Abstract

This work presents a new way to prepare and isolate nanometric cellulose fibrils as extracted from Citrullus Colocynthis (Cc) seeds. The nanofibrils were then characterized using spectroscopic, thermal and morphological/structural techniques. IR-Raman spectra of cellulose fibers confirmed that the treatment they went through, effectively removed all non-cellulosic material (i.e. hemicellulose and lignin). In addition to that, TGA results indicated a good and higher thermal stability of the extracted cellulose. HPLC and 1H NMR measurements were carried out to estimate the chemical composition of cellulose from Cc seeds. TEM confirmed the presence of nanofibers in the treated sample; XRD (WAXS-SAXS) data show that the cellulose nanofibers have a higher crystallinity. The preparation (extraction and treatment) of cellulose and cellulose nanofibers from the Cc seeds as well as their thermal, structural and morphological characterizations, were successful.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of biomass for the production of energy and materials has been the object of academic and industrial research for a sustainable development thus mitigating environmental problems [1, 2]. Now, the natural fibers are used that are naturally produced by animals and plants because being more economical, renewable, non-toxic, easily processable and biodegradable. Among natural fibers, cellulose fibers constitute rich sources of cellulose and are found to be the most abundant biopolymer on earth [3].

In this context, cellulose is one of the most representative bio-material that is richly present in plants because this biopolymer showed many advantages over other fibers [4, 5]. In the last decades, cellulose has given more importance in the field of nanotechnology which allows producing particles with nanometric dimensions [6]. Significant effort is being given to the development of Cellulose nanofibers as they are abundant in plants and woods, and their composites comprise an attractive contemporary research line [7] because of their unique characteristics, such as renewability, biodegradability, processing flexibility, low density, high specific strength and low-cost [3, 8]. Also, nanofibers have applications in various fields such as bioenergy industries, automobiles, paper manufacturing and textile owing to their properties and broad availability [9, 10]. Among various methods applied for nanocellulose and nanofibers production is acid hydrolysis. This treatment helps in the digestion of less ordered amorphous region of cellulose microfibrils leaving the nanocrystalline particles [9].

Several plants are rich in cellulose; besides, cellulose fibers have been extracted from several sources [8]. In the present study, the isolation of cellulose and cellulose nanofibers from Citrullus Colocynthis (Cc) (a renewable resource from many biomasses) is investigated.

Cc (Cucurbitaceae family) is an herbaceous perennial plant that is widespread in the sandy soils of the hot and arid regions [11, 12]. Cc has been studied for its biological activities [13] and for their wide range in traditional medicine uses. The fruits and most parts of Cc have been investigated for the presence of several compounds [14, 15].

This work aimed, firstly, to add value to Cc by using their seeds as raw material. Secondly, to produce cellulose from Cc seeds. Then, this cellulose was transformed into nanocellulose for its future use as nanofibers for biodegradable matrices. Through such a study, we aimed also to complete a previous work on the same materials (see Kouadri and Satha, 2018) [11] which focused on thermal and structural properties. Finally, the purified cellulose and cellulose nanofibers were examined by analytical techniques for shows its different aspect and properties.

Materials and Methods

Raw Material

The fruits of Cc of the family Cucurbitaceae was collected from the surroundings of the city Ouargla (located in the south-east region of Algeria). The seeds are recovered from the fruits and dried in the dark. The dried seeds are then ground into a fine powder (Fig. 1).

Isolation of Cellulose

The cellulose extraction method used in this work, has been fully described by Kouadri and Satha, 2018 [11]. In brief, A three-step extraction protocol was carried out: (i) a deproteinization process with NaOH solution, followed by (ii) a lipid extraction process with a chloroform/methanol solution, then (iii) a bleaching process with an aqueous chlorite solution.

Nanofibers Production

Nanofibers were prepared by the acid hydrolysis of obtained cellulose from Cc according to the acid-hydrolysis method of Kouadri and Satha, 2018 [11]. This step could be summarized as follows: the acid hydrolysis was carried out with sulfuric acid (H2SO4) solution 40 wt% at room temperature, 4 h in the ratio powder/ solution 20:1 (mg/mL), under vigorous stirring. The obtained product was referred to as cellulose nanofibers.

