issues such as slagging in furnace and contamination of heating surface [7]. In addition, these problems severely restrict the large-scale application of this coal. As a clean coal utilization technology, pyrolysis technology is capable of substantially reducing the content of water-soluble sodium in the Zhundong coal [8]. Due to this reason, the technology has gradually become an important means potential commercial use of the Zhundong coal.

Sludge usually is rich in sulphur contaminant content, complex chemical reaction happens and release amount of sulphur contaminant during the pyrolysis process, such as H2S, COS, SO2 which will cause serious contamination [9]. The sulphur of sludge consists of sulphide, sulphate and organic sulphur, mainly on organic sulphur [10], and the release of H2S during the pyrolysis is in the temperature ranges of 200–400 °C, the release of SO2 during the pyrolysis is mainly concentrated in two mutually independent temperature stages, these temperatures stages consist of 200–300 °C and 400–600 °C [10]. Zhang et al. [11] found that Ca, Mg have an inhibitory effect on the release of H2S, SO2, also the research result of Folgueras and Díaz [12] shows that FeCl3 mixed with CaO can inhibit the release of sulphur-bearing gas.

On one hand, catalysis of metals can improve the sludge’s pyrolysis characteristics during the co-pyrolysis of sludge and Zhundong coal, and hence, achieve an effective utilization of solid waste. On the other hand, the emissions of sulphur contaminant can also be controlled. Chang et al. [13] found that, in comparison with the individual material, a mixture of coal and sludge is more suitable for pyrolysis, and that there exists a synergistic effect for the mixture to a certain extent. Xiao et al. [14] conducted thermogravimetric tests on pure coal, pure sludge and a mixture of the two in an inert atmosphere and found that the co-pyrolysis of coal and sludge can reduce the activation energy required for the chemical reaction and promote the pyrolysis reaction. While researching the pyrolysis of high-volatile bituminous coal and its mixture with sludge using thermogravimetric analyser, Folgueras et al. [15, 16] found that the pyrolysis behaviour of the mixture of sludge and coal lies between that of the pure coal and pure sludge. Meanwhile, they [15, 16] also found that the sludge has higher reactivity than coal, and the temperature at which it devolatilizes is also lower than that of the coal. At present, only a handful of studies have focused on the co-pyrolysis of sludge and Zhundong coal (which contains comparatively higher amount of metals). In particular, the formation of sulphur contaminant, such as H2S, COS and SO2 during the co-pyrolysis process, and their corresponding control mechanisms have not yet been reported in the literature, and therefore require further research.

In this paper, thermogravimetric, differential scanning calorimetry and mass spectrometry (TG–DSC–MS), inductively coupled plasma optical emission spectroscopy (ICP–OES), in situ diffuse reflectance infrared Fourier transform spectroscopy (in situ DRIFTS) and other experimental techniques were employed to study the co-pyrolysis characteristics of sludge mixed with Zhundong coal, the release characteristics of sulphur contaminant such as H2S, COS and SO2 during the pyrolysis process. The results are of great significance in understanding the emission mechanism of sulphur contaminant during the co-pyrolysis of sludge mixed with Zhundong coal, and also contribute towards theoretically exploring an effective way of using sludge.

Experimental

Materials

Zhundong coal was obtained from the Xinjiang Uygur Autonomous Region, whereas the primary sludge was produced at Shanghai Songshen Water Environment Purification Co., Ltd., China. All the samples are prepared according to the ASTM Standards (D 2013-72). Tables 1 and 2 show their industrial analysis, elemental analysis and ash composition analysis. Prior to experiments, Zhundong coal and sludge were mixed in an even proportion and dried to a constant mass in N2 atmosphere. After being ground, standard sample sieve of 0.18 mm was used to screen the mixture. The mass percentages of Zhundong coal in the mixture were adjusted to 0% (pure sludge), 25%, 50%, 75% and 100% (pure Zhundong coal). For the convenience of discussion, these mixed samples were marked as coal 0, coal 25, coal 50, coal 75 and coal 100, respectively. In this nomenclature, the word “coal” stands for Zhundong coal, while the number represents the mass percentage of Zhundong coal in the mixture, the quality of each test sample is 10 mg.

