Abstract

This paper reported creating the all-chromatographic technique for the recovery of americium radionuclides from solutions of the complex composition generated in the radiochemical industry. The technique was based entirely on the displacement complexing chromatography; neither additional precipitation nor extraction stages were necessary. The technology used the elution with DTPA and NTA-based solutions containing the citric acid additives and the sequential elution with these eluents, emphasizing the separation of americium from the heavy rare earth elements, lead, and cadmium. The complete separation of americium from lead and cadmium was a peculiar exercise; the elution order of lead and cadmium changed in the presence of the citric acid additives. The recovery and separation of americium from actual radioactive waste solutions of different origins demonstrated 96 and 99% chemical purity of the final product.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Unique nuclear properties of Americium-241 are widely used in small-scale nuclear engineering. Americium-241 has almost monochromatic α-(5.44 and 5.49 MeV) and γ-(59.6 keV) radiation [1]. It is used primarily as a gamma-radiation source and as a fast neutron source in the mix with beryllium and boron. Americium-241 served as a starting material for the production of Curium-242 and Plutonium-238. Again, Americium-241 could be a potential alternative to plutonium 238 in radioisotope thermoelectric generators for satellites, deep space missions, and unscrewed remote facilities [1, 2].

Isotopically pure Americium-241 radionuclide is produced in the decay of plutonium-241 (see Eq. 1). Hence, a readily available source of Americium-241 is the liquid waste of plutonium processing by PUREX technology [1, 2].

The advantage of the plutonium processing waste as a source of Americium-241 is that the minor actinides are almost entirely removed by the PUREX process [2].

The method of the displacement complexing chromatography (DCC) on cation exchange resins, or cationites [3], is well known as a powerful tool for the recovery and separation of radionuclides of transplutonium elements (TPE) and rare earth elements (REE) from solutions generated in the spent nuclear fuel (SNF) processing. [1, 5,6,7]. The cationites containing active sulfonic functional groups, or sulfocationites [3], possess high ion exchange capacity, good kinetic and desorption properties, and sufficiently high radiation stability to withstand the radiation exposure on the resin in the separation process [7, 8]. Therefore, this type of cationite was chosen for the DCC. The diethylenetriaminepentaacetic (DTPA) and nitrilotriacetic (NTA) acids are the best for separating solutions containing both REE and TPE.

DTPA is useful for removing radionuclide impurities, such as europium-154,155 from Curium-244 and Americium-241, 243, and providing the separation of americium from alkaline earth elements, light rare earth elements, gadolinium and corrosion products. Moreover, due to its higher solubility, it allows the use of the cationite in the hydrogen form [4,5,6,7]. NTA is the best for the efficient separation of curium and americium; it has better kinetic properties and the higher radiation resistance; hence, the less effect of radiation on the separation process [8]. The use of DTPA and NTA as sequential eluents or mixed eluents is reported for the recovery of valuable radionuclides in [4,5,6,7].

In [4], Wheelwright presented results on the recovery of kilogram amounts of isotopically pure Americium-241 from solutions of the cooled plutonium processing. The feed concentrate contained plutonium in the Pu/Am mass ratio from 0.01 to 2 and the impurities of Fe, Cr, Ni, Al, Si, Ca, Mg, and Na in the wide range of concentrations. The final purification of Americium-241 was performed using NTA on the cationite in Zn2+-form; the concentration of Americium-241 in the eluates reached 8.6 g L−1.

In [9], the feed concentrate, apart from the above-listed impurities, contained cerium in the Am/Pu/Ce mass ratio of 1/(0.05–0.2)/(0.5–3). Therefore, americium was separated using eluents containing 20 g L−1 (0.0509 mol L−1) of DTPA and 10 g L−1 (0.0254 mol L−1) of DTPA + 5 g L−1 (0.025 mol L−1) of citric acid. The concentration of Americium-241 in the eluates reached 7–8 and 5–6 g L−1, respectively. The separation was performed on the KU-2 cationite in Ni2+ or H+-form.

This study was aimed primarily at the development of techniques and optimum conditions for the recovery and separation of the high-grade product of Americium-241 radionuclide from solutions of a complex composition containing alkaline, alkaline earth, all rare-earth elements, and transition metals. The quality requirements imposed on the final Americium-241 dioxide product were as follows: the mass content of the neutron absorbers B, Cd, and Gd not higher than 0.3%; the mass content of Americium-241 in the dioxide not less than 82.8% considering the maximum theoretical content of 88.3%; the chemical purity of Americium-241 not less than 94%. Within this range, the content of other individual chemical impurities was not limited.

