Abstract

A novel carbon aerogel with network pore and surface group of hydroxyl was prepared from cellulose colloid, through sol-gel reaction, freeze-drying and carbonization. Surfactant like isooctyl alcohol ether phosphate was taken as structure inducer in sol-gel reaction, for construction of porous network in the prepared samples. Characteristic of a specific area about 725.12 m2/g and total pore volume about 0.64 cm3/g, the prepared cellulose-based carbon aerogel of CCA2, has a maximum capacity about 55.25 mg/g for Cu2+ in neutral aqueous solution. Its adsorption equilibrium can be reached within 10 min in an aqueous solution of pH7.0 at 25 °C, while desorption of Cu2+ need about 1 h eluted by HCl or HNO3 solution of 0.01 M. And regeneration of the carbon aerogel in adsorption of Cu2+ can be repeated for five times, remaining 96% adsorption capacity. It is also found in adsorption process the kinetics nicely follows pseudo-second-order rate expression, and the isotherm fits Langmuir model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With rapid development of industries like electroplating, mining, electrical and electronics production, more and more copper ion were discharged into outdoor water, which has become a prominent environmental problem. The discharged copper ion is recalcitrant and can be accumulated in the environment and living tissues, while a high concentrations intake of copper ion in human body will cause serious diseases and disorders. At present, the main methods to remove toxic metal ions from water are adsorption, membrane separation, and ions exchange etc. Adsorption is widely adopted due to its simplicity, low cost and effectiveness, and many researchers keep doing their efforts to develop the lower cost and more effective adsorbent for treating metal ion pollution in aqueous solution [1–3].

Porous materials like active carbon or zeolite have been used as adsorbents to adsorb heavy metal ions or other toxic chemicals for many years [4–6]. Recently, more and more novel porous materials, such as inorganic, polymers, biological, and carbon-based porous materials, have been studies to deal with heavy metal ions in aqueous solution [7, 8]. Among them, carbon-based adsorbents have received increasing attention because of their excellent properties such as chemical inertness, mechanical stability, homogenous components, low contaminant content and innoxiousness [9, 10].

Micropore in the adsorbent can only adsorb small molecules while mesopore or macropore can transport small molecules or adsorb large molecules; and chemical groups on the absorbent surface will function as specific sites for chemical adsorption of metal ion in solution. So, the surface chemical groups and porous structure of adsorbent may decide the transport or adsorption of adsorbate in adsorbent, according to the molecule size and chemical structure of adsorbate.

In order to prepare an effective carbon absorbent, numerous studies have been carried out, such as generating micropores into the wall of mesopores, modification of porous surface. However, it is still a great challenge to synthesize porous carbons with porous network structure and functional groups on the surface [11–13].

Here we developed a novel cellulose-based carbon aerogel with network pore and surface group of hydroxyl through sol-gel reaction, freeze-drying and carbonization process. The prepared sample has an adsorption capability of Cu2+about 55.25 mg/g, implying it may be a potential adsorbent for toxic metal ion in water solution.

2 Materials and methods

2.1 Materials

Microcrystalline cellulose (MCC),Sodium hydroxide (NaOH, 96%), Urea (CO(NH2)2, 99%) and Copper(II) sulfate pentahydrate (CuSO4·5H2O, 99%) were purchased from Sinophrm Chemical Reagent Co., Ltd. Isooctyl alcohol ether phosphate (oep-70) was procured from Shang Hai Beko Chemical Co., China. All reagents used in the experiment were analytical reagent grade and used as received. Deionized water was used for all experiments.

2.2 Preparation of carbon aerogel

In a typical synthesis, NaOH and urea were dissolved into deionized water under −12 °C at a mass ratio of 7:12:81, which was prepared as a mother solution. 4 g of microcrystalline cellulose and 3 g of NaCl were added into 100 ml of the prepared mother solution stirring vigorously for 10 min, then surfactant of isooctyl alcohol ether phosphate (oep-70) was added into the mixture at a ratio like 2% (w/v), stirred to obtain a homogenous solution. The mixture solution was subjected to centrifugation at 5000 rpm for 10 min under 5 °C; the supernatant was transferred to a beaker under 50 °C for sol-gel reaction about 24 h. The solidified cellulose jell was washed with deionized water, following freeze-dried under −55 °C for 48 h, so that the cellulose aerogels were obtained and denoted as CAx, where x indicates the percent of oep-70 added in sol-gel reaction. The prepared CAx was heated to 600 °C in nitrogen air at a heating rate of 2 °C/min and kept at 600 °C about 2 h for carbonization; finally carbon aerogels were obtained and denoted as CCAx.

