Abstract

The aim of this study was to develop the methodology for collection and analysis of radon from a natural gas pipeline. Activated charcoal was used as collection media. Two methods were designed for collecting radon gas samples from onshore and offshore production sites. For onshore sites a continuous gas sampling method from the pipeline was developed. In case of offshore sites, a batch sampling method was designed. Gamma spectroscopy was utilized to determine the concentration of radon by analysis of radon daughters on the charcoal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The radionuclides identified in oil and gas streams belong to the decay chains of the naturally occurring primordial radionuclides 238U and 232Th. These parent radionuclides have very long half-lives and are ubiquitous in the earth’s crust with activity concentrations that vary depending on rock type. Radioactive decay of 238U and 232Th produces several series of daughter radioisotopes of different elements that have different physical characteristics such as the half-lives, modes of decay, and types and energies of the emitted radiation [1–3].

Radon (Rn) is a radioactive noble gas that occurs in the uranium and thorium decay series (222Rn for uranium series and 220Rn for thorium series). It is chemically inert and is preferentially partitioned into a gas phase relative to water [4]. 222Rn, which is one of the important radionuclides in the 238U decay chain, forms directly from the alpha decay of 226Ra. This radioactive gas has a half-life of 3.8 days, making it the most likely radon source for exposure of the general public. Since radon is an inert radioactive gas, it does not react chemically with other elements. The burning process will not cause the radon to oxidized or change its form or radioactivity. Moreover if the gas is inhaled, it will mostly be exhaled out of the body without causing direct health effect. Nevertheless, the hazard of radon comes from its radioactive decay products such as polonium, bismuth, and lead. These products are solid and fine radioactive particles that once inhaled may reside within the lung. In the petroleum industry, it has been known for over 40 years that radon (222Rn), a radioactive gas, is present in natural gas [5–7]. There were some studies that have potential effect to the human. The issue of radon has gained increasing interest after Resnikoff reported possible human exposure to radon in the natural gas used in household settings [8]. In this study, radon at the wellhead could be transported through a natural gas pipeline to the gas distribution centers and then to households if distance between the source and the user point is not too far.

Since radon is a decay product of 226Ra, typically, to calculate radon levels it is necessary to know the concentrations of 226Ra [8, 9]. As the commercially available automated radon-in-air analyzer cannot be directly employed for measurement of radon inside the natural gas pipeline because its detector and other components are sensitive to hydrocarbon which is the main composition of natural gas. This research therefore aims to develop method and system for indirect measurement of radon in a natural gas pipeline by utilizing the activated charcoal as collection media.

Activated charcoal

Radon can be trapped into a certain material via a physical process that involves long-range but weak interaction between the radon molecule and the surface [10]. While not a chemical absorption process, radon trapping can occur at “adsorption sites”, only when the radon molecule dissipates sufficient amount of energy on the surface. This process releases around 17 kJ mol−1 of radon. Factors that affect radon trapping from a flowing stream of radon gas onto charcoal include (a) the properties of the charcoal used such as granularity, material type, and porosity; (b) the concentration of water or other competing molecules in the gas; (c) the rate of movement of the gas through the charcoal; and (d) the half-life of the radon isotope being evaluated.

For a given specific adsorption bed and gas composition, the dominant variable that was expected to control 222Rn collection effectiveness was the linear flow velocity according to the model by Blue [11]. To characterize the collection efficiency, we ran some controlled experiments to investigate the effect of gas flow rates that are expected to be used during actual operation.

Materials and methods

Radon analysis

All sample tests were analyzed for radon concentration using a high purity germanium (HPGe) gamma spectrometry system following the standard guidelines published in ORNL/TM-6782 (ORNL 1995). The amount of adsorbed radon in the activated charcoal was measured by counting the gamma emitted from 214Bi (609 keV) in a high resolution (1.85 keV at 1.33 MeV), high relative efficiency (80 %), and low background HPGe spectrometer (ORTEC’s system). The values obtained from measurement are corrected to the time of sample collection.

Trapping efficiencies

Experiments were setup with the goal of creating a data set that directly represented the collection efficiencies of activated charcoal at various flow rates and radon concentrations of interest. Since the trapping ability of charcoal for radon should be relatively insensitive to radon concentration [12], a series of measurements were performed on a fixed concentration of radon (about 500 Bq m−3) from a radon standard source: Pylon electronics (RN-1025), source activity 98.138 kBq (6 September 2006). The apparatus (Fig. 1) is a closed system of fixed volume composed of a sample cell.

