Abstract

Copolymers of (D,L-lactide-random-ε-caprolactone)-block-poy(ethylene glycol)-block-(D,L-lactide-random-ε-caprolactone) or PLEC were explored as materials for injectable drug delivery system. A series of six PLECs were successfully synthesized with varied D,L-lactide (LA) content (0, 10 and 20%) and molecular weight (20 and 50 kDa). All polymers were able to form depots with more than 90% encapsulation efficiency of trypan blue leading to the loading density as high as 27% w/w. The variation of trypan blue loading, LA content and molecular weight were found to have profound effects on trypan blue release profiles. Even though, GPC and SEM confirmed the higher degradation of PLEC chains, trypan blue release rate and burst release was greater as the content of hydrophilic moiety, i.e. LA, was decreased. This was primarily due to the smooth and dense surface and cross-section of PLEC depots. The results from this study suggest a possible application of these depots as injectable, self-solidifying drug delivery systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodegradable polymer depots are attractive for the development of drug delivery systems. However, progress towards this goal has been hindered by many limitations. First, a large open wound is required to administer drugs inside the body. For example, Gliadel wafers® are disc-shaped polymer wafers with 1.4 cm in diameter and 1 mm in thickness which are approved by FDA for brain cancer treatment [1]. Smaller depots, for example, millirods with 1.6 mm in diameter required a 14-gauge tissue biopsy needle for the implantation [2]. Second, heat and pressure are required to fabricate these depots in order to anneal and mold materials to a desired shape which may affect the stability of drugs especially gene, protein or hormone. Polymeric microspheres are also used as drug delivery systems for brain cancer chemotherapy [3, 4]. However, fabrication of these particles is difficult to control size and porosity. Moreover, polymeric microspheres can migrate from a placement site and cause a unexpected toxicity and drug release [5]. To overcome this limitation, injectable drug delivery systems have been proposed as an alternative approach for drug delivery systems to delivery hormone and gene [6]. In situ forming depots have the advantages of minimally invasive administration which can be accomplished by injecting through a small needle. Injectable polymer depots require only small injection wound to deliver a high dose of therapeutic agents directly at target sites [7, 8]. These systems also have relatively less complicated manufacturing procedures providing the ease of preparation. Moreover, the in situ solidification process lead to the ease of administration allowing the multiple injections throughout the area of interest [9]. Therefore, these drug delivery systems can be used as platforms for pharmaceutical applications. Recently, we evaluated the biocompatibility of glycofurol and in situ forming depots in rat brains. Results suggest that both could be used for local delivery of therapeutic agents to the brains [10, 11]. An injectable polymeric drug delivery system in this study is in a liquid form comprised of polymer and trypan blue dissolved in glycofurol, a pharmaceutically accepted water-miscible solvent. Depots can be formed by injecting a polymer gel into aqueous environment then it subsequently solidifies and forms solid depots upon contact with water (i.e., body fluids) [12]. Copolymers of (D,L-lactide-random-ε-caprolactone)-block-poy(ethylene glycol)-block-(D,L-lactide-random-ε-caprolactone) or PLEC were selected as materials which comprised of a randomized D,L-lactide and ε-caprolactone section at the two sides of poly(ethylene glycol) (PEG). PCL is a semicrystalline polymer with high hydrophobicity and melting temperature (Tm) around 60 °C because of long methylene groups in each unit. Outside the crystalline region, these methylene groups provide high flexibility to polymer chains leading to low glass transition temperature (Tg) (−60 °C) and high permeability [13]. Even though PCL can be hydrolyzed to 6-hydroxycaproic acid and eliminated via the tricarboxylic acid cycle and kidney, its degradation rate is more than 2 years. The limitation in the hydrophobic property and slow degradation of PCL can be overcome by introducing lactide and PEG in polymer chains. P(DL)LA, an amorphous polymer, is one type of polylactide with Tg approximately 50–60 °C. It is less hydrophobic and has faster degradation rate than PCL [14]. Polylactide is hydrolyzed by esterification into lactic acid and eliminated via tricarboxylic acid cycle, i.e., water, carbondioxide. PEG is well-known for its solubility and its biocompatibility [15]. PEG was introduced as one of copolymer composition so that the hydrophilicity and degradation of depots can be tuned without using external excipient compounds such as sodium chloride or sugar. A series of six PLEC copolymers were synthesized with varied copolymer composition (0, 10, and 20% D,L-lactide) and molecular weight (20 and 50 kDa) to obtain depots with the desired controlled release behavior. Degradation, morphological and thermal characteristics of these depots were evaluated.