2.3 Characterization of the prepared samples

Thermal stability and carbonization yield of cellulose aerogel (CAx) were determined using thermo-gravimetric (TG) analyzers (GA; STA449C; Netzsch, Germany). The specific surface area and pore structure parameters of the prepared carbon aerogel (CCAx) were determined from the adsorption isotherm of nitrogen at 77 K (Tri-star 3020, Micromeritic, USA). The morphology of carbon aerogel was observed by scanning electron microscopy (Hitachi S4800, Japan). The chemical group on the surface of CCAx was determined by Fourier transform infrared (FTIR) spectroscopy (IRAffinity-1, Japan).

The concentration of the Cu2+ in the aqueous solution was then analyzed by UV spectrophotometer (Hitachi U-3010) according the method in reference [14]. The amount of Cu2+absorbed Q t (mg/g) at time t (min), were calculated as follows:

where C 0 (mg/l), C t (mg/l) are Cu2+ concentrations of the solution at the initial and final adsorption, respectively. V (ml) is the volume of the solution, and m (g) is the weight of the dry CCAx.

The pH of the tested solution can be adjusted by hydrochloric acid with a concentration of 0.01 M.

3 Results and discussion

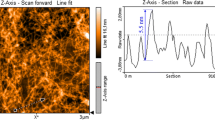

The optimal temperature for sol-gel reaction of cellulose colloid is about 50 °C in our experiment. When reaction temperature is lower than 50 °C, the gelation of cellulose colloid will be hold up greatly; when reaction temperature is higher than 50 °C, it will result the prepared cellulose gel with huge capillaries that will become cracks in the prepared cellulose aerogel after freeze-drying. In our experiment, cellulose gelation can be completed within 30 min as shown in Fig. 1.

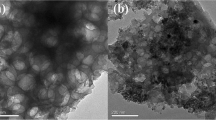

After gelation reaction and freeze-drying, the cellulose gel turned to cellulose aerogel as Fig. 2a shown. The cellulose aerogel formed without cracks can turn to a monolith of carbon aerogel through carbonization as Fig. 2b shown, in which a network pore was remained from its precursor cellulose aerogel. But the cracks in cellulose aerogel will cause the prepared carbon aerogel collapse and broken during the carbonization process.

Thermo-gravimetric analysis of different cellulose aerogel prepared in our experiment is shown in Fig. 3. It can be seen that the cellulose aerogel prepared without oep-70 inducing structure, having its pyrolysis reaction in a temperature range from 250 to 380 °C, gives a final carbon yield about 7.5%; while the cellulose aerogels prepared with oep-70 inducing structure, having their pyrolysis reactions in a temperature range from 250 to 340 °C, give a carbon yield range from 15 to 22% which depends on the percent of oep-70 in the cellulose sol-gel reaction. Since cellulose aerogel with a high degree of polymerization will give a higher carbon yield, it may be thought besides serving as structure inducer there should be some roles of oep-70 in the sol-gel reaction, such as knitting the assembly cellulose molecular into cross-link state and making them ultimately polymerize to aerogel with a three-dimensional network.

Since oep-70 is adaptive to alkalic solution and has a required molecular structure, it was used as structure inducer in sol-gel reaction of cellulose colloid, to form a network pore in the prepared cellulose aerogel. And the porous network in cellulose aerogel can remain into carbon areogel after carbonization. It can be seen from Fig. 4a, the porous structure is very poor in the carbon aerogel prepared from cellulose aerogel without oep-70 inducing the porous structure. While a cross-linked pore network is well formed in the carbon aerogel prepared from cellulose aerogel that was induced by ope-70 at a ratio of 2% as shown in Fig. 4b. But, the inner skeleton of carbon aerogel will increase with the percent of oep-70; the wall framework becomes thicker and pore volume become small when the percent of oep-70 is over 4%, which can be seen in Fig. 4 (C).