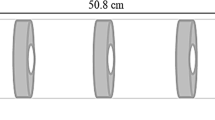

Radon collection tests under various flow-rate conditions were carried out in using a 100 L radon gas standard chamber made of stainless steel. The charcoal used for these tests was Calgon Carbon PCB-6×16. The activated charcoal was coconut shell-based with a 6 × 16 mesh sizing and the bulk density was measured to be 0.44 g cm−3. The pore space volume was estimated to be 0.72 cm3 g−1. Two cylindrical charcoal PVC canisters, each has a dimension of 8 OD × 5 cm are arranged in series and connected to radon the gas supply. The diameter of the canister is the same as diameter of the HPGe detector. Each canister contains 80 g of charcoal. The air pump model. Σ500 siebeta was used to control the gas flow rate to the canister cell. The arrangement of the charcoal canister is shown in Fig. 1. During bench-scale tests, the gas flow rate was varied between 0.5 and 4.0 L min−1 by flowing gas through the series of charcoal canister for 15–30 min. Then, each charcoal canister was sealed tight by capping the canister inlet and outlet nozzles by rubber cap and tape, respectively and kept it in the air tight plastic Ziploc bag for at least 3.5 h to allow radioactive equilibrium between 222Rn and 214Bi before all measurements were performed. The theoretical equilibrium curve between 222Rn and 241Bi is shown in Fig. 2.

The activity of radon was calculated by the following equation,

where A is sample activity concentration in Bq m−3, N L is net counts measured under the photo peak, ε is system detection efficiency, P γ is absolute transition probability by gamma decay for the selected energy, V is sample volume in m−3, t is counting time in seconds.

For the radon collection efficiency of charcoal canister A, the following equation was used,

This equation is valid under assumption that the efficiency of charcoal in both canisters is the same and is sufficiently large so that most radon is absorbed after passing through second canister. Table 1 shows the radon adsorption efficiency on activated charcoal under five different flow rates.

To test whether the radon adsorption efficiency in the natural gas samples is the same as in air, we carried out the experiment in a 20 L plastic chamber. The chamber was filled with radon mixed with methane to mimic the composition of natural gas. We choose methane as a mixture because it is the highest composition (65–70 %) in the Thai natural gas [13]. During this test, a gas flow rate of 2 L min−1 was used to flow the gas through the two charcoal canisters for 30 min. The result of the experiments is shown in the last column of Table 1.

Field experiment

The field experiment was carried out at two petroleum companies to determine the amount of radon contained within the production lines mixed with natural gas that may enter the downstream processors and distributers. The volume of gas sample required for analysis should be more than 18–20 L with a sampling flow rate of 2–4 L min−1. The same gamma spectroscopy technique, used for the laboratory experiments was utilized to determine the concentration of radon on the charcoal. Due to the difference of gas processing scheme between the on shore and the off shore petroleum fields, two different methods were designed for proper collection of radon gas samples.

For the onshore case, a direct continuous gas sampling method from the pipeline was used. The test was done at the natural gas processing plant. The arrangement of gas sampling is shown in Fig. 3. Two sampling points were chosen before and after the methane (C1) and ethane (C2) separations. Since the boiling point of radon is −61.7 °C, which is between the boiling points of ethane at C2 (−88.5 °C) and propane at C3 (−42.1 °C), then we expected to find more radon in the downstream of the C3 reservoir.

The offshore case the samples were done at three different natural gas production platforms, which imposed additional constraints in terms of space and time for conducting the experiment. Thus, a batch sampling method was designed and employed. The gas sample was collected in an industry-approved sample container (bomb) capable of direct sampling from high-pressure (60–140 bar) distribution lines, and then transferred to the offshore laboratory facility to be discharged into the charcoal canister apparatus. A gas regulator was used to control the flow rate of the gas in order to estimate the volume of the gas that passed through the charcoal canister. The charcoal apparatus was transferred to Chulalongkorn University laboratory for radon analysis on the same day of the sampling.

Table 2 shows the 222Rn content in natural gas samples obtained in this study.

Results and discussions

In this study, a methodology for collecting and analyzing radon gas from a natural gas pipeline was developed. A set of charcoal collection devises was setup for this study. The trapping efficiency of charcoal was first determined. The result was that for the flow rate between 0.5 and 4 L min−1 the adsorption efficiency of the charcoal was in the range of about 98–83 %. To avoid disturbing the plant’s operation during gas sampling, we reduced the sampling time as much as possible. The flow rate of 2 L min−1 was selected for the field experiment. It was experimentally found that the radon collection efficiency of the charcoal was around 88 % inside the methane-air mixture. This was lower than the efficiency in pure air. Accordingly, the measured radon activities were divided by 0.88 to obtain the actual values.