Materials and methods

Materials

Chemical reagents

Poly(ethylene glycol) (PEG) MW = 1,000 Da, D,L-Lactide (3,6-Dimethyl-1,4-dioxane-2,5-dione) and epsilon-Caprolactone were purchased from ACROS. PEG was dissolved in acetone, precipitated from diethyl ether and vacuum-dried for 6 h. D,L-Lactide was recrystallized by dissolving in ethyl acetate until saturated after that it was vacuum-dried. epsilon-Caprolactone was distilled with calcium hydride prior to use. Glycofurol, trypan blue dye, and Tin(II)2-ethylhexanoate (Sn(Oct)2) were purchased from Sigma Aldrich (St. Louis, MO, USA). Toluene was refluxed with sodium and benzophenone under argon. Other reagents were purchased from Sigma Aldrich (St. Louis, MO, USA).

Methods

Synthesis of PLECs

PLECs were synthesized following the previous publications [16, 17]. D,L-lactide (LA), ε-caprolactone (CL) and poly(ethylene glycol) (PEG) were weighted in the dry two-necked round-bottomed flask and the mixture was dried under reduced pressure for 6 h. PEG was dried under vacuum for 48 h at 50 °C before LA and CL were introduced into the flask. Then dehumidified argon was purged through the system. Dry toluene was added into the flask as a solvent. The flask was immersed in an oil bath and maintained at 140 °C. Stannous octoate was introduced at 0.04 mole (%) into a polymerization flask and the reaction was carried out for 48 h. The product was obtained by precipitating in cold methanol 3 times and dried with vacuum for 24 h. PLEC copolymers were characterized by H1 NMR and gel permeation chromatography (GPC). This polymerimerization can control the copolymer composition by monomer feed ratio. Thus, the desired hydrophilicity, degradation rate and property can be obtained. In this experiment, we synthesized the six types of PLEC copolymers as shown in Table 1.

Preparation of polymer depots

The copolymer and trypan blue was dissolved in glycofurol with the concentration ranging from 10 to 50% w/v of glycofurol. Trypan blue loading was controlled at 5, 15, and 30% w/w compared to the polymer weight. The mixtures were mixed in glass vial and vigorous shaken with a vortex mixing. A 1 mL syringe with 25 G needle was used to draw the polymer solution then the mixture was injected to form depots in 10 mL phosphate-buffered saline (PBS) pH 7.4 at 37 °C. Trypan blue encapsulation efficiency was calculated by the following equation.

In vitro release study

Trypan blue was used as a model hydrophilic drug which was incorporated in polymer/glycofurol mixture. After depot formation in vitro, the release studies were carried out by placing the sample vials in an orbital shaker with a rotating speed at 90 rpm and temperature at 37 °C. Buffers were withdrawn at a certain time period. The trypan blue release was determined at its maximum absorption wavelength (λmax) at 586 nm in PBS pH 7.4. Fresh PBS solution 10 mL was added into the vial. The amount of trypan blue release was determined by the Beer’s law. The polymer concentration was used at 30% w/v (polymer 30 mg in glycofurol 100 μL). The release study was carried out in triplicate.

