Abstract

Al13 polycations containing alumina sols, prepared by a modified Yoldas procedure were mixed with polyvinylpyrrolidone (PVP). Although Al speciation in freshly prepared sols was not affected by PVP addition the decay rate of Al13 polycations was slightly decreased in PVP-containing sols. PVP does not show any influence on particle size and particle growth. The influence of PVP addition on viscosity and flow behavior of modified Yoldas sols depends on their solids content and \( {\text{NO}}_{3}^{ - } / {\text{Al}} \) molar ratio.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

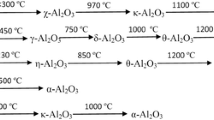

The modified Yoldas sols under study here show peculiarities concerning their alumina speciation. In [1] it was shown by 27Al NMR spectroscopy, that sols prepared by a modified Yoldas method having a pH range between 3.1 < pH < 3.7 contain Al13 polycations besides further Al species. Via studying viscosity behavior [2] it was deduced that the shape of the particles in such sols changes from spherical to chainlike polymeric when altering \( {\text{NO}}_{3}^{ - } / {\text{Al}} \) molar ratio and alumina content. It was furthermore reported elsewhere [3] that alumina sols prepared via the before mentioned procedure are suitable for coating preparation. Addition of binders like polyvinylpyrrolidone (PVP) to modified Yoldas sols is favorable to adjust the rheological properties to the requirements of the applied coating procedure [4] and to avoid cracking of coatings during drying and succeeding thermal treatments [5].

PVP is a non-ionic polymer which is often used as additive to cosmetics or pharmaceuticals. The addition of PVP to suspensions of different aluminum oxides is also common [6–12]. Mixtures of different sols, e.g. lead zirconate titanate (PZT) [13], Pd [14] or TiO2 [15] with PVP have also been described. Yoldas [16] tested addition of PVP to AlO(OH) sol for the design of sol–gel coating media for ink-jet printing. Since the desired properties for this special application were not achieved, detailed studies were not reported.

The work presented here focuses on microscopic and macroscopic properties of mixtures of modified Yoldas sols with PVP. Especially three aspects shall be regarded:

-

(i)

Al speciation of the sols is a key factor controlling the thermal evolution of resulting products [17]. Hence any influence of PVP addition on Al speciation of the sols has to be known.

-

(ii)

Particle size and particle growth, i.e. long-term colloidal stability, observed for pure modified Yoldas sols could be altered by PVP addition.

-

(iii)

From the technological point of view the work was aimed on finding relations between PVP addition and viscosity as well as flow behavior of the mixtures. Such relations should also allow discussing possible interactions between alumina particles and PVP molecules.

2 Experimental

2.1 Sol preparation

Sols were prepared according to a schema described in detail in [1, 2]. Diluted aluminum tri-sec-butoxide (ASB, 75 wt% ASB in sec-butoxide, Aldrich), was weighed in a beaker and poured in one step into aqueous aluminum nitrate [Al(NO3)3 · 9H2O, puriss p.a., Merck] solution at 85 °C. Alternatively, ASB was added in portions with a pipette into the aluminum nitrate solution. Since the results presented here do not depend on these differences the samples will be treated without special regard to this detail.

One important parameter characterizing a sol is the molar nitrate/aluminum ratio [n(\( {\text{NO}}_{3}^{ - } \))/n(Al)], which will be abbreviated with \( {\text{NO}}_{3}^{ - } / {\text{Al}} \) in the following. If sols with low \( {\text{NO}}_{3}^{ - } / {\text{Al}} \) molar ratios were synthesized, e.g. (\( {\text{NO}}_{3}^{ - } / {\text{Al}} \) = 0.6), a separate sec-butoxide phase formed on top of the sol. After cooling down to room temperature the sec-butoxide was removed with a pipette. As it was impossible to remove all sec-butoxide with this method, the sols were again heated to 85 °C and left at this temperature for at least 1 h. To obtain sols with higher solids content, prolonged dwell times at 85 °C were necessary. It should be noted that some highly concentrated sols could only be prepared via the evaporation route since precipitates formed when too much ASB was added to the hot aluminum nitrate solution in one step. Sols with lower solids content were obtained via dilution with water at room temperature after synthesis. Solids content c(Al2O3) refers to the Al concentration in terms of wt% Al2O3.