Methods

The release of sulphur contaminant from sludge, Zhundong coal and mixed samples (of sludge and Zhundong coal) in the process of pyrolysis was studied by thermogravimetric analysis and mass spectrometry (TG–MS). The STA 449C type TG obtained from NETZSCH-Gerätebau GmbH, Germany, and QMS 403 type MS obtained from the same supplier were used for the analyses of samples. During the experiments, the transfer line between the TG and MS was heated such that the temperature difference between the exit of TG and the entrance of MS was maintained at values of 220 °C, 240 °C and 260 °C to prevent the condensation of volatile products. Furthermore, a constant mass of samples was taken, which were then placed in the Al2O3 crucible of the thermogravimetric analyser. Then, the system was purged using high purity (99.999%) argon. The purging process was repeated more than 3 times. Afterwards, procedural heating kicked off when the signal of mass spectrometer became stabilized and online recording of the data was initiated. The volumetric flow rate of argon was set to be 50 mL min−1, whereas the heating rate was set to be 20 °C min−1 in the temperature range of 50–900 °C. Also, prior to experiments, mass and temperature calibrations were performed for TG–MS system, and all of the results have been dealt with normalization correction. During the experiments, ICP-OES obtained from Teledyne Technologies Inc., USA, was used for qualitative and quantitative elemental analyses of the Zhundong coal. The chemical structure and functional groups on the surface of the pyrolysis coke were determined using in situ DRIFTS (Nicolet iS50) purchased from Thermo Fisher Scientific Pty., Ltd., USA. In addition, for these experiments, the heating rate of the solid in situ pool was set to be 20 °C min−1 within the temperature range of 30–650 °C. The type of detector used was MTC/A, which was cooled by liquid nitrogen to improve the signal–noise ratio. All the samples were scanned for sixteen times with a resolution of 4 cm−1, whereas the same atmosphere was used as in the TG–MS experiments. Each group of experiments was repeated three times under the same conditions to ensure accuracy of the obtained experimental data.

Results and discussion

Analyses of pyrolysis and co-pyrolysis processes

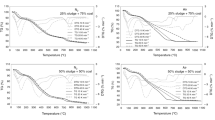

Figures 1, 2 and 4 show the TG curve, DTG curve and DSC curve of five samples which underwent the process of pyrolysis, and the data of pyrolysis characteristics are given in Table 4. Figure 3 shows the in situ DRIFTS of Zhundong coal and sludge, while each underwent a separate, individual pyrolysis. The analysis of various functional groups shown in the spectra can be analysed according to relevant literature [17,18,19] and is given in Table 3.

