Abstract

Conductive hydrogels with adjustable mechanical properties, good flexibility, and high sensitivity are considered to be promising and reliable materials for next-generation wearable devices. To enhance the mechanical properties of hydrogels, double-network (DN) strategy was always brought in hydrogel preparation. However, chemical crosslinks in DN hydrogel will lead to lack self-recovery properties and biocompatibility. Thus, we developed a fully physical crosslinked DN gel by a large quantities of metal chelation and hydrogen bonds by adding ions in mixture of gum arabic (GA) and copolymer polymerized by acrylamide (AM), acrylic acid (AA), and N-Methylolacrylamide (NMAM). This hydrogel (we named GPFE gel) exhibited excellent mechanical properties such as superb tensile strain (2340%), tensile strength (198 KPa), and high toughness (1.59 MJ/m3). Besides, benefiting from the large number of hydrogen bonds brought by the introduction of EG, GPFE gel also showed intriguing self-healing property (97.0% healing efficiency after 2 h), adhesive property (both in the air and underwater), and environmental stablity (could be used normally at –20 °C). Wearable flexible sensors prepared directly from GPFE gel can sensitively monitor both daily activities and slight physiological movements, exhibiting high sensitivity (GF = 2.16) and a wide strain detection window (to eleven times the original length). Therefore, the prepared GPFE gel as a high-performance wearable flexible sensor in this study shows tremendous potential applications in a complex environment.

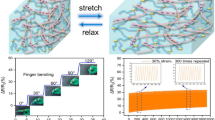

Graphical Abstract

Highlights

-

The GPFE gel was a fully physical crosslinked double-network (DN) hydrogel with excellent mechanical properties.

-

The addition of GA to the GPFE gel served to render it transparent while simultaneously conferring upon it the desirable properties of self-adhesion, both in the air and underwater.

-

The GPFE gel exhibited an intriguing self-healing property, with 97.0% healing efficiency observed after 2 h.

-

The GPFE gel demonstrated environmental stability, with no adverse effects observed when used at temperatures as low as –20 °C.

-

The GPFE gel exhibited high sensitivity (GF = 2.16) with a wide strain detection window (to eleven times the original length).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hydrogels are three-dimensional network structures provided via chemical or physical crosslinks. Among them, ion hydrogels have been increasingly utilized in soft and intelligent electronic devices like wearable strain sensors thanks to their unique properties such as stretchable, conductive, biocompatibility, wide raw material sources, and simple preparation method [1, 2].

Unlike traditional conductive hydrogels comprising nano-conductive fillers (conductive polymers, MXene, metal nanoparticles and carbon-based materials), in ionic conductive hydrogels, polymer networks incorporated with ions and an abundance of absorbed water molecules, which could construct a stable ion transportation pathway, may serve as a large change detector [3]. Zhu et al. [4] successfully synthesized a physically cross-linked PVA ionic hydrogel with a gradient structure through a directional ion diffusion process in NaCl solution at a low temperature. As a wearable strain/pressure sensor, the gradient gel sensor has advantages of long-term signal stability, high sensitivity, a broad detection range, and rapid response speed. Inspired by the geometric deformability and robustness of fishing nets, Zheng et al. [5] prepared PAA-PVA/PAM/Zn2+ organohydrogels, which exhibited outstanding tensile strength, high stretchability, excellent anti-fatigue properties, skin-like mechanical behaviors and ionic conductivity.

Nevertheless, conventional hydrogels show poor mechanical performance (e.g. toughness, modulus, and recoverability) because of the permanent covalent bonds. To enhance the mechanical properties of hydrogels, a DN structure is usually introduced, which qualified its unique synergistic effects network structure with an efficient energy dissipation mechanism and therefore exhibited extremely high mechanical strength [6, 7]. Lei et al. [8] introduced tannic acid-borax (TA-B) complexes into classical DN polyacrylamide/agarose (PAM/Agar) hydrogels. These PAM/Agar/TA-B hydrogels have good mechanical properties, light transmission, electrical conductivity, and adhesion. Pang et al. [9] developed a temperature-responsive DN hydrogel with excellent stretchability, fast temperature responsiveness, and good conductivity by introducing a polyvinylpyrrolidone (PVP)/ tannic acid (TA)/Fe3+ cross-linked network into the N,N-methylene diacrylamide (MBAA) cross-linked poly(N-isopropylacrylamide-co-acrylamide) (P(NIPAAm-co-AM)) network. Zhang et al. [10] fabricate a homogeneous polymer DN hydrogel by pre-seeding calcium carbonate (CaCO3) microparticles into sodium alginate (SA)/PAM hydrogels, followed by the triggered release of Ca2+ from the microparticles in acidic solution. The acid-triggered cross-linking generates sacrificial ionic bonds capable of dissipating energy, which endows the Ca2+/SA/PAM DN hydrogels with high tensile strength, stretchability, and fracture toughness. In addition, the Ca2+/SA/PAM DN hydrogel exhibits high strain sensitivity with a wide strain detection range and excellent durability, which can be used as a strain sensor to monitor human motions with a fast response.

