Abstract

Possibility of uranium extraction on titanium oxide (TiO)–polyacrylonitrile (PAN) and sodium titanate (NaTiO)–PAN composite absorbers prepared from hydrated TiO and NaTiO embedded into a matrix of PAN binder was studied. Both TiO–PAN and NaTiO–PAN absorbers might be advantageous for repeated extraction of uranium from fresh water. Appropriate flow rates were found up to 60 BV h−1 for both the absorbers. Elution of uranium and regeneration of both the absorbers may be accomplished by hydrochloric acid solutions of concentration 0.1 mol L−1 and more. Practical sorption capacity (up to 10 % break-through) from tap water containing 2.3 μg U mL−1 was ~4.6 and ~1.5 mg of uranium per 1 mL of swollen TiO–PAN and NaTiO–PAN absorber, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Separation and concentration of uranium from different types of water has been an important problem that may grow even more important in the future. Apart from the separation of uranium from uranium-contaminated waste water [1, 2] (e.g. waste water from mining and milling of uranium, or waste from nuclear fuel reprocessing), it is the extraction of uranium from sea water—which could partially cover future global needs of uranium—that has been drawing attention to this field. Possibilities of uranium extraction from sea water have been subject of several international conferences (e.g. Topical Meetings on the Recovery of Uranium from Seawater in 1980s, ACS National Meetings 2012 etc.) and are critically evaluated in a review by Bitte [3] or recently by Kim et al. [4]. In the Czech Republic uranium-selective inorganic ion exchangers might be applied for treatment of various waste waters from uranium industry, namely underground water, uranium milling over-balance water, or acid waste water from underground uranium leaching. Another field where uranium separation from water is required is the still increasing number of uranium isotopic composition determinations in forensics, environmental and similar analyses [5, 6].

Efficient selective separation materials are needed for all these purposes. Extensive effort has been dedicated to the use of organic materials with selective functional groups (e.g. amidoxime or iminodiacetate) [7, 8]. However, it is especially the inorganic ion exchangers that have been extensively tested and that are showing the greatest promise. Among the best inorganic ion exchangers for these purposes, hydrated titanium oxide (abbreviated as TiO) and sodium titanate (abbreviated as NaTiO) can be listed. Their properties were reviewed in detail by Lehto [9].

Titanium oxide

Three crystalline modifications of TiO occur in nature (anatase, rutile, brookite). The best ion-exchange properties exhibits the amorphous TiO of general formula TiO2−x (OH)2x ·yH2O resulting from the hydrolysis of titanium(IV) salts in alkaline solutions. In industrial scale TiO is produced as titanium white, while for laboratory purposes TiO can be easily prepared by the hydrolysis of titanium organic compounds [10, 11]. Properties of TiO strongly depend on the way of its preparation, namely the temperature is the most important factor. Amorphous TiO is produced in synthesis at ambient temperature. Either the preparation at higher temperatures or ageing of amorphous TiO give anatase modification [12]. Amorphous TiO is soluble in both acids and alkalis, its solubility decreases with developing crystalline structure and decreasing contents of water. Hydrated TiO is a typical ampholyte, its isoelectric point being pH 4–6. The exchange capacity is proportional to the number of OH− groups; its maximum value reaches approximately 4.5 meq g−1. Bitte [3] concluded that TiO was advantageous for uranium extraction from sea water. Among the disadvantages, interference of calcium and magnesium ions on the sorption of uranium is given. Alexandre and Vistoli [1] developed a new procedure for preparation of TiO. Their TiO exhibited sorption capacity for uranium from sea water 350 μg U g−1. For elution of uranium from the bed of spent ion exchanger 1 M (NH4)2CO3 solution was tested. Pilot plan experiments with uranium extraction from sea water, and uranium separation from underground and fresh surface water were performed [1].

Sodium titanate

Most of the NaTiO absorbers described belong to one of the two groups characterized by formulae [9] Na2Ti n O2n+1 (n = 1–9) and Na4Ti n O2n+2 (n = 1, 3, 5, or 9). Only titanates with layered structure exhibit ion exchange properties. Different procedures of production of NaTiO at low temperatures have been developed [13–15]. It has been shown [15] that under certain conditions all the procedures result in Na4Ti9O20·xH2O exhibiting the same properties. Maximum exchange capacity of this ion exchanger has been shown to be 5.32 meq g−1, which is pretty close to the theoretical value [16]. Sodium titanate Na4Ti9O20·xH2O was used for uranium extraction from sea water by Heinonen [17]. Dynamically measured sorption capacity for sorption of uranium from sea water containing 10−3 mol L−1 of uranium was found to be 350 mg of uranium per 1 g of the ion exchanger. 1 M HNO3 was used for elution of uranium, the kinetics of elution was found to be very rapid.