The TG curve shows that the rate of mass loss in the samples increases with the increase in the mass percentage of sludge. The DTG curve for the separate pyrolysis of Zhundong coal shows that there were two distinct mass loss stages between the temperatures of 50 °C and 900 °C. The first stage occurred during the drying and degasification stage (50–240 °C), wherein a big-span absorption peak was observed in the infrared spectra which corresponded to the stretching vibration of O–H. The absorption peak obviously declined as the temperature increased, whereas no distinct change was observed in the absorption peaks located in other vibration frequency ranges. This indicates the necessity of dehydrating coal and removing the physically adsorbed gases, including CO2 and N2. Additionally, a distinct absorption peak was observed in the corresponding DSC curve for this stage. The absorption peak matched with the temperature corresponding to DTG curve’s mass loss peak. The second stage lied between the temperatures of 300 °C and 600 °C and was the main pyrolysis stage of the coal. The infrared spectra of the stage shows that the stretching vibration peak of aliphatic C–H continued to decline, while that of the aromatic C–H and C=C (i.e. the skeletal vibration of benzene ring) slightly enhanced after first declining. This indicates that continuous fracture, reforming and polycondensation with the coal matrix macromolecule occurred during this stage. Meanwhile, the stretching vibration peak of both C=O in carbonyl and C–OH in carboxylic acid continuously weakened as the temperature increased, indicating that the variation of functional groups also occurred during this stage which released the pyrolysis gases mainly in the form of CH4, CO2, CO and tar that formed the semi-coke. Additionally, at this stage, the TG curve dropped sharply, whereas the peak value of the DTG curve was observed to be lying around the temperature of 480 °C, where a large-span absorption curve was observed in the DSC curve. The pyrolysis temperature of sludge mainly lied within the range of 120–600 °C, whereas the infrared spectra showed that the stretching vibration peak of aliphatic C–H was distinctively larger than that of the aromatic C–H. In addition, the stretching vibration peak of C–O–C (ether bond) declined as the temperature increased. This, with the fact that the macromolecular structure of sludge mainly combines through ether bond [20], indicates comparatively lower degree of aromatization of sludge, which is relatively low in binding energy, high in reactivity and is more prone to undergo pyrolysis. Meanwhile, with the increase in temperature, there were distinct changes in the stretching vibration peaks of O–H in hydroxyl, C=O in carbonyl, C–OH in carboxylic acid, C=O and C–N in amide and other functional groups containing O and N in the sludge. This indicated that the pyrolysis of sludge turned out to be a process where old bonds fractured, volatized and eventually, new bonds recombined and formed. This stage is mainly about the decomposition of organics and emissions of volatile content with the largest gas production. The corresponding DSC curve of the stage shows a significant heat-absorption effect, and reaches the highest rate of mass loss at 288 °C. Since the sludge is rich in organics such as protein, carbohydrate and lipids [3], and the chemical bonds of each component are weak, it is more prone to undergo pyrolysis and generate macromolecular condensable matter (such as the aliphatic hydrocarbon), and some small molecule gases including H2, CO2, CH4, C2 and C3 [21]. Compared to the Zhundong coal, its pyrolysis temperature corresponding to the highest rate of mass loss increased substantially. Additionally, the aromatic nucleus, which acts as the basic structural unit of coal, possesses a higher degree of condensation, has relatively stable chemical bonds, and has the pyrolysis temperature corresponding to the highest rate of mass loss which actually lags behind that of the sludge (Table 4).

Figure 4 shows that the co-pyrolysis process mainly consists of two effects, namely the endothermic and exothermic. Among these effects, the endothermic effect plays the major role in the whole pyrolysis process. There is a significant difference between different mixing ratios on the peak temperature and peak shape corresponding to the DSC curve. Compared with independent separate pyrolysis, the DSC curve of co-pyrolysis shows less fluctuations, which indicates that the Zhundong coal mixes very well with the sludge and that they are undergo copolymerization and co-fusion with relative ease. During the high temperature stage, an exothermic peak with a larger span occurred in the DSC curve of the pyrolysis of coal due to the polycondensation. With the increase in the Zhundong coal in the mixed samples, temperature corresponding to the exothermic peak increased slightly, and the area covered was reduced to a certain extent. This was mainly caused by the presence of sludge, which weakened the polycondensations (such as aromatization) of Zhundong coal, enhanced the activity of semi-coke and hindered the carbonization process. Analysis of the whole DSC curve reveals that, instead of the simple superposition of separate pyrolysis processes (of coal and sludge), complex heat transfer occurred due to the endothermic and exothermic reactions during the co-pyrolysis process. That is to say, the interaction occurred in the process of co-pyrolysis, which led to their complex endothermic and exothermic behaviours.

A comparison of the DTG curves of Zhundong coal and sludge shows that the pyrolysis curve of mixture at low temperature (from 120 to 400 °C) is similar to that of the sludge, whereas at high temperature (from 400 to 600 °C), it is similar to that of the Zhundong coal. Therefore, it can be concluded that the co-pyrolysis of Zhundong coal and sludge at lower temperatures is mainly dominated by the sludge pyrolysis, whereas at higher temperatures, it is mainly dominated by the pyrolysis of Zhundong coal. The peak value of DTG curve of Zhundong coal occurred around 480 °C, and corresponding temperature was substantially increased as the mass percentage of sludge in the sample increased, thus indicating that the activity of pyrolysis after mixing was greatly enhanced. To confirm whether there exists any synergistic effect after sample mixing and whether this is good for the release of volatile products, a comparison can be made between the experimental values measured from the volatile products and the solid products of sample generated in the overall pyrolysis process using theoretical values calculated using the weighted average method. The method used to make the calculations is represented by Eqs. (1) and (2), and the results are shown in Fig. 5.