Gel permeation chromatography (GPC)

Depots were taken out and washed by deionized (DI) water three times to remove residue salt and freeze-dried. Polymers were dissolved in tetrahydrofuran (THF) approximately 1% w/v. Samples were then filtered, and 100 μL of polymer solution was injected into GPC (Waters 510 pump with a Waters’ RI-410 refractive index detector) at a flow rate of 1 ml/min 30 °C where THF was used as a mobile phase. The averaged molecular weights and polydispersity index were determined.

Scanning electron microscopy (SEM)

Surface and interior morphologies of polymer depots from both non-incorporated and incorporated trypan blue dye were studied by SEM (Hitachi S-2500) at 15 kv. At various time intervals, depots were taken out and washed by deionized (DI) water three times to remove residue salt and then freeze-dried. Samples were mounted on metal stubs with double side of carbon tape, and coated with platinum/palladium by E 102 ion sputter at 20 mA, 240 s before examined.

Differential scanning calorimetry (DSC)

The polymer depots were prepared as mentioned above. Differential scanning calorimeter (DSC) was performed to determine the thermal properties of copolymers such as melting temperature (Tm) and melting enthalpy (ΔH). Samples were weighed approximately 7–10 mg after that polymer depots were placed into aluminum pan. Samples were then cooled down to −60 °C under a flow of nitrogen, held for five minute after that the sample was heated to 180 °C with the rate of 10 °C/min. The degree of crystallinity (%Xc) of copolymers was calculated from the following equation.

where ΔHm is melting enthalpy of samples and ΔH°m is melting enthalpy of 139.5 J/g of 100% crystalline poly(ε-caprolactone) [18]. Melting temperature (Tm) and melting enthalpy (ΔH) were measured from the peak melting.

Results and discussion

Synthesis and characterization

PCL is a hydrophobic polymer and has low degradation rate [19, 20]. These properties can be improved by introduction of D,L-lactide and poly(ethylene glycol) which provides the new copolymer so-called PLECs or D,L-lactide-random-ε-caprolactone-block-poly(ethylene glycol)-block-D,L-lactide-random-ε-caprolactone. PLEC copolymers were synthesized by ring opening polymerization of ε-caprolactone (CL) and D,L-lactide (LA) using polyethylene glycol (PEG) and Tin(II) 2-ethylhexanoate (Sn(Oct)2) as a macroinitiator and catalyst, respectively [21]. Six types of copolymers were obtained which composed of a PEG central block (1 kDa) bearing two random copolymers of CL and LA at both ends. These copolymers were characterized by 1H NMR and GPC which was summarized in Table 1. All of these copolymers exhibited a unimodal molecular weight distribution obtained by GPC.

Depot preparation

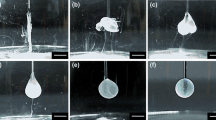

Six types of copolymers were investigated for depot formation by varying the concentration in the range of 10–50% w/v, i.e., polymer 10–50 mg in 100 μL of glycofurol. The characteristics of depot formation (Table 2 and Fig. 1a–d) were found to depend on copolymer composition, molecular weight and concentration. A decrease in molecular weight and ε-caprolactone content in copolymers increased the concentration of copolymers required to form depots in the following order: PCL2 < PCL1, PLEC2 and 4 < PLEC1 and 3. Polymers with higher D,L-lactide content (PLEC4) solidified slower than those with lower LA content (PCL1 and PCL2). The solidification rate depended on hydrophobicity and affinity between solvent (glycofurol) and non-solvent (PBS). All types of copolymers had the appropriate concentration at 30% w/v as indicated by two plus sign (++). Therefore, all of depots were prepared using this concentration for further investigation.