The main disadvantage of both the above described ion exchangers for industrial-scale application is their insufficient mechanical stability [3, 4]. Methods of improvement of mechanical and granulometric properties of inorganic ion exchangers have been already summarized [18, 19]. Different methods have been developed for preparation of granular TiO and/or NaTiO. Alexandre and Vistoli [1] prepared granular TiO by hydrolysis of TiCl4 in diluted NH4OH. Resulting gel has been dried and then immersed into water which resulted in production of granules of TiO. Freeze–thaw and sol–gel methods may be listed among other possible methods of TiO granules preparation [20–22]. Preparation of composite absorbers composed of hydrated oxides of titanium, zirconium or tin and thermosetting resin (binding matrix) as an epoxy, unsaturated polyester or polyurethane resin was described by Takeuchi et al. [23]. Phenolic resin was used for preparation of spherical particles of composite absorbers with metal hydroxides as active components [24]. Macroreticular anion exchange resin AG–MP–1 (Bio–Rad) and Dowex MSA–1, type MP were used by Dosch [25] for the preparation of NaTiO, sodium niobate and sodium tantalate-loaded resins. NaTiO loaded resins contained 30–40 % (w/w) of the active component in dry resin. Inorganic binding materials as alumina (Al2O3) or calcium aluminate were also used for the preparation of pellets with up to 70 % (w/w) of NaTiO [25].

The general procedure for preparation of composite absorbers using modified polyacrylonitrile (PAN) as a binding matrix enables preparation of suitably grained composite absorbers containing both TiO and NaTiO as active components [18, 26]. The contents of active component may reach up to 90 % (w/w) in dry residue.

The aim of this study was to verify possibility of extraction of uranium with TiO–PAN and NaTiO–PAN composite absorbers, to compare properties of these two absorbers and to conclude whether they are prospective for uranium concentration from surface and/or waste waters.

Experimental

Chemicals and instrumentation

Both the absorbers were prepared from industrial intermediate coming from production of titanium white (PRECHEZA, Czech Republic). Ethanol used was a technical product denatured by addition of 1 % of benzine. All other chemicals were p.a. commercial preparations.

Philips PU 8730 V/Vis spectrophotometer was used for spectrometric analyses, NETZSCH STA 409 thermobalance was used for TG and DTA analyses of produced ion exchangers. Mikrotechna SF 62 fraction collector was used for column experiments. In addition standard laboratory equipment (pH-meters, mixers, autoclaves, balance, ovens and/or drying ovens) was used.

Methods

Preparation of hydrated titanium oxide and sodium titanate

Hydrated TiO was prepared by filtration and careful washing (by distilled water) of industrial intermediate from production of titanium white. This intermediate was supplied in the form of suspension in water. The product was dried at room temperature on air, powdered and sieved. Fraction with grain size <0.1 mm was used directly for preparation of TiO–PAN composite absorber. The same fraction was used as starting material for the preparation of NaTiO. Slightly modified procedure of Heinonen et al. [14] was used for preparation of Na4Ti9O20·xH2O ion exchanger. 50 g of TiO were suspended in ethanol, solution of 80 g of NaOH in 160 g of H2O was added. The mixture was boiled for 3 h at continuous mixing under a reflux condenser. The product was repeatedly decanted by water, filtered, dried for 5 h at 105 °C, powdered, and sieved. Fraction with grain size <0.1 mm was used for preparation of NaTiO–PAN composite absorber. Both the PAN-based composite absorbers were prepared following to standard procedure [18, 26]. The procedure was performed so as the contents of active component in dry residue of the composite absorbers would be 93.7 % (w/w) for both the absorbers. The produced absorbers were wet-sieved. Fraction with grain size <0.6 mm was used for column experiments.