The analysis of radon concentration in the natural gas processing samples for onshore site revealed that the average 222Rn quantity sampled before the methane (C1) and ethane (C2) separation points was lower than the radon quantity collected after the C1 and C2 separation points. This finding agreed with our expectation that during the separation process of C1 and C2, radon was not separated out since the boiling point of 222Rn (−61.8 °C) was higher than that of ethane (−88.5 °C) at the C2 separation point. Therefore, the quantity of 222Rn was found accumulated in the downstream reservoir of C3 (propane, −42.1 °C) and C4 (butane, −11.73 °C). C3 and C4 are the main composition of liquefied petroleum gas (LPG) which is widely used for heating and cooking [14]. The results of the field measurements show that our developed methodologies are sufficient and efficient for determination of radon concentration in the natural gas pipeline. However, the comparison of our results of radon found in Thai natural gas with the other reports [15, 16] revealed that the radon content in Thai natural gas production was in the same range of other countries.

References

Lysebo I, Birovljev A, Strand T (1996) NORM in oil production: occupational doses and environmental aspects. In: Proceedings of the 11th Congress of the Nordic Radiation Protection Society. Reykjavik

Deborah LB, David SG, Karen PS (1999) Issues Related to setting exemption levels for oil and gas NORM. In: The six annual international petroleum environmental conference. Houston

Hamlat MS, Djeffal S, Kadi H (2001) Assessment of radiation exposures from naturally occurring radioactive materials in the oil and gas industry. Appl Radiat Isot 55:141–146

Kraemer TF (1986) Radon in unconventional natural gas from Gulf coast geopressured-geothermal reservoirs. Environ Sci Technol 20:939–942

Agency for Toxic Substances and Disease Registry (1988) Toxicological profile for ionizing radiation and U.S. National Research Council. In: Health, risks of radon and other internally deposited alpha-emitters, BEIR IV. National Academy Press

Johnson RH, Bernhardt DE, Nelson NS, Calley HW (1973) Assessment of potential radiological health effects from radon in natural gas, environmental protection agency (EPA-520-73-004)

Gogolak CV (1980) Review of 222Rn in natural gas produced from unconventional sources, environmental measurements laboratory, United States Department of Energy (DOE/EML-385)

Resnikoff M (2015) Radon in natural gas from Marcellus Shale: NEOGAP, network for oil & gas accountability and protection. http://www.neogap.org/neogap/wp-content/uploads/2012/01/Marcellus_Radon.pdf. Accessed 8 Apr 2015

Leventhal JS, Crock JG, Malcolm MJ (1981) Geochemistry of trace elements in Devonian Shales of the Appalachian basin, U.S. Geological Survey Open File Report 81-778

Atkins PW (1986) Physical chemise, 3rd edn. WH Freeman and Company, New York

Blue TE, Jarzemba MS, Fentiman AW (1995) Steady state response of a charcoal bed to radon in flowing air with water vapor. Health Phys 68:809–816

Coleman RL (1999) Use of activated charcoal for 220Rn adsorption for operations associated with the uranium deposit in the auxiliary charcoal bed at the molten salt. Reactor experiment facility. ORNL/TM-13733

Laoonual Y, Jugjai S, Chanchaona S, Chollacoop N (2007) An analysis of composition variation of natural gas for vehicles (NGV) in Thailand. In: Proceeding of 3rd conference on energy network of Thailand, Bangkok, pp 4–6, 23–25 May 2007

HS Wah (2013) Gas for households: LPG for cooking as first step. Petroliam Nasional Berhad (Petronas)

Hamlat MS, Kadi H, Djeffal S, Brahimi H (2003) Radon concentrations in algerian oil and gas industry. Appl Radiat Isot 58:125–130

Holland (1998) Experience with operations involving NORM in the United Kingdom (UK) and some other regions. Report of the RCA expert advisory group meeting to review and develop radiation protection guidance for naturally occurring radioactive materials in the oil and gas and other mineral extraction and processing industries. Australian Nuclear Science and Technology Organisation, Lucas Heights, Sidney, 16–20 Mar 1998

Jonkers G, Hartog FA, Knaepen (1998) NORM baseline studies and surveys for the E and P industry. In: Proceedings of NORM II, Krefeld, pp 22–26, 10–13 Nov 1998

UNSCEAR (United Nations Scientific Committee on Effects of radiation) (1977) Radon concentrations in natural gas at the well heads, UN Scientific Committee on the effects of atomic radiation; sources and effects of ionizing radiation. United Nations, New York

Acknowledgments

The researchers would like to give special thanks to petroleum companies, the Chulalongkorn University and the Thai government for providing necessary funding and other resources. The authors express their gratitude for the support. We also thank Dr. William C. Burnett from Florida State University and anonymous reviewers for making valuable suggestions of an earlier draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chanyotha, S., Kranrod, C., Pengvanich, P. et al. Determination of radon in natural gas pipelines. J Radioanal Nucl Chem 307, 2095–2099 (2016). https://doi.org/10.1007/s10967-015-4405-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-015-4405-x