Abstract

In the present work, results on the physico-chemical properties of the silica aerogels prepared by sol–gel process using mixtures of TMOS and MTMS as precursor are reported. The wide range of precursor mixture was studied with ratio of MTMS/TMOS in precursor mixtures as 0:100, 25:75, 50:50, 75:25, and 100:0 by volume. The gels with these precursor mixtures were successfully prepared using two step acid–base catalysis for gelation. Acetic acid (0.001 M) and NH4OH (1.5 M) were used for catalysis and resulting alcogels were subsequently dried by supercritical solvent extraction method. FTIR spectroscopy revealed that the aerogels show more intense peak at 1,260 and 790 cm−1 attributed to Si–CH3 resulting in more hydrophobic nature and these results were concurrent with adsorbed water content measurements made using Karl Fischer’s titration technique. The resulted aerogels were characterized using differential thermal analysis, thermo gravimetric analysis and surface area measurements. The surface area measurements showed an interesting trend that the surface area increased from 395 to 1,037 m2/g with increase in MTMS content in the precursor mixture from 0 to 50% and then again decreased to 512 m2/g for further increase in MTMS content from 50 to 100% in the precursor mixture. It was observed from our studies that silica aerogels prepared using a starting mixture of 50% TMOS and 50% MTMS resulted in high moisture resistance (adsorbed water content of 0.721% w/w), low density of 90 kg/m3 and the highest surface area of 1,037 m2/g, which has great potential for catalysis support applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Silica aerogels are unique materials having novel combination of properties like high porosity (98%), high surface area (600–1,600 m2/g) and high optical transparency (90%) because of its nanometer sized particles and pores [1]. Due to these properties, aerogels have many scientific and industrial applications such as storage media for liquid rocket propellants [2], efficient catalytic supports [3], transparent insulation window panels, etc. For such applications, hydrophobicity of the aerogels is an essential requirement. A widely accepted route to make hydrophobic silica aerogels by chemical modification is to use alkyl-alkoxy compounds as co-precursor in earlier stage of preparation i.e. in sol stage. Methyltrimethoxysilane (MTMS) is one of the popular co-precursors used in the preparation of silica aerogels using Tetramethoxysilane (TMOS) as precursor chemical. Addition of MTMS to TMOS at sol preparation stage increases the moisture resistance of silica aerogels but at the cost of reduction in optical transmission. Silica aerogels can also be prepared using only MTMS precursor and base catalyst (10 M NH4OH) [4] for the applications where optical transparency is not required but the aerogels thus obtained show high volume shrinkage (about 6–20%). Therefore, the starting precursors and process parameters needs to be optimized to achieve desired properties suitable for intended applications.

The present work has been aimed to optimize the precursor composition to synthesize aerogel objects that have high surface area, good moisture resistance and retain hydrophobicity at elevated temperature which is useful for catalysis applications. The detailed study on physico-chemical properties of silica aerogels prepared by two step acid—base catalyzed sol–gel process using mixture of TMOS and MTMS as precursors followed by supercritical drying of alcogels, was carried out. In the literature silica aerogels have been obtained using TMOS and MTMS precursor mixture with only 60% MTMS content in the mixture. Beyond that the aerogels could not be obtained due to precipitation in sol state [5]. For the first time, we have studied the wide range of TMOS and MTMS composition in precursor mixture from 100% TMOS and 0% MTMS to 0% MTMS and 100% TMOS. The two step acid base catalysis process has been optimized for the gelation to take place from these precursor mixtures. In the two-step acid–base catalyzed process, acid catalyst increases the rate of hydrolysis and then addition of base catalyst after specified time interval, enhances the condensation of already hydrolyzed species resulting in monolithic gels. The effect of increasing percentage of MTMS with respect to TMOS in precursor composition on gelation time, density and surface area are explained on the basis of hydrolysis, condensation reaction forming colloidal clusters. FTIR studies and moisture content studies reveal that higher proportion of MTMS in precursor mixture leads to more number of non—polar methyl groups in aerogel network and increases hydrophobicity. The surface area and thermal analysis measurements of these aerogels are also studied and reported in the present paper. It is commonly observed that silica aerogels prepared with higher content of MTMS in the precursor stage suffers by volume shrinkage and reduced surface area. We have optimized the precursor composition using 50:50 mixture of TMOS and MTMS that resulted in hydrophobic aerogels with low density of 90 kg/m3 and high surface area of 1037 m2/g.

