Abstract

The ability of ordered mesoporous carbon CMK-3 has been explored for the removal and recovery of uraium from aqueous solutions. The textural properties of CMK-3 were characterized using small-angle X-ray diffraction and N2 adsorption–desorption, and the BET specific surface area, pore volume and the pore size were 1143.7 m2/g, 1.10 cm3/g and 3.4 nm. The influences of different experimental parameters such as solution pH, initial concentration, contact time, ionic strength and temperature on adsorption were investigated. The CMK-3 showed the highest uranium sorption capacity at initial pH of 6.0 and contact time of 35 min. Adsorption kinetics was better described by the pseudo-second-order model and adsorption process could be well defined by the Langmuir and Freundlich isotherm. The thermodynamic parameters, ∆G°(298 K), ∆H° and ∆S° were determined to be −7.7, 21.5 k J mol−1 and 98.2 J mol−1 K−1, respectively, which demonstrated the sorption process of CMK-3 towards U(VI) was feasible, spontaneous and endothermic in nature. The adsorbed CMK-3 could be effectively regenerated by 0.05 mol/L HCl solution for the removal and recovery of U(VI). Complete removal (99.9 %) of U(VI) from 1.0 L industry wastewater containing 15.0 mg U(VI) ions was possible with 2.0 g CMK-3.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

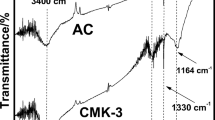

Many activities dealing with radioactive materials produce low, intermediate and high level radioactive wastes that require advanced treatment [1, 2]. Over the last few decades, a variety of technologies, such as solvent extraction [3, 4], ion-exchange [5] and adsorption, have been developed for the removal and recovery of uranium from radioactive wastes in consideration of the dual significance of the potential environmental health threat and an nonrenewable resource of nuclear energy [6]. Recently, adsorption, due to its high efficiency and ease of handling, based on carbonaceous materials such as activated carbon [7, 8], carbon nanotubes [9, 10] and carbon fiber [11] has been gradually applied to this area because of their higher thermal and radiation resistance than organic exchanger resins and better acid–base stability compared with familiar inorganic sorbents [8].

In addition, as a new member of the carbonaceous material family, the ordered mesoporous carbon CMK-3, which is synthesized through the nanocasting technique [12], has attracted considerable attention because of its unique features, such as high surface area, regular mesoporous pore structure, narrow pore size distribution, large pore volume, as well as excellent chemical and physical stabilities [13, 14]. These features make CMK-3 more attractive in the fields of biological medicine, electrochemistry, energy storage and environment [15–17]. CMK-3 and its composite have been used to remove VE [18], VB12 [19], phenol [20], lysozyme [21], Pb2+ [22] and Hg2+ [23]. However, to the best of our knowledge, CMK-3 has not been reported for adsorption of uranyl ions from aqueous system so far. Therefore, it would be interesting to explore the possibility of CMK-3 for the environmental purpose mentioned above.

The aim of the present investigation was to study the efficiency of ordered mesoporous carbon CMK-3 prepared by the hard-templating method for removing uranium from aqueous solutions. Various techniques were used to characterize the structure and textural property of CMK-3, including small-angle X-ray diffraction (SAXRD) and N2 adsorption–desorption. The effect of various experimental parameters including pH of the solution, ionic strength, contact time, initial concentration, and temperature, as well as adsorption kinetics, isotherm models, and thermodynamics were studied. In addition, the regeneration method of CMK-3 and attempt for uranium(VI) removal from industry wastewater were also investigated.

