Abstract

The present study reports the results of investigation on the role of metakaolin in the formation of ettringite in a model relevant to Portland cement. The model consists of ternary system (Trio) metakaolin–lime–gypsum. Five samples of defined ternary system were cured at different temperatures 20, 30, 40, 50 and 60 °C. Conduction calorimeter TAM AIR was mainly used to capture heat evolution at different temperatures. Thermoanalytical (simultaneous TGA/DSC) and X-ray diffraction methods were used to identify different products after curing. It results that ettringite is the main hydration product supplemented by calcium silicate and calcium aluminosilicate hydrates according to sample composition. The mechanism and kinetics of hydration, as displayed by calorimetric curves, depend on composition of samples and curing temperatures. Two main types of processes have been elucidated: reaction of aluminum ions with sulfate ones in the presence of calcium ions in aqueous solution to form ettringite supplemented by pozzolanic activity leading to the formation of calcium silicate and calcium aluminosilicate hydrates. Concomitant condensation of alumina and silica species and carbonation have influenced the course of hydration. Activation energy E a depends slightly on composition of ternary system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Metakaolin (Al2Si2O7–Al2O3·2SiO2 or AS2) is largely used as supplementary cementitious materials to replace partially Portland cement or to produce geopolymers [1,2,3,4,5,6]. It is obtained by calcination of clay rich in kaolinite at temperature between 500 and 800 °C [7, 8]. Keeping in mind the chemical point of view, metakaolin is a pozzolanic material which reacts with calcium hydroxide released during hydration of Portland cement (PC) to form additional cementitious binders [4,5,6,7,8]. An additional or specific hydration heat due to the exothermic effect of the pozzolanic reaction is generated. With the concept that metakaolin is a thermally activated amorphous aluminosilicate compounds, much of studies [1,2,3,4,5,6, 9, 10] have reported that calcium silicate hydrate (CSH) and calcium aluminosilicate hydrates (C2ASH8) are the main (sometimes the only) products resulting from the alkali activation of pozzolanic metakaolin. It was demonstrated that the use of MK can perform durability and pore refinement of mortars or concretes [3, 8,9,10,11], particularly during the early period of curing. In this case, MK acts as both filler and reactive micro-aggregate depending on calcining temperatures, clay types and relative particle size. Hydration reactions of cements containing MK are more complex chemical and physical processes. The complexity of this processes resists in the fact that firstly hydrolysis of calcium silicate and calcium aluminate phases from Portland cement must take place, generating calcium hydroxide (CH) to ensure alkaline environment responsible for activation and pozzolanic reaction of MK [1, 2, 5].

As MK is a source of both alumina and silica ions, the formation of non-crystalline calcium silicate hydrate in solution can be evidenced by following pozzolanic reactions (Eqs. 1–2):

where x is the ratio C/S or CaO/SiO2.

Likewise, the precipitation of calcium aluminosilicate hydrates runs via the following equation

The formation of non-crystalline products depends mainly on the AS2/CH ratio and reaction temperature [1, 2, 12].

With regard to \({\text{Al}}\left( {\text{OH}} \right)_{4}^{ - }\) resulting from hydrolysis of MK, ettringite formation (Eq. 3) is possible according to the following reaction:

where \(\bar{\text{S}}\) = SO3, C = CaO, A = Al2O3, H = H2O.

MK is more soluble than C3A; rapid MK-ettringite is formed rather than C3A-ettringite during the hydration of PC. This reaction consumes gypsum together with calcium hydroxide resulted from C3S or C2S hydrolysis.

From the literature dealing with silicate chemistry [13,14,15], ettringite is one of the main hydration products of Portland formed at sooner period between C3A and gypsum according to Eq. 4

It is also precipitated during the hydration of sulfoaluminate belite cement by reaction between Klein’s compound and gypsum [15,16,17,18,19]

In alkaline environment, calcium hydroxide can also participate in the formation of ettringite via Eq. 6

The possible formation of ettringite in a cement blend containing MK can be resumed by following equation using silicate symbols

while the first three reactions of ettringite formation (Eqs. 4–6) were extensively investigated because of their importance in PC and SAB hydration, the last one was scarcely studied as a hypothetic reaction in blend cements with aluminosilicate compounds. Our recent works [20,21,22,23] and also other studies [24] on early hydration of ternary PC–BFS–MK blends have determined the important role of MK in the formation of rapid ettringite (due to the activity of Al3+) when gypsum and calcium hydroxide are present. When calcium hydroxide, gypsum and metakaolin are abundant in aqueous solution, ettringite formation cannot be neglected, as it affects the content of gypsum as set regulator of Portland cement. For this purpose, Palou et al. have proposed additional gypsum to the blend containing MK in order to balance sulfate/aluminate ratio. The primordial role of ettringite formation during Portland cement hydration is to hinder the fast reaction of C3A allowing thus a relative enough time for mortar or concrete preparation and for the transport and deposit on working site.