2 Experimental

2.1 Preparation of aerogels

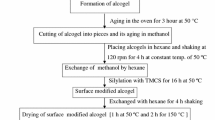

Synthesis of silica aerogels involves two major steps viz. (a) preparation of alcosol which then forms alcogel due to hydrolysis and condensation of organ silicates and (b) supercritical drying of alcogels to yield aerogels.

The TMOS used in the present work is of ‘Pursis’ grade (Fluka Chemicals, Switzerland) where as MTMS is of ‘Purum’ grade (Fluka Chemicals). Methanol (MeOH), ammonium hydroxide (NH4OH) and acetic acid (CH3COOH) used are of analytical grade from Thomas and Bakers. Double distilled water (H2O) was used to prepare base (NH4OH) and acid (CH3COOH) catalyst.

To prepare silica alcosol, MTMS and TMOS were mixed in different ratio of x:y (x and y is % of MTMS and TMOS) in precursor composition such that x + y = 100% and the precursor mixture were diluted with MeOH in a 100 mL glass beaker. This solution was partially hydrolyzed with addition of 0.001 M acetic acid with constant stirring for ten minutes. In the second step, after 3 h from addition of acetic acid, 1.5 M NH4OH was added to the partially hydrolyzed solution under stirring. The as prepared alcosols were transferred to glass test tubes of 15 mm inside diameter and 150 mm length. The gelation took place by hydrolysis and condensation and alcogels were obtained. After gelation, additional methanol was poured into test tubes to prevent shrinkage and cracking of the alcogels. The proportion of MTMS (x) in precursor mixture was varied from 0 to 100 in steps of 25%. The molar ratio of H2O/(MTMS + TMOS) and MeOH/(MTMS + TMOS) were kept constant at 6 and 16, respectively. The alcogels were aged at room temperature for 2 days and then supercritcally dried in an autoclave of 3,000 mL capacity. An additional 350 mL of methanol and initial pressure of 0.5 MPa of dry N2 gas was used in the autoclave during drying of gels. The autoclave was heated to attain the temperature and pressure inside the autoclave above the critical state of methanol (critical temperature ~263 °C and critical pressure ~8 MPa) and then the autoclave was depressurized with maintaining the temperature in the autoclave above the critical temperature of methanol. Finally, the autoclave was flushed with 0.5 MPa dry N2 gas to remove the traces of alcohol and then allowed to cool to an ambient temperature to get aerogels.

2.2 Methods of characterization

Gelation time of the alcogels was recorded using the non fluidity test of sol on transforming to gel. The apparent bulk density was measured by mass to volume ratio. The mass of the aerogel samples was measured using a Dhona microbalance (Model: Dhona 100 DS) having a least count of 1 × 10−5 g where as the volume was derived from the dimensions measured using vernier caliper with a least count of 0.01 mm. The adsorbed water content in the aerogel was measured by Karl Fischer’s (K–F) Titrator (model MA-101C) of Spectralab, India. To measure the adsorbed water content, the silica aerogel were placed in 80% relative humid atmosphere for 15 days. The aerogel powder sample (50 mg) was suspended in anhydrous methanol and titrated in a closed vessel with Fischer’s reagent. The density and adsorbed water content measurements were carried out for five times and the variation in the density measurements was found to be less than ±5% whereas the variation in adsorbed water content values was around ±7–8%. For recording Fourier Transform Infra-Red (FTIR) spectra, the aerogel materials (3% by weight) were mixed with potassium bromide and 25 mm diameter pelletized samples were made by using 3 ton of load. FTIR spectra of aerogels were obtained between wave number ranges 4,000–400 cm−1 on a JASCO make Spectrophotometer (Model No. 610). Normally 100 scans at a resolution of 4 cm−1 were co-added to get the IR spectrum of the sample. Specific surface area of the aerogels was measured by using a Brunauer, Emmett and Teller (BET) surface area analyzer (Make: Quantachrome, Model: Autosorb-1). The amount of N2 gas adsorbed at 77 K at various partial pressures (eleven points 0.05 < p/p0 < 0.3, nitrogen molecule cross sectional area = 16.2 Å2) was used to determine the surface area. The measurements were repeated twice and the variation in surface area values was found to be less than ±5%. Thermo gravimetric analysis (TGA) and differential thermal analysis (DTA) measurements on the aerogels within the temperature range from room temperature to 700 °C were carried out in an Argon atmosphere using ‘Setaram Thermal Analysis System—Model No. 92-16.18’.

