Abstract

The influence of potassium lactate (PL) on the combustion behavior and semi-volatile compounds of tobacco during smoking is investigated in this study. The addition of PL showed no effect on the content of total particulate matter, nicotine-free dry particulate matter, puff number, and nicotine. Meanwhile, a 22.5 % increase in moisture content and 3 % decrease in CO content of mainstream smoke were observed when the added amount of PL was up to 2 %. The differential thermogravimetric curves indicated that PL decreased the maximum combustion rate and influenced the thermal degradation stage of tobacco by shifting the peak point of temperature to a higher value. The gas evolution profiles obtained from Fourier transform infrared spectroscopy during combustion showed that PL could lower the CO and CO2 yield, but did not affect the generation of CH4 and carbonyl compounds. A great variation in semi-volatile components of the mainstream smoke was also observed from the tobacco containing PL compared with the control. The comprehensive two-dimensional gas chromatography coupled to time-of-flight mass spectrometry analysis showed that PL increased the yield of alcohols, lactons, miscellaneous oxygenated compounds and amides, but decreased that of aldehydes, acids, pyrroles and pyrazines. A small added amount (0.2 %) of PL reduced the content of total semi-volatile substances, ketones, esters, phenols, hydrocarbons, pyridines, tobacco alkaloids, and nitrogenous compound. However, the contents of these substances were not affected when the added amount was >0.2 %. PL bound the ash during combustion, thereby leading to the change of combustion behavior and certain smoke components.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cigarette would lose moisture when placed at a low humidity environment, and “dry” cigarettes could yield harsher and more irritating smoke [1]. As one of the natural moisturizing agents widely used in food industry, potassium lactate (PL) presents strong hygroscopicity. In our previous study, PL has been shown to enhance the water-holding capacity of tobacco, which has also been confirmed by the research of Zhou et al. [2]. Aside from its effect on the physical properties, the effect of PL on the combustion behavior and mainstream smoke of tobacco should also be understood.

Potassium in tobacco leaf has an important role on the mainstream smoke chemistry. Several studies have already reported the influence of potassium salts on cigarette mainstream smoke chemistry. Some researchers have found that exogenous organic potassium could decrease the deliveries of tar, nicotine, and carbon monoxide in the mainstream [3–5]. However, some controversial issues have arisen in these studies regarding the impact of organic potassium on puff numbers. Yamamoto et al. [3] have reported that potassium nitrate could decrease the puff number, while potassium malate could not. Liu and Pariy [6] have found that malate and citrate potassium could increase the puff number, while potassium tartrate does not influence the puff number. Moreover, Peng et al. [5] have indicated that the total particulate matter (TPM), tar and nicotine decrease with the increase of the added amount of potassium carbonate; whereas the puff number first decreases, then increases.

Potassium affects the cigarette mainstream smoke chemistry by impacting the combustion process. Tobacco can be regarded as a mixture of carbohydrates, cellulose, hemicelluloses, lignin, organic acids, and inorganic components. Thus, the combustion process of tobacco is very complex. Alkali metals are usually considered to have a catalytic role in the thermal degradation and char formation of biomass [7, 8]. However, in the study of pectin and related acid carbohydrates, sodium and potassium inhibit the oxidation process by shifting the oxidation temperature to a higher temperature [9]. The combustion process of biomass may depend on several factors, such as composition of material, content of alkali metal salts, type of alkali metal salts, and so on. However, the influence of PL on tobacco combustion process is still unclear. Therefore, thermogravimetric analysis coupled with Fourier transform infrared analysis (TG-FTIR), which has been widely applied for investigating the volatile products produced during the pyrolysis and combustion process of biomass [10–15], has been used in this paper to study the combustion behavior of tobacco samples treated with PL. Different from combustion, pyrolysis is a thermochemical decomposition of organic material and does not involve reactions with oxygen or any other reagents.

Alkali metals could also affect the smoke components by altering the thermal degradation of the biomass. Potassium salt in cigarette can significantly change the morphology of ash during smoking, in which the ash is closely adhered together by melted potassium salt. This condition could cause the air flow blocked during smoking; hence, certain changes in cigarette smoke would be observed [16]. Izawa et al. [17] have found that the presence of potassium malate in cellulose accelerates the formation of various lower molecular compounds. Nevertheless, Nowakowski and Jones [8] have considered that the addition of potassium does not produce a large change in the tar product distribution during the pyrolysis of cell wall components (e.g., cellulose, hemicelluloses, and lignin). The mainstream smoke is the exhaled smoke released after taking a puff on a lit cigarette. It is necessary to understand the effect of potassium lactate on the mainstream smoke. Consequently, the effect of additive on the semi-volatile components in mainstream smoke also aroused our interest. Comprehensive two-dimensional gas chromatography coupled with time-of-flight mass spectrometry (GC×GC-TOF-MS) is a powerful tool that is highly suitable for the separation of complex mixture, such as tobacco smoke [18, 19], pinotage wines [20], French cider [21], and crude oils [22]. GC×GC involves the combination of a long non-polar column with a short polar column connected in series through a modulator. This method exhibits many advantages, such as high resolution, high sensitivity (about 20–50 times higher than the conventional one-dimensional GC), short analysis time, high qualitative accuracy, and so on.