An example for the composition of a sol with \( {\text{NO}}_{3}^{ - } / {\text{Al}} \) = 0.6 shall be given here: 61.67 g of 75 wt% solution of ASB in sec-butoxide were added to a solution of 18.00 g aluminum nitrate in 128.88 g of water. At the end of the synthesis, i.e. after removal of sec-butoxide and reheating to 85 °C, the remaining sol mass was 72.61 g hence resulting in a solid loading of c(Al2O3) = 16.3 wt%. Solids content derived from the masses of the introduced chemicals was checked by evaluating thermal analysis results as described in [2, 17].

2.2 PVP

In this work PVP (M w = 360,000 g/mol, K90, Fluka) was used as a binder. PVP was added as an aqueous solution containing 15.0 wt% PVP. Concentration of PVP in sols will always be given in wt%.

2.3 pH

pH was measured at room temperature with a pH electrode (HI 1280, Hanna Instruments) with an accuracy of 0.1.

2.4 27Al NMR spectroscopy

The 27Al NMR spectra were acquired at a frequency of 104.2 MHz using a DMX400 spectrometer (Bruker Biospin GmbH) equipped with a 10 mm double channel probe. Short pulses (30°) were applied for excitation (7 μs, −2 dB). Sixty-four free induction decays were accumulated with a repetition time of 2 s. Temperature dependent measurements were carried out waiting for 10 min after the temperature reading showed the desired value. Chemical shifts have been reported relative to the 27Al NMR signal of a 0.1 M Al(NO3)3 solution. Unfortunately, the broad background signal of the aluminum containing ceramic material of the probe head was found at 70 ppm in all spectra. The intensity of this signal responded very sensitively to the tuning state of the probe. The maximum signal intensity was found when tuning the empty probe. The maximum signal intensity was compared with that measured with the spectrum of an 0.1 M Al(NO3)3 solution. The resulting factor was used to compute a signal of the probe with reduced intensity which was subtracted from the spectra of the samples.

2.5 PCS

Particle size of sols was determined using photon correlation spectroscopy (PCS, Zeta Sizer 3, Malvern) with a λ = 532 nm laser (200 mW, Adlas). A refractive index of boehmite (n = 1.65) and no absorption of the scattering particles was assumed. Measurements were carried out at 25 °C. PCS results are given as mean intensity weighted particle diameter (Z ave). Samples analyzed with PCS have to be sufficiently dilute to fulfill the single scattering approximation. In this work samples were diluted 1:100 (v/v). It was shown in a previous work [2] that these parameters yield particle size results which agree well with particle sizes determined with acoustic spectrometry which does not require dilution of the sols.

2.6 Rheology

A rheometer (RS300, Haake) with a cone-plate detector head was used for rheological measurements. The shear rate was increased in a step wise manner as illustrated in [2]. Measurements were carried out running the rheometer in controlled rate (CR) mode as recommended by the instrument supplier to increase accuracy. The size of the gap between cone and plate was set to 0.06 mm. According to the instrument supplier rheological measurements yield results with a precision of ±5%. A thermostat (Haake) was used to keep the temperature of the cone, plate and the sample between them at 20 ± 1 °C. When the highest shear rate (2,500 s−1) was reached the measurement was aborted.

Some measurements were carried out with a double-gap cylinder system. The maximum shear rate, (2,800 s−1) was reached in an analogous manner as for the cone-plate setup. Results being obtained via the double-gap cylinder configuration will be indicated in the text.

3 Results

3.1 27Al NMR spectroscopy

As can be seen in Fig. 1 the presence of Al13 polycations is clearly indicated by a narrow resonance at ~63 ppm [1, 18]. A second narrow resonance at ~0 ppm is caused by monomers [1, 19]. Higher polymerized species (oligomers) cause superimposed broad resonances in the region between ~20 and 5 ppm [1]. The resonance at ~10 ppm cannot unambiguously be assigned to the resonance of the AlO6 species being incorporated in the Al13 polycation. Such a resonance should be found in the region between 11 and 12 ppm [18, 20]. However, as pointed out by Allouche and Taulelle [20] these resonances of the Al13 polycation in the octahedral range are not easily observed due to their large linewidths.

