Abstract

In this study, we developed the ZnO aerogel through dispersed inorganic sol–gel method using citric acid as template, which employed the properties of high apparent specific surface areas. According to the results demonstrated by nitrogen adsorption/desorption and field-emission scanning electron microscope measurements, the aerogel produces extremely porous and homogenous material and monolithic mesoporous materials featuring high surface areas (122 m2/g). The thermal stability is investigated through TGA and FTIR, respectively. When the temperature reaches up to 500 °C, all the organic absorption peaks disappear and only ZnO emerges. In summary, the attractive properties of the aerogel promote the potential applications of their nanostructures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Aerogels are nanoporous materials with interconnected nanoscale pores, advantages of which include ultra-low density, large specific surface area and high porosity [1–4]. Besides, aerogels are also known for a variety of competitive properties and applications, including superinsulation, energy, catalysis, chemical sensors, biomedicine, and space [5–8]. Among above-mentioned aerogels, metal oxide aerogels possess remarkable potential applications in fuel cells, photocatalysis, gas sensors, dielectric materials and so on [1, 2, 9]. Gash et al. [10–12] firstly reported the use of epoxides as gelation agents to prepare metal oxide aerogels and xerogels from simple metal inorganic salts. Furthermore, Du et al. [13] modified the method by adopting polyacrylic acid as the template, which was then be named as dispersed inorganic sol–gel method (DIS method). Recently, the preparations of monolithic ZnO aerogel have been reported [14–17]. The monolithic ZnO aerogel was synthesized with the cost-effective zinc nitrate as the sol–gel precursor, but Gao et al. [14] did not conduct sufficient investigations on important chemical and physical changes of the thermal treatment process, which influences the final product significantly. Krumm et al. [15] successfully synthesized highly porous ZnO from expensive organometallic sol–gel precursors, and the ZnO aerogel was shown for application in photocatalysis. However, the preparation was greatly challenging and time-consuming. Chen et al. [16, 17] prepared the ZnO gels via DIS method with ZnCl2 as the sol–gel precursor. The as-synthesized monolithic pure ZnO aerogels exhibited many desirable properties such as high porosity, specific surface area, good crystallinity and unique photoluminescence.

Nowadays, with the developments in nanotechnology and the discovery of various diverse quantum size effects in nanoscale particles, nanomaterials are promising for many novel devices. Many advanced nanodevices will eventually need a three-dimensional assembly of nanoblocks with irregularly or periodically interconnected architectures. To meet the requirements of these applications, the as-synthesized monolithic pure ZnO aerogels should have many desirable properties such as uniform nanoscale pores, high porosity and big specific surface area. Therefore, the preparations of monolithic ZnO aerogels would be extended. As far as we know, there are few works on preparing the three-dimensional ZnO aerogel through DIS method with ZnCl2 and citric acid as the sol–gel precursor. In our work, we presented preparation of monolithic ZnO aerogel and subsequent thermal treatment. The sol–gel processing was moderated by using cost-effective ZnCl2 and time was shortened. The results were different from the reported nanostructures of ZnO aerogels. The desirable properties of ZnO aerogels are beneficial for new generations of nanoscale electronics and photonics.

2 Experimental

2.1 Preparation

In a typical dispersed inorganic sol–gel method, 0.03 mol ZnCl2 (Kelong, AR) was dissolved in a mixture of 15 mL ethanol and 5 mL deionized water. During stirring, 2 g citric acid (Kelong, AR) was added into the mixture solution. Half an hour later, 2 mL propylene oxide (Kelong, AR) was put into the previous solution. Within 30 min, the white solution became gel. Then the gel was removed out from the mold and exchanged with ethanol and acetone 3 times in 2 days. Finally, the wet gel would experience supercritical drying with liquid CO2, the status of which was above the critical point of CO2 (31 °C, 7.33 MPa), in an autoclave for a week, during which, the monolithic aerogels formed after being depressurized.

2.2 Characterization

The morphology of the aerogels were characterized by field-emission scanning electron microscope (FESEM, Sirion 200) and the high-resolution transmission electron microscope (HRTEM, JEM 2011), respectively. The specific surface areas were calculated through Brunauer–Emmett–Teller (BET) method and the use of QUADRASORB SI surface area analyzer with a relative pressure from 0.05 to 0.35. From the adsorption branches of isotherms, pore volumes and pore sizes distributions were obtained. The Fourier transform infrared spectroscopy (FTIR) was carried out by using a PerkinElmer series 2000 instrument and spectra were recorded in the range of 4,000–450 cm−1. Thermogravimetric analyses (TGA) were carried out on TGA/SDTA851 to determine the thermal stability of the prepared aerogel in air, with temperature ranging from room temperature to 800 °C.