The exothermic hydration of pure or blended cements can be successfully studied by means of calorimeter that provides useful information on the evolution of heat flow and hydration heat, and the results can be exploited to characterize the kinetics and mechanism of reaction. The influences of factors such as temperature, admixtures, fineness upon the hydration kinetics and mechanism were successfully investigated by using calorimeter [25,26,27,28,29,30]. Therefore, a lot of types of commercial and laboratory-developed calorimeters were used to record the temperature of hydration (adiabatic or semi-adiabatic calorimeter) or heat flow (isothermal or conduction calorimeter) [28, 31]. Then, heat evolution and total hydration heat are obtained by integration of measured heat flow outputs. Therefore, the use of calorimetry method plays an indispensable role in cement hydration.

Temperature is one of the main factors that affects the kinetics and mechanism of hydration; it determines the types of hydrated products and the engineering properties of concrete. Based on calorimetric measurements, the temperature dependence of the hydration rate was expressed using different mathematical methods (Jander’s equation, Ginstling and Brounstein’s equation, Johnson–Mehl–Avrami’s equation, etc.) in order to elucidate the mechanism that governs a given reaction, and it is globally found that the temperature dependence can be described by an Arrhenius equation [31,32,33]. For this reason, it is necessary to undertake a systematic study to establish the effect of temperature on the hydration of ternary model metakaolin–gypsum–calcium hydroxide in order to elucidate the role of MK in chemical process leading to the formation of ettringite.

Generally, the rate constant of a hydration reaction is described as function of the temperature and the composition of the sample and can be written as (Eq. 8):

where T is temperature and x is the composition of binder system

From the kinetic point of view, the trustworthy relationship between the rate of reaction and the composition of the system in heterogeneous reactions such as cement hydration is complicated to determine [33]. Therefore, “apparent activation energy” can be considered by determining the rate of hydration as a function of temperature at chosen composition [22], since the effect of temperature will depend on particular composition. By definition, “apparent activation energy” (E a) of cement is the minimum amount of energy required for this material to hydrate. Then, the “apparent activation energy” of different samples with different composition can be expressed as the dependence of time corresponding to the maximal hydration peak on temperatures at which hydration occurs. The peak of hydration heat denotes the maximal constant rate (k max) of conversion at given time.

The constant of maximal reaction rate dependence can be expressed for a special case of isothermal processes according to (Eq. 3):

where k max is maximal constant rate, T max is the time corresponding to the peak of hydration curves, A is the constant of proportionality, R is the gas constant, 8.314 J mol−1 K−1; and E a is the apparent activation energy.

As calorimetric curve presents different peaks describing different phases of exothermic processes related to chemical reactions, thereafter it may not be satisfactory to consider single “apparent activation energy” characterizing the whole process, but the “partial apparent activation energy” of individual reactions represented by different peaks [22].

The present study was undertaken to characterize the role of MK in ettringite formation and to explore the influence of temperature on hydration of ternary system metakaolin–gypsum–calcium hydroxide. Also the mechanism and kinetics of reactions using data from calorimetric measurement supplemented by phase analysis (XRD and DTA–TG) are elucidated.

Experimental

Materials

MK Mefisto K05 was produced in České lupkové závody, a.s., Nové Strašecí. Highly amorphous MK contains little amount of quartz, corundum and anatase. Ultrafine powder MK has its median particle size around 5 µm. Calcium hydroxide was provided by Calmit, a.s. Slovakia. Gypsum (CaSO4·2H2O) was laboratory-synthesized using calcium hydroxide and sulfuric acid in equivalent molar ratio. Then precipitate was washed and dried at 50 °C during 24 h. The purity of gypsum was controlled by RTG and DTA methods. The TG curve depicted a mass loss corresponding to water chemically bound is 20.96%. (In pure gypsum–CaSO4·2H2O, the mass loss is 20.91%.)