27Al NMR spectra of PVP-free and PVP-containing sols obtained after different stages of aging as indicated in the figure. The label “fresh” corresponds to spectra taken 2 days after synthesis of the sols. The initial sol has a molar ratio of \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.6 \) and a solids loading of ~10 wt%. Addition of aqueous PVP solution resulted in a decrease of alumina content to ~9 wt%

No distinct changes in the spectrum depicted in Fig. 1 were observed when adding 2.0 wt% PVP to such a sol (c(Al2O3) ~10 wt%, \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.6 \)). Two days after synthesis no difference between spectra of pure and PVP-containing sols depicted in Fig. 1 can be seen. Also corresponding spectra having been normalized on the signal intensity at ~63 ppm for PVP-free and PVP-containing samples (not shown here) are identical. Upon aging for 26 weeks the total amount of aluminum, being spectroscopically detectable via NMR, decreased for both, PVP-free and PVP-containing sols, and the spectra observed the following changes: (i) their peak height decreased at ~63 ppm. Additionally, a decrease of the linewidths of the Al13 resonance at ~63 ppm on aging has to be regarded. In both types of freshly prepared sols (PVP-free and PVP-containing) this resonance has a width of 0.25 ppm, whereas after aging for 26 weeks it has decreased to 0.06 ppm for both samples. (ii) the peak height at ~0 ppm increased in both, PVP-free and PVP-containing samples, without changes in linewidth, and (iii) the resonance at ~11 ppm which was merely a hump in the freshly prepared sols became more pronounced upon aging. Hence, PVP does not seem to provoke a different aging regime, which should have brought about completely different 27Al NMR spectra.

3.2 Particle size

The PCS-derived (Z ave) particle sizes in freshly prepared sols under consideration here (\( 0.5 \le {\text{NO}}_{ 3}^{ - } /{\text{Al}} \le 0.8 \) and 3.5 ≤ c(Al2O3) ≤ 5.1 wt%) ranged between 39 and 59 nm. Aging behavior as a function of \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio is shown in Fig. 2. In PVP-free sols the following was found. At comparatively high \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratios of \( 0.6 \le {\text{NO}}_{3}^{ - } /{\text{Al}} \le 0.8 \) (results only shown for \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.8 \)) almost no change in particle size was recorded during 80 days, whereas in sols with lower nitrate contents (\( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.5 \)) a constant increase in particle size could be observed starting right after synthesis. When adding PVP to these two types of sols with differing aging behavior, thus (i) to sols whose particle size remains unaffected (\( 0.6 \le {\text{NO}}_{3}^{ - } /{\text{Al}} \le 0.8 \)) and (ii) to sols who show an increase in particle size (\( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.5 \)), it was found that compared to PVP-free sols the PVP-containing samples of both types of sols were not significantly affected by PVP additions (~2 wt%) in their aging related particle size evolution.

Influence of aging in days (d) on particle size (Z ave) of PVP-free and PVP-containing sols as a function of \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio and aging time. Apart from differing \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio both sol types had comparable compositions (\( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.5 \): c(PVP) = 2.1 wt%, initial c(Al2O3) = 3.0 wt% and \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.8 \): c(PVP) = 2.0 wt%, initial c(Al2O3) = 3.7 wt%)

4 Rheology

Figure 3 shows the influence of PVP concentration in aqueous solutions on flow behavior. Newtonian behavior was found for concentrations up to 8.0 wt%. Structural viscosity appears if further increasing PVP concentration. As can be seen in the inset in Fig. 3, a strong, non-linear increase in viscosity at a shear rate of 2,500 s−1 can be observed with increasing PVP concentration in aqueous PVP solutions.

While Fig. 3 shows the influence of PVP addition to water only, the influence of PVP not only to water but to sols who not only contain water but also Al species (c(Al2O3)) can be seen in Fig. 4. The sols depicted in Fig. 4 have a \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) ratio of 0.6

Two aspects shall be stressed here: (i) viscosity of PVP-free sols increases with solids loading (c(Al2O3)) and becomes increasingly non-Newtonian if solids loading approaches ~25 wt% [2] [Ref. 23.0 wt% for \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.6 \)]. (ii) PVP addition does increase viscosity and also changes flow characteristics from Newtonian to structural viscosity behavior [Ref. c(Al2O3) = 18.1 wt% with c(PVP) = 0: Newtonian, and c(PVP) = 2.4 wt%: structural viscosity].