Experiment

Materials

The ordered mesoporous silica (SBA-15) was obtained from the Nanjing Cano technology Co., Ltd. For the preparation of a stock U(VI) solution, 1.1792 g U3O8 was put into a 100 mL beaker, and 10 mL hydrochloric acid (ρ = 1.18 g/mL), 2 mL 30 % hydrogen peroxide were added. The solution was heated until it was nearly dry and then 10 mL hydrochloric acid (ρ = 1.18 g/mL) was added. The solution was transferred to a 1,000 mL volumetric flask and diluted to the mark with distilled water to produce a U(VI) stock solution (1 mg/mL). The uranium solutions were prepared by diluting the stock solution to appropriate volumes depending upon the experimental requirements. All the other reagents were of AR grade.

Preparation of ordered mesoporous carbon CMK-3

Mesoporous carbon material (CMK-3) was prepared using the ordered mesoporous silica (SBA-15) as the hard template and sucrose as the carbon recourse [24, 25]. Typically, 1 g of SBA-15 was added into a solution of 1.25 g of sucrose and 0.14 g of H2SO4 in 5 g of water, the mixture was polymerized at 100 °C for 6 h and 160 °C for another 6 h. The obtained product was impregnated with 0.09 g H2SO4 and 0.8 g sucrose later, and subjected the same thermal treatments depicted above. The pre-products were then pyrolyzed at 900 °C for 6 h to be carbonized in an nitrogen flow with a heating rate of 5 °C/min, and resultant black powders was obtained. The mesoporous carbon was acquired by filtration after the silica template was dissolved by NaOH solution. Finally, the product was washed several times with deionized water and dried at 120 °C.

Characterization

SAXRD patterns were recorded using Cu Kα radiation (γ = 1.5418) on ARL X’TRA diffractometer operating at 40 kV and 40 mA with 0.25° divergence slit and 0.5° anti-scatter slit between 1.0° and 16° (2θ) at a step size of 2°/min. The surface area and pore structure were determined by an ASAP 2020 N2 adsorption–desorption device, and the surface area was calculated using the Brunaure–Emmett–Teller (BET) method [26], and the pore distribution was determined by Barrett–Joyner–Halenda (BJH) method [27].

Adsorption experiments

The adsorption of U(VI) was studied as a function of pH, ionic strength, contact time, initial concentration and temperature. The batch sorption was performed in a reciprocating water bath shaker with concussion speed of 200 rpm. In the experiments 0.01 g of sorbent was suspended in 50 mL solution containing different U(VI) concentration and different initial pH (adjusted with 0.1 mol/L HNO3 and 0.1 mol/L NaOH). The concentration of U(VI) in the solution was determined by the arsenazo III method [23] with a 721 type spectrophotometer at 650 nm. The amount of uranyl ions adsorbed per unit mass of the CMK-3 was calculated by Eq. 1.

where, q e is the adsorption capacity of the CMK-3 (mg/g); C 0 and C e are the uranium concentration in the initial and equilibrium solution (mg/L) respectively; V is the volume of the aqueous solution (L) and W is the mass of CMK-3 (g).

Results and discussion

Characterization

The ordered arrangement of the carbon nanorods in CMK-3 gives rise to the well-resolved XRD peaks shown in Fig. 1, which can be assigned to (100), (110), and (200) diffractions of the 2D hexagonal space group (p6mm) similar to the case of SBA-15. The N2 adsorption–desorption isotherm at 77 K and pore size distribution of CMK-3 were shown in the Figs. 2, 3 and Table 1. It was noteworth that N2 adsorption isotherms of CMK-3 was type-IV curve with clear capillary condensation steps [28]. In addtion, CMK-3 exhibited high BET specific surface area (1143.7 m2/g), large pore volume (1.10 cm3/g) caculated by BJH model and a narrow pore size distribution. The pore size of CMK-3 obtained from the N2 isotherm was about 3.4 nm.

