Abstract

Vanadium dioxide (VO2) thin films were fabricated on single crystal Si (100) substrates by sol–gel method, including a process of annealing a vanadium pentoxide (V2O5) gel precursor at different temperatures. The crystalline structure and morphology of the films were investigated by XRD, FE-SEM and AFM, indicating that the films underwent the grain growth, agglomeration and grain refinement process with increased annealing temperatures. The film annealed at 500 °C exhibits the formation of VO2 phase with a strong (011) preferred orientation and high crystallinity, the surface of the film is uniform and compact with a grain size of about 120 nm. Meanwhile, the film exhibits excellent phase transition properties, with a decrease of transmittance from 35.5 to 2.5% at λ = 25 μm and more than 3 orders of resistivity magnitude variation bellow and above the phase transition temperature. The phase transition temperature is evaluated at 60.4 °C in the heating transition and 55.8 °C in the cooling transition. Furthermore, the phase transition property of the VO2 film appears to be able to remain stable over repetitive cycles 100 times.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Vanadium dioxide (VO2) is a transition-metal oxide that undergoes a reversible first order phase transition from a low temperature semiconductor phase to a high temperature metal phase nearly 68 °C, which can be manipulated by doping or stress [1, 2]. The transition is accompanied by significant and abrupt change in optical and electrical properties [3, 4]. Recently, it has been observed that this phase transition can be triggered by not only temperature, but also electric field, light and pressure [5–7]. All these properties make VO2 as a candidate material for a variety of applications, such as thermochromic windows, IR uncooled bolometer, optical switching, and sensor devices [8–11]. Wherein, the electric field triggered phase transition in VO2 is particularly suitable for applications as electrical switching, modulator and memory devices [12, 13].

Single crystal Si is one of the most frequently used substrates in VO2-based devices due to its well-known electrical properties and low price. Moreover, the high-purity Si has been demonstrated to be not only the most transparent but also the least dispersive medium in the terahertz region, and hence is especially applicable as substrate contacts in VO2-based THz devices [14, 15]. Several methods including pulse laser deposition, reactive sputtering, chemical vapor deposition and sol–gel method have been used to deposit VO2 films. Of these methods, the sol–gel process is regarded as a quite promising and important method because of its low cost, easy coating of large-scale surface, flexible control of film thickness, and many other advantages [16–18]. However, it is usually difficult to obtain a good film of VO2 on Si substrate by sol–gel process, for their bad contact performance induced by the lack of hydrophilic nature of Si interface.

In this research, we described the fabrication of VO2 films on crystalline Si substrate using a sol–gel method followed by an annealing process at different temperatures. The Si substrate was pre-treated with hydrophilic solution and obtained an improved hydrophilicity, which resulted in a better contact performance between the film and Si substrate. The crystalline structure and morphology of the films were studied using X-ray diffraction (XRD), field emission scanning electron microscopy (FE-SEM) and atomic force microscopy (AFM). Moreover, the phase transition properties were investigated using an FT-IR method and a resistivity measurement system.

2 Experiments

2.1 Surface cleaning and hydrophilic treatment of Silicon substrate

In a surface treatment, the n-type single crystal Si (100) substrate (~2000 Ω cm resistivity, Hefei Kejing Materials Technology Co., Ltd., China) was first pre-treated by ultrasonic cleaning in ethyl alcohol for 30 min and rinsing with de-ionized (DI) water for 5 min, in order to remove some organic contaminations on the surface. And then a thin SiOx layer was formed by oxidizing the Si substrate in the hydrophilic solution composed of mixture of concentrated H2SO4 and H2O2 with a ratio of 1:1 at 90 °C for 120 min. Through the treatment, the Si surface underwent surface functionalization through hydroxylation [19]. The cation impurities could be also removed in this treatment. After these treatments, the substrate was rinsed again with DI water for 5 min, and blown dry at 60 °C for 15 min.

2.2 Sample preparation

We prepared V2O5 sol with a method described in the previous paper [20], in which the melting V2O5 underwent hydrolysis and polycondensation reaction to form a colloid. The sol then evolved toward the formation of inorganic network (gel) [21]. According to Ref. [22], the V2O5 gels obtained a structure as described in Fig. 1. Following by water adsorption and dissociation occurs at the oxide–water interface leading to the acid dissociation of V–OH groups, the V2O5 gels could then be described as polyvanadic acids HxV2O5. We proved this model in a later sub-section.