The measurement was taken in closed crucible. The peaks of thermal decomposition of the first and second steps are displaced toward higher temperatures due to humid atmosphere in closed crucible.

The chemical composition and sample composition are reported in Tables 1 and 2.

The present composition resulted from optimized trial mixture of metakaolin–lime–gypsum in which it was found that samples with MK/CH = 1 and various amount of gypsum have the highest mechanical properties [23] (Fig. 1).

Methods

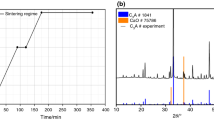

Heat evolution and the total heat evolved during the hydration of ternary blend cements at different temperatures were recorded using TAM AIR isothermal calorimeter. The TAM AIR 8-Channel calorimeter consists of an eight channel calorimeter block and data logging system required for use with the TAM AIR thermostat. The calorimeters are twin type (sample and reference) and designed for use with 20-ml glass or plastic ampoules or the 20-ml Admix ampoules. The sample is placed in an ampoule that is in contact with a heat flow sensor that is also in contact with a heat sink. The mixtures of blends were placed in ampoules and lid. Quantity of water corresponding to water/solid ratio 0.5 was injected in the ampoule using syringe. The samples were gently stirred after adding of the water and placed in the calorimeter. The measurement was taken few seconds after adding water.

Simultaneous thermogravimetric and differential thermal analysis (TGA/DSC—1, STARe software 9.30, Mettler Toledo) was used. After the samples were calorimetrically treated, hydration was stopped using acetone to remove water physically bound followed by application of ether in order to remove acetone. Though the samples were carefully conserved in ampoules safe from the air, carbonation has occurred during the period of preparation (drying, grinding, storing and transferring). Then, 50.00 (± 0.03) mg of powdered samples was heated in the open platinum crucibles up to 1000 °C at the heating rate of 10 °C min−1 in the atmosphere of synthetic air (purity 5.0).

Powder samples prepared from hardened pastes after stopping hydration were analyzed by X-ray diffractometer Empyrean. X-ray diffraction analyzer is equipped with 2D fast detector and Cu-anode (λKα1 = 0.15418 nm, λKα2 = 0.15418 nm) and automatic motorized divergence slits at convention Bragg–Brentano parafocussing Θ–Θ reflection geometry, scan range 5–90 2Θ, scan step size 0.0131303. Data were processed using High Score Plus software.

Results and discussion

Calorimetric curves of trial mixtures hydrated at different temperatures (30, 40, 50 and 60 °C) are depicted in Figs. 2–7. They present similar features of peaks and periods with different intensity and duration. Three main peaks can be distinguished. The first peak is a result of different physical (wetting reaction, dissolution and hydrolysis) and chemical process (ettringite formation) [15,16,17,18,19]. The second one follows a shortened induction period, after a “sluggish period” of steady reaction before a short intensive peak. More surprisingly is the last phase of hydration characterized by a jump peak before it declines suddenly. At each curing temperature, composition is a key factor that determines intensity of different peaks and duration of reaction. This behavior is unobvious with cement hydration even with MK. The intensity of these peaks and their drop decreases with decreasing content of CH/MK. It appears that at higher content of gypsum, the last peaks decline slowly.

During the hydration of MK–CH–GYP mixture, several physical and chemical processes can be considered. The first one consists of pozzolanic reactions between calcium hydroxide and metakaolin leading to the formation of CSH and C2ASH8, as described by several authors and according to Eqs. 4, 5 [1,2,3,4,5,6, 9,10,11,12]. The second process is a possible chemical reaction resulting in the formation of ettringite because of the presence of gypsum. In sum, the final products could be CSH, C2ASH8 and \({\text{C}}_{6} {\text{A}}{\bar{\text{S}}}_{3} {\text{H}}_{32}\) that coexist thermodynamically. The composition of these phases depends on the composition of initial mixture and curing temperatures as demonstrated in Figs. 2–8.