A study applying TG-FTIR was carried out in the present work to elucidate the effect of different added amounts of PL on the combustion behavior and gaseous products of tobacco. In addition, it is necessary to understand the effect of PL on the mainstream smoke. GC×GC-TOF-MS was used to examine in detail the product distribution in the mainstream smoke. The influence of PL on the ash morphologies from tobacco was also examined by SEM analysis.

Materials and methods

Raw materials

The Burley tobacco generously given by Anhui Cigarette Manufactory of China was used in this study. The sample was cut to a width of 0.8 mm. For the composition analysis, moisture content was determined by the oven method in dry basis according to YC/T 31-1996 (Tobacco Industry Standard, China). Total sugar, starch, and pectin content were determined through the salicylic acid method [23, 24]. Protein content was determined by continuous flow analysis on Auto Analyzer 3 (SEAL Analytical GmbH, Germany) according to the methods of YC/T 249-2008. Crude fiber content was analyzed according to the method of GB/T 5009.10-2003.

Subsequently, spraying method was applied to obtain the PL-added tobacco to increase the homogeneity of the samples [3, 6]. 20 mL of PL solution at different concentrations (0.02, 0.05, 0.1, and 0.2 g mL−1) were sprayed on 200 g samples of the cut tobacco corresponding to the mass ratios of PL to the tobacco of 0.2, 0.5, 1, and 2 %, respectively. The shredded control sample was then sprayed with 20 mL of water. These shreds were conditioned at 22 °C and 60 % relative humidity for a week, and processed to sample cigarettes. The final potassium content of samples was analyzed by the flam photometry method according to YC/T 173-2003. The sample cigarettes were then conditioned at 22 °C and 60 % relative humidity for at least 2 days and mass selected before being smoked.

Mainstream smoke chemistry of the cigarettes

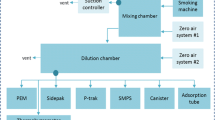

The mainstream smoke chemistry of the cigarettes, including TPM (mg cig−1), water (mg cig−1), nicotine (mg cig−1), nicotine free dry particulate matter (NFDPM) (mg cig−1), CO (mg cig−1), and puff number (cig−1) were determined using a smoking machine (Borgwaldt RM200A, Germany) and gas chromatography (HP7890A, Agilent Technologies, Wilmington, DE, USA) according to YC/T 157-2001 and GB/T 23355-2009. All measurements were conducted in triplicate.

Thermal analysis of the cigarettes

Sample preparation

The shred samples were dried in an oven at 40 °C and grinded. Particles passed through a 60 mesh screen were chosen to minimize the heat transfer effects [11, 25] and provide increased homogeneity for comparative purposes [26]. The particles were then conditioned at 22 °C and 60 % relative humidity for at least 2 days.

TG-FTIR analysis

Thermogravimetric/infrared spectrometry analysis was performed using a TGA Q5000 IR thermogravimetric analyzer coupled with a Nicolet 6700 FTIR spectrophotometer. About 60 mg of the sample was placed in an alumina crucible and heated from 30 to 900 °C with a ramp rate of 20 °C min−1. The atmosphere was composed of 10 % oxygen and 90 % nitrogen, and the flow rate was 100 mL min−1. The line transferred the evolved gases from the TG to the FTIR, and the IR cell was maintained at 210 and 200 °C, respectively. The FTIR was operated in the continuous scan mode covering 4,000–500 cm−1 at a resolution of 4 cm−1. All measurements were carried out in triplicate.

Semi-volatile components in the mainstream smoke: GC×GC system

Sample preparation

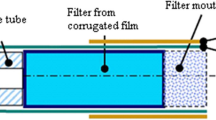

The particulate phase was collected onto a glass fiber pad from the mainstream smoke of 20 cigarettes under the conditions of the International Organization for Standardization (ISO) (35 cm2/2 s/60 s) on a smoking machine (Borgwaldt RM200A, Germany). The glass fiber pad and 30 mL of dichloromethane containing 6.7 μg mL−1 of 2-phenylethyl acetate (internal standard) were placed in a conical flask with a stopper. After shaking for 30 min, the aqueous extract was filtered through a 0.45 μm organic phase filter membrane, and the extract was used for analysis. All measurements were conducted in triplicate.