The precursor films were deposited on Si (100) substrate by dip coating method. Then the films were dried around 90 °C for 15 min to remove the residual moisture. The dip coating process was repeated to increase the film thickness. The binding of V2O5 gel with Si substrate includes two approaches: a direct adsorption and a chemical linker, which was similar to the phenomena reported in Ref. [23]. The chemical linker provided a nearly covalent-strength bond between the gel and the surface due to the hydroxylation of Si interface.

In order to form the VO2 films, subsequent annealing was done in a furnace at the temperatures of 110, 300, 500 and 700 °C for 1.5 h in a static atmosphere of nitrogen, with a heating rate of 8 °C min−1. The resulting films with a thickness of about 150 nm were obtained after cooling down from the annealing temperature.

2.3 Characterizations

Contact angles with DI water were performed by a pendant-drop method with an automatic contact angle analyzer combined with a flash camera equipment (DSA 100, Kruss, Germany) at room temperature. The reported measurements are averages of five contact angle measurements recorded on each sample.

Functional groups of the V2O5 gel were analyzed by FT-IR spectrometer (Tensor 27, Bruker, Germany) to confirm the existence of –OH groups. The resolution of detection was set as 4 cm−1. The sample was acquired by spreading the gel on KBr plates, and then measured after different roasting time at 110 °C.

Crystalline structure of the films was determined by XRD (X’ Pert, Philips) with Cu Kα (λ = 0.15406 nm) radiation source.

Surface morphology was studied by FE-SEM (Inspect F, FEI, Holland) with an accelerating voltage of 20 kV. The magnifying power was 80 000x. The morphology was also investigated by AFM (Nanoscope Multimode APM, Vecco Instrument, America) with a tapping mode under ambient conditions. Etched Si nanoprobe tip with spring constant of 40 N m−1 was used.

Optical properties of the films were investigated by FT-IR spectrometer to analyze the transmittance of the films at the middle infrared range bellow and above the VO2 phase transition temperature.

Electrical resistivity dependent on the temperature was measured by the conventional four-point probe method combined with a heater element.

3 Results and discussion

3.1 Contact angles

The Si substrate with no hydrophilic treatment has bad hydrophilicity and the contact angle is about 68.0° (t = 0 min). With the oxidization of the Si surface, the contact angle decreased obviously and showed a value of 12.1° after a 120 min oxidizing treatment, indicating a significant enhanced hydrophilicity. It was attributed to the increased compactness of SiO2 layer, followed by a combination of –OH groups on the substrate surface. The Si–OH groups increase the surface energy and then improve the hydrophilicity of Si surface.

3.2 FT-IR spectrum of V2O5 gel

The V2O5 gel is an inorganic network derived from hydrolysis and polycondensation reaction of melting V2O5 in DI water. Figure 2 shows the FT-IR spectra of the gel on KBr plates in the spectral range 4,000–400 cm−1. A broad peak below 850 cm−1 could be assigned to characteristic distribution of V–O groups. Moreover, two strong peaks at 3,460 and 1,639 cm−1 correspond to stretching vibration and bending vibration bands of -OH groups respectively, which could be assigned to water absorption or due to chemical bonding of -OH groups in the V2O5 gel. The intensity of these two peaks versus the roasting time at 110 °C shows a tendency of reduction, denoting a consumption of -OH groups with roasting. However, the two peaks still exist after roasting 10 min indicating a chemical bonding of –OH groups.

Furthermore, we tested the PH of the V2O5 gel, and observed a value in the range of 0.5–1.0, which means a strong acid. It could be explained by the acid dissociation of V–OH groups in the gel system. All these results confirm the gel structure existing in the form of polyvanadic acids HxV2O5 as described in Fig. 1.

