Abstract

177Lu-Tyr3-octreotide and 177Lu-PSMA(inhibitor) radiopeptides were obtained with radiochemical purities of 98.7–100%, from lyophilized formulations after reconstitution with sterile solutions of 177LuCl3 (40 GBq/mL) without the need for further purification or sterilization processes. More than 50 radiochemical syntheses were performed with a failure rate of 0% and radiochemical yields of 94–97%. From one lyophilized kit of DOTA-Tyr3-octreotide or DOTA-iPSMA, it was possible to obtain from 5 (7.4 GBq) to 10 (3.7 GBq) doses suitable for patients. Also, by using a sterile solution of 177LuCl3 approved as a radiopharmaceutical precursor for human use, it is possible to obtain GMP-compliant 177Lu-peptides from sterile freeze-dried formulations without the need of using commercially-available radiochemical synthesizers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, 177Lu is widely used as a therapeutic radionuclide for targeted radiotherapy because of its excellent nuclear properties (half-life of 6.647 d, β-max emission of 0.497 MeV and γ radiation of 0.208 MeV, useful for diagnostic imaging), coordination to different chelator-biomolecules and commercial availability [1, 2].

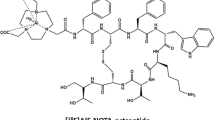

Of particular concern are the 177Lu-Tyr3-octreotide (177Lu-DOTA-Tyr3-octreotide; DOTA = 1,4,7,10-tetraazacyclododecane-N,N′,N″,N‴-tetraacetic acid) and 177Lu-iPSMA (iPSMA = prostate-specific membrane antigen inhibitor, e.g., DOTA-PSMA-617) radiopharmaceuticals, which have successfully been used in the treatment of patients with neuroendocrine tumors and advanced metastatic prostate cancer, respectively [3,4,5].

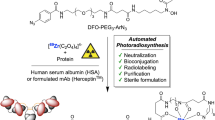

Nevertheless, the current challenge in the routine production of 177Lu radiopharmaceuticals is the development of quick and efficient processes that comply with the requirements established by regulatory authorities regarding Good Manufacturing Practices (GMP). One approach is the use of commercially-available radiochemical synthesizers connected or adjacent to ISO Class 5 areas, from which the automated procedure allows to perform and record critical steps during the batch production such as the filter membrane integrity test, as well as to carry out the dosing process under clean air conditions. However, the radiochemical yield using synthesizers ranges from 74 to 90%, and the number of therapeutic doses obtained by batch is usually limited to or less than three [6,7,8]. Furthermore, the acquisition of commercial disposable cassettes and specific reagent kits for each produced batch is mandatory, significantly increasing production costs.

It has also been previously reported that various lyophilized formulations for the one-step preparation of 177Lu-DOTA-Tyr3-octreotate (177Lu-DOTA-TATE) and 177Lu-DOTA-Tyr3-octreotide (177Lu-DOTA-TOC), with excellent results utilizing 177Lu prepared by neutron irradiation of 176Lu (carrier added) or 176Yb (non-carrier added) [9,10,11,12]. Nonetheless, said formulations are reported as kits for the preparation of mono-doses (up to 7.4 GBq, one dose for one patient), which are reconstituted with solutions of 177LuCl3 sterilized through a 0.22 µm membrane, for which its certification as a GMP product authorized for use in humans, is not clear.

The non-carrier added 177LuCl3, prepared as a sterilized solution with a content of bacterial endotoxin equal to or below 20 EU/mL and a radioactive concentration of 40 GBq/mL (EndolucinBeta, ITG, Germany), was approved in 2016 by the European Medicines Agency (EMA) as a radiopharmaceutical precursor for human use. Since the specific activity and the radioactive concentration of 177LuCl3 are routinely reproducible, it is possible to design freeze-dried sterile formulations to obtain 177Lu-peptides by simple reconstitution of a lyophilized powder with the sterile solution of LuCl3, followed by heating of the vial for a complete 177Lu-conjugate formation under sterile conditions.

The aim of this study was to develop freeze-dried, multi-dose formulations for the preparation of 177Lu-Tyr3-octreotide and 177Lu-iPSMA (up to 37 GBq/vial) in high radiochemical yields without the need for further purification or sterilization processes under GMP conditions.

