Abstract

The structure–viscosity relationship of GexS(1−x) (x = 0.30, 0.32, 0.33, 0.333, 0.34, 0.36, 0.38, 0.40, 0.42, and 0.44) glass melts was studied. The structure of studied glass melts was described by the thermodynamic model of Shakhmatkin and Vedishcheva. Thermodynamic modeling resulted in four components with significant abundance in the studied glasses, i.e., Ge, S, GeS, and GeS2. The results of thermodynamic model allowed interpretation of compositional dependence of T g in form of linear function of equilibrium molar amounts of system components. The experimental viscosity data were alternatively described by various commonly used viscosity equations—Adam and Gibbs, Avramov and Milchev, and MYEGA. The compositional dependence of parameters of the above viscosity equations was described by multilinear formulas with independent variables alternatively defined as the total molar fractions of Ge and S in glass, and the equilibrium molar amounts of components of the thermodynamic model. The statistical analysis of the nonlinear regression results was performed and only the statistically significant members were retained in the multilinear forms. The assumption of composition-independent high temperature–viscosity limit was checked for all used viscosity equations. It was found that statistically more robust description of experimental data is obtained for the compositional-dependent quantity. Simultaneously it was proved that the experimental viscosity data were better described by the equilibrium molar amounts of the thermodynamic model than by the overall elemental glass composition. The obtained results confirmed the structural information acquired from the thermodynamic model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to high transmittance in the infrared region, low phonon energies, and significant nonlinearity of their optical properties chalcogenide glasses have been the subject of intense fundamental and applied research for a long time [1–4]. Namely germanium sulfide glasses are interesting materials which can be used as sensitive media for optical recording, as light guides, as high resolution inorganic photoresistors, or antireflection coatings. A number of papers are devoted to the study of the crystallization behavior in GexS(1−x) glasses [5–8]. Surprisingly, there are only few references [9–13] available on the viscosity behavior of this or analogous selenide systems. Moreover, the available viscosity experimental data are not treated by the contemporary viscosity models.

In the present work, the experimental temperature dependence of viscosity of GexS(1−x) (x = 0.30, 0.32, 0.33, 0.333, 0.34, 0.36, 0.38, 0.40, 0.42, and 0.44) glass melts published by Málek and Shánělová [13] was studied by applying various commonly used viscosity models—Andrade or Frenkel constant activation energy model [3, 4, 14–18], Adam and Gibbs [17, 19], Avramov and Milchev [17, 20], and MYEGA [17, 21]. The compositional dependence of the parameters of considered viscosity models was alternatively described by multilinear forms using as independent variables the overall atomic glass composition—i.e., mole fractions x g(Ge) and x g(Ge), and using the equilibrium molar amounts of components considered in the thermodynamic model of Shakhmatkin and Vedishcheva (i.e., n(Ge), n(S), n(GeS), and n(GeS2)).

Methods

Thermodynamic model of Shakhmatkin and Vedishcheva

Mainly in the field of silicate glasses the thermodynamic model of Shakhmatkin and Vedishcheva was successfully applied in previous years [22–30]. This model considers glasses and melts as an ideal solution formed from salt-like products of equilibrium chemical reactions between the simple chemical entities (oxides, halogenides, chalcogenides, etc.) and from the original (un-reacted) entities. These salt-like products (also called associates, groupings, or species) have the same stoichiometry as the crystalline compounds, which exist in the equilibrium phase diagram of the considered system. The model does not use adjustable parameters only the molar Gibbs energies of pure crystalline compounds and the analytical composition of the system considered are used as input parameters. The minimization of the system’s Gibbs energy constrained by the overall system composition has to be performed with respect to the molar amount of each system species to reach the equilibrium system composition [31].

When the crystalline state data are used the model can be simply applied to most multicomponent glasses including the non-oxide ones. The contemporary databases of thermodynamic properties containing the molar Gibbs energies of various species (like the FACT database [32, 33]) enable the routine construction of the Shakhmatkin and Vedishcheva model for many important multicomponent systems.

