Abstract

Thermal analysis approaches give the opportunity to investigate structural changes in historical leather like as dehydration, crystallization, and melting process. An historical leather sample from nineteenth century was considered in this study. The leather samples were treated with a suspension of nano-hydroxyapatite and polyethylene glycol 400 (PEG 400) in an aqueous solution. The treatment effects on the structural changes in historical leather were studied by differential scanning calorimetry (DSC) and thermogravimetric analysis (TG). DSC technique has been employed to study the thermal-associated changes in historical leather to an artificial aging and the conservation of nanocomposite treatment. Moreover, thermogravimetric analysis and differential thermal gravimetry (TG–DTG) are used as useful methods for the investigation of the mass losses of the treated and untreated samples at the progressive heating in N2 gas flow. Furthermore, scanning electron microscopy studies indicated the collagen fibril changes in treated sample in comparison with those of untreated sample and after accelerated aging test.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Various leather products such as tanned leather, bookbinding leather, and parchment have been considered as valuable objects since the beginning of human civilization. Conservation and preservation of these valuable historical leather objects are matter of challenges by specialist heritage conservators [1].

The main element of the coherent structure of leather matrix is a complex biomaterial composed of collagen molecule that is made up of the triple helix formed of three polypeptide chains coiled together [2]. Collagen molecule is constrained by weak non-covalent inter-chain bonds, especially hydrogen bonds, and further aggregates in structural levels of increasing complexity [3]. The thermal stability of such a matrix depends on the amino acid arrangement of the proteins and environmental conditions [4].

The collagen-based objects are facing various problems such as the assessment of environmental condition risks and the evaluation of suitable treatments because these objects have very complicated construction components. They change in accordance with the materials used in skin, the materials that use for tanning, and other materials applied for the different finishing processes also differ in the chemicals that they receive from their different environments [5, 6]. The leather objects are usually treated with dressing products including fats or oil components [7, 8]. These materials do not contribute to the preservation of the constituent moisture and, on the other hand, destabilize collagen filaments, and the fibers dispose to overdrying. Recently, polyethylene glycol (PEG) is considered as an essential component in leather treatment [9, 10]. Aqueous solution of low molecular weight polyethylene glycol (PEG 400) does not need surfactants and is capable of preserving moisture and making the old leather softer [9–12].

Materials science is the principal area through which researchers in the chemical disciplines can influence technology. The key objective in making new and advanced materials was to find ways to generate new properties at three levels: the molecular level, the material level, and the surface or interface level. Recently, nanotechnology has pronounced impact on preserving cultural objects for the following reasons: by decreasing the size of the particles in nano-range and by improving better dispersion in the desired zone of historical object that can affect the chemical reaction and its rate [13–15].

Interaction of nanoparticles with collagen macromolecules has been investigated by many authors [16–19]. In this regard, Ionita et al. [20, 21] indicated that two peptide chains of collagen can be cross-linked with the formation of a silver bridge linking. Gaidau et al. [22] investigated the interaction of different kinds of silver nanoparticles with collagen, and their results indicated that silver nanoparticles react with collagen chain through hydrogen bonds in carbonyl groups.

In addition, it is observed that the dispersion of nanosilver particles in the chromium-tanned sheepskins showed the best resistance to fungi and bacterial exposure tests [23].

It is also reported that the archeological and paleontological demineralized bones can be preserved, and their mechanical strength is improved by in situ growth of CaCO3 in the presence of collagen within the deteriorated bones [24].

Hydroxyapatite (HA) nanoparticles and polyethylene glycol (PEG) are among the biocompatible materials that have been used for variety of biomaterial applications such as the development of mechanical properties of hydrogels and scaffolds with higher extensibility and toughness [25, 26]. In addition, incorporation of HA nanoparticles in the hydrophilic PEG can improve water adsorption and cell adhesion of nanocomposite [25]. However, very few reports are focused on the development of polymer–inorganic nanocomposite for the conservation treatment of collagen-based historical objects. We are interested in PEG–nano-hydroxyapatite nanocomposite (PEG 400–HA) that can be formulated to improve elastic and toughness properties of historical leather. In our previous paper, the mechanical properties and structural changes in untreated and treated bookbinding historical leather samples with nanocomposite (HA and PEG 400) at dynamic and static tensile mode were studied by DMTA and tensile tests [27]. The obtained results confirmed that the mechanical properties can be promoted by the movement of collagen fibers and decreased the frictional resistance of the fibers [27]. However, thermal properties of treated bookbinding historical leather samples with this nanocomposite have never been reported.