GC×GC-TOF-MS analysis

A GC×GC system consisting of an Agilent 7890 GC (Agilent Technologies, Wilmington, DE, USA) equipped with a single jet, liquid nitrogen cryogenic modulator(KT-2001) (Zoex Lincoln, NE,USA), and coupled with a Pegasus 4D time-of-flight mass spectrometer (Leco St. Joseph, MI, USA), was used for the analysis of semi-volatile components in the mainstream smoke. The column set consisted of a 30 m × 0.25 mm × 0.25 μm Rxi-5MS as a primary column (1D), coupled with a 1.75 m × 0.1 mm × 0.1 μm Rtx-17 (Restek, Bellefonte, PA, USA) as the second column (2D). A modulation period of 4 s was used with the cryogenic trap. The separation was performed using the following temperature program: the primary column was subjected to an initial temperature of 50 °C, which was kept for 0.2 min, then ramped at 3 °C min−1 to 250 °C, and held for 5 min; whereas the second column was subjected to an initial temperature of 60 °C, which was kept for 0.2 min, then ramped at 3 °C min−1 to 280 °C, and held for 5 min. The injector was in split mode, with a split ratio of 50:1. Helium was used as carrier gas at a constant flow rate of 1 mL min−1. The transfer line was maintained at 250 °C. Ions in the mass range of 35–400 amu were acquired at a rate of 100 spectra s−1. The ion source temperature was 240 °C and the detector voltage was set to 1,500 V. The filament voltage was 70 eV, and the modulation period was 6 s with a hot pulse time of 1.2 s. A solvent delay of 360 s was used.

Data processing was performed using the peak detection algorithm of the ChromaTOF software to automatically identify the peaks with signal to noise ratio higher than 100 and similarity value greater than 800. Compounds with authentic standards were identified by comparing their mass spectra and retention indices with those of the standards (marked with a superscript lowercase letter in Appendix 1). Compounds without authentic compounds were tentatively identified by matching the mass spectra with those in the NIST 08 libraries.

Quantitative data for an identified compound was obtained using the internal standard method. The method could improve precision of quantitative analysis by compensating for the potential sources of errors (such as sample preparation and variability inherent in the GC system). The tentative identified analytes without standards were quantified with respect to the internal standard, assuming that the calibration factor was 1.00 for all the compounds. A series of n-alkanes (C6–C20) were also used to establish the first-dimension retention indices (RI) for each peak.

Characterization of the tobacco ash

Ash preparation

The ashes from the tobacco and tobacco treated with PL were prepared in a tube furnace. The study was carried out in an atmosphere composed of 10 % oxygen and 90 % nitrogen under 370 and 580 °C, respectively, and held for 10 min.

SEM analysis

After coating with gold, the ash samples were examined with a scanning electron microscope (SEM, Hitachi S-4800) (Hitachi, Ltd., Japan).

Results and discussions

Mainstream smoke chemistry of the cigarettes

Composition analysis of the control tobacco (100 g product) exhibited an initial moisture content of 11.66 ± 0.13 g; total sugar of 8.49 ± 0.07 g; pectin of 4.84 ± 0.10 g; starch of 1.45 ± 0.24 g; protein of 5.64 ± 0.22 g and crude fiber of 21.82 ± 0.92 g. The final potassium content of tobacco treated with 0, 0.2, 0.5, 1, and 2 % PL were 3.60, 3.65, 3.75, 3.86, and 4.13 %, respectively. The results regarding the influence of PL on mainstream smoke chemistry are shown in Table 1. Generally, an appropriate increase in moisture content is conducive for improving the dryness taste during smoking. The decrease on the level of CO in mainstream smoke has aroused great concern in recent years due to its adverse health effect. The addition of PL has been shown to result in the increase of moisture content and the reduction of CO content in mainstream smoke. When the added amount was up to 2 %, the moisture content was largely increased by approximately 22.5 %, while the CO content was slightly reduced by about 3 %. Hence, the addition of PL has a positive role in the moisture content and CO content in the mainstream. In addition, PL did not exhibit significant effects on TPM, nicotine, NFDPM, and puff number. Our result is different with the findings of Liu and Pariy [6]. They found that three potassium organic acid salts (malate, citrate, and tartrate) could reduce the mainstream NFDPM, nicotine, and CO to different degrees. Malate potassium and citrate potassium could increase the puff number. This difference may be due to the different anionic groups of the salts used in these two studies.

