Abstract

In this study, the effects of thermo-mechanical processes on the 110 K phase of Bi2−x Pb x Sr2Ca2Cu3O y (x = 0.3–0.6) superconductors have been studied. In order to investigate the effects of thermo-mechanical processes, the samples were prepared in three groups with different sintering temperatures having intermediate grindings and pressings. The superconducting and structural properties of BPSCCO system were characterized by R(T), χ(T), and J c measurements; XRD; and SEM analysis. The thermo-mechanical processes were investigated to explain how they affect T c and metallic properties of the samples. According to the analysis, we obtained that the 110 K phase of BPSCCO samples was significantly affected by these thermal and mechanical processes. The preparation conditions were optimized in order to obtain a BPSCCO system having dominant phase of 110 K with the superior superconducting properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Among the various HTS materials, Bi(Pb)-Sr-Ca-Cu-O was considered as a very interesting material for various reasons, in particular for their rather high T c and high J c values. In Bi2Sr2Ca n−1Cu n O2n + y (BSCCO), three superconducting phases are commonly observed. These phases are Bi-2201 (n = 1), Bi-2212 (n = 2) and Bi-2223 (n = 3) having transition temperatures of 20, 85 and 110 K, respectively [1, 2]. The Bi-2223 phase is the most attractive one among the others, because it has the highest superconducting transition temperature, T c. Since the discovery of Bi2223 superconductor, great progress has been achieved in enhancing transport properties of this high- T c superconductor [1]. However the intergrain weak links and weak flux pining capability are the major limitations for superconductor applications of the Bi2223 system. In order to overcome these problems, there are many research have been done for the introduction of crystal defects that are on the order of the coherence length and provided satisfactory advantages for the applications [3, 4]. Starting composition, sintering time and intermediate grinding also affect critical current density significantly, because they influence microstructure and weak link profile, which strongly change its superconducting properties [5]. In our previous work [6] we have shown that the quality of electrical and structural properties of Bi-2223 bulk superconductors strongly depends on the compaction pressure during pellet formation. Compaction of bulk samples at 400 MPa produces textured grain alignment and causes microstructural modifications which enhances flux pinning and thus increases current carrying capacities.

There has been intense research on finding ways to enhance the growth of (2223) phase. For this reason, different methods are used such as doping Pb [7] and vanadium atoms [8] and adjustment of thermal treatment [9] in order to obtain a material, which has a homogeneous single phase and a high transition temperature value.

In this study, the effects of thermo-mechanical processes on the 110 K phase of Bi2−x Pb x Sr2Ca2Cu3O y (x = 0.3–0.6) superconductors have been studied. In order to investigate the effects of thermo-mechanical processes, the samples were prepared in three groups with different sintering times at 845 °C having intermediate grindings and pressings. The characterization of the samples was carried out by AC susceptibility, resistance-temperature (R–T), critical current density-magnetic field (J c–B), SEM, and XRD measurements.

2 Experimental Details

The bulk ceramic samples used in this study were prepared by a conventional solid-state reaction method. Bi2O3 (99.99 %), SrCO3 (99.99 %), CaCO3, CuO (99.99 %) and PbO (99.999 %) chemical powders were used as a starting materials. The powders with a molar ratio of [Bi]:[Pb]:[Sr]:[Ca]:[Cu] = 2 − x:x:2:2:3 were mechanically well mixed for 1 h in age mortar and then were calcined twice at 820 °C for 24 h. The calcined material was reground and pressed into pellets of 10 mm in diameter with a pressure of 400 MPa. The samples which were sintered at 845 °C for 120 h will be referred as group A. Some of the pellets were sintered at 845 °C for 60 h. These samples were denoted as group B. The third group of the samples which were sintered at 845 °C for 120 h with two intermediate grindings will be referred as group C.

The electrical resistance measurements were made by passing 1 mA dc current through the contacts in a four-probe configuration. The contacts were made by using silver paste. The temperature of the samples was monitored by using a calibrated Pt thermometer from Lakeshore. For critical current (I c) versus applied magnetic field (B) measurements, bulk samples were cut into rectangular bars from pellets and were thinned. The J c–B measurements were made by using fourprobe methods at 77 K, and contacts were made by using silver paste. For the critical current 1 μV/cm criterion was employed. For low magnetic fields a copper wire solenoid was used. The field direction was kept perpendicular to measuring current direction.