In these traditional DN hydrogels, chemical crosslinks with covalent bond formation are ubiquitous. However, the biggest disadvantage of irreversible covalent bonds was the inhomogeneity of chemically cross-linked structures and ineffective dissipation mechanisms, which largely limits their potential applications [11]. In contrast, fully physical crosslinked DN gels have outstanding self-recovery and mechanical properties, which can substantially prolong the service life of gels in flexible electronics [12]. What’s more notable is that physical hydrogels are crosslinked by non-covalent interactions without toxic chemical crosslinkers required, this will expand its application in the biological and environmental field [13, 14].

In this work, we successfully fabricated an ultra-stretchable, low-temperature-tolerant, self‑adhesive, and self-healing ion organogel for electronic sensors. The targeted GA/P(AM-co-AA-co-NMAM)-Fe3+ DN organogel (GPFE gel) was prepared via the formation of fully physical crosslinked double networks, including Fe3+-crosslinked GA as the first network and Fe3+- crosslinked P(AM-co-AA-co-NMAM) as the second network. Furthermore, Fe3+ can also connect the two networks as a common cross-linking site. This unique structure endows the obtained hydrogels with excellent mechanical properties and outstanding ionic conductivity. Moreover, hydrogen bonds might also occur between glycol and water molecules, which endow the hydrogel with good anti-drying and anti-freezing abilities, as well as high stretchability, conductivity, and transparency at low temperatures. The high-density hydrogen bond formed by the interface of the hydrogels and hydrophilic substrates owing to the presence of the isolated amide groups and carboxyl groups in the P(AM-co-AA-co-NMAM) chain and free abundant hydroxyl groups and carboxyl groups in the GA chains, which promoted GPFE gel to readily adhere on various surfaces including itself. The as-prepared gel exhibited splendid strain sensitivity to monitor tiny or vigorous human motions in real-time, expected a great potential in wearable electronic devices.

2 Experimental section

2.1 Reagents and materials

GA was purchased from Aike Reagent. The viscosity range was 60–120 mPa·s. The GA powder was dried and kept in a desiccator to avoid moisture absorption before use. FeCl3 and glycol (EG) were purchased from Tianjin Damao Chemical Reagent Factory. LiCl, Acrylamide (AM), potassium persulfate (KPS), acrylic acid (AA), and N-Methylolacrylamide (NMAM) were commercially available from Aladdin and were used without additional treatment.

2.2 Preparation of GPFE gel

First, EG/water binary solution (EG: water=1:1, 1:2, 1:3, 1:4, 1:5, vol: vol) was prepared. Then, GA powder was added to this solution under rapid stirring. After GA dissolution, LiCl•H2O (2.97 g), FeCl3•6H2O (0.0375), AM (8 g), AA (2 mL), NMAM (0.5 g), and KPS (0.07 g) were added to the above solution and stirred for 20 min. Then, the mixture solution was transferred to a mold (10 × 5 × 0.2cm3), and polymerization was performed at 60 °C for 4 h to obtain the GPFE gel.

2.3 Structural characterization

The chemical composition of P(AM-co-AA-co-NMAM), GA, GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel, and GPFE gel were determined by Fourier Transform Infrared spectroscopy (FT-IR). The first three hydrogels were dried at 80 °C and the GPFE gel was dried at 120 °C. After dried, all the samples were tested by the Nicolet 5700 instrument (Thermo, Waltham, MA, USA) over the wavenumber range of 4000 and 400 cm−1 and were obtained at room temperature.

The GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel and GPFE gel samples were transferred to a freeze drier for 7 days to remove liquid. The pore structure and morphology of the Au-coated samples were then observed using an SEM (FEI Q45, USA) at an acceleration voltage of 20 kV.

2.4 Mechanical property measurements

The tensile and compression tests were performed using a universal test machine (ASG-X, Shimadzu, Japan) equipped with a 10 kN load cell. The rectangular hydrogel sample (50 × 10 × 2mm3) was subjected to tensile testing with a loading rate of 50 mm/min. The tensile strength and strain were obtained from the failure point. The nominal stress (σ, MPa) was calculated as Eq. (1) and the nominal strain (ε) was defined as Eq. (2):

where F (N) was the loading force, A (mm3) was the original average transverse area, l (cm) was the resultant length, and l0 (cm) was the starting length of the sample.