Analyses of TiO and NaTiO ion exchangers

The water contents of both the absorbers were determined by calcinations of the samples for 4 h at ~800 °C. A sample of NaTiO was in parallel subjected to TG and DTA analyses. For Ti and Na determination, the samples were dissolved by autoclaving 30–60 mg of ion exchangers with ~200 mg of ammonium sulphate and 3 mL of cc H2SO4 for 6 h at ~110 °C. Volume of the resulting solutions was adjusted to 50 mL by 1 M H2SO4. Sodium was determined by flame AAS, titanium was determined by spectrophotometry as peroxotitanate at 408 nm.

Uranium determination

Uranium determination was performed by spectrophotometry of UO2 2+ complexes with Arsenazo III in 0.1 M hydrochloric acid (HCl) at 652 nm. Systematic error of determination of very low concentrations of uranium caused by the presence of Ti(IV) released from the column was observed. This error was compensated for by preparing standard and/or blank samples from water which has been passed through a “blank column” filled with the absorber used.

“Total hardness” determination

“Total hardness” determination was performed by complexometric titration of buffered sample by 0.01 M solution of disodium salt of ethylene diaminotetraacetic acid. Eriochrome Black T in a mixture with NaCl was used as indicator.

Break-through curves

A glass column with internal diameter of 1.8 cm containing exactly 10 mL of absorber was used for the experiments. Fresh (non-regenerated) absorbers were used for the study of uranium extraction from distilled water. In the study of uranium extraction from tap water series of experiments were performed with the same bed of absorbers. Both TiO–PAN and NaTiO–PAN absorbers were regenerated by 0.1 M HCl between the experiments. The bed of the absorber was carefully washed with water before start of the experiment. 10−3 M solution of UO2(NO3)2 in distilled water or 10−4 or 10−5 M solution of UO2(NO3)2 in tap water was pumped to the column. Treated solution was collected into polyethylene bottles. Exact volume of each fraction was determined by weighing.

Elution curves

Elution curves were determined for 1 M HCl and 1 M or 0.1 M Na2CO3 solutions. Flow rate of 0.3–0.5 mL min−1 (1.8–3 BV h−1) was used, fractions of eluates were collected either manually or using a fraction collector. Spent columns were carefully pre-washed by 50–100 mL of distilled water before elution of uranium. Model spent columns for tests of uranium elution were prepared by passing of surplus of UO2(NO3)2 solution in distilled water through the column at a flow rate of ~1 mL min−1.

Results and discussion

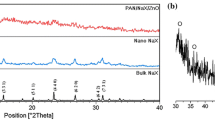

Analyses of TiO and NaTiO ion exchangers

Weight ratios of water and titanium in hydrated TiO as determined by calcination and spectrophotometry, respectively, were found to be w(H2O) = 0.213 and w(Ti) = 0.4718. From these results weight ratio of Ti in calcinated sample can be calculated to be w*(Ti) = 0.5995 which exactly corresponds to the expected formula TiO2. The prepared hydrated TiO can thus be represented by formula TiO2·1.2 H2O.

Weight ratio of water in NaTiO prepared was found to be 0.224 as determined by TG analysis. This result was verified by results of an independent analysis carried out by calcination of the sample. The results of spectrophotometric and AAS determination of titanium and sodium, respectively, yielded weight ratios of w(Ti) = 0.3937 and w(Na) = 0.0864 for the original sample. From these results weight ratios of titanium and sodium in the calcinated sample can be calculated to be w*(Ti) = 0.5074 and w*(Na) = 0.1113. Consequently the formula of our preparation can be written as Na4.11Ti9O20.2·13.6 H2O. This experimentally found formula is very close to the theoretical formula of Na4Ti9O20. The differences in abundance of sodium and oxygen are within experimental error of analytical methods used. Slightly higher contents of sodium might also result from imperfect washing of sodium hydroxide from the product in the course of preparation.

Sorption of uranium from distilled water

The aim of these introductory experiments was to establish whether TiO–PAN and/or NaTiO–PAN composite absorbers can be used for uranium extraction. Feed solution of 10−3 M UO2(NO3)2 in distilled water (pH ~3) was used for the experiments. Break-through curves obtained for both the absorbers are shown in Fig. 1. Except for uranium determination, pH of the collected fractions was determined, too. Uranium was retained on both the absorbers; on-going of the sorption was indicated by yellowish colouring of the absorbers.

With TiO–PAN composite absorber the break-through of uranium was close to zero up to volume of treated solution equal to ~90 BV. pH of these fractions of treated solution was somewhat lower than its original value (pH ~3.4). Increasing break-through of uranium was accompanied by steady decrease of pH. At the end of the experiment (break-through ~85 %) pH was stabilized at pH ~1.9.