The AC complex magnetic susceptibility (χ′ + i χ″) of the samples was measured by a mutual inductance bridge, using a two phase SR530 model lock-in amplifier to pick up in-phase and outof-phase signals of the secondary coils. X-ray diffraction patterns of the samples were obtained with Rigaku D. Max. 3CXRD by using monochromatic CuK α radiation in the 2θ = 3−60° range. SEM photographs for the study of surface morphology of the samples were obtained by using a XL 30S FEG SEM.

3 Results and Discussions

We performed electrical resistance measurements as a function of temperature between 80 and 130 K to investigate the effect of Pb substitution and thermo-mechanical processes on the superconducting properties of the Bi2−x Pb x Sr2Ca2Cu3O y (x = 0.3–0.6) samples. The variation of the R–T curve depending on the Pb content denoted as group A samples is shown in Fig. 1a. According to the R–T curves, all samples have shown a metallic character above the onset temperature and the superconducting transition temperature for all samples have varied between 100 and 101 K. The sharpest transition was obtained for the sample with x = 0.50.

The resistance of the group B samples as a function of the temperature is shown in Fig. 1b. A maximum zero-resistance temperature of 101 K was obtained for doped sample (x = 0.50) with an onset temperature at 111 K. The transition curves indicate two-step (double step) transitions, which is an indication of two phases present except for the samples with x = 0.50 and it is related to a structural phase transformation. We believe that the double step resistive transition is an indication of weak links in the samples.

Figure 1c shows the results of resistance measurement of group C samples with a Pb content of x = 0.3, x = 0.35, x = 0.40, x = 0.45, x = 0.50, and x = 0.60, as a function of temperature. The onset temperature, T c (onset), values for these samples were all measured as 110 K. The zeroresistance temperature, T c, for the samples shows a variation between 100 and 101 K. All group C samples exhibited a metallic behavior in a normal state (up to T c onset). In addition, the samples (x = 0.50) of group A and group C showed a very narrow transition width indicating a single superconducting transition. The reduction of ΔT c may be caused by the increase in the contact area between the superconducting grains.

AC magnetic susceptibility versus temperature and magnetization measurements of the samples were carried out by a twophase SR530 model lock-in amplifier to pick up in-phase and out-of-phase signals of the secondary coils. Measurements were done at the fixed applied magnetic field amplitude of B = 185 A/m and at the fixed frequency of 1 kHz. The measurement of complex AC magnetic susceptibility is widely used as a nondestructive method for the determination and characterization of the intergrain component in the polycrystalline hightemperature superconductors [10–12]. At the bulk high-temperature superconductors, AC magnetic susceptibility measurements show two kinds of signals for intergrain and intragrain responses [13]. The real part (χ′) provides information on the diamagnetic behavior and the imaginary part (χ″) displays the features of the coupling effect of the grains in the hightemperature superconductor.

Figure 2a–c shows the temperature variation of AC magnetic susceptibility for all groups (A, B and C) of samples. The diamagnetic transition temperature (T con) was obtained at about 107 K for the Pb doped samples with x = 0.30, x = 35, x = 0.40, x = 0.45, and x = 0.50 (Fig. 2a). Although the diamagnetic transition temperature shifted to 105 K for the Pb doped samples with x = 0.30 and x = 0.60, the strongest diamagnetic behavior was observed for the group A (x = 0.5) sample. The real (χ′) and imaginary (χ″) parts of the AC magnetic susceptibility for the group B samples are shown in Fig. 2b, which indicates that the diamagnetic transition temperatures showed a variation in values with Pb concentration. It is clear from Fig. 2b that as the Pb concentration increases up to x = 0.5, the peak of χ″ shifts to higher temperatures and then sharpens. Figure 2c shows the temperature dependencies of real and imaginary parts of AC susceptibility for the group C samples. It can be seen from curves that, while the superconducting transition temperature of the grains, T c, is almost the same for all samples, the intergranular diamagnetic transition temperatures T c, are slightly affected by Pb doping. These results suggest that the intergranular coupling between grains is enhanced by increasing the thermo-mechanical processing.

The critical currents of all samples were resistively measured at 77 K using 1 μV/cm criteria, and the critical current densities of the samples were calculated as 55 A/cm2 for the group A sample (x = 0.50), 33 A/cm2 for the group B sample (x = 0.50), and 105 A/cm2 for the group C sample (x = 0.50). As shown in Fig. 3a–c, the normalized critical current density, J c(B)/ J c(0), is plotted against the magnetic field, B, at 77 K. It was found that a strong increase of J c was obtained for the group C samples. The maximum critical current density is 105 A/cm2 for the group C Pb-doped sample with x = 0.5. This sample showed the slowest J c drop under the applied magnetic field. This means that the thermo-mechanical processing plays an important role in texturing mechanism and quality of intergranular parts of the samples.