Experimental

The processes of sorption and separation were studied using the KU-2x8 sulfocationite of 125–250 μm grain size. Before the experiments, the resin was conditioned by washing with 3–5 bed volumes (b.v.) of 3–4 mol L−1 HNO3 to remove the impurities and convert the ionite into the hydrogen form. The following rinsing with distilled water washed out the remaining nitric acid. The bench-scale experiments were performed using 2–4 jacketed glass columns of the successively decreasing diameter within the range of 1–0.25 cm2 and 80 cm height.

All solutions were filtered through the columns using a peristaltic pump. As a rule, the flow rate of 4 ml min−1 cm−2 of the column cross-section area was maintained.

The mixture of elements to be separated was loaded into the sorption column by filtering a solution of rare-earth element nitrate salts containing 0.01–0.5 mol L−1 of HNO3. During the filtering process, the elements were adsorbed in full on the cationite bed.

For every bench-scale experiment, approximately 300–500 mg of the separated elements were required. The application of similar quantities of Americium-241 would demand running the experiments in the hot cell facility; the accompanying arrangements, expensive radiochemical equipment needed, specific analytical sample preparation efforts, and the cost of Americium-241 product itself would make prohibitive the overall cost of multiple experiments required to tune up the technique.

Therefore, in the bench-scale experiments, Americium-241 was simulated by the elements from the REE group. In references [10, 11], the following elution series were reported for 0.105 mol L−1 NTA solution at pH = 6.4 and the temperature of 60 °C:

For 0.05 mol L-1 DTPA solution at pH = 6.5 and the temperature of 60 °C the elution order was:

Under the experimental conditions given, the best match was the element revealing the same position in the series as americium. Hence, from the elution series, with DTPA, americium is not separated with holmium, and with NTA-with europium. That is why holmium and europium were chosen to simulate the behavior of americium in the bench-scale runs.

The sorbent in the separation columns was converted into the barrier ion form (Zn2+, Ni2+) by washing the resin bed with 3–5 bed volumes of 0.2–0.5 mol L−1 solutions of the metal nitrate salt needed for the purpose. After the sorption, additional washing of the separation column with 3–5 bed volumes of 0.02–0.05 mol L−1 solution of the barrier ion removed from the resin the leftovers of hydrogen ions remained in the sorption column.

Every operation of sorption and conversion into the barrier ion form were followed by rinsing the columns with 2–3 b.v. of distilled water.

For the eluents, we used solutions of sodium or ammonium salts of DTPA and NTA, neutralized to the pH of 7–8. Citric acid salts were used for the buffer additives. In [11], Wheelwright preferred these as compared to HEDTA and EDTA. As a rule, the elution occurred at the flow rate of 4 ml min−1 cm−2 of the column cross-section area at 70–80 °C. The solutions emerging from the columns were collected into fractions and analyzed for the elements of interest.

The concentrations of Eu, Y, Zn, and Na were determined using the tracer technique with the corresponding radionuclide tracers. The concentrations of Er, Ho, Sm, Nd, and Pr were determined using the spectrophotometric technique. The concentrations of transition metals were determined by either atomic absorption or atomic emission spectroscopy, as described in [12].

Runs with the actual waste solutions were performed to validate the experimental conditions found in the bench-scale experiments. Content of Americium-241 in solutions was determined by α- or γ-activity measurements. In the final dioxide product, it was analyzed by the calorimetric method. The analytical techniques and equipment used were described in detail in [7].

The raw material of Americium-241 was an aqueous liquid waste generated in the radiochemical industry. The waste solutions were of the complex composition and contained alkali elements (Na, K); alkaline-earth elements (Mg, Ca, Sr, Ba); all elements of the REE group; and Al, Cr, Fe, Mn, Ni, Zn, Cd, Pb, and others in the mass ration to Am of 300/1. According to the standard operating procedure, the aqueous feed waste was concentrated by the precipitation of REE hydroxides; this stage also helped reduce the sorption time, secondary waste volume, remove alkaline earth elements and other impurities.

Experimental runs on the recovery of Americium-241 from the actual waste were performed on the chromatographic setup consisting of 8 jacketed stainless steel columns. The column’s characteristics were given in Table 1.