Miles and Ghelashvili in their studies have proposed a hyperbolic relationship between the denaturation temperature and the volume fraction of water in the fiber, which was justified by DSC data [28]. They have discussed that thermal stability of collagen is related to changes in the configurational entropy of the uncoupled, random-coil state. They relate the volume fraction of water in a fibril to the inter-axial spacing of collagen molecules.

In another study, it is indicated that mineralization of collagen increases the transition temperature [29, 30].

Okamoto and Saeki studied the phase changes in collagen on progressive heating from room temperature to 225 °C [31]. Their results indicated that collagen fiber is composed of three regions of different structure such as amorphous region, less oriented unstable crystalline region, and stable crystalline region. An endothermic process occurs between room temperature and 120 °C, and a second endothermic process begins around 170 °C and exhibits a minimum at 215 °C. The first process consists in the vaporization of the adsorbed and absorbed residual water, and the second stage is related to melting of crystalline phase of collagen [1].

However, the origin of the second endothermic is a challenging matter for some of the authors [32–34]. Budrugeac et al. [1, 35] related that the value of the melting temperature depends on the cross-linking degree and the degradation of collagen-based materials.

The aim of this research was to find an appropriate treatment for historical leather lubrication and conservation with the least interaction of these materials in the leather behavior in aging. Recently, Badea et al. [36] studied the effects of temperature and relative humidity on hydrothermal stability of parchments by DSC under the accelerated aging conditions that can induce changes in collagen thermal stability, increase in heterogeneity, structural disorder, and the loss of fibrillar structure. Cucos et al. [37] studied the effects of temperature and relative humidity on the degradation of recently manufactured parchments and vegetable-tanned leathers by DSC and DMA. Their results indicate that humidity condition of accelerated aging causes a progressive decrease in the temperature of denaturation, but has no or minor effect on that in dry state. In addition, deterioration degree of parchments is more affected than that of leathers under same aging conditions [37].

The age and storage conditions of the collagen-based materials can also be related to the number of DSC peaks of denaturation under nitrogen flow and of the normalized DTG peak of the thermo-oxidative process [38–40]. In addition, drying processes were investigated by dielectric and thermomechanical techniques in historical bookbinding leathers. In this study, TG measurements of the shrinkage temperature have been associated with their chemical state [41].

Thermal gravimetric analysis (TG) is a useful method to examine the thermal stability of the conservation treatment on historical samples. TG tests indicated that Ca(OH)2 nanoparticles improve the thermal stability of the canvas linings on wood samples [21, 42].

Recently, thermal stability of the methyl methacrylate/butyl acrylate copolymer nanoemulsions was confirmed by TG technique as efficient retanning and lubricating agents for chrome-tanned leather [43]. In another study, the thermal stability of water dispersible cloisite-g-methacrylic acid copolymer nanocomposites was investigated as retanning agent on goat leather [44].

The present work focuses on the thermal properties of untreated and treated samples with the PEG–HA nanocomposite by differential scanning calorimetric (DSC) and thermogravimetric analysis (TG) techniques. The present work aims to obtain further information on the thermal and to complete mechanical information that has been reported earlier [27]. The prepared nanocomposite suspension was considered as potential lubricating agents to improve the properties of vegetable-tanned historical leathers. So, the lateral information gained from morphological studies by electron microscopy was also included. In addition, the color changes in the treated leather with the prepared nanocomposite suspension will be reported separately.

Experimental

Materials and method

Old goat leather from the Qajar era (150 years ago) with vegetable tanning and hand colored was used as material substrate throughout this investigation.