In case of the binary Ge–S system two stable binary compounds, namely GeS and GeS2, can be found in the equilibrium phase diagram [34, 35]. Thus, the system components are {Ge, S, GeS, and GeS2}.

Temperature dependence of viscosity

As far as available experimental data [13] represent only the so called low temperature–viscosity (i.e., approximately 107 < η (Pa s) < 1013) their temperature dependence is for particular glass composition described with sufficient accuracy with the two-parametric viscosity equation (like the Andrade’s one) and the most frequently used three-parametric Vogel–Fulcher–Tammann empirical viscosity equation [3, 4, 17] cannot be applied in this case due to the strong linear bonds between estimates of its parameters. However, when the compositional dependence of viscosity is included into the regression analysis the three parametric equations can be used too. In the following text, all the considered viscosity equations are summarized:

-

(a)

Andrade’s viscosity equation [3, 4, 14–17]:

$$ \log \eta = \log \eta_{\infty } + B/T $$(1)this two-parameter equation corresponds to temperature-independent value of viscous flow activation energy E ≠ η , i.e.,

$$ E_{\eta }^{ \ne } = R\frac{\partial \ln \eta }{\partial (1/T)} = 2.303R\frac{\partial \log \eta }{\partial (1/T)} = 2.303RB, $$(2)where R is the molar gas constant. The experimental viscosity data for each glass composition were treated separately by this equation and the viscosity glass transition temperature T 12g defined by log[η(T g) (Pa s)] = 12 (sometimes the value of 12.5 is used instead of 12 [36]) were calculated by

$$ T_{\text{g}} = B/(12 - \log \eta_{\infty } ). $$(3)Analogously the experimental value of fragility, m, was obtained from the definition:

$$ m = \left[ {\frac{\partial \log \eta (T)}{{\partial (T_{\text{g}} /T)}}} \right]_{{T = T_{\text{g}} }} = (12 - \log \eta_{\infty } ). $$(4)It is worth noting that the fragility is directly proportional to the viscous flow activation energy at T g temperature

$$ E_{\eta }^{ \ne } (T_{\text{g}} ) = 2.303RT_{\text{g}} m. $$(5) -

(b)

Adam and Gibbs configuration entropy equation [17, 19]:

$$ \log \eta = \log \eta_{\infty } + \frac{B}{{TS_{\text{c}} (T)}}, $$(6)where log η ∞, and B are parameters and the configuration entropy S c(T) is given by

$$ S_{\text{c}} (T) = S_{\text{c}} (T_{\text{g}} ) + \int\limits_{{T_{\text{g}} }}^{T} {\Updelta c_{p} (T^{\prime})\,{\text{d}}\,\ln T^{\prime}} , $$(7)where T g is the glass transition temperature and Δc p represents the difference between the isobaric molar heat capacity of metastable melt, c p,m, and glass, c p,g, i.e.,

$$ \Updelta c_{\text{p}} = c_{{{\text{p}},{\text{m}}}} - c_{{{\text{p}},{\text{g}}}} . $$(8)Following the way used for Avramov and Milchev and MYEGA viscosity equation [36], we can reduce the number of unknown parameters by using the η (T g) = 1012 Pa s constrain. This way we can eliminate the log η ∞ or S c(T g) unknown parameter. The second possibility resulted in

$$ S_{\text{c}} (T_{\text{g}} ) = \frac{B}{{T_{\text{g}} (12 - \log \,\eta_{\infty } )}}. $$(9)Thus supposing the temperature-independent value of Δc p

$$ S_{\text{c}} (T) = \frac{B}{{T_{\text{g}} (12 - \log \,\eta_{\infty } )}} + \Updelta c_{\text{p}} \ln \frac{T}{{T_{\text{g}} }} $$(10)and consequently

$$ \log \eta = \log \eta_{\infty } + \frac{1}{{T\left[ {\frac{1}{{T_{\text{g}} \left( {12 - \log \,\eta_{\infty } } \right)}} + \frac{{\Updelta c_{\text{p}} }}{B}\ln \frac{T}{{T_{\text{g}} }}} \right]}}. $$(11)The fragility can then be calculated from

$$ m = \left( {12 - \log \eta_{\infty } } \right)\left[ {1 + \frac{{\Updelta c_{\text{p}} T_{\text{g}} (12 - \log \eta_{\infty } )}}{B}} \right]. $$(12) -