where Vt represents the content of volatile products generated from the co-pyrolysis of sludge and Zhundong coal as calculated using the weighted average method (%), St represents the content of solid products generated from the co-pyrolysis of sludge and Zhundong coal as calculated using the weighted average method (%), Vs represents the content of volatile products generated from the individual pyrolysis of sludge in thermogravimetric experiment (%), Ss represents the content of solid products generated from the individual pyrolysis of sludge in thermogravimetric experiments (%), Vc represents the content of volatile products generated from individual pyrolysis of Zhundong coal in thermogravimetric experiments (%); Sc represents the content of solid products generated from individual pyrolysis of Zhundong coal in thermogravimetric experiments (%), Pi represents the mixing ratio of sludge and Zhundong coal, V represents the content of volatile products generated from the co-pyrolysis of sludge and Zhundong coal in thermogravimetric experiments (%), and S represents the content of solid products generated from the co-pyrolysis of sludge and Zhundong coal in thermogravimetric experiments (%).

As can be seen in Fig. 5, as the mass percentage of sludge in the sample increases, volatile products generated throughout the complete pyrolysis process gradually increase, though the solid products gradually decrease with the increase in the mass percentage of sludge in the mixed samples. This is mainly due to the fact that sludge is comparatively rich in organics (such as protein, fat and fibre) and has a production rate of volatile matter which is 1.9 times that of the Zhundong coal. In addition, the experimental values for the variation trend of pyrolysis products is basically consistent with those of the theoretical values calculated using the weighted average method. However, the experimental values for the amount of volatile products released in the co-pyrolysis are substantially higher than the calculated theoretical values for the individual pyrolysis under the same mixing ratio. The experimental values for the solid products are substantially smaller than the calculated theoretical values for individual pyrolysis under the same mixing ratio. This indicates a synergistic effect between them and that the co-pyrolysis is good for releasing the volatile products. Additionally, the synergistic effect is the strongest at the mixing ratio of 75%. This is mainly due to the reason that there are comparatively larger amounts of fibre and semi-fibre in the sludge, and the high H/C ratio provides the pyrolysis of Zhundong coal with large amounts of hydrogen donors [22, 23]. In addition, coal, as a stabilizer of radicals, is a hydrogen deficient substance; therefore, the participation of hydrogen reduces the opportunity of metaplast solidification of Zhundong coal and polycondensation of radicals [24]. Furthermore, as the mixing ratio increases, sludge offers more and more hydrogen donors, which is more advantageous for increasing the conversion rate of co-pyrolysis [25]. Meanwhile, metal elements including Na, K, Ca and Fe contained in Zhundong coal play the role of a catalyst in the co-pyrolysis process, which reduces the aromatic compounds, increases the aliphatic compounds, promotes the release of volatile products and reduces the generation of semi-coke.

Release of sulphur contaminant in the pyrolysis process

As the sulphur in the sludge is far more than that in the Zhundong coal, the productivity of sulphur contaminant in individual pyrolysis is also far higher than that of the Zhundong coal. The sulphur contaminant are produced by the decomposition of protein (organic sulphur) and inorganic sulphate in the sludge. Since the organic sulphur is unstable and easily decomposed,the reaction begins at a lower temperature, and inorganic sulphates are stable, the decomposition occurs at a higher temperature [26]. Figure 6 shows the release of sulphur contaminant in the pyrolysis process of samples. Among them, M/Z = 34 stands for H2S, M/Z = 60 for COS and M/Z = 64 for SO2 [27].

Figure 6a shows the release process of H2S, which started from 200 °C and continued to 600 °C during the pyrolysis of sludge, with the fastest release rate at 320 °C. The temperature stage of the release of H2S is single, and H2S is mainly produced from the decomposition of organic [28]. In the temperature range from 200 to 280 °C, the break of carbon chain and the decomposition of the unstable aliphatic sulphur compound lead to the generation of H radicals. Moreover, the formed H radicals attack S–S bond and S–C bond of sulphide in protein to make them break, which recombine the formed H radicals to form H2S [29]. It may also be possible that organic sulphur like thioether, disulphide, aliphatic mercaptan, and aromatic disulphide converted to produce H2S [30]. With the increase in the mixing ratio of Zhundong coal, the release of H2S gradually decreased, and when the mixing ratio of Zhundong coal is 50%, the productivity of H2S decreased sharply.