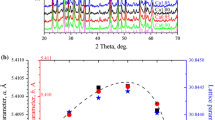

The XRD patterns of all samples (groups A, B, and C) for various thermo-mechanical processes are shown Fig. 4a–c. The diffraction patterns correspond mainly to the 2212 and 2223 phases with orthorhombic and tetragonal structures, respectively. The characteristic H(002) and L(002) peaks were observed at 2θ = 4.7° and 2θ = 5.7°, respectively, for the group C samples with different intensities. The intensity of the 2223 phase increased with increasing intermediate grinding and with increasing sintering time from 60 to 120 h at 845 °C.

SEM micrographs for samples A, B, and C display compacted layers of thin flaky plate-like grains with random distribution (Fig. 5a–c). The average grain size is approximately 6 μm. In the group B samples we can see the deformation in crystal structure. However, the grains became well aligned at 120 h sintering with two intermediate grindings as compared to the other samples, and thus, the connectivity between the grains was enhanced. This shows us that the thermo-mechanical processes improve the grain and grain boundary structure up to a certain degree, thus improving the superconducting properties, and hence give higher critical current densities.

4 Conclusions

In this study, we investigated the effect of Pb doping and thermo-mechanical process on the superconducting and transport properties of Bi2−x Pb x Sr2Ca2Cu3O y (x = 0.3–0.6) superconductors. The polycrystalline Pb-doped BSCCO samples were synthesized using a solid-state reaction method with different thermo-mechanical processes. The structural phase evolution, microstructural changes, and superconducting critical temperatures in the samples are clearly affected by the sintering time and intermediate grinding. The samples sintered at 845 °C for 120 h with two intermediate grindings showed good crystallinity with a high content of the 2223 phase and exhibited a higher T c. Among the samples, the group C sample (x = 0.50) exhibited the strongest intergranular coupling and, hence, the largest critical current density, which is an important parameter for a high-temperature superconductor.

References

Maeda, H., Tanaka, Y., Fukutomi, M., Asano, T.: Jpn. J. Appl. Phys. 27, L209 (1988)

Muralidhar, M., Satyavathi, S., Babu, V.H., Pena, O., Sergent, M.: J. Mater. Sci. Eng. B20, 312 (1993)

Neumüller, H.W., Gerhäuser, W., Ries, G., Kummeth, P., Schmidt, W., Klaumünzer, S., Saemann-Ischenko, G.: Cryogenics 33(1), 14 (1993)

Pate, R.H., Nabialek, A., Niewczas, M.: Supercond. Sci. Technol. 18, 317 (2005)

Tepe, M., Avcı, I., Kocoglu, H., Abukay, D.: Solid State Commun. 131, 319 (2004)

Tepe, M., Avcı, I., Abukay, D.: Phys. Status Solidi (a) 198(2), 420 (2003)

Takano, M., Takada, J., Oda, K., Kitaguchi, H., Ike, Y., Tomii, Y., Mazaki, H.: Jpn. J. Appl. Phys. 27, L1041 (1988)

Tepe, M., Abukay, D.: Solid State Commun. 108, 613 (1998)

Kameli, P., Salamati, H., Eslami, M., Akhavan, M.: Phys. Stat. Sol. (c) 3(9), 3011–3014 (2006)

Nikolo, M., Goldfarb, R.B.: Phys. Rev. B 39, 6615 (1988)

Khoder, A.F., Couach, M., Barbara, B.: Physica C 153–155, 1471 (1988)

Mel, Y., Luo, H.L.: J. Appl. Phys. 64, 2533 (1989)

Goldfarb, R.B., Lelental, M., Thompson, C.D.: Magnetic Susceptibility of Superconductors and other Spin System (Edited by R. A. Hein et al.), p 49. Plenum, New York (1991)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tepe, M., Baytosun, F. Effects of Thermo-Mechanical Processes in the 110 K Phase of Bi2−x Pb x Sr2Ca2Cu3O y (x = 0.3–0.6) Superconductors. J Supercond Nov Magn 30, 3565–3572 (2017). https://doi.org/10.1007/s10948-016-3743-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3743-4