(c)

Avramov and Milchev equation [17, 20]:

$$ \log \eta = \log \eta_{\infty } + (12 - \log \eta_{\infty } )\left( {\frac{{T_{\text{g}} }}{T}} \right)^{\alpha } , $$(13)where

$$ \alpha = m/(12 - \log \eta_{\infty } ). $$(14)This equation is also constrained by the condition η(T g) = 1012 Pa s. This way, the number of estimated parameters is reduced to two (log η ∞, and α or m). In the regression treatment it is then practically equivalent whether the α or m is considered as optimized parameter.

-

(d)

$$ \log \eta = \log \eta_{\infty } + (12 - \log \eta_{\infty } )\frac{{T_{\text{g}} }}{T}\exp \left[ {(\alpha - 1)\left( {\frac{{T_{\text{g}} }}{T} - 1} \right)} \right], $$(15)

where α parameter has the same meaning like in the case of Avramov and Milchev viscosity equation (14).

Accounting for viscosity–compositional dependence

Choosing one of the above viscosity equations describing the temperature–viscosity dependence, the viscosity–composition dependence can be introduced by expressing the unknown parameters (e.g., log η ∞, B, Δc p, and α) as linear functions of molar amounts of system components. In all viscosity equations considered in the present work the high temperature limit of viscosity value, log η ∞ (frequently abbreviated as A) represents one of the estimated parameters. There were some attempts [17] to treat this value as composition-independent. Therefore, both cases, i.e., composition-dependent and composition-independent, are considered in the present paper.

Here, we can use to different quantifications of system composition:

-

(A)

The commonly used treatment considers the glass as composed of individual sulfides. The molar amounts of individual sulfides are then given (for “1 mol of glass”) by the molar fractions of individual sulfides, x i. In the present case, independent variables x gl(Ge) ≡ x 1, x gl(S) ≡ x 2 are used for linear dependence of each unknown parameter on glass composition. We have abbreviated this treatment as “Pure Sulfides” model in Table 1. In this case, the values of unknown parameters are expressed as multilinear forms of system composition by the following way:

$$ \log \eta_{\infty } = a_{\text{gl}} ({\text{Ge}})x_{\text{gl}} ({\text{Ge}}) + a_{\text{gl}} ({\text{S}})x_{\text{gl}} ({\text{S}}) $$(16)$$ B = b_{\text{gl}} ({\text{Ge}})x_{\text{gl}} ({\text{Ge}}) + b_{\text{gl}} ({\text{S}})x_{\text{gl}} ({\text{S}}) $$(17)$$ \Updelta c_{\text{p}} = c_{\text{gl}} ({\text{Ge}})x_{\text{gl}} ({\text{Ge}}) + c_{\text{gl}} ({\text{S}})x_{\text{gl}} ({\text{S}}) $$(18)$$ \alpha = \alpha_{\text{gl}} ({\text{Ge}})x_{\text{gl}} ({\text{Ge}}) + \alpha_{\text{gl}} ({\text{S}})x_{\text{gl}} ({\text{S}}). $$(19)Table 1 Description and abbreviations of viscosity models considered in regression analysis -

(B)