As can be seen in Fig. 6b, the release of COS during the pyrolysis of sludge started from 170 °C. With the increase in the pyrolysis temperature, the release of COS gradually increased, and the fastest release rate was at 300 °C. Then, the release gradually slowed down and stopped at around 800 °C. COS comes from the reaction of H2S and CO, H2S and CO2; it also comes from the reaction among S/SH reactive groups produced during the pyrolysis of some organic sulphides, oxygen-containing functional groups in the coke and active carbon atoms [31]. Meanwhile, the reaction between FeS2 and CO in the sludge and Zhundong coal produces a small amount of COS, which has little effect on the overall release [32]. Comparing the results in Fig. 6a, b, it can be seen that the trend of generation curve of COS was similar to the H2S, which indicates that the release of COS during the process mainly comes from the conversion of H2S. During the co-pyrolysis process of sludge mixed with Zhundong coal, the release of COS was reduced. The impact on the reduction in COS release was obviously when the mixing ratio of Zhundong coal was 50%.

As can be seen in Fig. 6c, the peak corresponding to the release of SO2 in individual pyrolysis of sludge mainly concentrated in two mutually independent temperature stages, which ranged from 100 to 270 °C and 400 to 800 °C. In the low temperature range, the release of SO2 happened in the reaction of the S/SH active group in the sulphur organic compounds with the oxygen-containing functional group in the char [29]. Then, some inorganic sulphates participated in the pyrolysis reaction were decomposed to release SO2 [33]. With the addition of Zhundong coal, the release of SO2 gradually decreased, and the release of SO2 reduced most apparently when the mixing ratio is 50%.

With the addition of Zhundong coal, the release of sulphur contaminant reduced. The release of three substances decreased sharply when the mixing ratio was 50%. On the one hand, the reduction in the release of sulphur contaminant might due to the fact that a large amount of metal elements in Zhundong coal, which not only promote the pyrolysis process, but also contribute to the fixation of sulphur. On the other, it was due to the lower sulphur content in the Zhundong coal. Adding Zhundong coal inevitably leads to the reduction in the total release of Sulphur contaminant.

In order to further understand the influence of the co-pyrolysis of sludge and Zhundong coal on the release of sulphur contaminant, the experimental results generated from the pyrolysis of various substances compared with the theoretical results calculated from the weighted average method. It is shown in Fig. 7 that the black is the theoretical value and the red is the experimental value. The method is represented by Eqs. (3), (4) and (5):

where X1 represents the experimental value of sulphur contaminant generated from pure sludge, X2 represents the experimental value of sulphur contaminant generated from pure Zhundong coal, and C0.25, C0.5 and C0.75 represents the theoretical value of the release of sulphur contaminant, respectively, when the addition ratio of Zhundong coal is 25%, 50% and 75%.

Figure 7 shows that when the mixing ratio of Zhundong coal reached 25%, 50% and 75%, the experimental values of the release of H2S, COS and SO2 were less than the theoretical value, and the experimental values were much less than the theoretical value when the mixing ratio reached 50%. The result indicates that the co-pyrolysis of sludge mixed with Zhundong coal has an inhibitory effect on the release of sulphur contaminant [10], especially when the ratio of Zhundong coal reached 50%. It might be due to the metal elements in the Zhundong coal, including K, Na, Ca, Mg, Fe, which promote the conversion of volatile S-containing compounds into thermally stable and non-removable S-containing compounds [34, 35]. During this process, some volatile sulphur enter the char, resulting in the reduction in the release of sulphur contaminant.

Conclusions

In this work, characteristics of pyrolysis and the release of sulphur contaminant were investigated though pyrolysis experiments of Zhundong coal, sludge and their blends based on the TG–DSC–MS and in situ DRIFTS techniques. The following conclusions can be drawn from this work.