It can be seen in Table 1 that porous structure of the prepared CCAx is strongly depending on the percent of oep-70. CCA2 has an optimal porous structure for Cu2+ adsorption and gives the highest capacity of 55.24 mg/g in the neutral solution. As a contrasted material in our study, active carbon with the largest specific surface area about 2729.8 m2/g and a majority of micropore, but gives a lower adsorption capacity of Cu2+ about 43.28 mg/g in the neutral solution. So, it may be concluded CCA2 has some advantage properties for adsorption of Cu2+ in the neutral aqueous solution, such as porous structure and surface group.

Adsorption–desorption isotherm of nitrogen on CCAx at 77 K are shown in Fig. 5a(1). It can be seen that sharp inflection points are present at a low relative pressure of about 0.1, showing the transition from micropore filling to multilayer adsorption; then a slow isotherm rise following next indicates multilayer adsorption of nitrogen on the exposed surface of the fibrous network in carbon aerogels, on which unrestricted monolayer-multilayer adsorption occurs. A hysteresis loop exhibits relative high pressure, indicating the dominance of mesopores and macropores in the sample.

From the pore size distribution of CCAx shown in Fig. 5b(1), it can be seen that a mixture of micropore, mesopore and macropore is present in CCA2, which may benefit CCA2 for absorbing metal ion in aqueous solution, since adsorption in micropore need to be based on channeling or transitional function of mesopore and macropore.

The adsorption equilibrium of CCA2 can be achieved within 10 min, absorbed 90% of Cu2+ in the solution. The rapid uptake indicated high affinity between Cu2+ and the adsorbent, which may be explained as the interconnected porous structure and the chemical groups on the surface of CCA2 facilitate channels and active sites for metal ion adsorption. Since carbon aerogel can remain some chemical group from its precursor [15], the chemical groups on CCAx were determined by the FTIR spectrum, which are similar as that of CCA2 shown in Fig. 6. The peaks observed at 1200 cm−1 may be assigned to C–O bond stretching, and the peaks around 1600 cm−1 may be characteristics of C=C bond. The broad adsorption peaks from 3705 to 3125 cm−1 can confirm –OH groups on the sample. These residual chemical groups on CCA2 after carbonization can increase the net negative charge on the surface, and increase the binding potential to cationic ion in the solution.

The maximum adsorption capacity of Cu2+ on CCA2 was obtained at pH 7.0, and no adsorption was observed in the solution with a pH lower than 3.0, adjusted by hydrochloric acid solution with concentration of 0.01 M. This indicated the absorbed Cu2+ on CCA2 can be completely replaced by the protons in solution. So, desorption of copper ions from CCA2 was achieved by eluting with 0.01 M HCl or HNO3 about 1 h. After five cycles of adsorption–desorption of Cu2+ on CCA2, the maximum adsorption capacity of Cu2+ on CCA2 has slightly reducing about 4%.

Isotherms can show the relationship between metal ion concentration in solution and the amount of metal ion adsorbed on the specific sorbent at a constant temperature. In the present study, the adsorption experimental data of Cu2+ adsorption were analyzed according to Langmuir isotherm equation and Freundlich adsorption model [16, 17]. It was found that Langmuir model fits the experimental data very well with a correlation coefficient R2 of 0.97, which is much better than that of Freundlich model with R2 of 0.91, as shown in Fig. 7. The adsorption capacity calculated values obtained from Langmuir model is about 59.13 mg/g, which is very close to the experimental data of 55.24 mg/g. These results indicate Cu2+ adsorbed on CCA2 as a monolayer adsorption.

Adsorption kinetic studies are thoroughly studied due to their importance on the investigation of the adsorption mechanism. The pseudo-first-order and pseudo-second order kinetic models are employed to fit experimental data obtained from kinetic experiments [13, 18]. These two models can be expressed as Eqs. (2) and (3).

where Q t (mg/g) is the adsorption capacity at time t (min), Q e (mg/g) is the adsorption capacity at adsorption equilibrium, k 1 (min−1) and k 2 (g/mg/min) are the kinetics rate constants for the pseudo-first-order and pseudo-second-order models, respectively.