Elastic modulus (E) is calculated based on the linear fitting of the tensile curve. The toughness was defined according to the area under a stress-strain curve by integration. The measurements of each sample were repeated at least three times.

2.5 Adhesiveness tests

The adhesive properties of the hydrogels were measured by lap shear tests on the universal test machine (ASG-X, Shimadzu, Japan). The lap shear joint (20 mm length and 20 mm width) was fabricated and consisted of an adhesive gel between two substrates. Several substances such as metal, skin, glass, and plastic were applied for the adhesion test as adherends. The testing speed was 10 mm/min. The measurements of each sample were repeated at least three times.

2.6 Self-healing tests

The GPFE gel was stretched into two halves, and then the two halves were stained with methylene blue and methyl orange. The two dyed hydrogels were stretched after contact for different times without external stimulation, and the self-healing state of the hydrogels was observed macroscopically. After self-healing for 2 h, the tensile test was carried out to quantitatively evaluate the self-healing properties of the GPFE gel. The tensile test was performed with a constant stretching rate of 50 mm/min on the universal test machine (ASG-X, Shimadzu, Japan). HE [15] was used to indicate the magnitude of self-healing property and defined according to Eq. (3):

Where T1 and T0 (KPa) were the tensile stresses of the healed and original hydrogels at break, respectively.

2.7 Environmental stability tests

-

(1)

The light transmission of the hydrogels in different temperature was examined by an ultraviolet and visible spectrophotometer (UV-2600A, Unico, shanghai, visible light area: 400–800 nm).

-

(2)

The conductivity of hydrogels in different temperature were studied by the electrochemical impedance spectroscopy (EIS) method and conducted on an electrochemical working station (CHI660E, Chenhua, Shanghai). A hydrogel sample was sandwiched between two copper electrodes with the same area. Sinusoidal voltage waves with an amplitude of 0.1 V and frequency range from 0.1 to 105 Hz were applied to the sample. The conductivity is calculated from Eq. (4) [16]:

$$\sigma =\frac{{\rm{Z}}\mbox{'}}{{{\rm{Z}}\mbox{'}}^{2}+{{\rm{Z}}\mbox{''}}^{2}}\times \frac{L}{S}$$(4)Where σ(S/m) is the conductivity, Z’ and Z” are the real and imaginary parts of the impedance, S (m2) is the cross section area of the hydrogel, and L (m) is the hydrogel’s thickness.

-

(3)

Dehydration tests were performed on hydrogels. The hydrogel samples were cut into a same circular shape (d = 2 cm), respectively. The sample was left at 25 °C and 60% RH. for 60 days. The weight of the sample before and after dehydration was weighed. The water retention efficiency (WR) formula is as Eq. (5)

Where W0 (g) and W (g) are the weight before dehydration and the weight after dehydration, respectively. The measurements of each sample were repeated at least three times.

2.8 Electrical tests

A strain sensor was assembled using the GPFE gel. Copper wires that served as the electrodes were connected to both sides of the GPFE gel sensors. The strain-sensing properties of the hydrogel upon stretching were evaluated by mounting the samples on an in-house prepared stretching stage and the AGS-X universal tensile testing machine, respectively. The electrical signals of the hydrogel sensors were measured by using an electrochemical working station (CHI660E, Chenhua, Shanghai). In these tests, the conductive behavior of the gels at different strains was investigated, the real-time R–t (resistance vs. time) curves have recorded the ratio of resistance change (ΔR) to resistance at t = 0 (R0) was calculated to obtain the relative resistance changes (ΔR/R0). The gauge factor (GF) of the GPFE gel is defined according to Eq. (6):

Where ∆l was the ratio of length change for hydrogel sample (cm).

To test human body movement, a piece of striped GPFE3 gel was adhered on the target joint. The GPFE3 gel can remain attached on the epidermal surface by self-adhesion whether the joint bending or not. Copper wires were connected to both sides of the GPFE gel sensors and taped to the skin in place. The other end of the wires were connected to the electrochemical working station to measure electrical signals.

3 Results and discussion

3.1 Formation and characterization

The specific synthesis route and design strategy of GPFE gel are shown in Fig. 1a. P(AM-co-AA-co-NMAM) with multiple -COOH could be considered as polydentate ligands with Fe3+ and there are also a large number of -COOH in GA chains. Therefore, there were complex metal chelation structures between Fe3+ and -COOH of two polymer chains to fabricate fully physical crosslinked GA/P(AM-co-AA-co-NMAM)-Fe3+ DN gel. Moreover, hydrogen bonds could be formed between the amide group of AM, the carboxyl group of AA and GA, and the hydroxyl group of NMAM and GA to construct a crosslinked network (Fig. 1b).