The pH of leather is an important property for indicating the age and storage conditions of leather [45]. Therefore, prior to the treatment, the pH of historical leather bookbinding has been measured according to ASTM D 2810, 2001b. The average pH of three specimens from the leather sample was 5 ± 0.2, which indicates the leather is in a weak acidic condition. Figure 1 shows an image of the historical bookbinding from the Qajar era (150 years ago), from the library, museum, and documentation center of Islamic Consultative Assembly (ICAL).

Nano-hydroxyapatite (HA) suspension in water and polyethylene glycol (PEG) with molecular weight of 400 were provided from Sigma-Aldrich and Merck, respectively. Some information regarding the nature of HA and PEG is given in Table 1.

The leather sol treatment was prepared by a solution of 15 volume percent of PEG in deionized water and 0.1 volume percent of HA [27].

The historical leather was treated by placing the leather sample in the homogenous PEG and HA aqueous solution under magnetic stirring for 15 min at room temperature; after removing from the solution, the sample’s surface was softly dried by a soft cloth and stored in a desiccator at room temperature for about 1 week before thermal and morphological analyses. In addition, all samples were conditioned in the test room at 23 °C and 50 % RH for 24 h before any analysis.

The thermal analysis (i.e., DSC and TG) was repeated 2–3 times for the historical leather samples as well as natural aged, treated, and after artificial aging. The uncertainty of thermal analysis is in the error bar ±3 °C. In addition, the samples for the analysis were taken from the same area of the historical leather bookbinding due to the heterogeneity of these materials.

Characterization

Differential scanning calorimetric (DSC) analysis

Differential scanning calorimetric analysis was performed using a DSC calorimeter apparatus (PL-DSC, polymer laboratories, England). The samples were weighed (around 10.5 ± 0.2 mg) and heated at the constant rate of 10 K min−1, the whole 20–400 °C temperature range in open aluminum pans and nitrogen flow (50 mL min−1, nitrogen purity of 99.999 %).

Thermogravimetric analysis (TG) and Differential thermal gravimeter (DTG)

The TG and DTG analyses were recorded using TG apparatus (PL–TG, polymer laboratories, England). The samples were weighed (9 ± 1 mg) and heated at the constant rate of 10 K min−1 in gas flow (nitrogen; purity of gas in higher than 99.999 %; 50 mL min−1), in temperature range 20–600 °C.

Aging procedure

The leather samples have been artificially aged in a chamber under continuous cycling for 1,000 h. Table 2 shows two following aging cycle test conditions. UV radiation is provided by using a 8-W UVb lamp model Hitachi, Japan.

Scanning electron microscopy (SEM) study

The collagen fiber morphology of the leather samples was observed by SEM (TSCAN_VEGA, Cambridge, Checkoslavaki) at an accelerating voltage of 15 (kV). The fracture surface was provided by the temperature of liquid nitrogen, and the samples were coated with a thin layer of gold, thickness 15 (nm), density 19.32 (g cm−3).

Sample coding

The following codes are used to denote the samples:

-

“Control” for untreated historical leather

-

“treated” for the treated historical leather with the HA+PEG solution (see Section “Materials and method”)

-

“aged control” for artificial aged control sample

-

“aged treated” for artificial aged treated sample

Result and discussion

DSC analysis in N2 flow

Figure 2 shows the DSC curves for the untreated historical leather (denoted by “control”) and the historical leather treated with PEG and nano-HA aqueous solution (denoted by, “treated”), and Fig. 3 exhibits the similar results but after artificial aging of the leather samples (denoted by, “aged control” and “aged treated”). As mentioned above, all samples were placed in the test conditioned room at 23 ± 2 °C and RH 50 % for 1 week. Since the moisture content and volatile matters of the samples are considered to be in steady states, thermal analysis results are only related to thermal denaturation [48, 49].

T s corresponding to the temperature occurs the loss of physically adsorbed moisture can be calculated from the onset point of inflection curve in the initial part of DSC (see Figs. 2, 3). This temperature can be also correlated with T β in β relaxation peak of tan δ–T curve in our previous results [27].

T s and T β of the control sample occur at higher temperature in comparison with other samples. This indicates that T s of historical leather decreases by artificial aging as well as by the treatment with PEG and nano-HA aqueous solution. This may be attributed to the movement of some segmental sections of collagen chain due to the increase in their volumes because of water adsorption as shown in the later section of SEM results. In addition, the nano-HA particles placing between the collagen chains can induce decreasing of T s by increasing free volume.