The effect of solution pH

The pH of solution is one of the most crucial parameters for the sorption of metal ions. It can affect the surface charge, the metal speciation and surface metal binding sites. The effect of pH on the adsorption of U(VI) onto CMK-3 was carried out over the pH range 3.0–7.5 using 50 μg/mL initial uranium concentration at 298 K and the results were displayed in Fig. 4. The adsorption of U(VI) on CMK-3 was greatly depended on the variation of solution pH. The uptake amount of U(VI) increased from 3 to 6, and reached the maximum adsorption capacity of 117.81 mg/g at pH 6.0 and then declined subsequently. The low adsorption capacity at lower pH value could be attributed to the increasing positivity of the adsorbents and the competition of H+ ions with U(VI) on the adsorptive active sites. And with the increase of pH above 6, the hydroxide products of U(VI) such as UO2(OH)+, (UO2)2(OH)2 and (UO2)3(OH) 2+5 appeared and led to the decrease of the adsorption capacity [29]. Therefore, the solution pH of 6 was used for the further experiments for U(VI) adsorption on CMK-3.

The effect of contact time

Contact time is also an important factor which can reflect the adsorption kinetics. The variation of adsorption amount with contact time was studied using 50 μg/mL initial U(VI) concentration at pH 6.0 and 298 K. As showed in Fig. 5, the amount of U(VI) adsorbed on CMK-3 increased sharply at the beginning, and then gradually reached equilibrium after 35 min. The faster adsorption rate at the beginning would be due to the larger concentration gradient. Therefore, the contact time of 35 min was deemed sufficient to establish sorption equilibrium and used in all the subsequent experiments.

The effect of initial U(VI) concentration

The initial concentration provides an important driving force to overcome all mass transfer resistance of uranium between the aqueous and solid phases [30]. The effect of initial U(VI) concentration on sorption was studied at 298 K and revealed in Fig. 6. The adsorptive capacity increased with the increase of the initial U(VI) concentration. According to the actual situation, the concentration of uranium in next following experiments should be controlled at 50 μg/mL.

The effect of ionic strength

Ionic strength is another important factor reflecting adsorption. In the present study, the ionic strengths of the solutions were adjusted by KNO3. As shown in Fig. 7, an increase in the ionic strength from 0.01 to 0.1 mol/L had a rapid decrease in the amount of U(VI) ions adsorbed, and had little effect from 0.1 to 0.3 mol/L. The sorption capacity of U(VI) was 112.25 mg/g at the K+ concentration of 0.01 mol/L, and declined to 84.20 mg/g at 0.1 mol/L. This phenomenon could be attributed to two reasons: (1) The presence of KNO3 in the solution which screened the electrostatic interaction between the charges on CMK-3 surface and the U(VI) ions in solution and also competed with the U(VI) ions for surface adsorption sites. (2) Ionic strength of solution influenced the activity coefficient of U(VI), which limited their transfer to sorbent’s surface.

Adsorption isotherm

The equilibrium adsorption isotherms are one of the essential data to understand the mechanism of the adsorption systems. Langmuir and Freundlich equations are the most frequently used for describing sorption isotherms. The Langmuir model is based on assumptions of adsorption homogeneity such as equally available adsorption sites, monolayer surface coverage, and no interaction between adsorbed species. The Langmuir equation can be described by the linearized Eq. 2 [31].

where C e is the equilibrium concentration (mg/L), q e is the amount of solute sorbed per unit weight of sorbent (mg/g), q m is the Langmuir constant, which represents the saturated monolayer sorption capacity (mg/g). K L is a constant related to the energy of adsorption.

The Freundlich model can be applied to nonideal sorption on heterogeneous surfaces as well as multilayer sorption [32]. The empirical Freundlich equation can also be transformed into linearized Eq. 3.

where C e is the equilibrium concentration (mg/L), q e is the amount of solute sorbed per unit weight of sorbent (mg/g), K F is the Freundlich constant related to the adsorption capacity, and n is relevant to the adsorption intensity.

Figure 8 presented the effect of initial concentration on the uranium adsorption on CMK-3 at 298, 308 and 318 K.