While Fig. 4 depicts flow curves, Fig. 5 shows the combined influence of solids loading and PVP concentration on the resulting viscosity at a shear rate of 2,500 s−1. At similar PVP concentrations sols with increased solids loading (c(Al2O3)) show a more pronounced rise in viscosity.

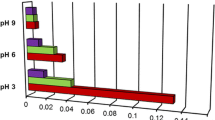

While Figs. 4 and 5 depict the influence of PVP content and solids loading (c(Al2O3)) at a constant \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio of \( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.6 \), Fig. 6 summarizes viscosity data of sols with comparable solids contents (c(Al2O3)) between 3.5 and 5.1 wt% but differing \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratios as well as different PVP additions. As all depicted samples have the same comparable solids loading (c(Al2O3)) it is evident, that at comparable PVP concentrations above 1.5 wt% the \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio has an influence on viscosity. It should be noted that all samples whose viscosity at 2,800 s−1 was depicted in Fig. 6 showed Newtonian flow characteristics (flow curves not shown here). Only if PVP concentration was increased well above 2.0 wt%, e.g. to 4.0 wt%, pronounced structural viscosity behavior was found. This finding is in line with the data shown in Fig. 4 where even for a sol having a much higher solids loading, i.e. c(Al2O3) ~10 wt%, a PVP concentration of 2.0 wt% provoked only a slight non-Newtonian behavior.

5 Discussion

5.1 Aluminum speciation and chemical stability of the sols

As shown in [1] Al speciation in modified Yoldas sols is determined by their pH values. These pH values are a result of the chemical composition of the sols, which can be described in terms of solids content (c(Al2O3)) and \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio. In this work PVP was added to the sols as aqueous solution in minor amounts. Because of the comparatively small PVP concentration the sols were only slightly diluted, i.e. their Al2O3-content expressed as c(Al2O3) changed only marginally as can be seen in Fig. 5. Addition of aqueous PVP solutions has no effect on the sols \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio. As a result of the only marginally changes in solids loading (c(Al2O3)) and the unaffected \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio only minor changes (~0.1) of pH values resulted when adding aqueous PVP solution to the sols. Thus, possible changes of Al speciation by PVP addition should not be due to dilution related changes in pH value but to PVP itself. Since no such changes have been observed in the spectra of the freshly prepared sols (aged for 2 days), it can be concluded that initially PVP does not change the Al speciation of the sols.

However, the differences between pure and PVP-containing sols, which become apparent after aging for 26 weeks will be discussed in detail in the following. As can be seen in Fig. 1, sols analyzed in this study, which all contain Al13 polycations, are subject to aging related changes in their composition in terms of Al speciation. The main characteristic of aging Al13 containing modified Yoldas sols is a decomposition of Al13 polycations [1] which was also observed in this work.

In addition, concerning the aging related changes of the resonances attributed to Al13 polycations at ~63 ppm, line narrowing and a decrease of intensities have to be taken into account. As was mentioned above in both types of freshly prepared sols (PVP-free and PVP-containing) the resonance at ~63 ppm has a width of 0.25 ppm, whereas after aging for 26 weeks it has decreased to 0.06 ppm for both samples (Fig. 1). The observed changes in linewidths of the sol samples can be explained by relaxation processes and geometric factors. Since viscosity, which would influence relaxation, does not change significantly during aging [2], viscosity effects can be excluded to explain the observed line width change between fresh (0.25 ppm) and aged samples (0.06 ppm). The conclusion whereas viscosity is of only little influence on line widths is justified as freshly prepared PVP-containing sols—having a markedly increased viscosity compared to fresh PVP-free sols—show similar line widths compared to PVP-free sols, i.e. 0.25 ppm. As a result geometric effects shall be considered here in order to explain the observed line width effects.