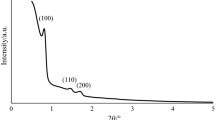

Differential thermogravimetric analysis

The Differential thermogravimetric (DTG) results obtained were the average values of the repeated experiments; the mass was reproducible to ±0.18 % and the temperature to ±1.0 °C. The comparison of DTG results indicating the influence of PL on the combustion of tobacco is shown in Fig. 1. The control sample had four main unresolved regions. The first step (from 30 to 140 °C, with the peak temperature at 83.1 °C) of thermal degradation was attributed to the moisture evaporation. The second step in the temperature range of 140–370 °C was due to the thermal decomposition of carbohydrates and cellulose. The third step between 370 and 573.9 °C was due to the combustion of other organic compounds (such as protein and acids) and the residual char of carbohydrates [27]. The subsequent process from 574 to 807 °C was due to the thermal decomposition of char [28]. With the addition of PL, the peaks in the second and third regions became slightly weak, indicating that the presence of potassium decreased the maximum combustion rate, consistent with that of Nowakowshi et al. [7]. In addition, the peak in the third step shifted slightly to a higher temperature when PL was added. For example, the peak temperature was at 422.9, 435.7 °C for the control and 2 % sample, respectively. The end-point temperature of the third stage slightly moves toward higher temperature depending on the PL concentration, especially the 2 % addition (from 573.9 to 580.1 °C). The char residue of tobacco treated with 0, 0.2, 0.5, 1, and 2% PL was 13.15, 13.38, 13.65, 14.02, and 14.69 % after the combustion process, respectively. This result revealed that PL hindered the combustion process and enhanced char formation in this study. However, some researchers considered that potassium has a catalytic role in product thermal decomposition. Wang et al. [27] have proven that potassium acetate could promote the pyrolysis of raw willow. Baskevitch and Horler [29] has pointed that potassium chloride in tobacco would have no effect on the burn rate but potassium malate would have a considerable catalytic effect because of the different anionic groups. The different results obtained in the current study may be due to the combined effect of the potassium and the lactate groups.

FTIR pyrolysis analysis

The FTIR technique can directly identify gaseous products and help in better understanding the thermal decomposition mechanism. A slight delay in time can be observed between the total FTIR absorbance data and the TG data because the gaseous products generated during the combustion would transfer from the TG analyzer to the FTIR gas cell. In the primary combustion stage, the peak intensity of the FTIR absorbance corresponded to the DTG peak. According to the comparison, the FTIR absorbance peaks were delayed by about 1 min compared with that of the DTG curve peaks. After being amended, the appearance of the DTG peaks coincided with that of the total FTIR absorbance peaks, as shown in Fig. 2.

Figure 3a shows the 3D FTIR spectra (absorbance-wave number-minutes) of the gaseous products obtained from the combustion of the control. The 2D spectra at the peak temperature in the four stages during combustion are shown in Fig. 3b. Some gas products with specific IR absorption can be identified easily. The attribution of the peaks at 3,078 cm−1 (C–H stretching of aromatic hydrocarbons) and 1,600–1,500 cm−1 (typical skeleton vibration of aromatic rings) to the aromatic compounds, such as phenols, benzene, and polyaromatic hydrocarbons, is definite. The peak at 965 cm−1, assigned to the N–H deformation vibrations, indicates the existence of NH3 [12]. The spectra around 3,700 and 1,500 cm−1 are due to the absorption of water vapor [13]. Carbon dioxide can be detected in the absorption region of 2,400–2,244 cm−1 (stretching vibration) and 669 cm−1 (bending vibration). The absorption found at 2,180 and 2,108 cm−1 is well known to be due to the absorption of carbon monoxide [28]. The absorption band at 3,200–2,850 cm−1 is ascribed to the presence of hydrocarbons, of which methane is the most abundant. The appearance of the absorption band at 1,740 cm−1 is due to the C=O (stretching vibration) in the carbonyl groups [10]. The main gases produced during the combustion of tobacco were H2O, CO, CO2, carbonyl compounds (such as aldehydes, ketones, and acids), NH3, alkanes and so on, as shown in Fig. 3. The FTIR intensity of CO2 was the strongest in the regions except for the first step.

The relationship between the intensity of the characteristic peak and temperature for some typical volatile components (CO2, CO, carbonyl compounds, and CH4) is presented in Fig. 4 to further understand the effect of PL on the generation of gaseous products.

Carbon monoxide and carbon dioxide are the major gaseous products in tobacco smoke, accounting for about 60 % by mass of the products in both mainstream and sidestream smoke [30, 31]. Two major CO peaks can be observed at about 290 and 420 °C, while three major CO2 peaks are observed at 290, 460, and 725 °C, respectively. CO and CO2 formed in the temperature range of 140–580 °C were attributed to the thermal decomposition of tobacco compounds (such as starch, cellulose, and acids), and part of the carbon monoxide is converted from carbon dioxide by carbonaceous reduction [32]. When the temperature was beyond 580 °C, the generation of CO2 was due to the combustion of residue char and thermal decomposition of inorganic matter in the tobacco leaf [12]. The addition of PL lowered the intensity of the CO peak in the temperature range of 140–580 °C as well as CO2 peak in the range of 370–580 °C. Recent studies have pointed that alkali metals, such as sodium or potassium, initially bind in the substrate, and then decompose during pyrolysis between 200 and 400 °C to produce a metal complex in the char, which inhibits the carbon char from oxidation at oxidation temperatures [9]. A similar mechanism may occur in tobacco. The potassium bound in char before 400 °C, thereby preventing the combustion of tobacco components.

Figure 4 shows three major peaks for C=O at about 110, 290, and 420 °C. The carbonyl compounds were mainly produced during the second stage (about 160–370 °C), in which the thermal decomposition of tobacco compounds (such as carbohydrate, starch, and cellulose) was the dominant process. However, the yield of carbonyl compounds was not affected by the addition of PL.