In addition, Figs. 2 and 3 also show minimum temperature of endothermic peaks (I and II). In the range of 30–120 °C, each investigated sample has also exhibited a wide endothermic peak, denoted by I, corresponding to the loss of material humidity. This process is followed by one or some smaller endothermic peaks.

Immersing of treated sample in the aqueous HA and PEG solution can be induced at higher hydration level in relation to natural aged sample (i.e., control). In this condition, collagen fibrils are swollen in water that is distributed in two phases, intra-fibrillar and external water. Therefore, the endothermic processes occurring between room temperature and about 150 °C can be related to the vaporization of the adsorbed and absorbed residual water [1].

As shown in Fig. 2, the endothermic process I can be displaced to lower temperatures in “treated” sample in relation to control, while in Fig. 3 and after artificial aging, both of the curves exhibit a similar trend (see “aged control” and “aged treated” curves). This may be attributed to higher hydration levels in “treated” sample rather than that of control while hydration levels are stabilized in the artificial aged samples.

The process II, earlier detected by Okamato and Saeki, could be explained by the biphasic amorphous–crystalline structure of collagen-based materials according to which the crystalline triple helix is embedded into an amorphous matrix (protein denaturation). Consequently, the process II might be related to the softening (melting) of crystalline part of material [23]. The results corresponding to this endothermic peak have led to the following.

In control sample, melting phase occurred in higher range temperature than those corresponding to “treated” that it means the amorphous structure in this sample was stiffer than those other samples. Between aged samples, softer amorphous structure belonged to the “aged treated” sample. These statements could be explained by the above-mentioned biphasic amorphous–crystalline structure collagen-based materials, according to which the softening of the crystalline part is hindered by the rigidity of the amorphous matrix. Melting temperature (T m) values in the case of aged samples (aged control and aged treated) are higher than those corresponding to treated and control, because the aging process induces heterogeneity in the structure of the crystalline region. It seems PEG by absorption of the environmental humidity induces more softness in “treated” and “aged treated” samples. In addition, the nano-hydroxyapatite particles have a hydrophilic character that can increase this quality.

TG analysis in N2 flow

Figures 4 and 5 show the TG and DTG curves obtained by the analysis in N2 flow of the leather samples. The shrinkage, the main heat damage in the collagen network, is coupled with some water loss. TG was used to quantify the extent of the mass loss; also, the DTG curve of the samples was studied for better interpretation of the TG data.

The analysis of all data obtained by TG–DTG analysis in N2 flow has been revealed. The initial slope in the TG curve of the “treated” sample is more than those corresponding with “control” and extends to the higher temperature (i.e., up to about 140 °C) that means the “treated” sample has lost more water and volatile contents in progressive heating than the control. Control has exhibited melting phase with the minimum peak at temperature range 300 °C while the “treated” has exhibited this phase at the temperature about 318 °C. The first peak in the DTG curve that related to loosing water content in the “treated” sample is sharper with higher amplitude than its of control sample; also, the second peak in this curve that related to denaturing of the leather structure in the control is boarder than those of the “treated,” and it means “treated” sample has shown more structural changes than control.

However, “aged treated” and “aged control” samples exhibit the same manner in the TG and DTG curves as well as the treated sample. It may be attributed to reach higher water and volatile contents after artificial aging or by the nanocomposite treatment in the treated sample. After accelerated aging, the temperature range of the melting phase has shifted to higher temperature. It may be attributed to the structural heterogeneity of leather and residual tanning materials that can induce the cross-linking interaction between collagen fibers under UV and humidity in aging condition. Aged control and aged treated samples have exhibited melting phase at the same temperature range while the DTG curve of aged treated is slightly boarder than those of aged control. It means aged treated has exhibited slightly more structural changes. In addition, the DTG curves of the control and treated show a small number of peaks at higher temperatures (above 350 °C); in addition to the first and second peaks, it demonstrates more structural heterogeneity in these samples. Although the general trend of water release was substantially analogous in either case, the control revealed a smaller water content than the treated, and in the aged samples (i.e., aged control and aged treated), the aged control revealed a smaller water content than the aged treated.