Al13 polycations are formed by a central AlO4 group which is surrounded by four three-membered rings of AlO6 polyhedra [21]. The line width of the 27Al resonance of the central AlO4 group (~63 ppm) is influenced by quadrupolar interaction with the neighboring atoms. Hence, the line width of 0.25 ppm in the case of freshly prepared sols—both PVP-free and PVP-containing—could be explained by the simultaneous presence of a mixture of well ordered Al13 polycations and distorted Al13 polycations. The former resulting in a chemical shift at 63.5 ppm. Only little changes in the geometric structure of the Al13 polycation can result in differing chemical shifts. For example Fu et al. [18] reported a change from 62.9 to 64.5 ppm for a change from a well ordered Al13 polycation to a defect structure called AlP1 resulting from loss of one octahedron from Al13. Hence one may hypothesize that the superimposition of single resonances of well formed Al13 and distorted Al13 polycations yields a broadened resonance. Based on this assumption the observed line narrowing from 0.25 to 0.06 ppm during aging can be interpreted as a hint to a preferred decomposition of more distorted Al13 polycations whereas less distorted ones remain.

These less distorted polyhedra should yield the narrower lines, void of signals resulting from distorted species, observed in the freshly prepared samples. This line narrowing is not influenced by PVP addition.

Otherwise, the differences in decrease of the intensities point to an influence of PVP on aging in terms of Al13 decomposition. In the case of the freshly prepared sols the intensity of the Al13 polycations related resonance at ~63 ppm is smaller in the case of the PVP-containing sample. Since the linewidths of both fresh PVP-free and PVP-containing samples are equal it can be concluded, that the PVP-containing sol contains less Al13 polycations. This is due to the little dilution as mentioned above. However, after aging for 26 weeks the resonances of the Al13 polycations are narrowed to the same extend for both samples. Thus, alike to the case of the freshly prepared sols, a comparison of intensity is justified to give an indication of relative amounts of Al13 polyhedra. In contrast to the freshly prepared sols the intensity for the Al13 related resonance at ~63 ppm of the PVP-containing sol aged for 26 weeks is larger than that of the aged pure one (Ref. Fig. 1). Hence, one may conclude that decomposition of Al13 polycations is slower in PVP-containing sol.

5.2 Particle size and colloidal stability of the sols

In analogy to boehmite sols modified Yoldas sols are electrostatically stabilized. As shown in Fig. 2 particle size of freshly prepared sols ranged between 39 and 59 nm and underwent only small changes on PVP addition.

Only sols with \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratios of 0.5 showed a pronounced particle growth on aging, i.e. these sols are not well stabilized. Addition of PVP solution neither changed particle sizes nor the rate of particle growth. Thus, in the case of a badly stabilized alumina sol (\( {\text{NO}}_{3}^{ - } /{\text{Al}} = 0.5 \)), PVP addition in the amounts under consideration here [c(PVP) ~ 2 wt%] does not prevent or worsen particle growth.

On the other hand, in the case of well stabilized sols (0.6 ≤ \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) ≤ 0.8), who do not show a significant increase in particle size even after aging for 80 days, PVP addition does not destabilize them, i.e. does not lead to a marked increase of particle sizes. This was shown in Fig. 2 using a sol with \( {\text{NO}}_{3}^{ - } /{\text{Al}}\;{\text{ = }}\;0.8 \) as an example.

Summarizing these observations, from the point of view of colloidal stability, PVP addition has no effect on the modified Yoldas sols under consideration here.

5.3 Viscosity and flow characteristics of PVP solutions

At constant temperatures viscosity of PVP solutions depends on concentration and molecular weight [22]. The aqueous PVP solutions under study here showed Newtonian behavior in a wide range of concentration (up to 8.0 wt%). However, as was shown in Fig. 3 viscosity did not increase linearly with PVP concentration. This result is consistent with the findings reported in [22] which analyzed Luvitec®K 90.

A useful tool to investigate the interaction of dispersed polymers in solutions is the concept of reduced viscosity. Reduced viscosity is calculated according to the following equations:

where c is the solids loading in g/100 mL and η stands for viscosity [23]. If reduced viscosity is independent of solids loading the polymers are assumed to be spherical [23]. In the case of reduced viscosity being a function of solids loading the polymers are assumed to be chainlike or linear [23]. According to Fig. 7 reduced viscosity of aqueous PVP solutions shows a rather linear increase with PVP concentration, hence within the frame of the concept of reduced viscosity PVP molecules have a chainlike/linear appearance in aqueous solutions.

Mixing PVP with alumosols results in marked viscosity effects as well as will be illustrated in the following.