CH4 was generated during the two stages which were in the temperature range of 150–370 °C and 370–590 °C, respectively. CH4 is mainly produced from the cracking of methyl, oxymethylene, and polymethylene components, and the aliphalic hydrocarbons [33]. The presence of PL showed no significant influence on the formation of CH4.

Semi-volatile components in the mainstream smoke

In the mainstream smoke of cigarette, different contents among the components will strongly affect the quality of the flavor. In the aforementioned studies, we have proven that PL affects the combustion process, which may result in changes in the distribution of semi-volatile products during smoking. To study the influence of PL on the semi-volatile compounds in mainstream smoke, high resolution of the GC×GC-TOF-MS method has been introduced to analyze the semi-volatile compounds. Given the large number of semi-volatile compounds, small peaks (signal to noise ratio of less than 100) and some peaks (similarity value of less than 800) were not analyzed in this study. Table 2 shows the summary of the number and the concentration of the components. And, the semi-volatile components of the samples listed by chemical function groups are shown in Appendix 1. Similar components were obtained in the samples, but with different concentrations in some compounds.

Compared to the control, the addition of 0.2 and 0.5 % PL to the tobacco could increase the number of semi-volatile compounds (from 200 to 207, 202), while a large added amount (higher than 0.5 %) has opposite effect (from 200 to 196,184) (Table 2). Considering the quantitative analysis, samples containing PL (except the sample containing 0.2 % PL) showed no significant differences in the total amount, while a small added amount (0.2 %) could lead to the reduction of the content of semi-volatile substances (reduced by about 22 %) compared with the control. Table 2 and Appendix 1 showed different details in different classes of compounds.

The yield of alcohols increased with the addition of PL. The semi-volatile compounds produced by the samples all showed that 2-amino-benzenemethanol was the most abundant alcohol (nearly 50 % in the control). The presence of PL could promote the generation of 2-amino-benzenemethanol. (Z)-nerlidol, which could provide a rose and apple aroma to tobacco, was not found in the control, while abounded in the samples containing PL.

Most aldehydes in the mainstream smoke were formed by thermal degradation of the tobacco components (such as cellulose, pectin, wax, and protein), which would have an adverse health effect. Suitable added amount of PL could reduce the amount of some aromatic aldehydes. The dominant components of aromatic aldehydes, such as benzaldehyde and benzeneacetaldehyde, showed the highest level in the control, but the lowest level in the 0.2 % sample. Meanwhile, high added amount of PL (2 %) could inhibit the generation of certain aldehydes, such as 2-methyl-butanal, d-allose. As a long-chain aliphatic aldehyde, 9, 12, 15-octadecatrienal was only found in the control with high amount. The total aldehyde content could be reduced by about 60 % in the presence of PL, but the decreased degree did not increase with increase of the added amount of PL.

Containing a number of important tobacco flavors, ketones greatly contributed to the smoke flavor [34]. Ketones are a big class in the mainstream and contain about 25 compounds in this study. Adding PL in the cigarettes did not have a role on the ketone formation when the added amount was higher than 0.2 %. Only small added amount could significantly reduce the ketone content.

Both phenols and acids are acidic components of smoke condensates, which reflect the quality of tobacco products. Some phenols have been considered to arouse an oral astringent process during smoking, which is one of the reasons that lead to dry mouth sensation [35]. The total content of phenols, produced by the tobacco sample containing 0.2 % PL, showed the lowest level among all the samples. When the added amounts were over 0.2 %, PL did not affect the content of phenols, but reduced the quantity of the compounds. As the highest content compound of phenols, phenol could be reduced by the addition of PL. Phenol exhibited the lowest content, which was about 75 % percent that of the control, when the added amount was 0.2 %. In the acid class of the control sample, hexadecanoic acid was the dominant compound, followed by linolenic acid. The yield of hexadecanoic acid decreased with the increase of PL amount. The content of hexadecanoic acid in the control was about two times higher than that in the 2 % sample. Linolenic acid, which could lead to more rough taste of the smoke [36], was only found in the control. In the presence of PL, both the quality and quantity of acids were reduced. Contrary to its effect on acids, PL had an opposite effect on amides.

Esters have an aroma or taste acceptable to consumers [37]. Tricetin, found in largest amount in the ester class, exhibited the lowest level (489.88 μg cig−1) in the sample with 0.2 % PL. The result showed that a proper dose of PL could decrease the production of tricetin, whereas a high dose had no effect. The 1, 2-benzenedicarboxylic acid, diisooctyl ester was another compound with a large amount aside from tricetin. Different from the effect of PL on the yield of tricetin, the higher the amount of PL being added, the lower the amount of 1, 2-benzenedicarboxylic acid, diisooctyl ester produced. Compared with the control (63 μg cig−1), the content of 1, 2-benzenedicarboxylic acid, diisooctyl ester was lowered to only 1.3 μg cig−1 in the sample with 2 % PL. However, from the point of view of the total content, only low addition amount (0.2 %) reduced the yield of esters. When the added amount of PL (>0.2 %) was increased, the yield of esters in the samples containing PL exhibited no significant difference compared with the control.