3.3 XRD

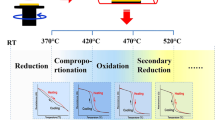

Figure 3 shows XRD patterns of VOx films annealed at various temperatures. As seen in Fig. 3a, only one broad peak extending from 20° to 27° is observed for the sample annealed at 110 °C. It means the film is still amorphous. The XRD pattern of the film annealed at 300 °C indicates amorphous characteristics (Fig. 3b), but peaks 1(2θ = 20.30°) and 2(2θ = 24.44°) are shown, due to diffractions from (001) planes of V2O5 and (210) planes of V4O9 phases, respectively. When the film was annealed at 500 °C, Fig. 3c shows peaks 1(2θ = 27.86°) and 2(2θ = 37.14°) that are related to (011) and (200) planes of VO2 phase respectively. No other vanadium oxides are detected. In addition, the (011) peak is strong, but the (200) peak is weak. It indicates that the film has a strong orientation relation to the Si substrate, which may be either due to the lattice match between the film and the substrate [24]. The full width at half maximum (FWHM) of the (011) peak is narrow with a value of 0.42, implying high crystallinity of the film. The number of the observed peaks for the film annealed at 700 °C increases. Figure 3d shows peaks 1(2θ = 19.15°), 2(2θ = 33.89°), 3(2θ = 35.74°), 4 (2θ = 37.24°), 5(2θ = 40.76°), 6(2θ = 53.54°), 7 (2θ = 56.51°) and 8(2θ = 68.57°), which may be coincide with the diffractions from (200) planes of V3O5, \( \left( {\bar{3}11} \right) \) planes of VO2, (311) planes of V6O13, (200) planes of VO2, \( \left( {\bar{4}11} \right) \) planes of V3O5, (221) and (222) planes of V6O13 and (611) planes of VO2 phases, respectively. The variation in the XRD patterns is resulted from differences in the crystallinity of the films annealed at different temperatures.

Furthermore, concerning the phase transition of the VO2 films illustrated in this work, the changes in temperature-controlled XRD patterns of the film annealed at 500 °C was shown in Fig. 4. The diffraction peak at 2θ = 27.86° corresponds to the (011) planes of monoclinic VO2 (taken at room temperature about 25 °C). But the peak shifts to a lower angle of 2θ = 27.75° (taken at 90 °C above the phase transition temperature), with a tiny increase of the diffraction intensity. It is attributed to the changes of the film from monoclinic to tetragonal phase transition, which has been also illustrated in our previous paper [25].

3.4 FE-SEM and AFM

The morphology and microstructure of the films were further investigated by FE-SEM and AFM. Figure 5 shows the FE-SEM photographs for the films annealed at different temperatures. The film annealed at 110 °C (Fig. 5a) shows a flat surface. According to the former XRD results, we assume that the film was formed by the dry V2O5 gel film without crystallizing. Figure 5b exhibits the similar morphology, while extremely weak particles are formed at this annealing temperature (300 °C). Increasing annealing temperature at 500 °C resulted in more clear grain boundaries and grain growth. It is seen in the Fig. 5c that the surface of VO2 film is uniform and compact with a grain size of about 120 nm. There are no obvious surface defects observed in the image, which may be formed during the dip coating and drying process. But the film annealed at 700 °C shows obvious microcracks, due to the pronounced grain refinement. The microcracks are harmful for the phase transition properties of VO2 films [26].

AFM image (Fig. 6) shows the area of 2 μm × 2 μm morphologies of the films annealed at 300, 500 and 700 °C. It suggests that the films underwent the grain growth, agglomeration and grain refinement process with increased annealing temperatures, as illustrated by FE-SEM photographs.

3.5 FT-IR in VO2 thin films

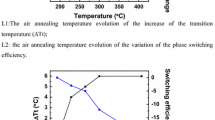

Figure 7 shows a graph of transmittance against temperature at λ = 25 μm, the wavelength at which the sharpest contrast was observed bellow and above the phase transition temperature. The films annealed at 110 and 300 °C did not show any phase transition properties during the detecting temperature range from 30 to 90 °C, for there is no VO2 phase existed. The transmittance for the film annealed at 700 °C decreases from 36.2 to 25.8% during the phase transition. The low variation could be attributed to the multiphase coexistence and the obvious microcracks. However, for the film annealed at 500 °C, the curve exhibits a decrease of transmittance from 35.5 to 2.5%. Moreover, as the derivative of the temperature dependence of transmittance (dTr/dT) (Fig. 8), the phase transition temperature of the film annealed at 500 °C could be evaluated to be 60.4 °C in the heating transition and 55.8 °C in the cooling transition. The significant decrease in transition temperature and hysteresis width of VO2 film on Si has been attributed to either the compressive strain along [011] direction [27], or larger fraction of +4 valence vanadium [28].