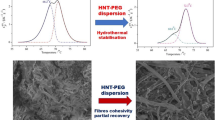

SEM studies

In our previous research, the size and uniformity of HA in the leather microstructure was investigated by TEM and SEM–EDX analyses [27]. Here, SEM studies have done to investigate the fibril form of collagen and the collagen fibers packing. Figures 6 and 7 show the microstructure control and “treated” in two magnifications. As shown in these figures, the collagen filaments in the control sample have little connection to each other and fragile form than the collagen filaments in treated sample that shows better connection; wider fibril thickness (swollen) can support more flexibility than collagen, which is presented in lower value of T s as shown in Figs. 2 and 3. In addition, the packing between filaments of the “treated” sample is less than those belong to the control sample. It may be attributed to higher water absorption in the collagen filaments. Figures 8 and 9 indicate the SEM analysis on the microstructure aged treated and aged control in two magnifications. As shown in these figures, the untreated aged sample has more spacing area and gaps between collagen filaments than those of the aged treated sample, and in both samples, the gaps and torn fibers are more than treated sample, which can be attributed to the loss of humidity and the effect of UV and heat on damaging collagen fibers under artificial weathering assay.

Conclusions

DSC analysis has shown that for nanocomposite-treated historical leather sample, the temperature at which loss of physically adsorbed moisture occurs is lower for treated sample compared to untreated sample. Therefore, the nanocomposite treatment can be considered as a dressing agent in increasing flexibility of collagen fibers. In addition, the treated historical leather exhibited melting phase in higher range of temperature (i.e., minimum second peak and its shoulder in DTG curve) than those corresponding to the untreated leather that may be attributed to occur cross-linking between collagen and nano-hydroxyapatite. However, the artificial aging can induce their thermal behaviors to be close to each other. The results of the TG have shown that the historical leather sample revealed smaller water content and more structural heterogeneity, and the lowest first and second mass losing temperatures occurred between the treated leather and aged samples.

The nanocomposite treatment and artificial aging can affect the temperature range of the melting phase by shifting to the higher temperatures. It may be explained by increasing cross-linking interaction between collagen fibers under UV and humidity.

The SEM studies show that the collagen filaments in the treated leather sample have more thickness, uniformity, and better interaction to each other in comparison with untreated historical leather sample even after aging test.

References

Budrugeac P, Cucos A, Miu L. The use of thermal analysis methods for authentication and conservation state determination of historical and/or cultural objects manufactured from leather. J Therm Anal Calorim. 2011;104:439–50.

Cucos A, Budrugeac P, Mitrea S, Hajdu C. The influence of sodium chloride on the melting temperature of collagen crystalline region in parchments. J Therm Anal Calorim. 2013;111:467–73.

Gómez-Guillén MC, Giménez B, López-Caballero ME, Montero MP. Functional and bioactive properties of collagen and gelatin from alternative sources: a review. Food Hydrocoll. 2011;25:1813–27.

Krishnamoorthy G, Sadulla S, Sehgal PK, Mandal AB. Green chemistry approaches to leather tanning process for making chrome-free leather by unnatural amino acids. J Hazard Mater. 2012;215–216:173–82.

de Wolf FA. Chapter V collagen and gelatin. Prog Biotechnol. 2003;23:133–218.

Horie CV. Materials for conservation. second ed. Oxford: Elsevier; 2010.

Johnson A. Evaluation of the use of SC6000 in conjunction with klucel G as a conservation treatment for bookbinding leather: notes on a preliminary study. J Inst Conserv. 2013;36:125–44.

Kite M, Thomson R. Conservation of leather and related materials, Butterworth-Heinemann series in Conservation and Museology. Oxford: Elsevier; 2006.

Liu CK, Latona NP, DiMaio GL. Lubrication of leather with polyethylene glycol. J Am Leather Chem Assoc (JALCA). 2002;97:355–68.

Liu CK, Latona NP. Lubrication of leather with mixtures of polyethylene glycol and oil. J Am Leather Chem Assoc (JALCA). 2006;101:132–9.

Chahine C. Changes in hydrothermal stability of leather and parchment with deterioration: a DSC study. Thermochim Acta. 2000;365:101–10.