We tried to prepare organic gels in EG/water solutions with different ratios (EG: water = 1: 1, 1: 2, 1: 3, 1: 4 and 1: 5, vol: vol) and marked 1, 2, 3, 4 and 5, respectively. These organic gels are all composed of two networks that are purely physically cross-linked via hydrogen and ionic bonds. Among these gels, the GPFE1 gel is in an indeterminate state, so beyond the scope of this article. The other four organic gel samples are all baby yellow, uniform and delicate, transparent gel-like.

Fourier transform infrared (FT-IR) spectroscopy in Fig. 2a shows the characteristic of P(AM-co-AA-co-NMAM), GA, GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel, and GPFE gel. In the FTIR spectra of GA, the broad peak of 3450 cm–1 was attributed to -OH stretching vibration; 2925 cm–1 was due to CH2 asymmetric stretching vibration; 1620 cm–1 caused by C = O stretching band, 1403 cm–1 associated with -OH of carboxylic acid groups; and 1076 cm–1 corresponded to asymmetric C-O-C stretching vibration of 1,3-linked-β-D-galactopyranosyl. The P(AM-co-AA-co-NMAM) exhibited a broad peak of 3450 cm–1 for stretching vibration of -OH and -NH3 and the peaks at 1647 cm–1 for asymmetric stretching of -COO−. The band at around 1399 cm–1 ascribed to the symmetric stretching of -COO−. Due to AM, AA, and NMAM was polymerized, there were no C = C peak (1680 cm–1 and 1750 cm–1) in the FTIR spectra of P(AM-co-AA-co-NMAM).

In the FTIR spectra of GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel, the -COO− stretching bands shifted to a higher wavenumber (1653 cm–1) due to formation of ionic bonding between Fe3+ and -COO− of the two polymer chains. No other new peaks appeared. For GPFE gel, the characteristic peaks of EG at 1085, 1043, and 874 cm–1 were C-O stretching vibration and O-H bending vibration, respectively. The shifting of stretching vibration of O-H from 3450 to 3425 cm–1 indicates the formation of hydrogen bonding between water and EG molecules.

Furthermore, the SEM image of the GPFE gel was captured. Figure 2b shows that the freeze-dried GPFE3 gel hydrogel exhibited an obviously typical three-dimensional network microstructure with abundant regularly distributed holes and diaphragms between holes. This structural character ensured good tensile properties and good diffusion of liquid. Figure 2c is the EDS mapping images of C, O, N, and Fe elements, respectively. The above results demonstrate that the two kind of polymer chains were mixed well and a small amount of iron ion uniformly distributed in the gel plays a bridging role.

3.2 Mechanical Properties

Good mechanical strength, elastic properties and high toughness largely contributes to the application of hydrogels. Due to the hydrogen bonds among GA, P(AM-co-AA-co-NMAM), EG and water, and the chelation of Fe3+ with the GA and P(AM-co-AA-co-NMAM) chains, the mechanical performances of the GPFE gels were significantly enhanced. For example, the GPFE3 gel could be stretched to more than six times its initial length under a 4 mm notch at the edge, and more than ten times its initial length under a 4 mm diameter gap in the middle (Fig. 3a, b). What’s more, under twisting and knotting, this organic gel could be stretched to more than fifteen times (Fig. 3c). In addition to its excellent flexibility, it could bear a 500 g weight without breaking, and revealed excellent puncture resistance, demonstrating that the organic gel possessed good mechanical strength.

The mechanical properties of the GPFE gel: (a) photos showing the stretching of the GPFE3 gel under a 4 mm notch at the edge. b Photos showing the stretching of the GPFE3 gel under a 4 mm diameter gap in the middle. c Photos showing the knotted stretching of the GPFE3 gel. d Tensile stress-strain curves of GPFE2 to GPFE5 gel and the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel; (e) elongation, fracture stress at break and toughness of GPFE2 to GPFE5 gel and the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel; (f) loading-unloading curve of the GPFE3 gel up to 600% strain. g Dissipated energy of 1st, 2nd, 3rd, 4th, and 10th loading-unloading curve of the GPFE3 gel

In order to study the mechanical properties of the organic gels more clearly, the mechanical properties of the GPFE2 to GPFE5 gel and the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel were measured via the tensile test. As shown in Fig. 3d, e, the breaking strain of the hydrogel gradually increased from 958 to 2340% and the breaking stress decreased from 198 KPa to 71.5 KPa as the EG content increased. The toughness of the GPFE3 gel achieve the maximum values of 1.59 MJ/m3 among these five hydrogels. Considering all the elongation, the strength, and the toughness, the GPFE3 gel exhibits a satisfactory strain range and mechanical safety.