As for the cycle stability, the repeated phase transition with 30, 50 and 100 times and the accompanied optical changes of the VO2 film annealed at 500 °C were measured, shown in Fig. 9. The hysteresis curves of transmittance against temperature suggest that the thermal triggered change of transmittance at λ = 25 μm can revert back to its original value over a large number of cycles without deviations of the critical transition temperatures and hysteresis widths. The phase transition property of the VO2 films appears to be able to remain stable during repetitive cycles. They would therefore be convenient for the variety of applications discussed earlier.

3.6 Resistivity

The electrical phase transition property of VO2 film annealed at 500 °C and 700 °C were studied by the four-point probe method to record variations in resistivity with temperature (Fig. 10). A typical hysteresis cycle, similar to that of the FT-IR curves, was also observed. For the film annealed at 700 °C, the resistivity of the film drops from 14.9 Ω cm at 25 °C to 0.52 Ω cm above 75 °C. By contrast, the resistivity of the film annealed at 500 °C has an abrupt drop from 11.6 Ω cm at 25 °C to 0.01 Ω cm above 75 °C. The resistivity of the VO2 film changes by more than 3 orders of magnitude when cycled through the phase transition. This amplitude of variation is also larger than the usually obtained change of 2–3 orders of VO2 films.

4 Conclusions

In summary, we fabricated VO2 thin films on single crystal Si (100) substrates by sol–gel method, including a process of annealing a vanadium pentoxide (V2O5) gel precursor at 110, 300, 500 and 700 °C. The Si substrate was pre-treated with hydrophilic solution and obtained an improved hydrophilicity. A decrease of contact angle from 68.0° to 12.1° resulted in a better contact performance between the film and Si substrate.

The film annealed at 110 °C is still amorphous, but the films underwent the grain growth, agglomeration and grain refinement process with increased annealing temperatures. The film annealed at 500 °C exhibits the formation of VO2 phase with a strong (011) preferred orientation and high crystallinity, the surface of the film is uniform and compact with a grain size of about 120 nm. Meanwhile, the films annealed at 110 and 300 °C did not show any phase transition properties during the detecting temperature range from 30 to 90 °C, for there is no VO2 phase existed. The transmittance for the film annealed at 700 °C decreases from 36.2 to 25.8% at λ = 25 μm during the phase transition. But the film annealed at 500 °C exhibits excellent phase transition properties, with a decrease of transmittance from 35.5% to 2.5% and more than 3 orders of resistivity magnitude variation bellow and above the phase transition temperature. The phase transition temperature is evaluated at 60.4 °C in the heating transition and 55.8 °C in the cooling transition. Furthermore, the phase transition property of the VO2 film appears to be able to remain stable over repetitive cycles 100 times. These results indicate that the sol–gel method could be a suitable process for fabricating VO2 film with excellent phase transition properties on Si substrate.

References

Manning TD, Parkin IP, Pemble ME, Sheel D, Vernardou D (2006) Intelligent window coatings: atmospheric pressure chemical vapor deposition of tungsten-doped vanadium dioxide. Chem Mater 16:744–749

Muraoka Y, Ueda Y, Hiroi Z (2002) Large modification of the metal-insulator transition temperature in strained VO2 films grown on TiO2 substrates. J Phys Chem Solids 63:965–967

Lappalainen J, Heinilehto S, Jantunen H, Lantto V (2008) Electrical and optical properties of metal-insulator-transition VO2 thin films. J Electroceram 22(1–3):73–77

Morin FJ (1959) Oxides which show a metal-insulator transition at the neel temperature. Phys Rev Lett 3:34–36

Kim HT, Chae BG, Youn DH, Kim G, Kang KY, Lee SJ, Kim K, Lim YS (2005) Raman study of electric-field-induced first-order metal-insulator transition in VO2-based devices. Appl Phys Lett 86:242101

Cavalleri A, Tóth Cs, Siders CW, Squier JA et al (2001) Femtosecond structure dynamics in VO2 during an ultrafast solid–solid phase transition. Phys Rev Lett 87:237401

Cao J, Ertekin E, Srinivasan V, Fan W, Huang S et al (2009) Strain engineering and one-dimensional organization of metal-insulator domains in single-crystal vanadium dioxide beams. Nat Nanotechnol 4:732–737

Manning TD, Parkin IP (2004) Atmospheric pressure chemical vapour deposition of tungsten doped vanadium (IV) oxide from VOCl3, water and WCl6. J Mater Chem 14:2554–2559