3 Results and discussion

3.1 Gelation time

The effect of increase in MTMS content (x) in precursor mixture on gelation time of silica alcogel is presented in Fig. 1. The gelation time is observed to increase from 10 min for alcogels prepared using only TMOS as precursor (x = 0) to more than 12 h for those prepared using only MTMS as precursor (x = 100). The hydrolysis rate of TMOS is faster than that of MTMS [6]. The hydrolysable alkoxy groups in TMOS produce hydroxides that are the centers for condensation of Si–O–Si. MTMS has a non—hydrolysable methyl group which forms hydrolytically stable Si–CH3 group, therefore, as the MTMS component in the precursor mixture (x) increases, the hydrolysis and condensation is retarded leading to an increase in the gelation time.

3.2 Bulk density

The result for bulk density of the resulted aerogels obtained with varying amount of TMOS and MTMS in the precursor mixture is shown in Fig. 2. In the aerogels made using only TMOS as precursor (x = 0), TMOS undergoes hydrolysis and subsequent condensation forming cluster type aerogels resulting in larger pore and particles that result in lower density of 75 kg/m3 of aerogels. With increase in MTMS content (x) up to 50% in the precursor mixture, due to non hydrolysable Si–CH3 group in MTMS polymeric type networking is preferred which causes to form smaller pores and particles resulting in increase in density of the aerogel up to 90 kg/m3. For further increase in ‘x’ from 50 to 100, the density decreases from 90 to 55 kg/m3. This may be because the methyl group in MTMS affects the condensation process causing wide separation of sol clusters that result in larger size pores reducing the density of the aerogel.

3.3 Surface area

The results for surface area measurements of the aerogels are as shown in Fig. 3. It has been found that for the aerogels prepared with pure TMOS precursor i.e. x = 0, the measured surface area is 395 m2/g, which was increased to 1,037 m2/g for the aerogels prepared with precursor composition TMOS: MTMS as 50:50 (x = 50). The reason for this may be that with TMOS precursor, aerogels forms with cluster like network that has large size pores and particles. With increase in MTMS content in precursor composition, polymer type networking is preferred that forms more uniform but smaller particle and pore size network. This causes to increase in surface area along with increase in density of aerogels. For further increase in MTMS from 50 to 100% in precursor composition, the surface area decreases down to 512 m2/g; for the aerogels prepared with 100% MTMS precursor. The likely reason for this could be that the polymeric network is formed at localized sites for higher concentration of MTMS in precursor mixture. Increase in—CH3/Si ratio with higher MTMS content leads to smaller number of Si–OH groups that reduce the condensation reaction and minimize the progress of cross linkage of the siloxane chains. It causes large separation of sol clusters producing particles and pores of increasing size [7]. It reflects in lowering of the surface area value.

3.4 Hydrophobicity

The hydrophobicity was determined by measuring the moisture uptake by aerogel in moist atmosphere. The adsorbed water content values obtained from K–F titration are shown in Fig. 4. With an increasing concentration of MTMS (x) in precursor composition from 0 to 100%, the water content decrease monotonically from 5.05 to 0.259% (by weight). The higher water content recorded for the aerogels prepared with x < 25% is due to hydrolylization of methoxy groups available from TMOS. The—OCH3 groups in these aerogels are hydrolyzed to—OH groups and provide sites for adsorption of water. As each monomer of MTMS contains one non hydrolysable—SiCH3 group, increase in MTMS content (x) > 25% in the precursor mixture leads to R/Si ratio towards 1 resulting in increase in moisture resistance that reflects in lower value of water content.

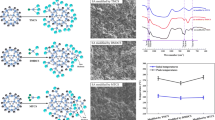

The results on hydrophobicity are confirmed by FTIR studies. Figure 5 depicts the FTIR spectra for the aerogels prepared with precursor mixtures having 0, 50 and 100 vol. % MTMS (x) and are represented as (a), (b) and (c), respectively. The peaks at around 1,100, 800 and 470 cm−1 are due to Si–O vibrations of the Si–O-Si network and are characteristics of silica aerogels [8]. The broad peak at 3,450 cm−1 accompanied with a peak at 1,630 cm−1 are due to stretching and bending vibrations of the hydroxyl groups, arising due to adsorbed water present on the surface of silica aerogels. The peaks around 1,260 and 790 cm−1 are for the absorption from Si–CH3 [9]. For sample containing no MTMS (x = 0%) there is negligible absorption in the region of C–H stretching (~3,000 cm−1) and bending (~1,400 cm−1) while presence of peaks at ~3,450 and 1,630 cm−1 suggested hydrophilic nature of this sample. Increase in MTMS content (x) in the precursor mixture resulted in appearance of several new bands at around 2,977, 2,849, 1,400, 1,260 and 790 cm−1 whose intensity increased with MTMS content, as can be seen in the spectra (b) and (c) of Fig. 5. With increase in MTMS content (x) in the precursor mixture, Si-CH3/Si ratio increases leading to more intense peaks at around 1,260 and 790 cm−1. These observations suggested increasing hydrophobic character of the silica aerogel samples with increasing MTMS content. Also the intensity ratio of IR bands observed at 2,977 and that at 3,450 cm−1 in spectra (a), (b) and (c) increased from 0 to 1.15 and 2.7 for samples with MTMS content of 0, 50 and 100%, respectively, further confirmed the increased hydrophobic nature of these samples [10].