For NaTiO–PAN composite absorber pH of the treated solution significantly increased after passing the bed of the absorber (from pH ~3 to ~8–9). Increasing break-through of uranium was also accompanied by steady decrease of pH value. For break-through of ~80 % pH approached its value in the original solution. Some break-through of uranium in the beginning of the experiment may be ascribed either to partial washing of the active component out of the composite absorber or, more probably, to low pH value (similarly to break-through of uranium in the range of volume of treated feed solution 150–200 BV). Elevation of pH of effluent is probably a result of exchange of UO2 2+ ions for Na+ ions in NaTiO. Other reason might be the dissociation of NaTiO [15] and its gradual conditioning to the pH value of the feed solution. Values of pH ~8–9 and more intensive yellow colour of the bed of NaTiO–PAN absorber (when compared with the TiO–PAN one) indicate that precipitation of sodium diuranate Na2U2O7 may take place in the bed of NaTiO–PAN absorber.

Elution of uranium from the absorbers

Similarly to other cations, uranium may be desorbed from hydrated TiO and/or NaTiO by solutions of mineral acids [9, 17, 25]. Alexandre and Vistoli [1] eluted uranium (in the form of carbonate complex [UO2(CO3)3]4−) from their TiO ion exchanger by ammonium carbonate solutions. Both these possibilities were tested for TiO–PAN and NaTiO–PAN composite absorbers. Elution of uranium from both the absorbers was at first performed by 1 M HCl. For both the absorbers, uranium was eluted immediately after void volume of the column. Maximum of the rather sharp elution peak is found for ~15 mL (1.5 BV) of HCl, most of the uranium was eluted in the first 30 mL (3 BV) of 1 M HCl. Then, 0.1 and 1 M Na2CO3 solutions were used for study of uranium elution from both the absorbers. It has been found that both absorbers decompose carbonate solutions producing bubbles of CO2 which harm the bed of absorbers in the columns. In the case of TiO–PAN, it is probably due to the decrease of pH caused by the exchange of H+ cations from the absorber for Na+ cations from the elution agent. However, repeated regenerations yielded better results and when using 1 M Na2CO3 uranium is eluted rather rapidly (within 5–6 BV). With 0.1 M Na2CO3 the elution curve is broader and some 7–10 BV of elution agent are needed for total recovery of uranium. It can be concluded that in principle both 1 and 0.1 M Na2CO3 can be used for elution of uranium from TiO–PAN composite absorber. On the other hand, the uranium elution from NaTiO–PAN absorber bed (fresh or regenerated) was more complicated; the effluent was turbid and it seemed that the elution agent washed out also some precipitate, probably sodium diuranate Na2U2O7. Thus these carbonate solutions are not suitable for elution of uranium and regeneration of NaTiO–PAN composite absorber.

Sorption of uranium from tap water

Tap water was used to model fresh surface and/or underground water. Concentration of uranium equal to 10−4 mol L−1 (~23 mg U L−1) was used for the establishment of influence of flow rate of the treated solution on uranium sorption. Concentration of uranium equal to 10−5 mol L−1 (~2.3 mg U L−1) was used in experiments modelling extraction from natural surface or underground water.

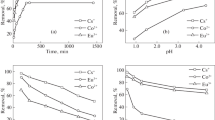

Sorption of uranium on TiO–PAN composite absorber

Break-through curves of uranium on TiO–PAN composite absorber were measured for flow rates from 18 BV h−1 up to 100 BV h−1. The influence of “freshness” of the absorber was also tested in the first two experiments performed at a flow rate of 18 BV h−1 with fresh and regenerated absorber and the results of these experiments are shown in Fig. 2. For the elution of uranium and regeneration of the absorber between individual sorption experiments, 0.1 M HCl was chosen for the minimization of active component dissolution [25]. The start of the elution peak was observed only after passing some 60 mL (6 BV) of elution agent, some 130 mL (13 BV) were needed for elution of all the uranium. When compared with the results of elution by 1 M HCl, decrease of the concentration of acid resulted in slower elution of uranium. From comparison of curves 1 and 2 in Fig. 2 it can be seen that the sorption cycle was somewhat shorter after regeneration of the absorber. This may correspond either with the decrease of sorption capacity of the absorber after regeneration or even with partial dissolution of active component during regeneration. For the uranium sorption from tap water, it is possible that the sorption of calcium and magnesium ions could compete with the sorption of uranium. Hence, the break-through of total hardness was determined in the course of the second experiment (regenerated absorber) at flow rate 18 BV h−1. It was found that uranium breaks through only after nearly 100 % break-through of total hardness is reached (Fig. 2). From curves 3 and 4 in Fig. 2 it can be seen that flow rate up to 60 BV h−1 does not seriously influence the character of break-through curves and that higher flow rates cause the decrease of sorption capacity.