Jerominek H, Picard F, Vincent D (1993) Vanadium oxide films for optical switching and detection. Opt Eng 32:2092–2099

Huang WX, Yin XG, Huang CP, Wang QJ, Miao TF, Zhu YY (2010) Optical switching of a metamaterial by temperature controlling. Appl Phys Lett 96:261908

Messaoud TB, Landry G, Gariépy JP, Ramamoorthy B, Ashrit PV, Haché A (2008) High contrast optical switching in vanadium dioxide thin films. Opt Commun 281:6024–6027

Driscoll T, Palit S, Qazilbash MM, Brehm M, Keilmann F et al (2008) Dynamic tuning of an infrared hybrid-metamaterial resonance using vanadium dioxide. Appl phys lett 93:024101

Driscoll T, Kim HT, Chae BG, Kim BJ, Lee YW et al (2009) Memory metamaterials. Science 325:1518–1521

Dai JM, Zhang JQ, Zhang WL, Grischkowsky D (2004) Terahertz time-domain spectroscopy characterization of the far-infrared absorption and index of refraction of high-resistivity, float-zone silicon. J Opt Soc Am B 21:1379–1386

Jeon TI, Grischkowsky D (1997) Nature of conduction in doped silicon. Phys Rev Lett 78:1106–1109

Partlow DP, Gurkovich SR, Radford KC, Denes LJ (1991) Switchable vanadium oxide films by a sol-gel process. J Appl Phys 70:443–452

Ozer N (1997) Electrochemical properties of sol-gel deposited vanadium pentoxide films. Thin Solid Films 305:80–87

Yuan NY, Li JH, Lin CL (2002) Valence reduction process from sol-gel V2O5 to VO2 thin films. Appl Surf Sci 191:176–180

Guhathakurta S, Subramanian A (2007) Effect of hydrofluoric acid in oxidizing acid mixtures on the hydroxylation of silicon surface. J Electrochem Soc 154:136–147

Yan JZ, Zhang Y, Huang WX, Tu MJ (2008) Effect of Mo-W Co-doping on semiconductor-metal phase transition temperature of vanadium dioxide film. Thin Solid Films 516:8554–8558

Nag J, Hanlund RF Jr (2008) Synthesis of vanadium dioxide thin films and nanoparticles. J Phys-Condens Mat 20:264016

Livage J, Guzman G, Beteille F, Dacadson P (1997) Optical properties of sol-gel derived vanadium oxide films. J Sol-Gel Sci Technol 8:857–865

Bhushan B, Tokachichu DR, Keener MT, Lee SC (2005) Morphology and adhesion of biomolecules on silicon based surfaces. Acta Biomater 1:327–341

Chan BG, Kim HT, Yun SJ, Kim BJ et al (2007) Comparative analysis of VO2 thin films prepared on sapphire and SiO2 substrates by the sol-gel process. Jpn J Appl Phys 46:738–743

Yan JZ, Huang WX, Zhang Y, Liu XJ, Tu MJ (2008) Characterization of preferred orientated vanadium dioxide film on muscovite (001) substrate. Phys Stat Sol 205:2409–2412

Jepsen PU, Fischer BM, Thoman A et al (2006) Metal-insulator phase transition in a VO2 thin film observed with terahertz spectroscopy. Phys Rev B 74:205103

Yang TH, Aggarwal R, Gupta A et al (2010) Semiconductor-metal transition characteristics of VO2 thin films grown on c- and r-sapphire substrates. J Appl Phys 107:053514

Youn DH, Kim HT, Chae BG, Hwang YJ, Lee JW, Maeng SL, Kang KY (2004) Phase and structural characterization of vanadium oxide films grown on amorphous SiO2/Si substrates. J Vac Sci Technol A 22:719–724

Acknowledgments

This work was financially supported by the National Science Foundation of China (Grant Nos. 61072036) and the Science and Technology Supporting Programs Fund Project of Sichuan province (2009SZ0199). We would also thank Analytical and Testing center of Sichuan University for their XRD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Q., Huang, W., Yan, J. et al. Preparation and phase transition characterization of VO2 thin film on single crystal Si (100) substrate by sol–gel process. J Sol-Gel Sci Technol 59, 591–597 (2011). https://doi.org/10.1007/s10971-011-2533-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2533-5