Optical images of polymer depot characteristic with different polymer concentrations. a Depots could not be formed (−); b unstable depots (−); c depots were extruded as cylindrical shape (+); d depots could be formed and used in this study (++). Photo sequence of depot formation (PLEC 4, MW = 48.6 kDa) with 0 (e–h) and 5% (i–l) trypan blue loading at the concentration of 30% w/v in PBS at 37 °C. The photo sequences were taken within 1 min after injection (scale bar = 0.2 cm)

Figure 1e–h showed a clear PLEC gel right after injection which was then gradually turned opaque as a result of water influx and diffusing out of glycofurol from the gel. Finally, polymers aggregated themselves to form solid depots because these copolymers were insoluble in phosphate buffer saline pH 7.4 (Fig. 1h). Trypan blue dye was used instead of drugs (Fig. 1i–l). PLEC4 depots were formed at the concentration of 30% w/v with 30% trypan blue loading. This dye was encapsulated in all types of PLEC depots with more than 91% encapsulation efficiency as summarized in Table 3.

In vitro release of trypan blue from depots

In vitro release of depots with 5, 15, and 30% w/w trypan blue loading from different polymers were carried out. The release profiles were obtained in the percentage of cumulative trypan blue release versus time as shown in Fig. 2. Unexpectedly, trypan blue release from PCL depots was found to be the fastest where the release profile showed high burst release and comparatively fast release compared to all types of PLEC depots. In general, the release profiles had an initial burst at the beginning followed by slow release rate consistent with the first order kinetics. Interestingly, release kinetics of trypan blue (5 and 15% loading) from PLEC4 depots fitted very well to the zero order kinetics (r 2 = 0.9942 and 0.9858). With 5 and 15% trypan blue loading, the burst release was drastically reduced in PLEC3 depots and even disappeared in PLEC4 depots. The cumulative amount of trypan blue release over the first 24 h of PCL2 depots containing 30% trypan blue loading was 86.9 ± 4.1%. At higher D,L-lactide content (20%), the cumulative trypan blue release from PLEC4 in the first day was surprisingly decreased by half to 45.0 ± 1.6%. This was attributed to the hydrophobicity of PCL that caused hydrophilic dye molecules to migrate closer to the depot surface as reported previously in PCL microspheres [22]. Depots prepared from PCL were reported to have high phase inversion containing interconnecting channels which were the paths for dye molecules to diffuse out of depots. Depots from copolymers with an increasing LA fraction showed a delay burst release whereas the slowest trypan blue release was found in PLEC depots with 20% LA. The slow release rate was primarily due to low drug permeability as a result of D,L-lactide as previously reported [23]. For example, the slower release rate of 5-FU from PLEC copolymer films was observed as a result of increasing D,L-lactide content [21]. In addition, phase inversion was another factor that had the effect on the trypan blue release from depots. Low aqueous affinity from increasing hydrophilic property of polymer solution caused slow phase inversion which produced dense or non-porous matrix.

Molecular weight is one of the important factors that have an impact on the drug release profiles. High molecular weight was reported to limit the diffusion of drugs through polymer matrix as confirmed by the study of the injectable PLGA depot where high molecular weight PLGA depots showed lower protein release rate [7, 16]. High molecular weight polymers also had comparatively higher entanglements. This led to longer time for drug and water molecules to travel outward and inward of polymer matrix, respectively which resulted in slow release rate [24]. As shown in Fig. 2, a higher molecular weight copolymer (PLEC 4, 48.6 kDa) had slower release rate than a copolymer with lower molecular weight (PLEC 3, 26.4 kDa). Another variable is the amount of trypan blue (5, 15, and 30% w/w) in the depots. It was found that depots contained higher trypan blue loading had faster release rate. This effect was also reported by Rom E et al. who observed the enhancement of protein release from PLGA depots as a function of protein content [7].