Experimental

Design of the freeze-dried formulations

Lutetium (177Lu) chloride was obtained from ITG, Germany (EndolucinBeta 40 GBq/mL, in aqueous 0.04 M HCl solution, > 3 TBq/mg). DOTA-iPSMA (1,4,7,10-tetraazacyclododecane-N,N′,N″,N‴-tetraacetic acid -hydrazinonicotinyl-lysine-urea-glutamate derivative) and DOTA-Tyr3-octreotide (GMP grade) were supplied by Ontores Biotechnologies (China) and ABX (Germany), with certified chemical purities of > 98%. Sodium acetate, ascorbic acid, and mannitol were purchased as pharmaceutical-grade reagents from Sigma-Aldrich (USA).

Freeze-dried kits were preformulated by using different amounts of DOTA-Tyr3-octreotide and DOTA-iPSMA peptides (ng/MBq), to evaluate the effect of the variations on the 177Lu-peptide radiochemical purity. The amount of each component in the formulation was designed for the labeling of one lyophilized vial with 40 GBq of 177LuCl3, applying a factorial experimental design (Table 1). The analysis of variance (ANOVA) was performed with the GraphPad Prism software.

Manufacturing process of freeze-dried kits (3 validation runs)

Preparation of the lyophilized formulations was done in aseptic conditions under GMPs. DOTA-iPSMA (12 mg) or DOTA-Tyr3-octreotide (16 mg) were dissolved in 20 mL of injectable-grade water (stirring and incubation at 70 °C). Posteriorly, 1 g of mannitol and 2 g of ascorbic acid were also dissolved, with stirring, in 20 mL of injectable-grade water. The peptide and mannitol/ascorbic acid solutions were then mixed (pH = 2.5–3.5). Finally, the formulation was sterilized by filtration (Millipore, 0.22 µm) and 2 mL were dosed in 20 previously-depyrogenized ampoule vials to then be lyophilized for 19 h (freezing at −40 °C/1 h, primary drying for 6 h and secondary drying at 0 °C/4 h, 25 °C/4 h and 29 °C/4 h). After freeze-drying the formulation, the kit was stored at 2–8 °C.

Additionally, 30 mL of 1 M sodium acetate buffer solution pH 5.0 was prepared, which was filtered through a 0.22 µm membrane, and 1.5 mL were dosed in 20 sterile ampoule vials.

For each one of the precursors, a manufacturing process validation was done, which consisted in the fabrication of three consecutive batches with a batch size of 20 vials each. The same manufacturing conditions were maintained to guarantee reproducibility. Process controls were established, such as solution pH, determination of dose volume through weight (n = 3), filter integrity (bubble point test, Millipore, BP > 56 psi), as well as the environmental monitoring of viable and non-viable particles for ISO-5 and ISO-6 areas, in accordance with the guidelines established by the official Mexican regulation (NOM-241-SSA1-2012).

Quality control and stability tests of freeze-dried kits

For the quality control of the lyophilized formulations, parameters such as color, appearance, pH, sterility, bacterial endotoxins and radiochemical purity (reversed phase HPLC, with a 3.9 mm × 30 cm µBondapak™ C18 column, using a gradient system), were evaluated in accordance with the Mexican Pharmacopeia [13], in its section referring to “General Methods of Analysis” (MGA). The retention time of the radiolabeled peptide (177Lu-DOTA-Tyr3-octreotide or 177Lu-DOTA-iPSMA) was 15.0 ± 2.0 min, while the retention time of 177LuCl3 was 3.0 ± 1.0 min. All batches were subjected to stability tests for 12 months after their manufacturing dates.

Production process: Radiochemical synthesis

177Lu-DOTA-iPSMA and 177Lu-DOTA-TOC were prepared in a shielded cell (Comecer, Italy) which has a main compartment, waste compartment, and material entry/exit compartments. All compartments contain shielding made up of lead ingots (98% purity, with 2% Sb). The main chamber was equipped with a dose calibrator operated through specialized software and controlled through a touchscreen. It is also equipped with a UV lamp and a laminar flow system with HEPA terminal filters (99.997% efficiency), which was programmed with a vertical laminar flow of 0.3 m/s, granting an ISO Class 5 degree of cleanliness. For the incubation step, a Cole Palmer dry bath was placed within the shielded cell.

For the radiochemical synthesis, the 177LuCl3 original vial (40 GBq/mL) was vented with a needle, and then 1.0–1.5 mL of the 1 M acetate buffer pH 5.0 was added. The total volume was withdrawn using a sterile syringe and was afterward employed for the reconstitution of the DOTA-iPSMA or DOTA-Tyr3-octreotide lyophilized kit. The reconstituted vial was heated in the dry bath at 95 °C for 30 min. After cooling to room temperature, the vial was vented with a needle, and the volume was taken up to 10 mL with injectable-grade water (Pisa, Mexico) through using a sterile syringe. The dosing step was carried out directly in delivery syringes using leaded glass shielding or using a dosing module (Timo-2, Comecer, Italy).