3 Results and discussion

3.1 The structures of the aerogel

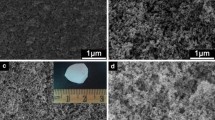

The as-synthesized monolithic aerogel is shown in Fig. 1a. The FESEM image shown in Fig. 1b provides a morphological network of the as-prepared aerogel, and the measurement taken at higher magnification shows very well the structure of the network. The microstructure of the aerogel indicates the aerogel has a three-dimensional structure formed with irregular pores of nanometer, and citric acid plays an important role in the nucleation during the sol–gel process. The complex is formed through chelating the citric acid with Zn2+ via the carboxylate anions in aqueous solution. Citric acid can provide steric hindrance to prevent the particles from aggregation as well as improve crosslinkage through the coordination and charge-attraction between carboxyl and zinc ion. Subsequently, a three-dimensional structure will be formed owing to the cross-linking of these colloidal particles. As the amount of citric acid is decreased, the effect provided by citric acid will be weakened, which can put the zinc oxide particles together [14]. Additionally, mesopores exist during the formation of the aerogel, which indicates that the aerogel has a three-dimensional network of interconnected particles. All above proves that the as-synthesized aerogel with a larger percentage of pores possesses large specific surface area and high porosity.

The structure of the aerogel and the mechanism proposed for their formation (Fig. 1) could be supported by HRTEM measurements shown in Fig. 2. It can be seen very obviously that the network of the secondary aggregates forms a porous structures with irregular pores in the range of 50–100 nm. The thickness of the pore walls demonstrates the size of the secondary aggregates, which are composed by the primary particles.

The nitrogen adsorption/desorption isotherms at 77 K for the aerogel exhibit non-type IV isotherms and a hysteresis loop (Fig. 3a). The plot cannot be classified as type IV isotherms, because plateau does not appear after hysteresis loop. The phenomena may be caused by the macroporosity, which appeared both inside and outside of the aerogel [18]. There is a hysteresis loop in the isotherms, which is attributed to capillary condensation occurring in mesopores and macropores. It can be clearly observed that the aerogel has a more desirable pore volume of 0.22 cm3/g and a high specific area of 122 m2/g. The Barrett–Joyner–Halenda (BJH) approach was applied to analyze the pore size distribution, which is suitable for the analysis of mesopores in the aerogel [13, 19]. Figure 3b shows a majority of pore size are in a range of 20–50 nm, which indicates this porous material could be regarded as mesoporous material.

3.2 Analysis of thermal process

TG image (Fig. 4) shows three-stage weight loss in the thermal treatment. In the first stage, when the temperature reaches to 195 °C, 9.1 % weight loss happens due to the loss of absorbed water. During the second-stage decomposition, the complex gradually loses the weight, almost 23.5 % at 350 °C, which is believed to be caused by the water evolution from anhydride formation and dioxide evolution during anhydride decomposition [20, 21]. Subsequently, the third-stage decomposition occurs when the temperature ranges from 340 to 506 °C. Furthermore, an intense weight loss is observed when the temperature is between 350 and 500 °C, and the weight drops to 31.5 %. In this process, the citric acid chains break and organic group turns into carbon dioxide and water.

As demonstrated in Fig. 5, FTIR is employed to analyze the structural changes of samples heated in successive temperatures. Citric acid is the primary composition of the aerogel. The strongest peak is stretching vibration of C=O, 1,610 cm−1. The decrease of wave number is believed to be the consequence of conjugated bond formed in the complex, among which, 3,452 cm−1 stands for ν(O–H) stretching vibration, 1,610 cm−1 for the remaining ν(C=O) and 1,400 cm−1 for ν(COO). The spectra exhibit no apparent differences when the temperature is below 300 °C. However, when it reaches up to 500 °C, all the organic absorption peaks disappear. This unique sharp peak emerged in fingerprint area is the vibration of Zn–O [22].