If the first peak was attributed to hydrolysis and precipitation of primary products, the position of “jump peak” followed by rapid slope is function of gypsum content. Indeed, the lack of gypsum shortens hydration process. It can be assumed that the formation of ettringite is a continuous process linked to the presence of reactants. As long as all reactants are present (mainly gypsum, as CH and MK are enough), heat is evolved at constant rate. The last peak demonstrates the “reveille” or “affinity” of reaction toward depleting third compound in order to form the last product (ettringite). It characterizes the end of “sluggish period” duration of which depends on gypsum content. This hypothesis will be demonstrated later based on result of DTA/TG and XRD. Figure 2 depicting heat flow of different mixture demonstrates prolonged reaction, and the position of the last important peak varies from 25 to 315 h. At ambient temperature, the effect of pure calcium hydroxide can different from that formed by hydrolysis of C3S and C2S according to Eq. 1. To characterize the kinetic behavior of the peaks appearing after “sluggish period,” peak position and peak intensity were recorded.

Figure 3 depicts a similar picture as in Fig. 2 with difference in peak position and peak intensity. It is clear that the “sluggish period” is shortened and intensities of third peak increased. The slope of decreasing last peaks is more spread over time with gypsum content while it is more steep with increasing CH/AS2 ratio. The position of the last varies from 15 to 115 h.

The influence of temperature is more emphasized at 40 °C of curing hydration. The temperature has activated some exothermic reaction during the “sluggish period.” The “sluggish period” presents a curvature of course and is activated. The chemical processes that could not occur at lower temperatures are now activated. Indeed during this phase, continuous formation of ettringite has been recorded on the light of XRD and DTA/TG results. The position of the last varies from 8 to 45 h.

In Fig. 5 a sharp “pseudo-peak” at hydration of Trio2–Trio5 appears proving the effect of temperatures on some undefined reactions. Calorimetric curves show the end of reactions within 35 h. Exothermic reactions that were less emphasized during “sluggish period” at low temperatures are activated as presented by continuous growing heat flow before the third peak. The “pseudo-peak” observed at curves of Trio5, Trio4, Trio3 and Trio2 characterizes the acceleration of exothermic reaction represented by “shoulder” before third peak at low temperatures.

Figure 6 depicts the influence of composition on the hydration behavior at 60 °C. While in Trio1 and Trio2 one can distinguish clearly the third peak, in the last three samples it seems to be continuously integrated to the course of hydration. Hydration is ended within 20 h for all samples.

It is noticeable to remark that, regardless of temperature and composition, all calorimetric curves present similar phases of hydration: first peak, short induction period, “pseudo-active sluggish period” with a peak-shoulder, third peaks and decline phase of hydration. In order to follow hydration reaction and hydration products, a specific approach has been chosen considering different periods (5, 8, 13.5, 16 and 30 h) of calorimetric curves of sample Trio 3 cured at 50 °C. Hydration was stopped by above procedure described in Experimental part. Then samples together with reference one were analyzed by XRD and simultaneous DTA/TG.

The results of XRD (detecting only the crystalline phases) show that ettringite formation is a continuous process from the beginning to the end of reaction. In the meantime, gypsum and calcium hydroxide are consumed gradually. Before the main last peak (13.5 h), gypsum and CH are still in mixture, but at 16 h CH is missing. Ettringite intensity remains the same after 16 h. DTA curve brings supplementary results as it is useful to detect the presence of amorphous phases. Figures present some endothermic peaks charactering the presence of CSH at 100–120 °C, ettringite at 100–140 °C, gypsum at 130–160 °C, calcium hydroxide between 400 °C and 500 °C and calcium carbonate at 600–800 °C. A weak sign of C2ASH8 can be observed at interval 160–200 °C. If the temperature intervals are overlapped in some cases, nevertheless, peaks are well distinguished. Peak position as well as peak intensity is sifted to higher thermal decomposition temperature demonstrating thus the dominant phase of ettringite to the detriment of CSH. In the meantime, gypsum and CH decomposition peaks gradually come to the end (Figs. 9–11).

Dependence of time position of third peak upon temperature and its linearization according to Eq. 11

XRD denotes the changes of the main initial phases E-ettringite, CH-calcium hydroxide, CC-calcium carbonate. Metakaolin is amorphous phase.