Moreover, it is necessary to test the fatigue resistance property concerning mechanical stability in practical applications. A GPFE3 gel patch was selected to undergo ten consecutive loading–unloading cycles at 600% strain with a loading rate of 50 mm/min, and the result is shown in Fig. 3f, g. The result shows that the GPFE3 gel could dissipate strain energy efficiently, as illustrated by the observed discernible hysteresis loop. The hysteresis loop is ascribed to the energy dissipation by the entanglements of dissociated chains as well as destruction and reconstruction of dynamic non-covalent bonds. What is more, the hysteresis behaviors have almost remained after the first loading–unloading cycle, suggesting a steady structure has been obtained. What is more, it can be noted that the tensile strength gradually decreased with the increasing number of cycles, suggesting the partially broken non-covalent bonds in the network were broken and could not recover immediately (Fig. 2g).

3.3 Self-adhesive properties

Self-adhesive is an essential property for wearable sensors because reliable signal transmission desired stable contact between interfaces. However, it is a challenge for traditional gels to achieve gentle and strong adhesion on various surfaces, especially in a humid environment or underwater [17, 18].

Owing to the large number of multiple interactions (hydrogen bonding, metal complexation, etc.), it is expected that the GPFE gel deserve a good conformability and excellent self-adhesive abilities. As shown in Fig. 4a, the GPFE3 gel could tightly adhere to arbitrary shape surfaces and diverse materials, including stainless steel, rubber, plastic, glass, ceramic, stone, paper, wood, and leaf, at room temperature to support a 1.5–130 g weight. Due to the reversibility of physical interaction, the GPFE3 gel has repeatable adhesion behavior to these substances. Even in the process of adhesion-stretch and separation-re-adhesion, the adhesive strength is slightly changed. This indicate the gel has a substantial broad application in various substrates. Besides, an GPFE3 gel can firmly adhere two weights together and support a heavy load. Moreover, the GPFE3 gel also showed unique underwater adhesion ability for various substrates mentioned above. To achieve underwater adhesion, two objects of the same material are glued together by the GPFE3 gel by gently pressing them against each other. The two parts are still tightly bonded after immersed them in water together, suggesting its adhesive property underwater (Fig. 4b). Strong underwater adhesion contributes to the practical use of ionic hydrogel sensors and accurate acquisition and output of sensing signals.

a Adhesive properties of the GPFE gel to different materials (stainless steel, rubber, plastic, glass, ceramic, stone, paper, wood, and leaf) in the air; (b) adhesive properties of the GPFE gel to different materials (rubber, plastic, stainless steel, glass, and ceramic) underwater; (c) adhesive strength between hydrogels and different substrates (metal, glass, skin, paper, and plastic)

A lap shear test was choosed to characterize further the adhesive strength on various substrates of the GPFE gel and the results are shown in Fig. 4c. Compared to the other substrates, the GPFE3 gel possesses higher adhesiveness on hydrophilic interfaces, especially on glass, paper, and porcine skin with values of 7.57, 8.60, and 8.32 KPa, respectively. Among these three hydrophilic interfaces, the concave and convex surface structure of the paper and skin increases the contact area with the GPFE3 gel, thereby increasing the number of bondings and mechanical interlockings on the interface, resulting a stronger adhesion. Massive hydroxyl binding sites contained in the skin keratin and paper cellulose render high-density hydrogen bonds between the interface of the GPFE3 gel and the surface. Moreover, the GPFE3 gel has a versatile chemistry bonding metal coordination and hydrogen bonds, which can interact with amino and sulfhydryl groups on the two surfaces through Michael addition and the Schiff base reaction. And between glass and hydrogel, a large number of hydrogen bonds and the reaction of negatively charged silicate with protonated amino and hydroxy groups by ion-dipole and dipole−dipole interaction lead to the extremely adhesive property. As for the PVC and PTFE film, this GPFE3 gel shows the smallest adhesion force due to the lowest amount of hydro phobic interaction sites existing. In this case, the interaction between the amphiphilic polymer chain and the PVC and PTFE interface may play a key role in the interfacial adhesion between the gel and the substrate. The adhesive strength with metal materials is between hydrophilic interface and hydrophobic interface. The adhesion force among hydrogels and metals is mainly derived from the stable adhesion with metal complexation and electrostatic inter actions.

In contrast to the mussel-inspired hydrogels, the GPFE gel exhibits high skin-adhesion meanwhile possessing high transparency, a powerful indication that our GPFE gel is an effective route for application flexible devices such as ionic skin for wearable sensors and visual display.