Break-through curves of uranium (BT) and total hardness (H) on TiO–PAN composite absorber (BV = 10 mL) from 10−4 M UO2(NO3)2 in tap water (1-BT, fresh absorber, flow rate 18 BV h−1; 2,3,4-BT, regenerated absorber, flow rate 18, 60 and 100 BV h−1, respectively; 5-H, regenerated absorber, flow rate 18 BV h−1)

Sorption of uranium on NaTiO–PAN composite absorber

The experiments were similar to those performed with TiO–PAN composite absorber to be able to compare the performance of both the absorbers. Experimental break-through curves are shown in Fig. 3 together with the dependence of relative hardness of the fractions on the volume of treated solution during the first and repeated usage of the absorber. The elution of uranium from NaTiO–PAN absorber by 0.1 M HCl is somewhat more rapid when compared with its elution from TiO–PAN absorber. Approximately 10 BV of elution agent are sufficient for total elution of uranium. It can be seen from Fig. 3 that the regeneration has similar influence on the sorption cycle as in the case of TiO–PAN absorber, i.e. sorption capacity reduction. Break-through curve of total hardness was determined in the experiment performed at flow rate 100 BV h−1 (see Fig. 3) and its character suggests that the influence of calcium and magnesium ions on the sorption of uranium is much higher for this absorber than for TiO–PAN one.

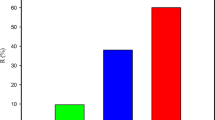

Comparison of uranium sorption on TiO–PAN and NaTiO–PAN absorbers

To model separation of uranium from slightly contaminated natural fresh water, an experiment was performed with sorption of uranium from tap water containing 2.3 mg U L−1 (10−5 mol L−1). Flow rate of 100 BV h−1 was used. The break-through curves obtained are shown in Fig. 4. For TiO–PAN, 10 % break-through is reached approximately after treatment of 2,000 BV of water which corresponds to practical sorption capacity of ~4.6 mg of uranium per mL of swollen absorber containing 213 mg hydrated titanium dioxide corresponding to ~20 mg or uranium per gram of TiO. This value of the sorption capacity is substantially larger when compared with the results achieved by Alexandre and Vistoli [1] for special “pure” granular hydrated TiO. This could be explained by the dispersion of fine-grained TiO in the composite material. From Fig. 4 it can be seen that the efficiency of NaTiO–PAN composite absorber is significantly worse than that of TiO–PAN one. 10 % break-through is reached approximately after treatment of 650 BV. This volume of treated water corresponds to practical sorption capacity (10 % break-through) of ~1.5 mg of uranium per mL of swollen absorber. These values of sorption capacities are much lower than the uptake of uranium from distilled water with higher uranium concentrations. This difference could be caused by the precipitation of sodium diuranate in the bed of NaTiO–PAN absorber occurring in parallel to the sorption from the solutions of higher uranium concentrations.

Conclusions

TiO–PAN and NaTiO–PAN composite absorbers were proven to be applicable for extraction of uranium from aqueous solutions. Both TiO–PAN and NaTiO–PAN composite absorbers can be used for repeated extraction of uranium from tap water. Appropriate flow rates are up to 60 BV h−1 for both TiO–PAN and NaTiO–PAN absorbers. Elution of uranium and regeneration of the absorber may be accomplished by 0.1 M HCl for both the absorbers.

Practical sorption capacity (10 % break-through) from tap water containing 2.3 μg U mL−1 measured at flow rate of 100 BV h−1 was ~4.6 and ~1.5 mg of uranium per mL of swollen TiO–PAN and NaTiO–PAN absorber, respectively. TiO–PAN composite absorber is thus for the given purpose more advantageous. This finding contradicts results obtained with more concentrated solutions of uranium in distilled water, where NaTiO–PAN composite absorber was found to be more efficient. Probable reason for this discrepancy is that precipitation of sodium diuranate in the bed of NaTiO–PAN absorber occurs in parallel to sorption of uranium from solutions with higher uranium concentration. The apparent sorption capacity of NaTiO–PAN absorber in such experiments is thus higher.