Siggel L, Molnar F. Computer modelling of a type-1 collagen fibril in water. 1. Model development and validation. J Am Leather Chem Assoc (JALCA). 2006;101:179–90.

Blee A, Matisons JG. Nanoparticles and the conservation of cultural heritage. Mater Forum. 2008;32:121–8.

Odlyha M. Introduction to the preservation of cultural heritage. J Therm Anal Calorim. 2011;104:399–403.

Baglioni P, Giorgi R, Dei L. Soft condensed matter for the conservation of cultural heritage. C R Chim. 2009;12:61–9.

Natali I, Tempesti P, Carretti E, Potenza M, Sansoni S, Baglioni P, Dei L. Aragonite crystals grown on bones by reaction of CO2 with nanostructured Ca(OH)2 in the presence of collagen. Implications in archaeology and paleontology. Langmuir. 2014;30:660–8.

Plavan V, Miu L, Gordienko I, Ibragimova A, Gavrilyuk N. Determination of the amino acid composition, structure and properties of the archaeological leather before and after restoration. Rev Chim. 2013;64:603–5.

Baglioni P, Giorgi R, Chelazzi D. Nano-materials for the conservation and preservation of movable and immovable artworks. Int J Herit Digit Era. 2012;1:313–8.

Baglioni P, Chelazzi D, Giorgi R, Poggi G. Colloid and materials science for the conservation of cultural heritage: cleaning, consolidation, and deacidification. Langmuir. 2013;29:5110–22.

Ionita I, Dragne AM, Gaidau C, Dragomir T. Collagen fluorescence measurements on nanosilver treated leather. Rom Rep Phys. 2010;62:634–43.

Odlyha M, Bozec L, Dahlin E, Grøntoft T, Chelazzi D, Baglioni P, Bonaduce I, Colombini MP, Larsen R, Scharff M, Hackney S, Thickett D. Memori project: evaluation of damage to exposed organic-based heritage materials and nanoforart: evaluation of nanoparticle based conservation treatment. Int J Herit Digit Era. 2012;1:319–24.

Gaidau C, Giurginca M, Dragomir T, Peticac A, Chen W. Study of collagen and leather functionalization by using metallic nanoparticles. J Optoelectron Adv Mater. 2010;12:2158–64.

Petica A, Gaidau C, Ma J, Simion D, Xu Q, Niculescu M. Antimicrobial electrochemically obtained nanosilver solutions for leather and furskin treatment. Rev Chim. 2013;64:1329–34.

Natali I, Tempesti P, Carretti E, Potenza M, Sansoni S, Baglioni P, Dei L. Aragonite crystals grown on bones by reaction of CO2 with nanostructured Ca(OH)2 in the presence of collagen. Implications in archaeology and paleontology. Langmuir. 2014;30:660–8.

Gaharwar AK, Dammu SA, Canter JM, Wu CJ, Schmidt G. Highly extensible, tough, and elastomeric nanocomposite hydrogels from poly(ethylene glycol) and hydroxyapatite nanoparticles. Biomacromolecules. 2011;12:1641–50.

Rajamanickam R, Kumari S, Kumar D, Ghosh S, Kim JC, Tae G, Gupta SS, Kumaraswamy G. Soft colloidal scaffolds capable of elastic recovery after large compressive strains. Chem Mater. 2014;26:5161–8.

Ershad-Langroudi A, Mirmontahai A. Hydroxyapatite nanoparticles and polythylene glycol treatment of historical leather Mechanical properties. J Am Leather Chem Assoc (JALCA). 2013;108:449–56.

Miles CA, Ghelashvili M. Polymer-in-a-box mechanism for the thermal stabilization of collagen molecules in fibers. Biophys J. 1999;76:3243–52.

Kronick PL, Cooke P. Thermal stabilization of collagen fibers by calcification. Connect Tissue Res. 1996;33:275–82.

Nielsen-Marsh CM, Hedges REM, Mann T, Collins MJ. A preliminary investigation of the application of differential scanning calorimetry to the study of collagen degradation in archaeological bone. Thermochim Acta. 2000;365:129–39.