The sequences of hydration reactions and their mechanism were never before elucidated, though products are identified as CSH, C2ASH8 and ettringite. Three concomitant reactions are running around aluminum species. While the first intensive peak confused with x-axis on calorimetric curve characterizes the exothermic effect of dissolution and hydrolysis, the “pseudo-dormant” active periods at which it is clear that reaction occurred is a result of different processes. This phenomenon can be explained as like as with geopolymerization in highly alkaline environment [36]. Metakaolin is used to prepare geopolymer binders by action of NaOH (alkaline activation). The principle of geopolymerization consists of dissolution of aluminosilicate, hydrolysis of Al3+, Si4 + and condensation of aluminate and silicate species. Weng et al. [37] have reported the existence of [Al(OH)4]−, [SiO2(OH)2]2− and [SiO(OH)3]− species in solution. In the present ternary model, condensation (geopolymer), pozzolanic reaction (alkaline activation) and ettringite formation occur concomitantly. Ettringite formation depends on the presence of gypsum, while the aforementioned processes detest gypsum presence. While calcium hydroxide will prefer [SiO2(OH)2]2− and [SiO(OH)3]− for the formation of CSH [1, 2] according to Eq. 1, gypsum will move toward [Al(OH)4]− to form ettringite in the presence of CH. These different reactions can explain the activation of “sluggish” with temperature.

The influence of temperature upon hydration of temperature on the formation of different hydrated products

To illustrate the influence of temperature on the formation of hydration products, samples cured at 20 and 60 °C were considered (two extreme temperatures). The samples here analyzed were those obtained after calorimetric measurement. They are from different time of hydration, but each was taken after the full decline of third peak at which one can expect that hydration is come to an end. Apart quantitative evaluation, hydration products are similar depending on the composition of initial mixture. One can remark the presence of CSH, ettringite and C2ASH8 with Trio1 and Trio2 (at 100–120 °C, 120–130 °C and 160–200 °C, respectively). Trio3 presents a particularity of one peak at 100–130 °C denoting the presence of ettringite as a major phase as it was demonstrated by aforementioned results by XRD measured at different periods of hydration. A negligible peak of C2ASH8 can be observed. Trio4 and Trio5 have an excess of gypsum, and a part remains unreacted in hydrated sample as demonstrated by peak located at 130–160 °C. With increasing content of gypsum and decreasing CH/AS2 ratio, CSH and C2ASH8 decrease while ettringite increases. Considering the intensity of peak located at 100–130 °C denoting ettringite, one can state that temperature supports ettringite formation. According to the DTA/TG and XRD results, carbonation occurs adding thus supplementary complication to hydration reaction of ternary system. Previous work of Feldman [34] and Bensted [35] has reported high affinity between calcium aluminate and carbonate phases to form monocarbonate. Also, the possible substitution of calcium sulfate with calcium carbonate in ettringite structure was considered and authors have found that calcium sulfate can be replaced up to 25% by calcium carbonate without any modification of the properties of the system [35].

Kinetics of hydration

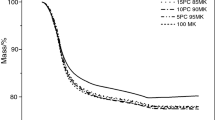

In order to characterize the kinetics of process represented by the last peak, time position and peak intensity were recorded and are collected in Table 2. Both parameters are influenced by temperature.

The activation energy E a was obtained using the software TAM Assistant, which is part of the isothermal calorimeter TAM AIR [22]. The program is based on principle that the relation between the maximum of heat flow (maximal peak—HFmax) and activation energy E a can be expressed by the Arrhenius equation (Eq. 10):

The value of heat flow at maximal peak intensity (HFmax) of the calorimetric curves was considered and plotted against 1/T. Applying the classical procedure to calculate apparent activation energy for the nucleation and crystallization, equation was linearized to obtain equation (Eq. 11):

The value of E a differs insignificantly with slight increase considering standard deviation with increasing content of gypsum. The graphical extend of reaction, in other words the duration of reaction, is function of temperature and composition. If we consider that the third peak results from “the affinity of system” to depleting reactants, therefore gypsum governs this process in Trio1 and Trio2. In Trio3, Trio4 and Trio5, this process is more depended on CH/AS2 because gypsum is in excess in these two last samples.