3.4 Self-healing properties

Self-healing ability is highly desirable property of materials that can effectively prolong the lifetime of materials and devices, especially for applications in complex environments [19]. In order to feel the self-healing ability of hydrogels more intuitively, the GPFE gel was cut into two halves, and then the two halves were stained with methylene blue and methyl orange. The two-color hydrogels were put together and stretched by hand after contacting for 60 s without any external stimulus. As expected, we could clearly see that the color of the interface of the two hydrogels was blurred and completely merged together (Fig. 5a). This indicates that the dynamic reversible network inside the hydrogel gives the hydrogel excellent self-healing properties. Furthermore, the tensile strength of the recovered gel was measured. As shown in Fig. 5b, c, The HE reached up to 97.0% when the hydrogel was healed for 2 h.

3.5 Environmental stability

The dryness and wetness of the hydrogel have a significant effect on various properties, such as transparency, flexibility, and electrical conductivity. So anti-drying and low temperature resistant properties are critical for hydrogel-based wearable sensors that can work properly in harsh temperature conditions and long-term use [20]. In the GPFE gel, EG is introduced as the strongly hygroscopic ingredient to form large amount of hydrogen bonds with water molecules and polymer chains. Salt ions can also block water molecules from forming the solid phase thus reduce the freezing point, and LiCl is proved to be the most effective electrolyte for water retaining [21]. Thus, the evaporating and freezing of water in polymer networks are efficiently suppressed, leading to the anti-drying and low temperature resistant properties of organic hydrogels.

High transparency is very important for visually interactive wearable products [22]. The free water of the conventional hydrogel would freeze in the low-temperature environment. This ice crystals would cause the hydrogel to turn white and harden. But in the GPFE gel, the movement of water molecules is restricted by the high concentration of salt and EG because of the strong hydrogen bonds formed among polymer chains, EG molecules and water molecules as well as ion-solvent interactions, inhibiting the tendency of water molecules to freeze.

Figure 6a shows the light transmission of the GPFE3 gel. The photograph below could be clearly seen through the gel in room temperature and –20 °C. A UV-vis spectrometer was used to characterize the optical properties of the gel (Fig. 6b). The results showed that the GPFE3 gel exhibited high transmittance up to 94% in the visible light region (400–800 nm) in room temperature and even over 90% in –20 °C. The result showed the transparency of the GPFE gel can be well kept at various temperatures. This all certifies the gel exhibiting superior optical properties in a wide range of temperatures. In addition, the nearly zero transmission below 400 nm suggests the excellent UV blocking property of the GPFE gel.

Considering that the freezing point of water is 0 °C, hydrogels tend to lose their conductivity at 0 °C, since water freezes and the free metal cations will lose the transmission medium, which will greatly reduce the conductivity of the hydrogel. The salt and water/EG synergistically enhance anti-freezing and conductivity properties of the GPFE gel because the coexistence of these components disrupts the formation of crystal lattices of ice at low temperatures and reduce the freezing point of the gel solution, so that our GPFE gel remined good conductivity below 0 °C. Figure 6c shows the conductivity of the four GPFE gels and the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel under various temperatures. the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel exhibited a high ionic conductivity (0.021 S/m) at 20 °C, but decreased rapidly to 0.0052 S/m at 0 °C and closed to zero at –20 °C. The conductivity of four GPFE gels at 20 °C were decreased with the EG content increasing, but almost the same at 0 °C and –20 °C. It proves that our GPFE gels still maintains high conductivity (approximately 0.007 S/m) at low temperature.

To simulate normal service environment, moisture retention test was conducted at 25 °C and 60% relative humidity for 60d. It can be observed from the moisture retention curve that the water loss weight of the GPFE2 to GPFE5 gel were in a state of convergence on the 2nd day and the water loss weight was decreased with the increased EG content (Fig. 6d). The GPFE2 gel had a high weight retention rate of 80 wt% on the 5th day while the GPFE5 gel only had a low weight retention rate of 55 wt% on the 5th day. After the 5th day, the rate of water loss remained stable, which demonstrates our GPFE gel is available for use when exposed to a room temperature environment for a long time. The results show that the water-locking effect formed by strong hydrogen bonds and salt ions can ensure that free water molecules are not easily evaporated and the concentration of EG in binary solvent plays an important role in determining the drying property of the hydrogel. Thermogravimetric analysis and dynamic scanning calorimetry were used to study the thermal stability and anti-freezing property of the GPFE gel (Fig. S1, S2). The result shows that compared with the GA/P(AM-co-AA-co-NMAM)-Fe3+ hydrogel, the GPFE3 gel exhibited excellent thermal stability and anti-freezing attributed to the inclusion of EG.

3.6 Strain-sensitive properties

We systematically investigated the electrical behavior of the GPFE gel to evaluate its potential capability for application in wearable electronic devices.