Results and discussion

The preparation of Americium-241 obtained in the first series of experimental runs of the recovery and separation with 0.0509 mol L−1 DTPA did not meet the imposed quality requirements.

First of all, the Americium-241 product contained much more impurities than allowed; the spectral analysis found the heavy REE, the separation of which from Americium-241 was not complete with the DTPA solution. Similarly, if the feed solution contained cadmium and lead in 40/1 mass ratio to Americium-241, the separation from these elements was not always sufficient.

Therefore, apart from the basic DCC process that removed the majority of impurities (the light REE, europium, gadolinium, and yttrium), two more operations had to be made for the final purification. First, cadmium and lead were separated from americium by the precipitation of sulfides; second, the heavy REE were separated by the extraction.

Those two additional operation stages required creating a new workplace in the hot cell for operations with the highly radioactive material. The procedure was time-consuming, and eventually resulted in extra radiation exposure of the personnel employed. The DCC method’s potential seemed high enough to eliminate the extra stages and perform the separation of lead, cadmium, and heavy REE in the same engineering embodiment. The following bench-scale studies proved the assumption.

Separation of americium, heavy REE, lead, and cadmium with NTA

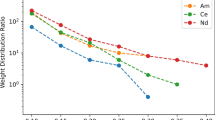

It was known from the reference data [13] that the separation of americium was expected with the NTA-based eluents. These eluents showed the highest separation coefficient value of 1.5 for americium from the most closely related Dysprosium and Terbium. europium simulated the behavior of americium in the bench-scale experiments with NTA. Elution curves of europium and the heavy REE with 0.07 mol L−1 NTA solution were shown in Fig. 1.

The satisfactory separation of the elements under study could be seen with a rather small mixed zone.

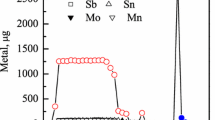

Under these conditions, lead was eluted before europium (see Fig. 2). However, the separation of cadmium did not occur (see Fig. 3).

Effect of citric salt additives to DTPA and NTA solutions on the separation efficiency

Table 2 presented the data on the effect of citric acid additives to 0.0254 mol L−1 DTPA eluent on the chromatographic process parameters.

The REE band movement velocity (v) was calculated using Wilson’s formula [12]

where v denoted the movement of the REE front along the column, cm h−1; \(\tilde{D}_{\text{p}}\) the dispacing ion concentration, mol L−1, u the eluent flow rate, ml min−1 cm−2 of the column cross-section area, \(\varepsilon\) a fraction of the liquid phase volume in the cavities between the resin granules in the column. As a rule, \(\varepsilon\) = 0.3.

The Height Equivalent to the Theoretical Plate (HETP), the separation coefficient of the elements separated (α), and (HETP/lgα) value [3] was used for the quantitative characterization of the separation efficiency and calculated according to the methods reported in our paper published earlier [12].

The content of rare earth elements in the solid resin phase was calculated according to the formula (3) [3]:

where XMR denoted the REE concentration in the resin phase, % of the capacity; Mp the concentration of the separated elements in the eluate, mol L−1; Dp the total concentration of the displacing ion, mol L−1.

The data presented in Table 2 showed that with the increased concentration of the citrate in the eluent, the REE band movement velocity increased, so as pH values and REE concentrations in the eluates. The content of REE in the solid phase crossed the maximum at 0.01 mol L−1 concentration of citrate in the eluent. This maximum value corresponded to the minimum value of HETP/lgα. At the citrate concentration in the eluent of 0.025 mol L−1, the REE concentrations in the filtrate were considerably higher than the DTPA concentration, which witnessed the citric acid took its part in the complex formation.

The competitive displacing ion, hydrogen, and complexing agent ions penetrated the REE zone and slowed the ion exchange processes of REE. The more ions penetrated, the slower were the exchange processes. The introduction of buffer additives into the eluent increased the content of REE in the solid phase and reduced the content of competitive ions, improving the kinetics of ion exchange. Besides, the introduction of buffer additives improved the complex formation kinetics due to the higher lability of DTPA-REE complexes in the presence of short-lived mixed complexes containing both DTPA and citrate ions [14].