Conclusions

The role of MK in the formation of ettringite in blended cement cannot be neglected. The work considered a model of ternary system consisting of MK–CH–GYP in which MK/CH ratio was kept equal to 1 with various addition of gypsum. The reaction runs under non-equilibrium conditions characterized by hydrolysis of Ca(OH)2, CaSO4·2H2O and Al2Si2O7 by effect of alkaline liquid environment. Condensation of silica species (likely in geopolymerization), formation of calcium silicate hydrate and calcium aluminate silicate hydrate (alkali activation), and ettringite formation were identified as concomitant processes with different affinity to form different hydrated products according to the composition of ternary system. The single activation energy characterizing the last third peak was found negligibly depending on composition.

References

Li C, Sun H, Li L. A review: the comparison between alkali-activated slag (Si+ Ca) and metakaolin (Si+ Al) cements. Cem Concr Res. 2010;40:1341–9.

Sha W, Pereira GB. Differential scanning calorimetry study of ordinary Portland cement paste containing metakaolin and theoretical approach of metakaolin activity. Cem Concr Compos. 2001;25:455–61.

Kuliffayová M, Krajči Ľ, Janotka I, Šmatko V. Thermal behaviour and characterization of cement composites with burnt kaolin sand. J Therm Anal Calorim. 2012;108:425–32.

Krajčí Ľ, Janotka I, Jamnický P. Burnt kaolin sand as pozzolanic material for cement hydration. Ceram Silik. 2007;51:217–24.

Snelson DG, Wild S, O’Farrell M. Heat of hydration of Portland cement–metakaolin–fly ash (PC–MK–PFA) blends. Cem Concr Res. 2008;38:832–40.

Ptáček P, Opravil T, Šoukal F, Wasserbauer J, Masilko J, Baracek J. The influence of structure order on the kinetics of dehydroxylation of kaolinite. J Eur Ceram Soc. 2013;33:2793–9. https://doi.org/10.1016/j.jeurceramsoc.2013.04.033.

Ptáček P, Kubatová D, Havlica J, Brandštetr J, Šoukal F, Opravil T. The non-isothermal kinetic analysis of the thermal decomposition of kaolinite by thermogravimetric analysis. Powder Technol. 2010;204:222–7.

Li Z, Ding Z. Property improvement of Portland cement by incorporating with metakaolin and slag. Cem Concr Res. 2003;33:579–84.

Kostuch JA, Walters GV, Jones TR. High performance concretes incorporating metakaolin—a review. In: Dhir RK, Jones MR, editors. Concrete 2000. London: E&FN Spon; 1993. p. 1799–811.

Nadeem A, Memon SA, Lo TY. Mechanical performance, durability, qualitative and quantitative analysis of microstructure of fly ash and metakaolin mortar at elevated temperatures. Constr Build Mater. 2013;38:338–47.

Minárik L, Kopecskó K. Impact of metakaolin—a new supplementary material—on the hydration mechanism of cement, Acta Tech. Napocensis Civ Eng Arch. 2013;56(2):100–110. https://constructii.utcluj.ro/ActaCivilEng/download/atn/ATN2013(2)_9.pdf.

Morsy MS, Al-Salloum Y, Almusallam T, Abbas H. Effect of nano-metakaolin addition on the hydration characteristics of fly ash blended cement mortar. J Therm Anal Calorim. 2014;116:845–52.

Gallucci E, Mathur P, Scrivener KL. Microstructural development of early age hydration shells around cement grains. Cem Concr Res. 2010;40:4–13.

Jansen D, Goety-Neunhoeffer F, Lothenbach B, Neubauer J. The early hydration of Ordinary Portland Cement (OPC): An approach comparing measured heat flow with calculated heat flow from QXRD. Cem Concr Res. 2012;42:134–8.

Copeland LE, Kantro DL, Verbeck GJ. Chemistry of hydration of Portland cement. Proc Symp Cem Chemistry Cem Concr Assoc Wash. 1960;1:429–68.

El-Didamony H, Tm El-Sokkari, Kha Khalil, Mohamed H, Ahmed IA. Hydration mechanisms of calcium sulphoaluminate C4A3S̄, C4AS̄ phase and active belite β-C2S. Ceram Silik. 2012;56:389–95.

Juenger MCG, Winnefeld F, Provis JL, Ideker JH. Advances in alternative cementitious binders. Cem Concr Res. 2011;41:1232–43.

Palou MT, Majling J. Effects of sulfate, calcium and aluminium ions upon the hydration of sulphoaluminate belite cement. J Therm Anal. 1996;46:549–56.