-

1.

In comparison with the Zhundong coal, the chemical bonds of macromolecular structure in the sludge had less binding energy and high reactivity, thus the sludge was easily pyrolysed. In the co-pyrolysis process, the sludge pyrolysis dominated at low temperatures, while Zhundong coal at high temperatures. Furthermore, the sludge enhanced the activity of semi-coke in Zhundong coal and hindered the carbonization process.

-

2.

The experimental values of the amount of the volatile matters released in the co-pyrolysis process were substantially larger than the theoretical values calculated in the individual pyrolysis process under the same mixing ratio. However, the experimental values of the solid products were substantially smaller than the theoretical values calculated in the individual pyrolysis process under the same mixing ratio, which indicating a synergistic effect between the two materials. It is also concluded that the co-pyrolysis is beneficial for releasing the volatile products. With the increase in the mixing ratio, the synergistic effect became increasingly obvious.

-

3.

The release of H2S, COS and SO2 happened during the pyrolysis process of sludge, and the co-pyrolysis with Zhundong coal has obvious inhibition effect on the release of sulphur contaminant during the co-pyrolysis process. Additionally, when the mixing ratio was 50%, the inhibitory effect of sulphur contaminant was most obviously.

References

Mills N, Pearce P, Farrow J, et al. Environmental & economic life cycle assessment of current & future sewage sludge to energy technologies. Waste Manag. 2014;34(1):185–95.

Wang Z, Gong Z, Wang Z, et al. A TG–MS study on the coupled pyrolysis and combustion of oil sludge. Thermochim Acta. 2018;663:137–44.

Chen J, Mu L, Jiang B, et al. TG/DSC-FTIR and Py-GC investigation on pyrolysis characteristics of petrochemical wastewater sludge. Bioresour Technol. 2015;192:1–10.

Xu J, Yu D, Fan B, et al. Characterization of ash particles from co-combustion with a Zhundong coal for understanding ash deposition behavior. Energy Fuels. 2013;28(1):678–84.

Yao Y, Jin J, Liu D, et al. Evaluation of vermiculite in reducing ash deposition during the combustion of high-calcium and high-sodium Zhundong coal in a drop-tube furnace. Energy Fuels. 2016;30(4):3488–94.

Wang Y, Jin J, Liu D, et al. Understanding ash deposition for Zhundong coal combustion in 330 MW utility boiler: focusing on surface temperature effects. Fuel. 2018;216:697–706.

Tabakaev RB, Astafev AV, Dubinin YV, et al. Autothermal pyrolysis of biomass due to intrinsic thermal decomposition effects. J Therm Anal Calorim. 2018;134(2):1045–57.

Ozgur E, Miller BG, Miller SF, Kok MV. Thermal analysis of co-firing of oil shale and biomass fuels. Oil Shale. 2012;29:190–201.

Yang N, Guo H, Liu F, et al. Effects of atmospheres on sulphur release and its transformation behavior during coal thermolysis. Fuel. 2018;215:446–53.

Jayaraman K, Kok MV, Gokalp I. Pyrolysis, combustion and gasification studies of different sized coal particles using TGA–MS. Appl Therm Eng. 2017;125:1446–55.

Zhang Y, Liang P, Jiao T, et al. Effect of foreign minerals on sulphur transformation in the step conversion of coal pyrolysis and combustion. J Anal Appl Pyrolysis. 2017;127:240–5.

Folgueras MB, Díaz RM. Influence of FeCl3 and lime added to sludge on sludge-coal pyrolysis. Energy. 2010;35(12):5250–9.

Chang F, Wang Q, Wang K. Thermogravimetric characteristics and kinetic analysis of co-pyrolysis of sewage sludge and coal. Chin J Environ Eng. 2015;9:2412–8.

Xiao P, Xu L, Wang X, et al. Co-pyrolysis characteristics of coal and sludge blends using thermogravimetric analysis. Environ Prog Sustain Energy. 2016;34(6):1780–9.

Kok MV, Ozgur E. Characterization of lignocellulose biomass and model compounds by thermogravimetry. Energy Sources. 2017;39(2):6.