Characterization Methods

Infra-red Raman Spectroscopy Analysis (IR-Raman)

Infra-red Raman spectra were obtained using an Infra-red Raman spectrometer (Ramspec 1064 from Bayspec/PhotonLines). The measurements were collected in the range from 0 to 4000 cm−1 with a resolution of 4 cm−1; each spectrum was an average of 4 scans. The laser (λ = 1064 nm) incident beam was focused on a spot diameter of about 1 mm on the sample.

Thermogravimetric Analysis (TGA)

Thermal degradation analysis of cellulose extracted from Cc was performed using a model TAG-Q500 (TA Instruments, New Castle, DE) instrument at a 10 °C/min heating rate from 25 to 800 °C under nitrogen flow. All the samples were vacuum oven-dried at 60 °C for 24 h before testing.

1H NMR Spectroscopy

1H NMR spectra were obtained using a Bruker DRX-300 MHz spectrometer (ULTRASHIELD) and Sulfuric acid-d2 solution (D2SO4) as a solvent. For hydrolysis of the glycosidic bonds; 20 mg of cellulose of Cc is hydrolyzed by 1 mL of Sulfuric acid-d2 solution (D2SO4/D2O) (50%), at room temperature for 12 h, in closed tubes. The 1H NMR spectra were treated with a TOPSPIN 3, 2 Software.

Transmission Electron Microscopy (TEM)

For imaging, a transmission electron microscope Philips CM120 at an accelerating voltage of 120 kV, was used. A droplet of 5 µl of ''cellulose nanofibers'' dispersion, was deposited onto a carbon film coated on a copper grid. To keep the sample onto the grid, excess solution was not blotted off, as usual, but was only let air-dried at room temperature.

High-Performance Liquid Chromatography (HPLC)

HPLC was used to determine the purity of extracted cellulose and to determine the monosaccharide composition simultaneously. Briefly, the polysaccharides samples were hydrolyzed with cellulase enzyme. After enzymatic hydrolysis, the monosaccharide was identified by analytical HPLC using a Shimadzu system equipped with an SPD-20A ultraviolet detector and a Shodex column. The mobile phase was a mixture consisting of a solvent A (Acetonitrile) and a solvent B (Water) at a ratio of 70%, 30% (v/v) respectively with a flow rate of 1 mL/min and UV absorption was measured at 195 nm. The injection volume was 20μL and the column temperature was 30 °C. The sugar was identified by comparison to a reference monosaccharide (glucose). The same steps were used to label the standard monosaccharide, D-Glucose. The Samples for HPLC analysis were filtered through the 0.22 μm membrane filters.

Enzymatic Hydrolysis

Enzymatic hydrolysis pretreatments of Cc cellulose were carried out at solids consistency of 125 mg in a 5 ml of acetate buffer of pH 4.5. Enzyme charge of 300 μl cellulase was used. The slurry was incubated at 50 C in an incubator shaker at 150 rpm for 6 h. This step aimed to attack the bonds present in the cellulose of Cc, cellulase helped to cleave the b-1,4 glycosidic bonds, also isolating the glucose monomers.

X-ray Diffraction (X-RD) (WAXS and SAXS)

SAXS measurements are widely used to analyze nanoscale dimensions, structures, and shapes of nanoparticles, biomolecules, polymers, and mesoporous solids [16]. In this study, Wide-angle and Small-angle X-ray scattering (i.e. WAXS and SAXS) were used to determine the crystalline structure of cellulose nanofibers from Cc.

Results and Discussion

IR-Raman Spectroscopy Analysis

Figure 2 shows the structural identification by IR-Raman spectroscopy analysis. The identification of the polysaccharide of cellulose, obtained by isolation from the raw materials of Cc in the range of 0–4000 cm− 1.