Quality control and stability testing for finished radiopharmaceuticals

For the quality control of the radiopharmaceuticals, a sample was taken for pH, sterility, bacterial endotoxins and radiochemical purity (reversed-phase HPLC/gradient system) tests in accordance with the Mexican Pharmacopeia [13], in its section referring to MGAs [13]. Stability of the radiolabeled products was evaluated at 72 h post-production by reversed-phase HPLC.

In vivo studies

LNCaP (PSMA-positive) human prostate cancer cells and AR42 J (somatostatin receptor-positive) rat pancreatic cancer cells were acquired from the ATCC (USA). Biodistribution and tumor uptake studies in mice were carried out in agreement with the Mexican regulation (NOM-062-ZOO-1999).

LNCaP or AR42 J tumors were induced using a subcutaneous injection of cancer cells suspended in 0.1 mL phosphate-buffered saline (1 × 106 cells), into the upper back region of 8-week-old nude mice. 177Lu-octreotide or 177Lu-iPSMA obtained from lyophilized kits (3.7 MBq in 0.05 mL) was injected into the tail vein of the mice. The mice (n = 5) were sacrificed at 1, 4, 48 and 96 h post-injection. Tumor, lung, liver, spleen, kidney, intestine and blood were dissected. The activity was determined in a NaI(Tl) detector, along with 0.5 mL aliquots of the diluted standard representing 100% of the injected activity. The activities were used to determine the percentage of injected dose per gram of tissue (% ID/g).

Results and discussion

Freeze-dried formulation design

As shown in Fig. 1, the mass per MBq necessary to obtain radiochemical purities (RP) of > 98% was different between peptides, but the number of DOTA moles required to achieve RP over 98% was the same in both peptides (~ 0.015 nmol/MBq). Therefore, differences between the spatial conformation of peptides with different steric hindrance are not factors which affect the radiochemical reaction yield, contrary to what occurs with other peptides [14]. These results correlate to those reported by Iori et al. [6], where amounts from 11 to 40 ng/MBq were found suitable to obtain RP over 98% for 177Lu-peptides. Based on the pre-formulation study (Fig. 1), the selected amount of peptide per vial to obtain 37–40 GBq of 177Lu-Tyr3-octreotide and 177Lu-iPSMA was 0.8 mg (571 nmol) and 0.6 mg (597 nmol), respectively.

The ANOVA results indicated that all components have a significant effect (p < 0.01) on the RP and present significant interaction amongst themselves (p < 0.01) (Fig. 2). When 1.0–1.5 mL of the acetate buffer was added to the 177LuCl3 vial (1 mL) for reconstitution of the lyophilized powder (total volume of 2.0 or 2.5 mL), the RP was over 98% at all levels of ascorbic acid mass, but after 72 h an amount of 50 mg of ascorbic acid was not enough to maintain the RP over 95%, which presented the same behavior when a reconstitution volume of 3 mL was used. Therefore, the selected kit composition was: (1) one lyophilized vial containing 0.8 mg (DOTA-Tyr3-octreotide) or 0.6 mg (DOTA-iPSMA) of the peptide, 100 mg of ascorbic acid and 50 mg of mannitol as a diluent, and (2) a second vial containing 1.5 mL of 1.0 M acetate buffer pH 5.0.

Manufacturing process

The results of all three lyophilized batches for DOTA-iPSMA and DOTA-Tyr3-octreotide production confirmed that control processes and environmental conditions complied with the specifications established by the regulatory authorities (GMP-grade formulations) (Table 2). Thus, the quality control tests performed to all three validation batches were also compliant with the specifications established in the Mexican Pharmacopeia as preparations suitable for human use. In general, limpid, colorless and sterile solutions were obtained after reconstitution, with bacterial endotoxins of < 20 EU/V, pH 5.0 and average radiochemical purities over 97% (Fig. 3) [13].

As can be seen in Fig. 4, DOTA-iPSMA and DOTA-Tyr3-octreotide lyophilized formulations were stable, since the three validation batches consistently produced 177Lu-radiopharmaceuticals with radiochemical purities in agreement with the established specification (> 97%) [13] over a period of 12 months after preparation.