Okamoto Y, Saeki K. Phase transition of collagen and gelatin. Kolloid Z Z Polym. 1964;194:124–35.

Nguyen AL, Vu BT, Wilkes GL. The dynamic mechanical, dielectric, melting behaviour of reconstructed collagen. Biopolymers. 1974;13:1023–37.

Samoillan V, Dandrirand-Lods J, Lamure A, Maurel E, Lacabanne C, Gerosa G, Venturini A, Casarotto D, Gherardini L, Spina M. Thermal analysis characterization of aortic tissues for cardiac valve bioprostheses. J Biomed Mater Res. 1999;46:531–8.

Pietrucha K. Changes in denaturation and rheological properties of collagen–hyaluronic acid scaffolds as a result of temperature dependencies. Int J Biol Macromol. 2005;36:299–304.

Budrugeac P, Miu L. The suitability of DSC method for damage assessment and certification of historical leathers and parchments. J Cult Herit. 2008;9:146–53.

Badea E, Della Gatta G, Usacheva T. Effects of temperature and relative humidity on fibrillar collagen in parchment: a micro differential scanning calorimetry (micro DSC) study. Polym Degrad Stabil. 2012;97:346–53.

Cucos A, Budrugeac P, Miu L. DMA and DSC studies of accelerated aged parchment and vegetable-tanned leather samples. Thermochim Acta. 2014;583:86–93.

Budrugeac P, Miu L, Bocu V, Wortmann FJ, Popescu C. The use of thermal analysis methods in investigation of the thermal degradation of collagen-based materials that are supports of cultural and historic objects. J Therm Anal Calorim. 2003;72:1057–64.

Budrugeac P, Miu L, Popescu C, Wortmann FJ. Identification of collagen-based materials that are supports of cultural and historical objects. J Therm Anal Calorim. 2004;79:975–85.

Popescu C, Budrugeac P, Wortmann FJ, Miu L, Demco DE, Baias M. Assessment of collagen-based materials which are supports of cultural and historical objects. Polym Degrad Stab. 2008;93:976–82.

Odlyha M, Foster GM, Cohen NS, Larsen R. Characterisation of leather samples by non-invasive dielectric and thermomechanical techniques. J Therm Anal Calorim. 2000;59:587–600.

Chelazzi D, Giorgi R, Baglioni P. Nanotechnology for vasa wood de-acidification. Macromol Symp. 2006;238:30–6.

Nashy EHA, Essa MM, Hussain AI. Synthesis and application of methyl methacrylate/butyl acrylate copolymer nanoemulsions as efficient retanning and lubricating agents for chrome-tanned leather. J Appl Polym Sci. 2012;124:3293–301.

Jaisankar SN, Ramalingam S, Subramani H, Mohan R, Saravanan P, Samanta D, Mandal AB. Cloisite-g-Methacrylic acid copolymer nanocomposites by graft from method for leather processing. Ind Eng Chem Res. 2013;52:1379–87.

Shao Y. Ch3: chemical analysis of leather. In: Fan Q, editor. Chemical testing of textiles. Florida: CRC Press; 2005. p. 47–71.

Hydroxyapatite Characterization in Sigma Aldrich http://www.sigmaaldrich.com/catalog/product/aldrich/702153?lang=en®ion=IR. Accessed 12 Jan 2015.

Polyethylene glycol 400 in Merck http://www.merckmillipore.com/GB/en/product/Polyethylene-glycol-400,MDA_CHEM-807485. Accessed 12 Jan 2015.

Della Gatta G, Badea E, Ceccarelli R, Usacheva T, Mašić A. Assessment of damage in old parchments by DSC and SEM. J Therm Anal Calorim. 2005;82:637–49.

Badea E, Della Gatta G, Budrugeac P. Characterisation and evaluation of the environmental impact on historical parchments by differential scanning calorimetry. J Therm Anal Calorim. 2011;104:495–506.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ershad-Langroudi, A., Mirmontahai, A. Thermal analysis on historical leather bookbinding treated with PEG and hydroxyapatite nanoparticles. J Therm Anal Calorim 120, 1119–1127 (2015). https://doi.org/10.1007/s10973-015-4461-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4461-z