Degradation study

The photo sequences of PCL2 (53.9 kDa, 0%LA) and PLEC4 (48.6 kDa, 19.9%LA) depots were evaluated over 56 days as shown in Fig. 3a–b. The color of PCL2 depots considerably changed as time progresses compared to those of PLEC depots. This observation showed a sign of the trypan blue release from depots. It should be noted that the shape and size of PCL2 depots were still intact (Fig. 3a). On the other hand, Fig. 3b clearly showed the slower release of trypan blue from PLEC4 depots even though the shape and size gradually decreased. Polymer degradation study was also performed by GPC. It was found that PCL depots had much lower rate of molecular weight loss than those of PLEC depots. The remaining molecular weight after degradation for 56 days of PCL1, PCL2, PLEC3, and PLEC4 was 82.4, 95.4, 47.9 and 51.9%, respectively. Generally, polyesters such as PLGA, PCL, P(DL)LA have bulk-degradation mechanism where degradation occurs as a result of randomize chain scission taking place throughout the whole samples. For both polymers, high molecular weight polymers were degraded slower than low molecular weight ones. Molecular weight increment was reported to increase the polymer chain entanglement acting as physical crosslink that limit water penetration into polymer matrix, hence decreasing the polymer degradation [7, 25]. The study of hydrophilic and hydrophobic agents released from biodegradable polymers showed the high entanglement points and longer relaxation time of high molecular weight chains. PCL is a semi-crystalline polymer and more hydrophobic than PLEC. These properties lower water absorption and diffusion which subsequently slows down the degradation [21]. Though PLEC depots showed faster molecular weight loss and degradation, the trypan blue release from these depots was much slower than those of PCL. Results from this study show that significant difference in degradation between PCL and PLEC depots was not the major cause for the distinct trypan blue release profiles. Therefore, a more in depth study of depots might prove useful in determining the factors responsible for the different in trypan blue release profiles.

SEM analysis

Degradation study of PCL2 and PLEC4 depots were further analyzed by scanning electron microscopy (SEM). Figure 4 showed that PCL2 depots had rough surface area (Fig. 4a) after preparation compared to smooth surface area of PLEC4 depots (Fig. 4c). For microspheres, it was also reported the rougher surface area and numerous interconnecting networks of semicrystalline polymers while amorphous polymers showed smoother surface areas [26]. Moreover, PCL blend with P(DL)LA was reported to have less interconnecting network, smoother surface areas and denser polymer matrix than PCL homopolymers [27]. Observation at day 14 reveals that roughness and pores started to increase on the surface of both types of depots. Higher extent of degradation was observed in PLEC4 depots as confirmed by the larger pore size and sample size reduction. The effect of trypan blue on the morphology of depots was also studied. Incorporation of trypan blue in depots clearly increased the amount of pores and the extent of degradation in both PCL2 and PLEC4 depots. It should be noted that PLEC4 depots with trypan blue showed a higher degree of porosity and degradation on the surface at day 14 and 28 (Fig. 4h and l) than those without trypan blue.

Changes of surface morphology of polymer depots with degradation over 28 days investigated by scanning electron microscopy (SEM) at day 1 (a–d), 14 (e–h), and 28 (i–l). PCL2 depot images with the magnification of ×600 (a, e, and i) and PCL2 depots with trypan blue with the magnification of ×400 (b, f, and j). PLEC4 depot images with the magnification of ×600 (c, g, and k) and PLEC4 with trypan blue with the magnification of ×400 (d, h, and l)