The linearized form of Langmuir and Freundlich adsorpiton isotherms obtained at 298, 308 and 318 K were presented in Figs. 9 and 10 respectively. And the adsorption constants evaluated from the isotherms with the correlation coefficients (R 2) were given in Table 2. The R 2 values of the Freundlich and Langmuir adsorption isotherm were over 0.98, which indicated that the sorption of U(VI) onto CMK-3 was suitable to Langmuir and Freundlich isotherm models. Morever, the saturated monolayer sorption capacity (q m) was 178.6, 204.1 and 232.6 mg/g at 298, 308 and 318 K, namely, with the increase of temperature, the saturated monolayer sorption capacity reduced, which indicated that the sorption of U(VI) onto CMK-3 was endothermic.

Adsorption kinetics

In order to explain the controlling mechanism of adsorption processes such as mass transfer and chemical reaction, pseudo-first-order and pseudo-second-order kinetic equations were applied to describe the kinetic characteristic of U(VI) onto CMK-3. The pseudo-first order kinetic model is usually given as Eq. 4 [33].

where k 1(min−1) is the rate constant of first order adsorption, q e and q t are the amounts of U(VI) adsorbed (mg/g) at equilibrium and time “t”, respectively. Using Eq. 4, linear plot of ln(q e−q t) versus t was plotted (Fig. 11). The k 1, q e,cal and correlation coefficient (R 2) were calculated from the plot and presented in Table 3.

The pseudo-second order kinetic model is always given as Eq. 5 [34].

Where k 2 (min−1) is the rate constant of second order adsorption. Using Eq. 5, linear plot of t/q t versus t was plotted (Fig. 12). The k 2, q e,cal and correlation coefficient (R 2) were calculated from the plot and presented in Table 3.

As showed in Table 3, the square of correlation coefficients (R 2) of pseudo-second order equation was better than the value of the pseudo-first order equation. Moreover, the values of the amounts of U(VI) adsorbed at equilibrium, q e,cal (125.0 mg/g) was very close to the experimental values, q e,exp (121.7 mg/g). Therefore, the adsorption process is more favor of the pseudo-second order equation, which indicate that adsorption involves chemical reaction in adsorption in addition to physical adsorption [35].

Adsorption thermodynamics

Thermodynamic parameters such as enthalpy (ΔH°), entropy (ΔS°) and Gibbs free energy (ΔG°) are useful in defining whether the sorption reaction is endothermic or exothermic, and spontaneity of the adsorption process [36]. The thermodynamic data were calculated using the following Eq. 6 and 7.

where k L is the Langmuir constant, ΔS° is the change of entropy (J mol−1 K−1), ΔH° is the change of enthalpy (kJ/mol), T is the absolute temperature in Kelvin (K) and R is the gas constant (8.314 J mol−1 K−1). ΔH° and ΔS° can be calculated from the slope and intercept of the straight line (Fig. 13). The change of Gibbs free energy values are calculated from Eq. 7.

The values of thermodynamic parameters for the sorption of U(VI) at different temperature were given in Table 4. The negative value of ΔG° at different temperatures confirmed the feasibility and spontaneous nature of adsorption process. Further, the increase in the value ΔG° with the decreasing temperature indicated that higher temperature favored the sorption process. The positive value of ΔS° reflected the affinity of the CMK-3 for U(VI) and confirmed the increased randomness at the solid-solution interface during adsorption [37].

Desorption and regeneration

Desorption is an important process in adsorption studies due to its enhancement of the economical value. Desorption studies will help to regenerate the spent adsorbent so that it can be reused to adsorb metal ions. Desorption efficiency of the spent CMK-3 was checked by 0.001–0.1 mol/L HCl solution. The results demonstrated that the adsorbed U(VI) could be desorbed completely from the spent adsorbent using 0.05 mol/L HCl, and hence to investigate the regeneration properties, the adsorption–desorption cycle was repeated four times with same adsorbent using 0.05 mol/L HCl. It was clear from Table 5 that the initial adsorption capacity, removal and desorption ratio were 117.45 mg/g, 99.31 and 97.33 %, and after four cycles decreased to 101.89 mg/g, 89.23 and 88.21 %. Therefore 0.05 mol/L HCl solution could regenerate the adsorbent effectively.