References

Alexandre D, Vistoli PP (1985) Advances in uranium ore processing and recovery from non-conventional resources. IAEA-TC-491/17. IAEA, Vienna, p 289

Heyne W (1995) In: Proc. GeoCongress, October 1995, Freiberg; Köln, Germany, p 255

Bitte J (1985) Advances in Uranium ore processing and recovery from non-conventional resources. IAEA-TC-491/18. IAEA, Vienna, p 299

Kim J, Tsouris C, Mayes RT, Oyola Y, Saito T, Janke CJ, Dai S, Schneider E, Sachde D (2013) Sep Sci Technol 48:367–387

Hotchkis MAC, Child D, Zorko B (2010) Nucl Instrum Methods B 268:1257–1260

Steier P, Bichler M, Keith Fifield L, Golser R, Kutschera W, Priller A, Quinto F, Richter S, Srncik M, Terrasi P, Wacker L, Wallner A, Wallner G, Wilcken KM, Wild EM (2008) Nucl Instrum Methods B 266:2246–2250

Nilchi A, Bablou AA, Rafiee R, Kalal HS (2008) React Funct Polym 68:1665–1670

Kiliari T, Pashalidis I (2012) Radiochim Acta 100:439–443

Lehto J (1987) Sodium titanate for solidification of radioactive wastes—preparation, structure and ion properties. Academic dissertation, University of Helsinki. Report series in radiochemistry 5/1987

Crisan M, Braileanu A, Raileanu M, Crisan D, Teodorescu VS, Birjega R, Marinescu VE, Madarasz J, Pokol G (2007) J Therm Anal Calorim 88:171–176

Valencia S, Vargas X, Rios L, Restrepo G, Marín JM (2013) J Photochem Photobiol A 251:175–181

Weiser HB, Milligan WO (1933) J Phys Chem 38:513–519

Lynch RW, Dosch RG, Kenna BT, Johnstone JK, Nowak EJ (1976) Management of radioactive wastes from the nuclear fuel cycle. IAEA, Vienna 361

Heinonen OJ, Lehto J, Miettinen J (1981) Radiochim Acta 28:93–96

Clearfield A, Lehto J (1988) J Solid State Chem 73:98–106

Lehto J, Clearfield A (1987) J Radioanal Nucl Chem 118:1–13

Heinonen OJ (1980) Radiochem Radioact Lett 43:293–300

Šebesta F (1997) J Radioanal Nucl Chem 220:77–88

Šebesta F (1999) Natural microporous materials in environmental technology. Kluwer Academic Publishers, Dordrecht, p 473 NATO science series

Berák L, Uher E, Marhol M (1975) Atomic Energy Rev 13:325–366

Baran V, Caletka R, Tympl M, Urbánek V (1975) J Radioanal Chem 24:353–359

Caletka R, Tympl M (1976) J Radioanal Chem 30:155–172

Takeuchi T, Sokukawa M, Kimoto R (1982) Ion exchanger of hydrated oxide of Ti, Zr, or Sn and cured polyester, and exchange method. U.S. patent 4362626

Echigo Y, Suematsu Y, Ishikura T (1986) Spherical ion exchange resin having matrix-bound metal hydroxide, method for producing the same and method for adsorption treatment using the same. U.S. patent 4576969

Dosch RG (1980) Final Report on the application of titanates, niobates and tantalates to neutralized defense waste decontamination—materials, properties, physical forms and degeneration techniques. Sandia National Laboratories, SAND 80-1212

Šebesta F (1992) Exchanger composed from an active component and a binding organic matrix and the way of its production. Czech patent A.O. 273369

Acknowledgments

Financial support by the Ministry of Industry and Trade of the Czech Republic under contract No. FR-TI3/245 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Motl, A., Šebesta, F., John, J. et al. Comparison of uranium extraction from model fresh water on TiO–PAN and NaTiO–PAN composite absorbers. J Radioanal Nucl Chem 298, 2057–2063 (2013). https://doi.org/10.1007/s10967-013-2641-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2641-5