The characteristic IR-Raman signals as depicted in Fig. 2, characterized by the presence of vibrations signals about 1094 cm−1, which are attributed to C–H and C–H2 stretching and asymmetric stretching vibration of the C–O–C glycosidic linkage [17,18,19]. However, the peaks at 1479 cm−1 indicate H–C–H bending; the characteristic peak at 1377 cm−1 represents H–O–C bending respectively [11, 12, 20, 21]. According to Kouadri and Satha (2018) [11], the final spectrum is indicative of commercial microcrystalline cellulose. Finally, and according to these results, there is no difference between the spectra of samples of the cellulose of Cc and pure cellulose [11, 12].

Thermogravimetric Analysis (TGA)

The thermal stability of commercial cellulose and cellulose extracted from Cc was studied by thermogravimetric analysis. The evolution of the percentage of the sample masses, as well as its derivatives in Figs. 3 and 4.

The thermograms show two main mass losses. The first, of the order of 4–5%, starts at room temperature up to 100 °C for both samples, and is characteristic of the loss of water, and the second from 100 to 700 °C, is characteristic of the degradation of vegetal material. The maximum of the peak of the derivative is at 324 °C and 318 °C for Cc cellulose and commercial cellulose respectively. Above 700 °C, the residues represent about 1% and 2%. TGA data are summarized in Table 1.

Experimental results of the thermogravimetric analysis allow observing a behavior common to the degradation between the commercial cellulose and the cellulose of Cc. So, there is a similarity between the two samples; thus, the final extract is cellulose. The extracted cellulose is a homogeneous material. This result is verified by another study, for the purest cellulose [22]. Chemical purity increases the thermal stability of cellulose [22, 23]. Lignin, on the contrary, begins to degrade towards 180 °C, because of its heterogeneous structure having less stability. The thermal stability of the plant wall depends on the chemical structure of its main constituents: several studies [24] have shown that cellulose more stable in front of lignin and hemicellulose. The thermal stability of the plant wall depends mainly on cellulose and lignin. The results indicate that the extracted cellulose has the same thermal behavior of the commercial sample.

1H NMR Spectroscopy

Figure 5 shows the 1H NMR spectra of commercial glucose, commercial cellulose, and Cc Cellulose.

The 1H NMR spectrum of the commercial cellulose was obtained in the D2SO4 solvent (50%). Also, the Cellulose of Cc was carried out under the same conditions to make comparisons. Regardless of the spectrum of commercial cellulose and commercial glucose, they show very similar peaks with the same chemical shift. In comparison with Cc cellulose, the spectrum also has characteristic signals that clearly distinguish cellulose from glucose. So, the spectra are identical, but they appear as small peaks in Cc Cellulose (are almost negligible); this may be due to impurities in the extract, or in the solvent. Thus, the results obtained by 1H NMR confirm that the structure of extract obtained from Cc after bleaching is very similar to commercial cellulose and glucose, and also confirm the efficiency of solubility of cellulose with this method of acid hydrolysis with D2SO4 of 50% concentration, at room temperature for 12 h. The conclusion from the results obtained by 1H NMR is that the insoluble final extract of Cc after bleaching is cellulose.

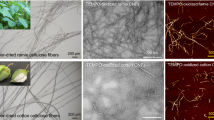

Transmission Electron Microscopy (TEM)

Morphological inspection in this study has been employed by Transmission electron microscopy (TEM). Figure 6 shows the TEM micrographics of the nanofibers of cellulose from Cc under various magnifications.

TEM images confirmed the presence of nanofibers obtained after the acid extraction and the cellulose nanofibers had nanometric diameters. The TEM images show that the chemical and mechanical treatments removed the amorphous components. The nanofibers comprised a network structure as entangled filaments are randomly oriented in arrangement and it have no regular surface because they consist of crystalline and amorphous regions.[25, 26]. The fibers underwent morphological alterations with all the treatment steps that changed the fibers structurally and chemically [27].

High-Performance Liquid Chromatography (HPLC)

Figure 7 shows the influence of chemical and enzymatic treatments on the crystalline nature of the resulting cellulose.