The cross-sectional morphology of depots was studied by high acceleration 15 kV with low magnification (×60) (Fig. 5) and high magnification (×400) (Fig. 6). At day 0, examination of PCL2 depots revealed a network of interconnecting pores surrounded by polymer framework throughout the samples (Fig. 5a–d). The pores of polymer depots were formed as glycofurol dissipated out while water diffused into polymer matrix [7]. As degradation progressed to day 28 (Fig. 5i and l), spherulites with diameter of 80–200 μm were clearly observed in the middle of depots approximately 500 μm below the surface. On the other hand, PLEC4 depots at day 0 (Fig. 6a–d) had dense cross-section and no pores were observed right after preparation which showed a typical slow phase inversion system. This was attributed to the higher LA content in PLEC4 depots providing lower affinity compared to those of PCL2. This was in agreement with the result from polymer membranes where high affinity between polymer solution and non-solvent media, i.e., water provided high porosity and rough membrane surface. On the other hand, low affinity polymer solution and non-solvent media produced dense and smooth membrane [28]. The difference between the surface and cross-section of PCL2 and PLEC4 depots was presumably due to the difference in these two materials. It was well known that PCL is more hydrophobic than PLEC which provided high affinity of solvent/non-solvent resulting in a rapid phase inversion in aqueous environment. Phase inversion of polymers is the transformation of polymer solution to semi-solid, and solid in aqueous environment (Physiological environment) or so-called liquid-liquid phase separation. The time of phase inversion or gelation rate have direct effect on the porosity of depots. High porosity was formed by a rapid phase inversion caused by high affinity of solvent with non-solvent (aqueous environment) while lower affinity solvent/non-solvent produced less porous and smooth surface areas in semi-solid phase or gel phase [29, 30]. In the study from Kevin J. Brodbeck et al. [30] and Liwei Wang et al. [31], poly(D,L-lactide-co-glycolide) (PLGA) depot containing protein could prolong the release and reduce the burst effect by slower phase inversion. Therefore, the release rate of trypan blue was related to these properties. We suspect that the slow release of PLEC4 depots was caused by the dense and nonporous matrix of PLEC4 depots which trapped trypan blue molecules inside.

Changes of cross-sectional morphology of polymer depots with degradation over 28 days investigated by scanning electron microscopy (SEM) at day 1 (a–d), 14 (e–h), and 28 (i–l). PCL2 depot images with the magnification of ×400 (a, e and i) and ×60 (b, f and j). PCL2 depots with trypan blue with the magnification of ×400 (c, g, and k) and ×60 (d, h and l)

Changes of cross-sectional morphology of polymer depots with degradation over 28 days investigated by scanning electron microscopy (SEM) at day 1 (a–d), 14 (e–h) and 28 (i–l). PLEC4 without trypan blue with the magnification of ×60 (a, e, and i) and ×400 (b, f, and j). PLEC4 with trypan blue with the magnification of ×60) (c, g, and k) and ×400 (d, h, and l)

Cross-section of PLEC4 depots without (Fig. 6a–b, e–f, and i–j) and with trypan blue (Fig. 6c–d, g–h, and k–l) was smooth and nonporous which suggests the slow phase inversion upon contact with water. In contrast, cross-section of PCL2 depots with trypan blue (Fig. 5c–d, g–h, and k–l) showed a lot of pores, the diameter of which were as low as a few micron to large pores with 100 μm in size compared to relatively fine and uniform pore size of those without trypan blue. This characteristic supports the trypan blue release results that the burst and fast release was due to trypan blue stayed near interconnecting pores in PCL depots, while the slow release was caused by entrapment of trypan blue molecules in dense and nonporous matrix.

The amount of pores and pore size of both PCL and PLEC depots increased with time. These pores can produce interconnecting channels through out the samples which could be the path of trypan blue releasing out of the depot. Comparison of surface and cross-section of PCL and PLEC depots clearly showed the heterogeneous degradation pattern. The surface of both depots was comparatively less porous while the extent of cross-section degradation was greater. This suggests slower degradation on the surface than inside the matrix.

Thermal behaviors of polymer depots with trypan blue incorporation

The DSC thermograms of PCL2 and PLEC4 were shown in Fig. 7a. PCL2 had higher melting temperature, melting enthalpy, and crystalline than those of PLEC4 as shown in Table 4. The thermal properties of PCL were decreased when D,L-lactide was introduced as a copolymer [21]. The melting temperature, melting enthalpy and degree of crystallization of PCL2 were 1.4, 2.1 and 2.1-fold higher than those of PLEC4. Thermal property of PCL2 and PLEC4 depots containing trypan blue at 0, 2, 4, 8, 12, and 16% loading were evaluated by DSC as shown in Fig. 7b–c. It should be noted that trypan blue was used in the lyophilized form so the melting enthalpy of trypan blue was observed as a broad range from 80 to 120 °C.