In addition gradual reduction in the band intensity of peak at 1,630 cm−1 with increasing MTMS content can be observed. This may be due to reduction in hydrolysable—SiOCH3 groups which provides site for—OH groups.

3.5 Thermal analysis

The thermo gravimetric and differential thermal analysis (TG–DTA) curves for the aerogel samples are depicted in Fig. 6. Figure 6 a, b and c represents curves for aerogels prepared with 0, 50 and 100% MTMS in precursor composition. The weight loss observed up to temperature 200 °C is due to evaporation of adsorbed water and residual solvent. In Fig. 6 b and c, observed decrease in weight loss up to 200 °C is due to low adsorbed water content because of increased hydrophobicity of aerogels. The weight loss observed at around 300 °C and at around 500 °C accompanied with strong exothermic peaks corresponds to decomposition of surface organic groups like Si–OCH3 and Si–CH3 groups, respectively.

4 Conclusions

The silica aerogels have successfully been prepared using mixture of TMOS and MTMS as precursor with a wide range from 100% TMOS and 0% MTMS to 0% TMOS and 100% MTMS in precursor mixture using two step acid–base catalysis for gelation and subsequent supercritical drying of derived gels. The aerogels prepared with only TMOS precursors had less moisture resistance (moisture content 5.05% w/w) and also had the least surface area (395 m2/g). On the other hand, aerogels prepared with only MTMS precursors are the most moisture resistant (moisture content 0.259% w/w) and least density (55 kg/m3) but have relatively low surface area (512 m2/g) among the studied compositions. A starting mixture of 50% TMOS and 50% MTMS has been optimized as a good choice for having silica aerogels with high moisture resistance (adsorbed water content of 0.721% w/w), low density (90 kg/m3) and the highest surface area (1037 m2/g). Such low density and high surface area aerogels are suitable for applications as catalyst supports.

References

A.V. Rao, P.B. Wagh, G.M. Pajonk, D. Haranath, Mater. Sci. Technol. 14, 236 (1998)

G.M. Pajonk, S.J. Teichner, in Proceedings of the First International Symposium on Aerogels, ed. By J. Fricke (Wirzburg, Germany, 23–25, September 1985), p. 193

G.M. Pajonk, Appl. Catal. 72, 217 (1991)

N.D. Hegde, A.V. Rao, J. Mater. Sci. 42, 6965 (2007)

F. Schwertfeger, W. Glaubitt, U. Schubert, J. Non-Cryst. Solids 145, 85 (1992)

N. Husing, F. Schwertfeger, W. Tappert, U. Schubert, J. Non-Cryst. Solids 186, 37 (1995)

A.V. Rao, G.M. Pajonk, J. Non-Cryst. Solids 285, 202 (2001)

P.B. Wagh, S.V. Ingale, Ceram. Int. 28, 43 (2002)

T. Tanaka, Bull. Chem. Soc. Jpn. 31, 762 (1958)

A.V. Rao, S.S. Latthe, S.L. Dhere, S.S. Pawar, H. Imai, V. Ganesan, S.C. Gupta, P.B. Wagh, Appl. Surf. Sci. 256, 2115 (2010)

Acknowledgments

Authors are thankful to I. K. Singh, Rakesh Patel, Sandeep Viranak and Sonu Gavit from APD, BARC for experimental assistance. The help form A. N. Shirsat, S. B. Phapale, Chemistry Division, BARC, in thermal analysis of aerogel samples is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ingale, S.V., Wagh, P.B., Tripathi, A.K. et al. Physico-chemical properties of silica aerogels prepared from TMOS/MTMS mixtures. J Porous Mater 18, 567–572 (2011). https://doi.org/10.1007/s10934-010-9410-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9410-4