Test with simulated nuclear industry wastewater

The simulated U(VI) nuclear industry wastewater was recovered by CMK-3 to demonstrate its adsorption potential and utility in removing U(VI) ion from wastewater in the presence of other ions. The wastewater was prepared according to the composition of resin adsorption tail liquid from uranium hydrometallurgy plant. The wastewater contained U(VI) (15 mg/L), SO4 2−(10 g/L), NO3 −(1 g/L), Mg2+(0.2 g/L), Ca2+(0.5 g/L) and Fe3+(1.6 g/L). The effect of adsorbent dose on U(VI) removal from wastewater was investigated (Fig. 14). The percentage of U(VI) adsorption increases with increasing HDTMA+-bentonite dosage and almost complete removal (≈100 %) of U(VI) from the wastewater containing 15 mg/L was achieved with 2.0 g HDTMA+-bentonite in 1.0 L.

Conclusion

In this paper, ordered mesoporous carbon CMK-3 was prepared using SBA-15 as the hard template and sucrose as the carbon recourse with the BET specific surface area of 1143.7 m2/g, pore volume of 1.10 cm3/g and pore size of 3.4 nm abtained from N2 adsorption–desorption isotherm. The sorption performances were controlled by solution pH, contact time, initial uranium concentration, ionic strength, and temperature. The maximum capacity of CMK-3 was observed at the pH value of 6.0 and contact time of 35 min. The U(VI) sorption on CMK-3 was well fitted to the Langmuir, Freundlich adsorption isothermal and pseudo-second kinetics models. The thermodynamic parameters, such as ∆G°, ∆H° and ∆S°, clearly indicated that the adsorption process was feasible, spontaneous and endothermic in nature. The adsorption–desorption study showed that U(VI) sorbed CMK-3 could be effectively regenerated by 0.05 mol/L HCl solution for the removal and recovery of U(VI) from aqueous solution. Attempts for the U(VI) removal from industry wastewater using CMK-3 revealed acceptability. Almost complete removal (≈100 %) of U(VI) from the wastewater containing 15 mg/L was achieved with 2.0 g CMK-3 in 1.0 L.

References

Sakr K, Sayed MS, Hafez MB (2003) J Radioanal Nucl Chem 256:179–184

Özdemir T, Usanmaz A (2009) Prog Nucl Energy 51:240–245

Sato T (2008) Solvent Extr Res Dev Jpn 15:61–69

Bayyari MA, Nazal MK, Khalili FA (2010) J Saudi Chem Soc 14(3):311–315

ElSweify FH, Shehata MKK, ElShazly EAA (1995) J Radioanal Nucl Chem 198(1):77–87

Rao TP, Metilda P, Gladis JM (2006) Talanta 68:1047–1064

Coleman SJ, Coronado PR, Maxwell RS, Reynold JG (2003) Environ Sci Technol 37:2286–2290

Zhao YS, Liu CX, Feng M, Chen Z, Li SQ, Tian G, Wang L, Huang JB, Li SJ (2010) J Hazard Mater 176:119–124

Schierz A, Zanker H (2009) Environ Pollut 157:1088–1094

Shao DD, Jiang ZQ, Wang XK, Li JX, Meng YD (2009) J Phys Chem B 113:860–864

Xu Y, Zondlo JW, Finklea HO, Brennsteiner A (2000) Fuel Process Technol 68:189–208