Separation of americium, europium, gadolinium, and cadmium with DTPA solutions in the presence of citric acid additives

In the presence of DTPA, transition metals made more stable protonated complexes than REE and less stable 1/1 complexes [11]. As shown in [15], at low pH values of the eluates, transition metals possessed a lower affinity to the sorbent. They emerged from the sorbent before or together with the zone of REE and TPE, and the efficient separation of REE, americium, cadmium, and lead with 0.0254 mol L−1 DTPA solution was not possible. In Figs. 4 and 5, the output elution curves were shown. Extensive tailing of the separated element fronts was observed, decreasing the yield of the pure product.

For DTPA, the stepwise protonation constants of divalent transition metals are higher than those for REE and TPE by 2–3 orders of magnitude [13]. With the citric acid salts introduced into the eluent, the eluate’s pH value increased, and hence, the protonated complexes fraction decreased. That caused the change in the elution order of lead and cadmium; their zones shifted towards the light REE. However, with the 0.01 mol L−1 additive of citric acid, s-shaped isotherms of Am and REE with Cd and Pb caused the penetration of transition metals into the Am and REE zones (see Figs. 6, 7). Further increase of the citric acid concentration resulted in the full inversion of the selectivity; at 0.015 mol L−1 of citric acid, lead and cadmium emerged after europium, whereas at 0.025 mol L−1 they came out after neodymium (see Figs. 8, 9).

Combined application of DTPA and NTA-based eluents: recovery of Americium-241 using sequential elution with DTPA and NTA solutions

The studies showed that americium could be separated from the heavy REE and lead with a 0.07 mol L−1 NTA solution. On the other hand, americium could be separated completely from lead and cadmium with 0.0254 mol L−1 DTPA solution containing 0.015–0.025 mol L−1 of citrate, without sacrificing the separation efficiency from europium, gadolinium, and light REE.

These results allowed to refine the technique for recovering Americium-241. The development of the technique was finalized in two chromatographic cycles with real radioactive waste solutions. In the first cycle, waste solutions of the radiochemical industry were reprocessed. For the second cycle, aqueous waste streams of earlier chromatographic separation runs were used.

In Stage 1, with the eluent containing 0.0254 mol L−1 of DTPA and 0.015 mol L−1 of ammonium citrate, americium was separated from the majority of impurities, including the light REE, Gd, Pb, Cd, and AEE. In Stage 2, the final purification of americium from the heavy REE was performed with a 0.073 mol L−1 NTA solution.

The feed concentrate composition of Cycle 1 expressed in gram per 1 g of Americium-241 was the following: Fe-0.08; Ca-1.10; Al-0.03; Pb-0.03; Ba-0.08; Mg0.08; Cd-0.03; Mn-0.03; K-0.03; Gd-0.45; Nd-0.17; Pr-0.17; Y-0.06; Sm-0.56; Ln-0.56. The volume of the feed was 190 L. The concentration of Americium-241 in the feed was 355 mg L−1; the total content of Americium-241 was 67.45 g; concentration of HNO3 was 0.9 mol L−1; 239Pu to Americium-241 ratio was 0.3%; the mass ratio of Americium-241 to the total impurities was 1/3.5.

In Cycle 1, the elements separated were loaded by sorption onto Column 2; the separation was made on Columns 4–7 on the KU-2 cationite in the hydrogen form. Columns 2–5 were loaded with the sorbent bed of 0.5–1.5 mm grain size; Columns 6 and 7 contained cationite of 0.125–0.25 mm grain size. The output curve of Americium-241 was shown in Fig. 10.

The emerged Gd-free fractions of Americium-241 were acidified with HNO-3- up to 0.3 mol L−1 and used for the feed concentrate of Stage 2. The concentrate was loaded on Column 4 by sorption; Columns 5–7 were used for the separation. Column 4 contained the cationite in the hydrogen form; the separation columns contained the cationite in Zn-form. The output curve was given in Fig. 11. The americium-containing fractions were combined, oxalate of Americium-241 precipitated and calcined. The characteristics of the final product were listed in Table 4.

As a result of Cycle 1, 55.02 g of americium dioxide was obtained, the total yield was 72.4%. The content of Americium-241 in the product was 88.7%.

The feed composition of Cycle 2 was given in Table 3. It was more complicated than in Cycle 1: the mass ratio of Americium-241 to the total impurities was 1/67. The feed concentrate was loaded by sorption on Columns 1 and 2.