Lactons are a rich source of flavor for tobacco, and many of the lower molecular mass lactones are used as flavorants for candies, gums and so on [34]. The results showed that adding PL to the cigarette was conductive for the generation of lactons. The content of lactones generated from the sample containing 2 % PL was more than three times of that generated from the control. Similar to the effect of PL on the formation of lactones, the amount of miscellaneous oxygenated compounds was increased both qualitatively and quantitatively.

Hydrocarbons containing 56 compounds were the largest class in the control sample. PL showed a decreasing effect on the quantity of hydrocarbons. The number of detected hydrocarbons decreased from 56 to 48 with the increase of added PL amount. However, from the point of quality, the reducing effect could only be observed when small dose of PL was added. When the added amount was beyond 0.2 %, PL showed no effect on the hydrocarbon content. Limonene, which exhibited about 50 % of the sum of hydrocarbons, was regarded as the major compound in this class. Limonene is used extensively in fragrance compositions, particularly in soap and detergent products [34]. Compared with the control, the addition of 2 % PL could significantly increase the limonene content by about 35 %.

Pyrroles, pyridines, pyrazines, and nitrogenous compounds are important because of their positive flavoring properties [34, 37]. However, the generation of pyrroles and pyrazines was inhibited by PL in the study. When the added amount of PL reached 2 %, the yield of these two compounds was reduced by about 29 and 45 %, respectively. The yield of pyridines and nitrogenous compounds was only reduced in the sample containing 0.2 % PL. The other samples showed no differences in the formation of pyridines and nitrogenous compounds.

The concentration of tobacco alkaloids in the mainstream smoke is very large. Alkaloids are not considered positive flavorants because they contribute a harsh, irritating flavor to the smoke. However, cigarettes that contain no or very low levels of tobacco alkaloids have never found consumer acceptance [37]. Alkaloids have a complex role in contributing tobacco smoke flavor. The results showed that the content of nicotine first decreased, and then increased to the original level, and no longer increased with the increase of the added amount of PL.

Based on the above, it could be seen that adding PL in the tobacco could increase the yield of alcohols, lactons, miscellaneous oxygenated compounds, and amides, but decrease the yield of aldehydes, acids, pyrroles, and pyrazines. A small added amount (0.2 %) could lead to the reduction of the content of ketones, esters, phenols, hydrocarbons, pyridines, tobacco alkaloids, and nitrogenous compound compared with the control; when the added amount was beyond 0.2 %, the content of these substances was not affected by the presence of PL. PL may play different mechanisms on the combustion process of tobacco, such as acting as catalysts [7] and altering the ash morphology [6]. The mechanism that played a leading role may depend on the adding amount of PL, therefore leading to the different effects of PL on the formation of the semi-volatile components.

Characterization of the tobacco ash

The SEM ash morphologies from the control tobacco and the PL-added tobacco obtained at 370 and 580 °C are shown in Figs. 5 and 6, respectively. Figure 5 clearly shows that the microscopic features from the two samples were distinctively different. The ash from the tobacco treated with PL appeared to be more sticky or connected. Consistent with previous studies [6, 9], the potassium salt melted or decomposed, and then bonded the ash closely. Thus, the air flow was restricted and the carbon char was inhibited from combustion during smoking. As the sample was charred to higher temperature (580 °C), the microscopic characterizations of the two samples showed no obvious difference (Fig. 6). The ash bound by the melted PL decomposed at 580 °C, which would not shield the ash from combustion at higher temperature (>580 °C). The result agrees with the aforementioned DTG analysis, where PL did not affect the fourth stage from 580 to about 800 °C. It was indicated that the majority of the components of cigarette smoke were formed from tobacco at temperature below 600 °C [32]. The change in the morphology of the ash before 580 °C may be one of the reasons that lead to the alteration of the combustion behavior, resulting in the variation of certain smoke components.

Conclusions

The effect of PL as an additive on tobacco combustion behavior and mainstream smoke was investigated in this study.

The mainstream smoke chemistry detection of the cigarettes presented that PL had no effect on the content of TPM, NFDPM, puff number, and nicotine. However, moisture content showed a 22.5 % increase and CO showed about 3 % decline in the mainstream smoke when the added amount was up to 2 %.

The combustion tests showed the additive properties of the tobacco containing potassium lactate based on the features of the DTG profiles compared with those of the control tobacco. DTG analysis revealed that tobacco thermal degradation occurred in four steps. PL inhibited the high temperature thermal degradation process. The peak temperature of the combustion stage for the control tobacco was about 13 °C lower than that for the tobacco containing 2 % PL. The yields of some combustion gaseous products were also influenced by the presence of PL: the evolution of CO and CO2 were in relatively lower amount, while the yield of carbonyl compounds and CH4 remained unchanged.