Lu AH, Schüth F (2006) Adv Mater 18:1793–1805

Kruk M, Jaroniec M, Kim TW, Ryoo R (2003) Chem Mater 15:2815–2823

Darmstadt H, Roy C, Kaliaguine S, Kim TW, Ryoo R (2003) Chem Mater 15:3300–3307

Joo SH, Choi SJ, Oh I, Kwak J, Liu Z, Terasaki O, Ryoo R (2001) Nature 412:169–172

Lei ZB, Bai SY, Xiao Y, Dang LQ, An LZ, Zhang GN, Xu Q (2008) J Phys Chem C 112:722–731

Peng X, Cao DP, Wang WC (2009) Langmuir 25:10863–10872

Vinu A, Hartmann M (2005) Catal Today 102–103:189–196

Guo Z, Zhu G, Gao B, Zhang DL, Tian G, Chen Y, Zhang WW, Qiu SL (2005) Carbon 43:2344–2351

Haque E, Khan NA, Talapaneni SN, Vinu A, Jegal J, Jhung SH (2010) Bull Korean Chem Soc 31:1638–1642

Vinu A, Hossian KZ, Srinivasu P, Miyahara M, Anandan S, Gokulakrishnan N, Mori T, Ariga K, Balasubramanian VV (2007) J Mater Chem 17:1819–1825

Baniamerian MJ, Moradi SE, Noori A, Salahi H (2009) Appl Surf Sci 256:1347–1354

Wu ZX, Webley PA, Zhao DY (2010) Langmuir 26:10277–10286

Lee JS, Joo SH, Ryoo R (2002) J Am Chem Soc 124:1156–1157

Vinu A, Hossain KZ, Kumar GS, Ariga K (2006) Carbon 44:530–536

Pickett G (1945) J Am Chem Soc 30:1958–1962

Barrett EP, Joyner LG, Halenda PP (1951) J Am Chem Soc 73:373–380

Zhang F, Meng Y, Gu D, Yan Y, Yu C, Tu B, Zhao D (2005) J Am Chem Soc 127:13508–13509

Bayramoglu G, Celik G, Arica MJ (2006) Hazard Mater 136:345–353

Aytas S, Yurtlu M, Donat RJ (2009) Hazard Mater 172:667–674

Hazer O, Kartal Ş (2010) Talanta 82:1974–1979

Parab H, Joshi S, Shenoy N, Verma R, Lali A, Sudersanan M (2005) Bioresour Technol 96:1241–1248

Ghaemi A, Torab-Mostaedi M, Ghannadi-Maragheh MJ (2011) Hazard Mater 190:916–921

Psareva T, Zakutevskyy O, Chubar N, Strelko V, Shaposhnikova T, Carvalho J, Correia M (2005) Colloids Surf A 252:231–236

Anirudhan TS, Rijith S, Tharun AR (2010) Colloids Surf A 368:13–22

Anirudhan TS, Divya L, Suchithra PS (2009) J Environ Manag 90:549–560

Donat RJ (2009) Chem Thermodyn 41:829–835

Acknowledgment

This work is financially supported by the National Natural Science Foundation of China (Grant No. 21101024), Key Project of Chinese Ministry of Education (Grant No. 211086), Natural Science Foundation of Jiangxi Province (No. 2010GQH0015), Sci. & Tech. Project of Jiangxi Provincial department of education (No. GJJ11139), Open Project Foundation of the Key Laboratory of Radioactive Geology and Exploration Technology Fundamental Science for National Defense (East China Institute of Technology) (2010RGET08), Open Project Foundation of the Engineering Research Center of Nano-Geomaterials of Ministry of Education (China University of Geosciences) (CUGNGM201205), and Open Project Foundation of the State Key Laboratory of Biogeology and Environmental Geology (China University of Geosciences) (BGEG201105).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, Bw., Zhang, Zb., Cao, Xh. et al. Sorption study of uranium from aqueous solution on ordered mesoporous carbon CMK-3. J Radioanal Nucl Chem 295, 663–670 (2013). https://doi.org/10.1007/s10967-012-1820-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-012-1820-0