5.4 Viscosity and flow characteristics of sols

It is a remarkable finding that mixtures of (i) aqueous PVP solution with (ii) modified Yoldas sols with \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio of 0.6, result in mixtures having a drastically increased viscosity although both starting media (i and ii) have comparable viscosity values. Since neither Al speciation nor particle size was changed on PVP addition as was discussed above, these results suggest a possible interaction between alumina components of the sols and PVP molecules. When comparing viscosity data collected in Figs. 3 and 4 it can be concluded that there is an interaction between PVP macromolecules and particles being present in modified Yoldas sols. A “pure” aqueous PVP solution having a PVP content of 2.5 wt% PVP shows a viscosity of 9 mPas (Ref. Fig. 3). If mixing a modified Yoldas sol having a solids loading of 23.0 wt% Al2O3 and a viscosity of 19 mPas (2,500 s−1) with aqueous PVP solution to yield a resulting concentration of 2.4 wt% PVP, then the mixture shows a viscosity of 81 mPas (2,500 s−1). This viscosity value of the resulting mixture is much higher than the viscosities of the single components. As can be seen in Fig. 4 such an increase in viscosity of the resulting “PVP solution/modified Yoldas sol” mixtures could not only be observed for a sol having a comparatively high solids loading of 23.0 wt% Al2O3 but also in sols having smaller solids loadings, i.e. c(Al2O3) = 18.1 wt% and c(Al2O3) = 10.9 wt%.

The idea of a possible interaction between PVP macromolecules and particles being present in modified Yoldas sols is substantiated by the shape of the recorded flow curves. Sole aqueous PVP solutions containing up to 8.0 wt% PVP as well as PVP-free sols with solids contents up to 18.0 wt% Al2O3 showed Newtonian flow characteristics. If at least 2.4 wt% PVP was added to those sols then they exhibited structural viscosity behavior. Structural viscosity behavior is generally seen as an indication of particle interaction like formation of network structures [24].

Possible interactions between alumina particles and PVP molecules shall be discussed now. According to Esumi et al. [11] PVP interacts with alpha-Al2O3 particles. The authors in [25] mention that “…the oxygen atom on the pyrrolidone ring provides a preferential site for hydrogen bonding.” Hydrogen bonding between dispersed silica and PVP [26] and PVP with clay minerals [27] is described in the literature. Most important for the results presented here is the discussion on the interaction between C=O groups of PVP and surface OH groups of alumina colloidal particles in Yoldas sols through hydrogen bonding as described by Jing and Hou [28]. As was already mentioned above, freshly prepared modified Yoldas sols contain Al13 polycations if their pH value lies above ~3 [1]. Al13 polycations as well as other species being present in modified Yoldas sols like “highly” and “poorly” polymerized aluminum species posses OH groups. Hence, PVP molecules may interact with these aluminum species via hydrogen bonding. Al13 polycations consist of a central AlO4 tetrahedron which is surrounded by 12 AlO6 octahedra [21]. If one assumes possible hydrogen bonds of the outer AlO6 species one might have expected to find changed 27Al NMR spectra as hydrogen bonds should slightly distort the state of coordination of these outer AlO6 species. However, the resonances attributable to the AlO6 octahedra in the Al13 polycation, which should be found at 11–12 ppm [18, 20] are not easily observed because this signal is broad. Thus 27Al NMR spectra recorded in this work do not allow to judge whether hydrogen bonds are formed in PVP-containing sols or not.

It is interesting to note that the degree of interaction between PVP and alumina particles being present in modified Yoldas sols depends on solids loading of the used sol. As was shown in Fig. 5 PVP-free modified Yoldas sols exhibit an only marginal increase in viscosity (at 2,500 s−1) when solids loading is increased from 4.2 to 18.0 wt% Al2O3. Viscosity rose only from 2 to 5 mPas. Addition of PVP on the other hand provoked an increase in viscosity at 2,500 s−1 from 9 to 49 mPas. This finding corroborates the above drawn conclusion that there are indeed interactions possible between PVP macromolecules and particles being present in modified Yoldas sols.

The resulting viscosity of sol-PVP mixtures is not only influenced by the solids loading of the sols but also by their \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio. As can be seen in Fig. 6, sols with differing \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratios but similar solids loadings between 3.5 and 5.1 wt% show—albeit having the same PVP concentration of 2.0 wt%—markedly different viscosity values (2,800 s−1). It is interesting that reduced PVP concentrations, e.g. 1.5 wt% PVP do not provoke an influence of \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio, as can be seen in Fig. 6.