Folgueras MB, Díaz RM, Xiberta J, et al. Thermogravimetric analysis of the co-combustion of coal and sewage sludge. Fuel. 2003;82(15):2051–5.

Weng SF. Fourier transform infrared spectrum analysis. 2nd ed. Beijing: Chemical Industry Press; 2010.

Domínguez A, Menéndez JA, Inguanzo M, et al. Production of bio-fuels by high temperature pyrolysis of sewage sludge using conventional and microwave heating. Bioresour Technol. 2006;97(10):1185–93.

Jayaraman K, Kok MV, Gokalp I. Combustion properties and kinetics of different biomass samples using TG–MS technique. J Therm Anal Calorim. 2017;127(2):1361–70.

Zhu K, Chen L, Ma A, Huang G. Study on the pyrolysis characteristics and kinetics of biomass of the biomass and coal. J Agric Mech Res. 2010;32:202–6.

Domínguez A, Menéndez JA, Pis JJ. Hydrogen rich fuel gas production from the pyrolysis of wet sewage sludge at high temperature. J Anal Appl Pyrolsis. 2006;77(2):127–32.

Li Z, Xu S, Wei Z, et al. Co-pyrolysis of biomass and coal in a free fall reactor. Fuel. 2007;86(3):353–9.

Zhu X, He Q, Hu Y, et al. A comparative study of structure, thermal degradation, and combustion behavior of starch from different plant sources. J Therm Anal Calorim. 2018;132(2):1–9.

Kok MV, Ozgur E. Thermal analysis and kinetics of biomass samples. Fuel Process Technol. 2013;106(2):739–43.

Cai Z, Ma X, Fang S, et al. Thermogravimetric analysis of the co-combustion of eucalyptus residues and paper mill sludge. Appl Therm Eng. 2016;106:938–43.

Jia X, Wang Q, Cen K, et al. Sulphur transformation during the pyrolysis of coal mixed with coal ash in a fixed bed reactor. Fuel. 2016;177:260–7.

Wang X, Wang X, Xu S, Xu W, Tan H. Release characteristics of N/S/Cl species during pyrolysis of biomass and coal. J China Coal Soc. 2012;37:426–31.

Weng H, Dai Z, Ji Z, et al. Release and control of hydrogen sulfide during sludge thermal drying. J Hazard Mater. 2015;296:61–7.

Liu S, Wei M, Qiao Y, et al. Release of organic sulphur as sulphur-containing gases during low temperature pyrolysis of sewage sludge. Proc Combust Inst. 2015;35(3):2767–75.

Zhang J, Zuo W, Tian Y, et al. Release of hydrogen sulfide during microwave pyrolysis of sewage sludge: effect of operating parameters and mechanism. J Hazard Mater. 2017;331:117.

Xu L, Yang J, Li Y, et al. Behavior of organic sulphur model compounds in pyrolysis under coal-like environment. Fuel Process Technol. 2004;85(8–10):1013–24.

Baruah BP, Khare P. Pyrolysis of high sulphur Indian coals. Energy Fuels. 2007;21(6):3346–52.

Liu H, Zhang Q, Hu H, et al. Dual role of conditioner CaO in product distributions and sulphur transformation during sewage sludge pyrolysis. Fuel. 2014;134(9):514–20.

Karaca S. Desulphurization of a Turkish lignite at various gas atmospheres by pyrolysis. Effect of mineral matter. Fuel. 2003;82(12):1509–16.

Wang Baofeng, et al. Effect of some natural minerals on transformation behavior of sulphur during pyrolysis of coal and biomass. J Anal Appl Pyrolsis. 2014;105(6):284–94.

Acknowledgements

This work was supported by Key Project in Fundamental Research of Science and Technology Commission of Shanghai Municipality (Grant No. 14JC1404800).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, B., Jin, J., Li, S. et al. Co-pyrolysis characteristics of sludge mixed with Zhundong coal and sulphur contaminant release regularity. J Therm Anal Calorim 138, 1623–1632 (2019). https://doi.org/10.1007/s10973-019-08300-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08300-x