The separation at Stage 1 of Cycle 2 was performed on Columns 4–8. For the eluent, we used 0.0254 mol L−1 DTPA and 0.015 mol L−1 ammonium citrate solution. The gadolinium-free americium fractions of the eluate were combined and acidified. In Stage 2, the mixture to be separated was loaded by sorption on Column 4, followed by the end-polishing of americium on Columns 5–8 using the elution with 0.073 mol L−1 NTA solution.

As a result of Cycle 2, 18.58 g of AmO2 was obtained. The content of americium in the final product was 84.4%. The characteristics of the final product were given in Table 4.

It should be noted here that although the full spectrometric analysis of the individual impurities in the Americium-241 product could be performed at that time, those analyses were beyond the requirements imposed on the Americium-241 product. Hence, it was not made to avoid the unnecessary radiation exposure of the personnel in the analytical lab.

Results obtained in the reprocessing operations of both the prime americium concentrate and aqueous waste witnessed the reliability of the developed recovery technique. The final preparations of americium met the imposed requirements in full. Content of the restricted impurities, namely, Gd, Cd, and B, was below the detection limits of the analytical methods used.

Thus, the enhancements made in the technological processes of the americium recovery produced a substantial positive effect. Stage 1 of the chromatographic cycle provided the primary purification of americium from the light REE, Gd, Cd, and Pb. The eluent used contained 0.0254 mol L−1 DTPA and 0.0148 mol L−1 ammonium citrate solution. The purification of americium from the heavy REE occurred in Stage 2, using a 0.073 mol L−1 NTA solution. The chemical grade of the final americium product obtained from the prime feed concentrate exceeded 99%; the product yield was 72%. Reprocessing of aqueous waste of more complex composition resulted in 96% chemical grade americium with 80% yield.

The combined application of DTPA and NTA-containing eluents and those eluents with the citric salt additives, in different sequence and process operation modes, enabled the recovery of the high-grade americium without the additional operations of the sulfide precipitation and extraction purification.

In the last decade, several papers on the recovery of americium were published. No sorption-based technologies were investigated; however, various extraction techniques for the recovery of americium were reported. One of them reported the recovery of Americium-241 from aged plutonium dioxide [2]; several discussed the recovery of americium from highly active PUREX raffinates [16,17,18] and directly from fast reactor fuels (EURO-GANEX process, [19]). In [20], a review of 10-year R&D work on the recovery and separation of americium from PUREX waste was given. A comparison of the processes detailed above with the technology presented in our paper showed that they all possessed the advantages and drawbacks of their own. For instance, the chemical composition of the feed concentrate used for the recovery of Americium-241 in our work was much harder to separate as compared to the other ones. Rather simple engineering embodiment of the sorption process and its capability to operate with relatively small batches of the target radionuclide makes the DCC technique perfectly competitive with the extraction ones for the semi large-scale production of the americium radionuclide products.

Conclusions

-

1.

The effects of the citric salt additives to the eluent on the separation of americium and REE were studied. It was found that during the separation of americium and REE on the cationite in the hydrogen form with 0.0245 mol L−1 DTPA and 0.01 mol L−1 citric acid salt solution, the minimum value of HETP was observed, corresponding to the maximum relative content of the separated components in both phases.

-

2.

The introduction of the citric acid salts into a DTPA-based eluent resulted in the change in the elution order of lead and cadmium; their zones shifted towards the light REE. When the concentration of citric acid in the eluent exceeded 0.05 mol L−1, the complete separation of americium from lead and cadmium was observed.

-

3.

The technique for the recovery of americium from radiochemical waste using the sequential elution with the DTPA and NTA-based eluents and the citric salt additives was developed. The eluents containing DTPA and citric acid salt additives were used in Stage 1, where the light REE, europium, gadolinium, lead, cadmium, and other impurities were separated. In Stage 2, the NTA-containing eluents solved the problem of the heavy REE removal.

-

4.

The chemical grade of the americium products obtained was 96% and 99%. The yield of americium into the final product amounted to 80% and 72%, respectively.