6 Conclusions

PVP is a commonly used additive during sol–gel processing. It was found in this work, that in freshly prepared modified Yoldas sols PVP addition does not lead to differing 27Al NMR spectra indicating that PVP does not affect the intricate Al speciation in this particular type of sol. During aging PVP slows down the decomposition of Al13 polycations.

No influence of PVP on particle size in the freshly prepared state was found. Aging related changes in particle sizes of modified Yoldas sols were unaffected by the presence of PVP.

Otherwise, PVP shows some interaction with the particles being present in modified Yoldas sols. This interaction is reflected in increased viscosity values when mixing aqueous PVP solution with modified Yoldas sols having both comparable viscosity values. Higher PVP concentrations lead to strongly increased viscosity values and increasingly structural viscosity behavior. Parameters influencing this interaction are solids loading (c(Al2O3)) and \( {\text{NO}}_{3}^{ - } /{\text{Al}} \) molar ratio.

References

Nofz M, Pauli J, Dressler M, Jäger Ch, Altenburg W (2006) J Sol-Gel Sci Technol 38(1):25

Dressler M, Nofz M, Gemeinert M (2006) J Sol-Gel Sci Technol 38(3):261

Dressler M, Nofz M, Saliwan-Neumann R, Dörfel I, Griepentrog G, Surf Coat Technol (under review)

Morlens S, Roma N, Ricart S, Moreto JM, Puig T, Pomar A, Obradors X (2006) J Phys Conf Series 43:182

Chen YY, Wei WCJ (2001) J Europ Ceram Soc 21:2535

Blum AE, Eberl DD (2004) Clays Clay Miner 52(5):589

Esumi K, Iitaka M, Torigoe K (2000) J Colloid Interface Sci 232:71

Pattanaik M, Bhaumik SK (2000) Mater Lett 44:352

Séquaris JM, Baßmann F, Hild A, Narres HD, Schwuger MJ (1999) Colloids Surf A 159(2–3):503

Ishiduki K, Esumi K (1997) J Colloid Interface Sci 185:274

Esumi K, Takaku Y, Otsuka H (1994) Langmuir 10:3250

Sakai K, Yoshimura T, Esumi K (2002) Langmuir 18:3993

Linardos S, Zhang Q, Alcock JR (2006) J Europ Ceram Soc 26:117

Hoogsteen W, Fokkink LGJ (1995) J Colloid Interface Sci 175(1):12

Zheng MP, Jin YP, Jin GL, Gu MY (2000) J Mater Sci Lett 19:433

Yoldas BE (1998) J Sol-Gel Sci Technol 13:147

Dressler M, Nofz M, Malz F, Pauli J, Jäger C, Reinsch S, Scholz G (2007) J Solid State Chem 180(9):2409

Fu G, Nazar LF, Bain AD (1991) Chem Mater 3(4):602

Shafran K, Deschaume O, Perry CC (2004) Adv Eng Mat 6:836

Allouche L, Taulelle F (2003) Inorg Chem Commun 6:1167

Allouche L, Huguenard C, Taulelle F (2001) J Phys Chem Solids 62(8):1525

www.specialchem4adhesives.com/tc/polyvinylpyrrolidone/index.aspx?id=non-thixotropic, Accessed 26.6.2007

Sakka S, Kamiya K (1982) J Non-Cryst Solids 48(1):31

Sacks MD, Sheu RS (1987) J Non-Cryst Solids 92(2–3):383

Yang H, Yan Y, Zhu P, Li H, Zhu Q, Fan C (2005) Europ Polym J 41:329

Guzenko NV, Voronina OE, Pakhlov EM, Voronin EF (2001) Pharm Chem J 35:49

Bajpai AK, Vishwakarma N (2000) J Appl Polym Sci 78(12):2122

Jing C, Hou J (2007) J Appl Polym Sci 105:697

Acknowledgments

The financial support of the Deutsche Forschungsgemeinschaft (DFG) is gratefully acknowledged. The authors thank A. Marek and W. Altenburg for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dressler, M., Nofz, M., Pauli, J. et al. Influence of polyvinylpyrrolidone (PVP) on alumina sols prepared by a modified Yoldas procedure. J Sol-Gel Sci Technol 47, 260–267 (2008). https://doi.org/10.1007/s10971-008-1798-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1798-9