The other possibility uses the results of thermodynamic modeling where the equilibrium molar amounts, n i , of system components are used as independent variables. In the present study, the independent variables n(Ge) ≡ n 1, n(S) ≡ n 2, n(GeS) ≡ n 3, n(GeS2) ≡ n 4 are used. These values are for 1 mol of glass constrained by

$$ n({\text{Ge}}) + n({\text{S}}) + 2n({\text{GeS}}) + 3n({\text{GeS}}_{2} ) = 1\,{\text{mol}} . $$(20)We have abbreviated this treatment as “TD-model” in Table 1. In this case, the values of unknown parameters are expressed as multilinear forms of system composition by the following way:

$$ \log \eta_{\infty } = \sum\limits_{i = 1}^{4} {a_{\text{i}} n_{\text{i}} } \quad B = \sum\limits_{i = 1}^{4} {b_{\text{i}} n_{\text{i}} } $$(21, 22)$$ \Updelta c_{\text{p}} = \sum\limits_{i = 1}^{4} {c_{\text{i}} n_{\text{i}} } \quad \alpha = \sum\limits_{i = 1}^{4} {\alpha_{\text{i}} n_{\text{i}} } . $$(23, 24)

In both cases, the unknown parameters (e.g., a gl(Ge), a gl(S), a i, b gl(Ge), b gl(S), a i,…, α gl(Ge), α gl(S)) are obtained by nonlinear regression analysis. Only the statistically significant parameters identified at the 95 % significance level by the Student’s t value are retained in the model. In the case of Adam and Gibbs equation, the values of a and c parameters cannot be obtained unambiguously. It can be seen that by multiplying of all a i and c i values (a gl and c gl values) or by the same non-zero constant value, χ, the same result is obtained. The situation is illustrated for AG–AV–TD model by

The Andrade model contains in fact only one adjustable parameter. The attempt of using this model for the above description of viscosity–temperature–composition dependence resulted in unacceptably high standard deviation of approximation of log η (on the level of 0.3–1.0 in log(η (Pa s)) units). Therefore, these results are not given here in detail. The other models considered in the nonlinear regression treatment are summarized in Table 1.

Results and discussion

The experimental viscosity values of ten Ge–S glass compositions taken from [13] were described by the Andrade’s viscosity equation. The viscosity value of T g (abbreviated as T (12)g ), fragility, m, and viscous flow activation energy, E ≠ η , were calculated for each glass composition (Table 2). Comparing the DSC values of T DSCg reported in [13] with the calculated viscosity values of T (12)g resulted in the following relationship:

It can be seen that the fragility increases with increasing content of geranium, while the glass transition temperature reaches the maximum value for the stoichiometric composition with x gl(Ge) = 1/3.

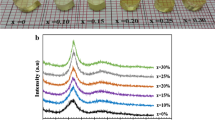

Thermodynamic model was evaluated for each glass composition at the T (12)g temperature. Despite the relatively narrow region of glass compositions studied (0.30 ≤ x gl(Ge) ≤ 0.44) the substantial changes of all components equilibrium molar amount take place with increasing content of Ge (Fig. 1). The significant correlation with the correlation coefficient of 0.93 was found between the n(GeS) and n(Ge) molar amounts. It is worth noting that for x gl(Ge) = 1/3 the system consists solely from GeS2, while for the lower Ge content the system is composed of the mixture of S and GeS2, and for the higher Ge content the GeS2 is combined with GeS and Ge. This can explain the non-monotonous compositional dependence of T g (i.e., T DSCg as well as T 12g ) that reaches the maximum value for x gl(Ge) = 1/3. Thus, the T g compositional dependence cannot be expressed by the linear function of x gl(Ge) and x gl(S). On the other hand, the multilinear regression resulted in the formula:

possessing the T g value with the standard deviation of approximation of 3 K.

On the other hand, for the viscosity T g value the best estimate

reproduces the experimental data with the standard deviation of approximation of 10 K. This is due to relatively high standard deviation of T (12)g values that are calculated according to the Eq. (27) and reflect the standard deviation of estimates of log η ∞ and B of the Andrade’s equation (1).