Parameters of these two kinds of model are shown in Table 2. It was found that the adsorption capacity at equilibrium Q e,cal that was calculated from the pseudo-first-order model is about 7.16 mg/g, deviating from the experimental value Q e of 9.53 mg/g with a correlation coefficient R2 only 0.5552. While Q e,cal calculated from pseudo-second-order model is about 8.94 mg/g, which is very close to the experimental Q e with R2 about 0.9984. These data suggest Cu2+ adsorption on the CCA2 may be a pseudo-second-order kinetic model, which means chemisorption is the rate-limiting step in the adsorption of Cu2+ on the CCA2.

4 Conclusions

By skills of sol-gel reaction, freeze-drying and carbonization, a novel carbon aerogel with hydroxyl groups on the surface was synthesized as adsorbent for adsorption of metal ion in water. The porous network of the prepared carbon aerogel was inherited from its mesophase of cellulose aerogel, which depends on the surfactant like oep-70 added to cellulose colloid as structure inducer in sol-gel reaction. The prepared CCA2 displays good properties for adsorption of Cu2+ in aqueous solution, implying it may have potential application in treatment of metal ion pollution in water. The strategy in this study also provides a novel pathway for preparing carbon-based adsorbent with specific pore structure and functional groups on the surface.

References

S. Hokkanen, A. Bhatnagar, M. Sillanpää, Water. Res. 91, 156 (2016)

L. Chen, Y. Shuang, Y. Tong, C.F. Zeng, C.Q. Wang, L.X. Zhang, J. Porous Mater. 22, 1263 (2015)

M.X. Tan, Y.N. Sun, J.Y. Ying, Y.G. Zhang, Energy Environ. Sci. 6, 3259 (2013)

S. Cataldo, A. Iannì, V. Loddo, E. Mirenda, L. Palmisano, F. Parrino, D. Piazzese, Sep. Purif. Technol. 171, 111 (2016)

A. Cincotti, A. Mameli, A.M. Locci, R. Orru, G. Cao, Ind. Eng. Chem. Res. 45, 1084 (2006)

W. Qiu, Y. Zheng, Chem. Eng. J. 145, 488 (2009)

Y.G. Ko, H.J. Lee, H.C. Oh, H.C. Oh, U.S. Choi, J. Hazard. Mater. 260, 497 (2013)

Ihsanullah, A. Abbas, A.M. Al-Amer, T. Laoui, M.J. Al-Marri, M.S. Nasser, M. Khraisheh, M.A. Atieh, Purif. Technol. 157, 161 (2016)

Z.Z. Huang, G.Q. Chen, G.M. Zeng, A.W. Chen, Y.N. Zuo, Z. Guo, Q. Tan, Z.X. Song, Q.Y. Niu, J. Hazard. Mater. 289, 183 (2015)

Z. Han, Z.H. Tang, S.L. Shen, B. Zhao, G.P. Zheng, J.H. Yang, Sci. Rep. 4, 6 (2014)

P. Veselá, V. Slovák, J. Anal. Appl. Pyrol. 109, 271 (2014)

W. Maatar, S. Bouf, Carbohyd. Polym. 126, 207 (2015)

M.J. Baniamerian, S.E. Moradi, A. Noori, H. Salahi, Appl. Surf. Sci. 256, 1354 (2009)

M.P.S. Andres, M.L. Marina, S. Vera, Analyst 120, 259 (1995)

J.Z. Wang, M.M. Chen, C.Y. Wang, J. Wang, J.M. Zheng, Mater. Lett. 68, 449 (2012)

Q. Wu, W. Li, S. Liu, Mater. Res. Bull. 60, 523 (2014)

S.B. Deng, Y.P. Ting, Langmuir 21, 5948 (2005)

M.A. Tofighy, T. Mohammadi, Mater. Res. Bull. 68, 59 (2015)

Acknowledgements

This work was supported by open fund from Key Laboratory of spray deposition technology and application in Hunan Province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Zheng, L. & Liu, H. A novel carbon aerogel prepared for adsorption of copper(II) ion in water. J Porous Mater 24, 1575–1580 (2017). https://doi.org/10.1007/s10934-017-0397-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-017-0397-y