Radiochemical synthesis

A total of 51 radiochemical syntheses (51 batches) were performed by using one lyophilized vial for each batch. Thirty-seven corresponded to 177Lu-Tyr3-octreotide and fourteen to 177Lu-iPSMA. The radiochemical yield in all cases ranged from 94.0 to 97.0% (to obtain 37.5–38.8 GBq of the 177Lu-peptide), with the main loss of activity in the 177LuCl3 original vial. This yield is higher than those previously reported (from 70 to 90%), in which radiochemical synthesizers were used [6,7,8]. The radiochemical purity for all batches was 98.7–100% and remained stable after 72 h (Fig. 5). This radiochemical purity was slightly higher than the mean value reported by Iori et al. [6]. Although the general formulation was designed for the preparation of 37.5–38.8 GBq 177Lu-peptides, some batches with 20–37 GBq were also successfully prepared with radiochemical purities of 100% by using 0.5–1.0 mL of 177LuCl3 (40 GBq/mL) plus 1–1.5 mL of 1 M acetate buffer pH 5.0 for reconstitution of the lyophilized powder. From each batch, it was possible to obtain from 5 (7.4 GBq, 5.55 GBq or 3.7 GBq) to 10 (3.7 GBq) doses, suitable for patients. Quality control tests also confirmed that no post-production sterilization is required since the 177Lu–iPSMA and 177Lu-Tyr3-octreotide radiopharmaceutical solutions maintained their sterility and level of bacterial endotoxin after the radiosynthesis procedure (Fig. 5).

Maus et al. [7] evaluated the effect of final volumes (5, 20 and 100 mL) on the quenching effect of ascorbic acid. They found that at 5 mL final volume, re-addition of ascorbic acid with a concentration of 100 mM after purification resulted in radiochemical purity ≥ 95% at 72 h post-labeling, whereas no re-addition of ascorbic acid resulted in a radiochemical purity of 92% at 72 h post-labeling. In the case of this study, no such re-addition was necessary, since purification after radiolabeling was not necessary and the removal of ascorbic acid does not occur. It is also worth noting that in the formulations reported in this study, a concentration of 57 mM ascorbic acid was used, and was still capable of producing a sufficient stabilizing effect.

It is important to note that the multi-dose kits for the preparation of 177Lu-iPSMA and 177Lu-octreotide, here developed, are limited to the exclusive use of non-carrier added 177Lu (40 GBq/mL, GMP-grade), with the finality of preparing 5 (5 doses of 7.4 GBq) or 10 (10 doses of 3.7 GBq) doses of radiopeptide with clinical usefulness from only one vial.

In Table 3, results of the biodistribution and biokinetic studies are shown. Establishing whether 177Lu-Tyr3-octreotide prepared from the multi-dose kit has a different biodistribution pattern concerning that previously reported for other somatostatin analog radiopeptides such as 177Lu-DOTA-TATE is difficult, since studies were not carried out under the same experimental conditions. However, one piece of data that may be valuable for comparison under different experimental conditions is the tumor-to-organ ratio, rather than the absolute value of % ID/g in the tumor. In this study, the average tumor-to-blood ratio was 20.6 at 4 h for 177Lu-Tyr3-octreotide, which is in agreement with previously reported preclinical results for 177Lu-DOTA-TATE [15].

Conclusions

The production of radiochemical precursors (177LuCl3) and lyophilized ligand formulations as sterilized and GMP-grade products, allows fast and routine preparation of 177Lu therapeutic radiopharmaceuticals with a quality suitable for clinical use. This procedure lacks the need for the use of an automated synthesizer and thus reduces production costs.

References

Banerjee S, Pillai M, Knapp F (2015) 177Lu therapeutic radiopharmaceuticals: linking chemistry, radiochemistry, and practical applications. Chem Rev 115(8):2934–2974

Ferro-Flores G, Ocampo-García BE, Santos-Cuevas CL, de Maria Ramirez F, Azorin-Vega EP, Meléndez-Alafort L (2015) Theranostic radiopharmaceuticals based on gold nanoparticles labeled with 177Lu and conjugated to peptides. Curr Radiopharm 8(2):150–159

Kim S-J, Pak K, Koo PJ, Kwak JJ, Chang S (2015) The efficacy of 177Lu-labelled peptide receptor radionuclide therapy in patients with neuroendocrine tumours: a meta-analysis. Eur J Nucl Med Mol Imaging 42(13):1964–1970