Furthermore, a variation in semi-volatile compounds during smoking was observed from the tobacco containing PL compared with the control tobacco. The substances were divided into 15 categories according to the functional groups, including alcohols, aldehydes, ketones, acids, esters, lactons, phenols, hydrocarbons, miscellaneous oxygenated compounds, pyrroles, pyridines, pyrazines, amides, tobacco alkaloids, and nitrogen compounds. A small added amount (0.2 %) could lead to the reduction of the content of semi-volatile substances compared with the control. However, when the added amount was beyond 0.2 %, the total content of semi-volatile substances was not affected by the presence of PL. The same results were also achieved during the generation of ketones, esters, phenols, hydrocarbons, pyridines, tobacco alkaloids, and nitrogenous compound. In addition, adding PL in the tobacco could increase the yield of alcohols, lactons, miscellaneous oxygenated compounds, and amides, but decreases the yield of aldehydes, acids, pyrroles, and pyrazines.

The SEM analysis of the tobacco ash revealed that PL altered the ash morphology in a way that bonded the ash stronger and restricted the air flow. This result could be one of the reasons that resulted in the modification of the combustion behavior and smoke components.

References

Bevan PC. A survey of the water activity-moisture content relationships of tobaccos and reconstituted. 1988. http://legacy.library.ucsf.edu/tid/flz77a99/pdf. Accessed 13 Dec 2012.

Zhou B, Zhang TD, Li G, Hu WY, Li CB, Yang XY, Zeng XY, Gao R. Lactic acid and lactate used as humectants in cigarettes. Acta Tabacaria Sin. 2011;17(6):8–12.

Yamamoto T, Umemura S, Kaneko H. Effect of exogenous potassium on the reduction in tar, nicotine and carbon monoxide deliveries in the mainstream smoke of cigarettes. Beitrage zur Tabakforschung International. 1990;14(6):379–85.

Liu Z, Cui L, Miao MM, Zhu ZZ, Hu Q. Effects of combustion improver potassium citrate and sodium citrate mixture on mainstream smoke. Tob Sci Technol. 2008;12:10–3.

Peng B, Jin ZY, Weng XY, Liu Y. Effect of K2CO3 on cigarette tar, nicotine, free nicotine, pH value and impact. Tob Sci Technol. 2007;7:8–10.

Liu C, Pariy A. Potassium organic salts as burn additives in cigarettes. Beitrage zur Tabakforschung International. 2003;20(5):341–7.

Nowakowshi DJ, Jones JM, Brydson RMD, Ross AB. Potassium catalysis in the pyrolysis behaviour of short rotation willow coppice. Fuel. 2007;86:2389–402.

Nowakowski DJ, Jones JM. Uncatalysed and potassium-catalysed pyrolysis of the cell-wall constituents of biomass and their model compounds. J Anal Appl Pyrolysis. 2008;83(1):12–25.

Waymack BE, Belote JL, Baliga VL, Hajaligol MR. Effects of metal salts on char oxidation in pectins/uronic acids and other acid derivative carbohydrates. Fuel. 2004;83(11–12):1505–18.

Fu P, Hu S, Xiang J, Li P, Huang D, Jiang L, Zhang AC, Zhang JY. FTIR study of pyrolysis products evolving from typical agricultural residues. J Anal Appl Pyrolysis. 2010;88(2):117–23.

Ahamad T, Alshehri SM. TG-FTIR-MS (evolved gas analysis) of bidi tobacco powder during combustion and pyrolysis. J Hazard Mater. 2012;199–200:200–8.

Zhou S, Ning M, Xu YB, Hu Y, Shu JS, Wang CH, Ge SL, Tian ZF, She SK, He Q. Thermal degradation and combustion behavior of reconstituted tobacco sheet treated with ammonium polyphosphate. J Anal Appl Pyrolysis. 2013;100:223–9.

Wu SL, Shen DK, Jun H, Rui X, Zhang HY. TG-FTIR and Py-GC-MS analysis of a model compound of cellulose-glyceraldehyde. J Anal Appl Pyrolysis. 2013;. doi:10.1016/j.jaap.2013.02.009.

Liu XX, Ma HX, Yu L, Chen L, Tong Z, Chen P. Thermal-oxidative degradation of high-amylose corn starch. J Therm Anal Calorim. 2013. doi:10.1007/s10973-013-3354-2.

Zhou S, Ning M, Xu YB, Shu JS, Wang CH, Hu Y, Ge SL, Tian ZF, She SK, He Q. Effects of melamine phosphate on the thermal decomposition and combustion behavior of reconstituted tobacco sheet. J Therm Anal Calorim. 2013;112(3):1269–76.

Liu ZH, Sun HL, Dong XC, Miao MM, Li B. Application of potassium salt in cigarette. J Yunnan Natl Univ (Nat Sci). 2005;14(4):32–325.

Izawa K, Matsukura M, Ishizu Y. Curie-point pyrolysis of cellulose in the presence of potassium malate. Agric Biol Chem. 1990;54(4):957–63.

Lu X, Cai JL, Kong HW, Wu M, Hua RX, Zhao MY, Liu JF, Xu GW. Analysis of cigarette smoke condensates by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry I acidic fraction. Anal Chem. 2003;75:4441–51.