Pelletier L, Winnefeld F, Lothenbach B. The ternary system Portland cement–calcium sulphoaluminate clinker–anhydrite: hydration mechanism and mortar properties. Cem Concr Comp. 2010;32:497–507.

Winnefeld F, Lothenbach B. Hydration of calcium sulfoaluminate cements—experimental findings and thermodynamic modelling. Cem Concr Res. 2010;40:1239–47.

Palou MT, Kuzielová E, Novotny RF, Žemlička M. Blended cements consisting of Portland cement–slag–silica fume–metakaolin system. J Therm Anal Calorim. 2016;125:998–1004.

Boháč M, Palou MT, Novotný R, Másilko J, Všianský D, Staněk T. Investigation on early hydration of Portland cement-blast-furnace slag-metakaolin ternary blends. Constr Build Mater. 2014;64:333–41.

Boháč M, Palou M, Novotný R, Másilko JF, Opravil T. Influence of temperature on early hydration of Portland cement-metakaolin-slag system. J Therm Anal Calorim. 2017;127:309–18.

Žemlička M, Kuzielová E, Kuliffayová M, Tkacz J, Palou MT. Study of hydration products in the model systems metakaolin–lime and metakaolin–lime–gypsum. Ceram Silik. 2015;59:283–91.

Frías M, Sánchez de Rojas MI, Cabrera J. The effect that the pozzolanic reaction of metakaolin has on the heat evolution in metakaolin-cement mortars. Cem Concr Res. 2000;30:209–16.

Rahhal V, Cabrera O, Talero R, Delgado A. Calorimetry of Portland cement with silica fume and gypsum additions. J Therm Anal Calorim. 2007;87:331–6.

Gruyaert E, Robeyst N, De Belie N. Study of the hydration of Portland cement blended with blast-furnace slag by calorimetry and thermogravimetry. J Therm Anal Calorim. 2010;102:941–51.

Morsy MS. Effect of temperature on hydration kinetics and stability of hydration phases of metakaolin–lime sludge–silica fume system. Ceramics. 2005;49:225–9.

Siler P, Kratky J, De Belie N. Isothermal and solution calorimetry to assess the effect of superplasticizers and mineral admixtures on cement hydration. J Therm Anal Calorim. 2012;107:313–20.

Pacewska B, Wilinska I, Bukowska M. Calorimetric investigations of the influence of waste aluminosilicate on the hydration of different cements. J Therm Anal Calorim. 2009;97:61–6.

Zielenkiewicz W, Kaminski M. A conduction calorimeter for measuring the heat of cement hydration in the initial hydration period. J Therm Anal Calorim. 2001;65:335–40.

Copeland LE, Kantro DL, Verbeck GJ. Chemistry of hydration of Portland cement. Proc Symp Cem Chem Cem Concr Assoc Wash. 1960;1:429–68.

Thomas JJ. The instantaneous apparent activation energy of cement hydration measured using a novel calorimetry-based method. J Am Ceram Soc. 2012;95–10:3291–6.

Ježo Ľ, Ifka T, Cvopa B, Škundová J, Kovár V, Palou M. Effect of temperature upon the strength development rate and upon the hydravion kinetice of cements. Ceram Silik. 2010;54:269–76.

Feldman RF, Ramachandran VS, Sereda PJ. Influence of CaCO3 on the hydration of 3CaO. Al2O3. J Am Ceram Soc. 1965;48:25–30.

Bensted J. Some hydration investigations involving Portland cement effect of calcium carbonate substitution of gypsum. World Cem Technol. 1980;11:395–406.

Weng L, Sagoe-Crentsil K. Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: part I—Low Si/Al ratio systems. J Mater Sci. 2007;42:2997–3006.

Weng L, Sagoe-Crentsil K, Brown T, Song S. Mater Sci Eng B Solid-State Mater Adv Technol. 2005;117(2):163.

Acknowledgements

The authors are grateful for Grant APVV-15-0631 and for the support of the project Sustainability and Development REG LO1211 addressed to the Materials Research Center at FCH VUT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palou, M., Kuzielová, E., Žemlička, M. et al. The effect of metakaolin upon the formation of ettringite in metakaolin–lime–gypsum ternary systems. J Therm Anal Calorim 133, 77–86 (2018). https://doi.org/10.1007/s10973-017-6885-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6885-0