Baum RP, Kluge AW, Kulkarni H, Schorr-Neufing U, Niepsch K, Bitterlich N, van Echteld CJ (2016) [177Lu-DOTA] 0-D-Phe1-Tyr3-octreotide (177Lu-DOTATOC) for peptide receptor radiotherapy in patients with advanced neuroendocrine tumours: a phase-II study. Theranostics 6(4):501

Rahbar K, Ahmadzadehfar H, Kratochwil C, Haberkorn U, Schäfers M, Essler M, Baum RP, Kulkarni HR, Schmidt M, Drzezga A (2017) German multicenter study investigating 177Lu-PSMA-617 radioligand therapy in advanced prostate cancer patients. J Nucl Med 58(1):85–90

Iori M, Capponi PC, Rubagotti S, Esposizione LR, Seemann J, Pitzschler R, Dreger T, Formisano D, Grassi E, Fioroni F (2017) Labelling of Y-and Lu-DOTA-bioconjugates for targeted radionuclide therapy: a comparison among manual, semiautomated, and fully automated synthesis. Contrast Media Mol Imaging. https://doi.org/10.1155/2017/8160134

Maus S, de Blois E, Ament SJ, Schreckenberger M, Breeman WA (2014) Aspects on radiolabeling of 177Lu-DOTA-TATE: after C18 purification re-addition of ascorbic acid is required to maintain radiochemical purity. Int J Diag Imaging 1(1):5

Kroselj M, Socan A, Zaletel K, Dreger T, Knopp R, Gmeiner T, Kolenc Peitl P (2016) A novel, self-shielded modular radiosynthesis system for fully automated preparation of PET and therapeutic radiopharmaceuticals. Nucl Med Commun 37(2):207–214

Das T, Banerjee S, Shinto A, Kamaleshwaran K, Sarma H (2014) Preparation of Therapeutic Dose of 177Lu-DOTA-TATE using a novel single vial freeze-dried kit: a comparison with in situ. Preparation at hospital radiopharmacy. Curr Radiopharm 7(1):12–19

Kunikowska J, Krolicki L, Hubalewska-Dydejcyk A, Mikolajczak R, Sowa-Staszczak A, Pawlak D (2011) Clinical results of radionuclide therapy of neuroendocrine tumours with 90Y-DOTATATE and tamdem 90Y/177Lu-DOTATATE: which is a better therapy option? Eur J Nucl Med Mol Imaging 38(10):1788–1797

Das T, Bhadwal M, Banerjee S, Sarma HD, Shinto A, Kamaleshwaran KK (2014) Preparation of DOTA-TATE and DOTA-NOC freeze-dried kits for formulation of patient doses of 177Lu-labeled agents and their comparison for peptide receptor radionuclide therapy application. J Radioanal Nucl Chem 299(3):1389–1398

Kwekkeboom D, Bakker W, Kooij P, Konijnenberg M, Srinivasan A, Erion J, Schmidt M, Bugaj J, Jong M, Krenning E (2001) [177Lu-DOTA0, Tyr3]octreotate: comparison with [111In-DTPA0] octreotide in patients. Eur J Nucl Med 28(9):1319–1325

Farmacopea de los Estados Unidos Mexicanos (2014). 11 edn. Secretaria de salud, Mexico City

Ferro-Flores G, de Ramirez FM, Melendez-Alafort L, de Murphy CA, Pedraza-Lopez M (2004) Molecular recognition and stability of 99mTc-UBI 29-41 based on experimental and semiempirical results. Appl Radiat Isot 61(6):1261–1268

Rodríguez-Cortés J, Arteaga de Murphy C, Ferro-Flores G, Pedraza-López M, Murphy-Stack E (2007) Biokinetics and dosimetry with 177Lu-DOTA-TATE in athymic mice. Radiat Eff Defects Solids 162(10–11):791–796

Acknowledgements

This research was carried out as part of the activities of the “Laboratorio Nacional de Investigación y Desarrollo de Radiofármacos, (Mexican National Council of Science and Technology, CONACyT)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luna-Gutiérrez, M., Hernández-Jiménez, T., Serrano-Espinoza, L. et al. Freeze-dried multi-dose kits for the fast preparation of 177Lu-Tyr3-octreotide and 177Lu-PSMA(inhibitor) under GMP conditions. J Radioanal Nucl Chem 314, 2181–2188 (2017). https://doi.org/10.1007/s10967-017-5595-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-017-5595-1