The nonlinear regression analysis was performed by the Statistica® ver. 6 software [37]. The sum of squares between the experimental and calculated log(η (Pa s)) values was minimized. The basic statistical characteristics obtained for considered models are summarized in Table 3 together with the estimates of statistically significant estimates of composition-independent log(η ∞ (Pa s)) values for “AC” models. It can be seen that most models reproduce the experimental data with the accuracy approaching the experimental error represented by the standard deviations of approximation s apr values reported for each glass in Table 2. The best results, i.e., s apr = 0.10, was obtained for AG–AV–TD, AM–AV–TD, and MY–AV–TD models. For these models, the experimental and calculated viscosity values are graphically compared in Fig. 2. It can be seen that in each case the model approximates the experimental data very well. Due to different number of degrees of freedom, the values of Fisher’s statistics (that prefers the models with less number of statistically significant parameters) reaches the higher value for AM–AV–TD, and MY–AV–TD models when compared with the AG–AV–TD model. Moreover, the need of using the thermodynamic model is supported by the fact that it is principally impossible to describe the non-monotone T g compositional dependence by multilinear form expressed by total sulfide glass composition (i.e., by the GL-model). On the other hand, the limited range of experimental viscosity values (so called low temperature–viscosity), which can be represented by the temperature-independent value of viscous flow activation energy, is the reason for the fact that most of the models applied gave relatively good description of the experimental data.

Only two AC models (AG–AC–GL and AG–AC–TD) posses the statistically significant value of log η ∞ estimate. But the value obtained for AG–AC–TD model seems to be too low. Thus, it may be concluded that the composition-dependent value of η ∞ estimate has to be preferred.

The estimates of coefficients of multilinear forms (Eqs. (16)–(24)) are summarized in Table 4. Here, we can see that that different number of statistically significant members is retained in different multilinear forms. It has be stressed here that the b and c coefficients are not defined unambiguously (see the Eq. (25)). Moreover, in some cases relatively high standard deviations are observed. Thus, the physical meaning of the obtained numerical estimates is probably questionable. Once again, the main reason for this resides in the limited range of viscosity experimental data. Moreover, the significant correlation between the n(GeS) and n(Ge) equilibrium molar amounts sometimes prevents the simultaneous inclusion of both these independent variables into the multilinear forms or, in case of their inclusion, increases significantly the standard deviations of obtained estimates.

Until now treated statistical characteristics are based on the comparison of the calculated and measured log η values. The fragility gives us the possibility to compare the slopes of experimental and calculated viscosity–temperature dependence—or, more precisely, the slope of the log η versus 1/T dependence at the point of η = 1012 Pa s. Such comparison is presented in Table 5. It can be seen that the most significant difference between the modal and experiment can be found for both MY–AC models. On the other hand, the best results were found for the AG–AC models and for the MY–AV–TD model. Moreover, taking into account the average standard deviation of experimental values (Table 2) it can be concluded that no straightforward preference of any model is obtained on the fragility basis.

Conclusions

The structure of studied glass melts is well described by the thermodynamic model of Shakhmatkin and Vedishcheva with significant abundance of Ge, S, GeS, and GeS2 components in the studied glasses. The results of thermodynamic model allowed interpretation of compositional dependence of T g in form of linear function of equilibrium molar amounts of system components. The experimental viscosity data were relatively well described by various commonly used viscosity equations—Adam and Gibbs, Avramov and Milchev, and MYEGA. The assumption of composition-independent high temperature–viscosity limit was checked for all used viscosity equations. It was found that statistically more robust description of experimental data is obtained by supposing the compositional dependence of this quantity. Simultaneously it was proved that the experimental viscosity data were better described by using the equilibrium molar amounts of the thermodynamic model than by using the overall elemental glass composition. The obtained results confirmed the structural information acquired from the thermodynamic model.