References

Morss LR, Edelstein N, Fuger J, Katz JJ (eds) (2011) The chemistry of the actinide and transactinide elements, vol 2, 4th edn. Springer, Switzerland

Sarsfield MJ, Campbell C, Carrigan C et al (2017) The separation of 241Am from aged plutonium dioxide for use in radioisotope power systems. In: E3S web conference. https://doi.org/10.1051/e3sconf/20171605003 Accessed 24 July 2020

Tremillon B (1965) Les separations par les resines echangeuses d`ions. Gauthier-Villars, Paris

Wheelwright EG (1970) Generic ion-exchange process for recovery and purification of valuable elements from the nuclear industry. In: Proceedings on conference in ion-exchange in the process industries, London. Rep.BNWL-SA-1945, 1968

Kharitonov OV, Firsova LA, Milyutin VV, Kozlitin EA (2019) Separation of curium and americium from spent fuel reprocessing solutions by displacement complexing chromatography on sulfocationites. J Radioanal Nucl Chem 321:511–518. https://doi.org/10.1007/s10967-019-06602-w

Kharitonov OV, Chuveleva EA, Gelis VM, Firsova LA (1998) Preparation of gram amounts of americium by displacement complexing chromatography. I. Separation of 241, 243Am, and 244 Cm from concentrate of rare-earth and transplutonium elements. Radiohimija 40:64–67

Hale WH, Love JT (1969) Rapid, gram-scale separation of curium from americium and lanthanides by cation exchange chromatography. Inorg Nucl Chem Lett 5:363–368

Firsova LF, Chuveleva EA, Nazarov PP (1986) Study of the ionizing radiation effect on the chromatographic process of REE separation with NTA solutions of different concentration. Zhurn Fiz Himii 60:1020–1022

Kharitonov OV, Chuveleva EA, Gelis VM, Firsova LA (1998) Preparation of gram amounts of americium by displacement complexing chromatography. II. Separation of isotopically pure 241Am from solutions after processing of long-stored plutonium. Radiohimija 40:130–132

Chuveleva JA, Haritonov OV, Firsova LA (1994) Modelirovanie povedenija kjurija i americija pri razdelenii metodom vytesnitel’noj kompleksoobrazovatel’noj hromatografii. Radiohimija 36:167–170

Wheelwright EG (1969) A comparison of eluting agents for the ion-exchange purification of promethium. J Inorg Nucl Chem 31:3287–3293

Kharitonov OV, Firsova LA, Milyutin VV, Kozlitin EA (2018) Modern sulfocationites for separation of lanthanides and transplutonium elements partitioning via displacement complexing chromatography. J Radioanal Nucl Chem 317:585–592. https://doi.org/10.1007/s10967-018-5906-1

Martell AE, Smith RM (1972) Critical stability constants. V.1: aminoacids. Plenum Press, New York

Martynenko LI, Artjuhina GA, Spicin VI (1969) O sushhestvovanii smeshannogo kompleksnogo soedinenija neodima s limonnoj i jetilendiamintetrauksusnoj kislotami. Doklady AN SSSR 185:600–604

Haritonov OV, Chuveleva JA, Firsova LA (1993) Razdelenie redkozemel’nyh jelementov hromatograficheskim metodom s ispol’zovaniem konkurirujushhego iona kadmija. Zhurn Fiz Himii 67:1866–1868

Chapron S, Marie C, Pacary V, Duchesne M-T, Arrachart G et al (2016) Separation of americium by liquid-liquid extraction using diglycolamides water-soluble complexing agents. Proc Chem 21:133–139

Marie C, Kaufholz P, Vanel V, Miguirditchian M (2019) Development of a selective americium separation process using H 4 TPAEN as water-soluble stripping agent. Solvent Extract Ion Exchange. https://doi.org/10.1080/07366299.2019.1643569

Narbutt J (2020) Solvent extraction for nuclear power. Liq Phase Extract. https://doi.org/10.1016/b978-0-12-816911-7.00024-4

Miguirditchian M, Vanel V, Marie C et al (2020) americium recovery from highly active PUREX raffinate by solvent extraction: the EXAm process. A review of 10 years of R&D. Solvent Extract Ion Exchange 38:1–23. https://doi.org/10.1080/07366299.2020.1753922

Malmbeck R, Magnusson D, Stéphane B, Wilden A (2019) Homogenous recycling of transuranium elements from irradiated fast reactor fuel by the EURO-GANEX solvent extraction process. Radiochim Acta 107:9–11

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kharitonov, O.V., Firsova, L.A. & Kozlitin, E.A. All-chromatographic method for the recovery of Americium-241 from solutions of complex composition. J Radioanal Nucl Chem 326, 627–636 (2020). https://doi.org/10.1007/s10967-020-07336-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07336-w