Dalliige J, van Stee LLP, Xu XB, Williams JT, Beens J, Vreuls RJJ, Brinkman UAT. Unravelling the composition of very complex samples by comprehensive gas chromatography coupled to time-of-flight mass spectrometry cigarette smoke. J Chromatogr A. 2002;974:169–84.

Weldegergis BT, Villiers AD, McNeish C, Seethapathy S, Mostafa A, Gorecki T, Crouch AM. Characterisation of volatile components of Pinotage wines using comprehensive two-dimensional gas chromatography coupled to time-of-flight mass spectrometry (GC × GC-TOFMS). Food Chem. 2011;129:188–99.

Villière A, Arvisenet G, Lethuaut L, Prost C, Serot T. Selection of a representative extraction method for the analysis of odourant volatile composition of French cider by GC-MS-O and GC×GC-TOF-MS. Food Chem. 2012;131(4):1561–8.

Wang GL, Shi SB, Wang PR, Wang TG. Analysis of diamondoids in crude oils using comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Fuel. 2013;107:706–14.

Ma D, Liu W, Wei Q, Liu G, Yang T. Determination of pectin in tobacco with 3,5-dinitrosalicylic acid colorimetry. Tob Sci Technol. 2006;8:38–41.

Yin J, Lu H, Xie Q, Ding J, Li N. A study on rapid colorimetric determination of water soluble total sugar, reducing sugar and starch in tobacco with 3,5-dinitrosalicylic acid. J Yunnan Agric Univ. 2007;22:829–37.

Cardoso CR, Miranda MR, Santos KG, Ataíde CH. Determination of kinetic parameters and analytical pyrolysis of tobacco waste and sorghum bagasse. J Anal Appl Pyrolysis. 2011;92(2):392–400.

Ge SL, Xu YB, Tian ZF, Zhou S, She SK, Hu YH, Sheng LS. Effect of urea phosphate on thermal decomposition of reconstituted tobacco and CO evolution. J Anal Appl Pyrolysis. 2013;99:178–83.

Wang W, Wang Y, Yang LJ, Liu BZ, Lan MB, Sun WL. Studies on thermal behavior of reconstituted tobacco sheet. Thermochim Acta. 2005;437:7–11.

Zhou S, Xu YB, Wang CH, Tian ZF. Pyrolysis behavior of pectin under the conditions that simulate cigarette smoking. J Anal Appl Pyrolysis. 2011;91:232–40.

Baskevitch N, Horler JW. Organic potassium: its role in controlling the rate of burn and tar content of tobacco products. 1993. http://tobaccodocuments.org/lor/87914514-4519.html. Accessed 15 Dec 2012.

Browne CL, Keith CH, Allen RE. The effect of filter ventilation on the yield and composition of mainstream and sidestream smokes. Beitrage zur Tabakforschung International. 1980;10(2):81–90.

Keith CH, Tesh PG. Measurement of the total smoke issuing from a buring cigarette. Tob Sci. 1965;9:61–4.

Baker RR. A review of pyrolysis studies to unravel reaction steps in buring tobacco. 1987. http://legacy.library.ucsf.edu/documentStore/c/o/n/con45a00/Scon45a00.pdf. Accessed 15 Dec 2012.

Han L, Wang QH, Ma Q, Yu CJ, Luo ZY, Cen KF. Influence of CaO additives on wheat-straw pyrolysis as determined by TG-FTIR analysis. J Anal Appl Pyrolysis. 2010;88:199–206.

Leffingwell JC, Leffingwell D, Foxfire F. Chemical and sensory aspects of tobacco flavor. 1998. http://legacy.library.ucsf.edu/tid/uid13c00/pdf. Accessed 16 Dec 2012.

Read GA, Baker RR, Stephenson AG, Wigand JS, Dunn PJ, Massey SR, Rittershaus E. Tobacco smoke afertaste—the role of catechol and other smoke phenols in the month dryness sensation. 1992. http://legacy.library.ucsf.edu/documentStore/o/s/f/osf51f00/Sosf51f00.pdf. Accessed 22 Dec 2012.

Xie JP. Tobacco and chemical components of the smoke. 1st ed. Beijing: Chemistry Industry Press; 2011.

Rodgman A, Perfetti TA. The chemical components of tobacco and tobacco smoke. 2nd ed. New York: CRC press; 2009.

Acknowledgements

This work was supported by the Scientific Foundation of China National Tobacco Corporation (No. 110200901002). The authors would also like to thank R&D Center of China Tobacco Anhui Industrial Corporation.

Author information

Authors and Affiliations

Corresponding author

Appendix 1

Appendix 1

See Table 3.

Rights and permissions

About this article

Cite this article

Yin, C., Xu, Z., Shu, J. et al. Study on the effect of potassium lactate additive on the combustion behavior and mainstream smoke of cigarettes. J Therm Anal Calorim 115, 1733–1751 (2014). https://doi.org/10.1007/s10973-013-3478-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3478-4