Without trypan blue, PCL depots clearly showed higher crystallinity (53.1%) compared to PLEC depots (28.4%) where the crystallization was decreased by the interruption from D,L-lactide [21, 28]. Polymer depots without trypan blue had Tm and ΔH less than raw polymer materials shown as 0 (polymer) in Table 4. This was due to the plasticizer effect of glycofurol as confirmed by the study of this effect of carbonate propylene on the reduction of the thermal behavior of PCL biodegradable polymer gel electrolytes [32]. With trypan blue, melting enthalpy and crystallinity of both depots were reduced as summarized in Table 4. Trypan blue was probably soluble in amorphous region and blocked polymer chain rearrangement to form crystalline region. In the study of poly(ε-caprolactone) crystallization, the degree of crystallization was reported to be reduced with different compositions such as flour, silk fibroin and poly(ethylene glycol) [33–35]. Increasing trypan blue from 0 to 16%, a 11% reduction in the crystallinity of PLEC4 was observed, while a more pronounced 34% decrease was observed in the crystallinity of PCL2 depots. Moreover, DSC and X-ray diffraction studies of polylactide blended with poly(ε-caprolactone) by electrospinning technique showed that drugs incorporated into polymer blend led to lower crystallinity [36]. The melting temperature of PCL2 and PLEC4 depots were found to fluctuate in the narrow range from 55 to 56 °C and 42–43 °C, respectively. The crystallinity and melting temperature of these depots indicated that the amount of crystalline was reduced while the size distribution of the polymer crystals was probably did not have much effect from the trypan blue incorporation. The PLEC4 depots had comparatively larger amorphous region than those of PCL2 that could accommodate trypan blue molecules and had less interruption of the formation of crystalline. The reduction of crystallinity as a result of trypan blue was also confirmed by a dramatic decrease in the number of spherulites in PCL2 depots containing trypan blue as evaluated by SEM (Fig. 5i–j).

Conclusion

This research described the development of injectable polymeric depots from D,L-lactide, ε-caprolactone and poly(ethylene glycol) or PLEC. PLECs were successfully synthesized in two molecular weights, 20 and 50 kDa which had varied D,L-lactide contents at 0, 10 and 20% w/w. This system used glycofurol as a biocompatible solvent to form solid depots with high encapsulation efficiency and loading density. Trypan blue release rate was found to be in proportion to trypan blue loading. Even though the molecular weight loss and degradation study of PCL depots were much slower than those of PLEC, trypan blue release rate from depots was found to be in proportion to the amount of ε-caprolactone. Burst release observed in PCL depots was reduced, and disappeared in depots with 10 and 20% LA contents, respectively. Closer observation by SEM revealed that surface and cross-section of PCL depots with and without trypan blue had rough and porous compared to dense and smooth surface and cross-section of PLEC depots. This suggests a possible role for surface and cross-section characteristics in controlling the trypan blue release. This study provides significant information of formulation variables that have an effect on burst release and release profiles of trypan blue from depots.

References

Dang W, Daviau T, Brem H (1996) Pharm Res 13:683–691

Qian F, Nasongkla N, Gao J (2002) J Biomed Mater Res 61:203–211

Chen W, He J, Olson JJ, Lu DR (1998) Drug Deliv 5:101–110

Menei P, Venier MC, Gamelin E, Saint-Andre JP, Hayek G, Jadaud E, Fournier D, Mercier P, Guy G, Benoit JP (1999) Cancer 86:325–330

Menei P, Daniel V, Montero-Menei C, Brouillard M, Pouplard-Barthelaix A, Benoit JP (1993) Biomaterials 14:470–478

Zare M, Mobedi H, Barzin J, Mivehchi H, Jamshidi A, Mashayekhi R (2007) J Appl Polym Sci 107:3781–3787