Firstly, the GPFE gel was connected to a 0.1 V simple series circuit with a small blue-light LED buld to qualitatively assess its conductivity. Thanks to the introduced iron and lithium ions, the gel could make LED light as soon as the circuit was switched on. the GPFE gel was cut off and re-contacted to verify the electrical recovery ability. We found that when the gel was cut off, the LED was extinguished, and when contacted, the LED was immediately relit and the brightness remained basically unchanged (Fig. 7a). For the increased length and decreased cross-section area when stretched, the brightness of the light bulb dimmed noticeably as the GPFE gel was gradually stretched to seven times the original length, manifesting this gel possessed resistive strain dependency (Fig. 7b). As an ionic conductive hydrogel, the stretch of the GPFE gel only changes the configuration of its polymer network and water molecules, which has a negligible effect on its ionic conductivity. The GPFE gel can thus be viewed as a block resistor, the resistance changes under applied strain solely depend on the stretch-induced reduction in cross-sectional area and increase in length, to realize the sensing function. This conforms to the sensing mode of resistive strain sensors.

a Image of the simple circuit composed of the hydrogel and blue LED, and the brightness changes of the LED under the cutting−healing cycle; (b) the brightness changes of the LED as the GPFE gel was gradually stretched; (c) relative resistance changes of the hydrogel along with strains (original to 11 times); (d) changes in the resistivity of the GPFE3 gel during cutting and healing; (e) relative resistance changes of the GPFE3 gel under continuous stretch and release from 0 to 200% strains for 50 cycles

Then, an electrical test was used to prove the electrical recovery ability of the hydrogel further (Fig. 7c). The results showed that when the hydrogel was cut off, the resistance instantly became infinite like the air resistance. After re-contacting, the transfer of free ions between the two hydrogel surfaces make the conductivity restored in a short time. the resistance of the hydrogel could be restored to the initial value in 0.28 s. To investigate the stain sensitivity of the GPFE gel strain sensor, its sensitivity was defined as the gauge factor (GF) calculated from the slope of the relative resistance change (△R/R0) versus strain (ε). As presented in Fig. 7d, the relative resistance changes in the GPFE3 increased with strain and demonstrated linear responsive regions. The GF of GPFE3 gel was 2.16 as stretched to eleven times the original length (R2 = 0.9). Meanwhile, as shown in Fig. 6e, the change in resistance of the strain sensor exhibited excellent stability and repeatability during continuous stretching for 50 cycles at fixed strain of 200%, indicating its prominent durability.

To demonstrate the feasibility of the GPFE gel for the human motion inspection, we employed it as a stain sensor attached to various portions of the human body for real-time motion detection. As depicted in Fig. 8a, the GPFE gel strain sensor was mounted on the wrist of a volunteer to monitor the signal response at different action. The signals could clearly sense the bending direction and the bending amplitude of the wrist. Then, the GPFE gel sensor was tied to the index finger joint to monitor the bending motion of the finger at different angles (45° and 90°). With an increase in the bending angle, the relative resistance change value was also enhanced. Once the finger was straightened, the relative resistance could fully recover to the original value. Simultaneously, the sensor could respond quickly, stably and repeatedly to monitor the wrist and finger bending cycle (Fig. 8b).

In addition to the above-mentioned successful detection of large-scale movements, the capacity of the sensor to be used for subtle movements was further confirmed. As presented in Fig. 8c, d, Subtle body motions, such as frowning and swallowing, could be accurately monitored by the GPFE gel strain sensor.

These wearable sensors could also detect external pressure like skin. As displayed in Fig. 8e, when a sensor was pressed by loads with different weight, the sensor could generate signals with different amplitudes, respectively. When prepared as a disc shaped pressing sensor and placed in shoes, the movements of walking could be responded in real time (Fig. 8f). The above test showed the sensor could accurately monitor a variety of different movement behaviors, indicating that the sensor could monitor all-round movement.

It is worth mentioning that our GPFE gel strain sensor displayed excellent sensitivity of both tensile and compressive strain and no leaking issues were observed in any demonstrations shown in Fig. 8. Based on these results, our GPFE gel could be considered as a promising platform for applications of wearable smart sensors and suitable for real-time sensing of the human body.

4 Conclusions

In summary, we have developed an adhesive, self-healing, transparent, and durable conductive GPFE gel by incorporating fully physical crosslinked double-network. The GPFE gel showed excellent mechanical properties (tensile strain of 2340%, tensile stress of 198 KPa, and toughness of 1.59 MJ/m3), which allows us to build wearable strain sensor. The GPFE gel-based sensor exhibited high sensitivity (GF = 2.16) and a wide strain detection window (to eleven times the original length), which could be used to distinguish quickly and accurately for both varied human daily activities and monitoring of slight physiological movements. Furthermore, the GPFE gel displayed excellent low temperature resistance and environmental stability. To sum up, our GPFE gel is anticipated as a multifunctional material for wearable devices, such as sports monitoring, healthcare monitoring or electronic skin.