4 Conclusion

The monolithic ZnO aerogel is prepared successfully on the basis of the dispersed inorganic sol–gel method with ZnCl2 and citric acid via supercritical fluid drying. By adopting FESEM, BET, FTIR and TGA, we learn that the aerogel has a typical three-dimensional porous structure featuring high surface area (122 m2/g) and we also analyze the chemical and physical changes during thermal treatment process. As far as we know, our report is able to provide a simple and cost-effective method for designing nanoarchitectures of new porous ZnO, which is promising for a wide range of future applications. Therefore, we will conduct further studies on the applications of the aerogel.

References

M.A. Aegerter, N. Leventis, M.M. Koebel, Aerogels Handbook (Springer, New York, 2011)

A.C. Pierre, G.M. Pajonk, Chem. Rev. 102, 4243–4266 (2002)

J. Fricke, T. Tillotson, Thin Solid Films 297, 212–223 (1997)

H.D. Gesser, P.C. Goswami, Chem. Rev. 89, 765–788 (1989)

B.E. Yoldas, M.J. Annen, J. Bostaph, Chem. Mater. 12, 2475–2484 (2000)

R.B. Bhatia, C.J. Brinker, A.K. Gupta, A.K. Singh, Chem. Mater. 12, 2434–2441 (2000)

J.N. Armor, E.J. Carlson, P.M. Zambri, Appl. Catal. 19, 339–348 (1985)

G.M. Pajonk, Appl. Catal. 72, 217–266 (1991)

T.F. Baumann, A.E. Gash, S.C. Chinn, A.M. Sawvel, R.S. Maxwell, J.H. Satcher, Chem. Mater. 17, 395–401 (2004)

A.E. Gash, T.M. Tillotson, J.H. Satcher Jr, L.W. Hrubesh, R.L. Simpson, J. Non-cryst. Solids 285, 22–28 (2001)

A.E. Gash, T.M. Tillotson, J.H. Satcher, J.F. Poco, L.W. Hrubesh, R.L. Simpson, Chem. Mater. 13, 999–1007 (2001)

A.E. Gash, J.H. Satcher Jr., R.L. Simpson, J. Non-cryst. Solids 350, 145–151 (2004)

A. Du, B. Zhou, J. Shen, S.F. Xiao, Z.H. Zhang, C.Z. Liu, M.X. Zhang, J. Non-cryst. Solids 355, 175–181 (2009)

Y.P. Gao, C.N. Sisk, L.J. Hope-Weeks, Chem. Mater. 19, 6007–6011 (2007)

M. Krumm, C.L. Pueyo, S. Polarz, Chem. Mater. 22, 5129–5136 (2010)

B.W. Chen, Y. Bi, X. Luo, L. Zhang, Mater. Technol. 29. doi:10.1179/1753555713Y.0000000125 (2014)

B. Chen, G. Chen, T. Zeng, T. Liu, Y. Mei, Y. Bi, X. Luo, L. Zhang, J. Porous Mat. 20, 1051–1057 (2013)

Y. Gao, G. Chen, Z. We, B. Chen, C. Huang, X. Luo, R. Yang, Y. Bi, L. Zhang, J. Sol–Gel Sci. Technol. 69, 407–411 (2014)

Y. Bi, H. Ren, B. Chen, G. Chen, Y. Mei, L. Zhang, J. Sol–Gel Sci. Technol. 63, 140–145 (2012)

M. McGaugh, S. Kottle, J. Polym. Sci. Part B Polym. Lett. 5, 719–720 (1967)

A. Eisenberg, T. Yokoyama, E. Sambalido, J. Polym. Sci. Part A Polym. Chem. 7, 1717–1728 (1969)

M. Kamalasanan, S. Chandra, Thin Solid Films 288, 112–115 (1996)

Acknowledgments

This work was supported by Chinese Academy of Engineering Physics Fund (2013B0302051, LPMT Grant No.: KF13003), Science Youth Project of Sichuan Education Department (14ZB0264) and Mianyang Normal University Fund (2014A03). The authors are grateful to Research Center of Laser Fusion, China Academy of Engineering Physics for providing instruments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, B., Wang, X., Zhang, S. et al. Monolithic ZnO aerogel synthesized through dispersed inorganic sol–gel method using citric acid as template. J Porous Mater 21, 1035–1039 (2014). https://doi.org/10.1007/s10934-014-9853-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-014-9853-0