Rom EE, Joseph K (2000) J Biomed Mater Res 50:388–396

Zhao SP, Xu WL (2010) J Polym Res 17:503–510

Weinberg BD, Patel RB, Wu H, Blanco E, Barnett CC, Exner AA, Saidel GM, Gao J (2008) Med Bio Eng Comput 46:1039–1049

Boongird A, Nasongkla N, Hongeng S, Sukdawong N, Sa-Nguanruang W, Larbcharoensub N (2011) Exp Biol Med 236:77–83

Nasongkla N, Boongird A, Hongeng S, Manaspon C, Larbcharoensub N (2011) J Mat Sci: Mat Med doi:10.1007/s10856-011-4520-3

Eliaz RE, Szoka FC (2002) Gene Therapy 9:1230–1237

Nair L, Laurencin C (2006) In: Lee K, Kaplan D (eds) Tissue engineering I. Springer, Berlin

Garlotta D (2001) J Polym Environ 9:63–84

Nasongkla N, Shuai X, Ai H, Weinberg BD, Pink J, Boothman DA, Gao J (2004) Angew Chem Int Ed 43:6323–6327

Astaneh R, Moghimi HR, Erfan M, Mobedi H (2006) Daru 14:65–70

Zhang Y, Wang C, Yang W, Shi B, Fu S (2005) Colloid Polym Sci 283:1246–1252

Crescenzi V, Manzini G, Calzolari G, Borri C (1972) Eur Polym J 8:449–463

Shen Y, Sun W, Zhu KJ, Shen Z (2000) J Biomed Mater Res 50:528–535

Coombes AGA, Rizzi SC, Williamson M, Barralet JE, Downes S, Wallace WA (2004) Biomaterials 25:315–325

Cho H, An J (2006) Biomaterials 27:544–552

Wang X, Wang Y, Wei K, Zhao N, Zhang S, Chen J (2009) J Mater Process Technol 209:348–354

Hu Y, Jiang X, Ding Y, Zhang L, Yang C, Zhang J, Chen J, Yang Y (2003) Biomaterials 24:2395–2404

Yamazaki S, Gu F, Watanabe K, Okada K, Toda A, Hikosaka M (2006) Polymer 47:6422–6428

Hatefi A, Amsden B (2002) J Control Release 80:9–28

Zhu KJ, Li Y, Jiang HL, Yasuda H, Ichimaru A, Yamamoto K, Lecomte P, Jerome R (2005) J Microencapsul 22:25–36

DesNoyer JR, McHugh AJ (2001) J Control Release 70:285–294

TaYB P (2009) Trends Appl Sci Res 4:107–115

Graham PD, Brodbeck KJ, McHugh AJ (1999) J Control Release 58:233–245

Brodbeck KJ, DesNoyer JR, McHugh AJ (1999) J Control Release 62:333–344

Wang L, Venkatraman S, Kleiner L (2004) J Control Release 99:207–216

Fonseca CP, Cavalcante FJ, Amaral FA, Souza CAZ, Neves S (2007) Int J Electrochem Sci 2:52–63

Wu C-S (2004) J Appl Polym Sci 94:1000–1006

Srisa-Ard M, Baimark Y, Srisuwan Y (2008) J Applied Sci 8:3518–3522

Sun JR, He CL, Zhuang XL, Jing XB, Chen XS (2011) J Polym Res 18:2161–2168

del Valle LJ, Camps R, Diaz A, Franco L, Rodriguez-Galan A, Puiggali J (2011) J Polym Res 18:1903–1917

Acknowledgements

This work was supported by Mahidol University for Norased Nasongkla. Financial support for Wannarong Khamlao from the Center of Excellence for Innovation in Chemistry (PERCH-CIC), Commission on Higher Education, Ministry of Education is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khamlao, W., Hongeng, S., Sakdapipanich, J. et al. Preparation of self-solidifying polymeric depots from PLEC-PEG-PLEC triblock copolymers as an injectable drug delivery system. J Polym Res 19, 9834 (2012). https://doi.org/10.1007/s10965-012-9834-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9834-4