References

Li W, Seal S, Rivero C, Lopez C, Richardson K, Pope A, Schulte A, Myneni S, Jain H, Antoine K, Miller AC. Role of S/Se ratio in chemical bonding of As–S–Se glasses investigated by Raman, X-ray photoelectron, and extended X-ray absorption fine structure spectroscopies. J Appl Phys. 2005;98:053503.

Carlie N, Musgraves JD, Zdyrko B, Luzinov I, Hu J, Singh V, Agarwal A, Kimerling LC, Canciamilla A, Morichetti F, Melloni A, Richardson K. Integrated chalcogenide waveguide resonators for mid-IR sensing: leveraging material properties to meet fabrication challenges. Opt Express. 2010;18:26728–43.

Varshneya AK. Fundamentals of Inorganic Glasses. Sheffield: Society of Glass Technology; 2006.

Rao KJ. Structural Chemistry of Glasses. Amsterdam: Elsevier; 2003.

Liška M, Holubová J, Černošková E, Černošek Z, Chromčíková M, Plško A. Nucleation and crystallization of an As2Se3 undercooled melt. Phys Chem Glasses. 2012;53:289–93.

Chovanec J, Chromčíková M, Pilný P, Shánělová J, Málek J, Liška M. As2Se3 melt crystallization studied by quadratic approximation of nucleation and growth rate temperature dependence. J Therm Anal Calorim. 2013. doi:10.1007/s10973-013-3085-4.

Holubová J, Černošek Z, Černošková E. A detailed study of isothermal crystallization of As2Se3 undercooled liquid. J Therm Anal Calorim. 2013. doi:10.1007/s10973-013-3110-7.

Málek J. The glass transition and crystallization of germanium–sulphur glasses. J Non Cryst Solids. 1989;107:323–7.

Seddon AB, Hemingway MA. Thermal properties of chalcogenide–halide glasses in the system: Ge–S–I. J Therm Anal Calorim. 1991;37:2189–203.

Shánělová J, Koštál P, Málek J. Viscosity of (GeS2) x (Sb2S3)(1−x) supercooled melts. J Non Cryst Solids. 2006;352:3952–5.

Gueguen Y, Rouxel T, Gadaud P, Bernard C, Keryvin V, Sangleboeuf JC. High temperature elasticity and viscosity of Ge x Se(1−x) glasses in the glass transition range. Phys Rev. 2011;B84:064201. doi:10.1103/Phys.RevB.84.064201.

Yang G, Gueguen Y, Sangleboeuf JC, Rouxel T, Boussard-Plédel C, Troles J, Lucas P, Bureau B. Physical properties of the Ge x Se(1−x) glasses in the 0 < x < 0.42 range in correlation with their structure. J Non Cryst Solids. 2013. doi:10.1016/j.jnoncrysol.2013.01.049.

Málek J, Shánělová J. Viscosity of germanium sulfide melts. J Non Cryst Solids. 1999;243:116–22.

Andrade EN. Theory of viscosity of liquidus. Part I. Philos Mag. 1934;17:497–511.

Andrade EN. Theory of viscosity of liquidus. Part II. Philos Mag. 1934;17:698–732.

Frenkel YI. Kinetic theory of liquids. Oxford: Oxford University Press; 1946.

Ojovan M. Viscous flow and the viscosity of melts and glasses. Phys Chem Glasses Eur J Glass Sci Technol B. 2012;53:143–50.

Ojovan M. Viscosity and glass transition in amorphous oxides. Adv Condens Matter Phys. 2008. doi:10.1155/2008/817829.

Adam G, Gibbs JH. On the temperature dependence of cooperative relaxation properties in glass-forming liquids. J Chem Phys. 1965;43:139–46.

Avramov I, Milchev A. Effect of disorder on diffusion and viscosity in condensed systems. J Non Cryst Solids. 1988;104:253–60.

Mauro JC, Yue Y, Ellison AJ, Gupta PK, Allan DC. Viscosity of glass-forming melts. Proc Natl Acad Sci USA. 2009;106:19780–4.