References

Li Y et al. (2022) Super tough and intelligent multibond network physical hydrogels facilitated by Ti(3)C(2)T(x) MXene nanosheets. ACS Nano 16(1):1567–1577

Palantöken S et al. (2019) Cellulose hydrogels physically crosslinked by glycine: Synthesis, characterization, thermal and mechanical properties. J Appl Polymer Sci 137(7):e48380

Liu YJ et al. (2017) Ultrasensitive wearable soft strain sensors of conductive, self-healing, and elastic hydrogels with synergistic “Soft and Hard” hybrid networks. ACS Appl Mater Interfaces 9(30):25559–25570

Zhu W et al. (2023) Preparation of gradient hydrogel for pressure sensing by combining freezing and directional diffusion processes. Chem Eng J 451:e138335

Zheng B et al. (2023) Fishing net‐inspired mutiscale ionic organohydrogels with outstanding mechanical robustness for flexible electronic devices. Adv Funct Mater 33(28):e2213501

Cong J et al. (2021) Polyacrylamide/chitosan-based conductive double network hydrogels with outstanding electrical and mechanical performance at low temperatures. ACS Appl Mater Interfaces 13(29):34942–34953

Zhang J et al. (2020) Highly transparent, self-healing, injectable and self-adhesive chitosan/polyzwitterion-based double network hydrogel for potential 3D printing wearable strain sensor. Mater Sci Eng C Mater Biol Appl 117:111298

Lei H et al. (2021) Antibacterial dual network hydrogels for sensing and human health monitoring. Adv Health Mater 10(21):e2101089

Pang Q et al. (2022) Temperature-responsive ionic conductive hydrogel for strain and temperature sensors. ACS Appl Mater Interfaces 14(23):26536–26547

Zhang X et al. (2023) Modulation of double-network hydrogels via seeding calcium carbonate microparticles for the engineering of ultrasensitive wearable sensors. J Mater Chem A 11(6):2996–3007

Zhao X et al. (2020) Physical double‐network hydrogel adhesives with rapid shape adaptability, fast self‐healing, antioxidant and NIR/pH stimulus‐responsiveness for multidrug‐resistant bacterial infection and removable wound dressing. Adv Funct Mater 30(17):e1910748

Yang J et al. (2019) Tough and conductive dual physically cross-linked hydrogels for wearable sensors. Ind Eng Chem Res 58(36):17001–17009

Luo Y et al. (2022) Highly sensitive strain sensor and self-powered triboelectric nanogenerator using a fully physical crosslinked double-network conductive hydrogel. Nano Energy 104

Tang S et al. (2020) Construction of physically crosslinked chitosan/sodium alginate/calcium ion double-network hydrogel and its application to heavy metal ions removal. Chem Eng J 393.

Zheng H et al. (2021) Self-healing, self-adhesive silk fibroin conductive hydrogel as a flexible strain sensor. ACS Appl Mater Interfaces 13(33):40013–40031

Wang Z et al. (2020) 3D printed ultrastretchable, hyper-antifreezing conductive hydrogel for sensitive motion and electrophysiological signal monitoring. Res (Wash D C) 2020:1426078

Zhang X et al. (2022) 3D printable conductive ionic hydrogels with self-adhesion performance for strain sensing. J Mater Chem C 10(38):14288–14295

Fu Q et al. (2021) Engineering self-adhesive polyzwitterionic hydrogel electrolytes for flexible zinc-ion hybrid capacitors with superior low-temperature adaptability. ACS Nano 15(11):18469–18482

Zhang W et al. (2021) Skin-like mechanoresponsive self-healing ionic elastomer from supramolecular zwitterionic network. Nat Commun 12(1):4082

Zhang X et al. (2020) Role of a high calcium ion content in extending the properties of alginate dual-crosslinked hydrogels. J Mater Chem A 8(47):25390–25401

Xu H, Shen Z, Gu G (2020) Performance characterization of ionic-hydrogel based strain sensors. Sci China Technol Sci 63(6):923–930

Sun C et al. (2021) Ultra-stretchable, self-adhesive, transparent, and ionic conductive organohydrogel for flexible sensor. APL Mater 9(1):e011101

Author information

Authors and Affiliations

Contributions

YZ proposed the idea and designed the scheme; H.F.provided laboratory supervision along with thesis revision; YL and QS assisted with the partial experimental operation; YZ wrote and submitted the paper. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Y., Liu, Y., Shang, Q. et al. A self-healing and environmental stable fully physical crosslinked double-network ion hydrogel sensor. J Sol-Gel Sci Technol 111, 806–818 (2024). https://doi.org/10.1007/s10971-024-06382-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-024-06382-0