Vedishcheva NM, Shakhmatkin BA, Shultz MM, Wright AC. The thermodynamic modelling of glass properties: a practical proposition? J Non Cryst Solids. 1996;196:239–43.

Shakhmatkin BA, Vedishcheva NM, Wright AC. Can thermodynamics relate the properties of melts and glasses to their structure? J Non Cryst Solids. 2001;293–295:220–36.

Vedishcheva NM, Shakhmatkin BA, Wright CA. Thermodynamic modeling of the structure of glasses and melts: single-component, binary and ternary systems. J Non Cryst Solids. 2001;293–295:312–7.

Vedishcheva NM, Shakhmatkin BA, Wright CA. Thermodynamic modeling of the structure of sodium borosilicate glasses. Phys Chem Glasses. 2003;44:191–6.

Vedishcheva NM, Shakhmatkin BA, Wright CA. The structure of sodium borosilicate glasses: thermodynamic modeling vs. experiment. J Non Cryst Solids. 2004;345–346:39–44.

Liška M. Studying structure and thermal properties of oxide glasses. In: Sestak J, Holecek M, Malek J, editors. Some thermodynamic, structural and behavioral aspects of materials accentuating non-crystalline states. Nymburk: University of West Bohemia in Pilsen; 2009. p. 344–62.

Liška M, Chromčíková M. Thermal properties and related structural and thermodynamic studies of oxide glasses. In: Šesták J, Holeček M, Málek J, editors. Glassy, amorphous and nano-crystalline materials: thermal physics, analysis, structure and properties, Chap. 11. New York: Springer; 2011. p. 179–97.

Chromčíková M, Liška M, Karell R, Gašpáreková E, Vlčková P. Thermodynamic model and physical properties of selected zirconia containing silicate glasses. J Therm Anal Calorim. 2012;109:831–40.

Chromčíková M, Liška M, Macháček J, Šulcová J. Thermodynamic model and structure of CaO–P2O5 glasses. J Therm Anal Calorim. 2013. doi:10.1007/s10973-013-2988-4.

Voňka P, Leitner J. Calculation of chemical equilibria in heterogeneous multicomponent systems. Calphad. 1995;19:25–36.

http://www.crct.polymtl.ca/fact/. Accessed 22 May 2013.

Bale CW, Bélisle E, Chartrand P, Decterov SA, Eriksson G, Hack K, Jung I-H, Kang Y-B, Melançon J, Pelton AD, Robelin C, Petersen S. FactSage thermochemical software and databases—recent developments. Calphad. 2009;33:295–311.

Bletskan DI. Phase equilibrium in the systems AIV–BVI: Part II. Systems germanium–chalcogen. J Ovonic Res. 2005;1:53–60.

Viaene W, Moh GH. The condensed germanium–sulfur system. Neues Jahrbuch fuer Mineralogie. 1970;21:283–5.

Avramov I. Interrelation between the parameters of equations of viscous flow and chemical composition of glassforming melts. J Non Cryst Solids. 2011;357:391–6.

StatSoft, Inc. Statistica (data analysis software system), version 6. www.statsoft.com (2001). Accessed 6 June 2013.

Acknowledgements

This work was supported by the Slovak Grant Agency for Science under the Grant VEGA 1/0006/12 and the bilateral Project SK-CZ-0007-11. This publication was created in the frame of the project ZDESJE, ITMS code 26220220084, of the Operational Program Research and Development funded from the European Fund of Regional Development. The Ministry of Education, Youth and Sports of the Czech Republic, Project CZ.1.07/2.3.00/30.0021 “Strengthening of Research and Development Teams at the University of Pardubice”, financially supported this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chovanec, J., Chromčíková, M., Liška, M. et al. Thermodynamic model and viscosity of Ge–S glasses. J Therm Anal Calorim 116, 581–588 (2014). https://doi.org/10.1007/s10973-013-3318-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3318-6