Enzymatic hydrolysis is a two-phase biochemistry process between cellulase and cellulose, and thus the greater the contact between the cellulases and the substrates, the higher the enzymatic hydrolysis efficiency [28]. The purpose of using enzymatic degradation is to assess the release of glucose unit after the treatment with cellulase. For compositional analysis, in Fig. 7(D) glucose is the predominant neutral sugar component in the raw cellulose samples, indicating a much higher purity compared to the corresponding raw cellulose preparations. This phenomenon revealed that, under the conditions given, the enzymatic medium could attack the bonds present in the cellulose of Cc, and the cellulase enzyme helped to cleave the b-1,4 glycosidic bonds. In other words, the enzyme cellulase had no difficulty in solubilizing cellulose; so, it was able to penetrate the cellulose chains, which made cellulose hydrolysis easy.

X-ray Scattering (SAXS/WAXS)

Figure 8 shows the WAXS and SAXS patterns of nanofibers cellulose after acid hydrolysis.

Approximately 6 well-defined diffraction peaks are observed. However, the behavior of the WAXS intensity depends on the range of the q value. In the 2D WAXS pattern that was measured from the precipitate after hydrolysis, several sharp diffraction rings appeared. In the azimuthally averaged WAXS profile, the corresponding diffraction peaks are visible underneath the diffuse scattering from the single particles. The peak positions can be explained by the formation of crystals. In other words, the crystallinity was improved. This may be attributed to the improvement in the integrity of the crystal structure. These results suggest that the structure of the amorphous phase of nanofibers cellulose changes after acid hydrolysis. The increase in crystallinity after hydrolysis is due to the different arrangements of the glucose chains after removal of the amorphous phase. Whereas the large increase of the crystallinity index highlights the preferential attack of the amorphous parts of cellulose during the sulfuric acid hydrolysis [16, 29,30,31,32].

Conclusion

The main goal of this work was to investigate the viability of Cc seeds as a novel, supportable, low-cost, renewable biosource, and the process of cellulose isolation and cellulose nanofibers are environmentally friendly. The purified cellulose and cellulose nanofibers were examined by analytical techniques for shows its different aspect and properties. Thermogravimetric analysis showed that, at 100 °C the water is evaporated from the surface and a maximum decomposition peak at 324 °C. The compositional analysis showed that formation of the molecular structure of cellulose from Cc seeds is that of glucose as confirmed by acid and enzymatic hydrolysis. Morphological analysis showed that cellulose nanofibers consist of uniform nanometer crystalline bundles and had a higher crystalline fraction. In conclusion, we successfully isolated the cellulose and cellulose nanofibers from the Cc seeds and these results are encouraging and could be translated to the use of this agroindustry residue as a renewable source of nanofibers. These findings indicate that cellulose nanofibers extracted to be used, in the future, as organic filler, with a good reinforcement effect in composite materials.

Abbreviations

- Cc :

-

Citrullus Colocynthis

References

Bano S, Negi YS (2017) Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr Polym 1041:1049

Hassouna F, Korbelářová J, Jaquet B, Kutorglo EM, Kopecký D, Ulbrich P, Šoóš M (2018) An environmentally benign methodology to elaborating polymer nanocomposites with tunable properties using core-shell nanoparticles and cellulose nanocrystals. Colloid Surf A 169:179

Khenblouche A, Bechki D, Gouamid M, Charradi K, Segni L, Hadjadj M, Boughali S (2019) Extraction and characterization of cellulose microfibers from Retama raetam stems. Polímeros: Ciência e Tecnologia 29:e2019011. https://doi.org/10.1590/0104-1428.05218

Long LY, Li FF, Weng YX, Wang YZ (2019) Effects of sodium montmorillonite on the preparation and properties of cellulose. Aerogels Polym 11:415

Rehman N, Alam S, Mian I, Ullah H (2019) Environmental friendly method for the extraction of cellulose from Triflolium resopinatum and its characterization. Bull Chem Soc Ethiop 61:68

Dufresne A (2019) Nanocellulose processing properties and potential applications. Curr For Rep 5:76–89

Jebali Z, Granados A, Nabili A, Boufi S, do Rego AMB, Majdoub H, Vallribera A (2018) Cationic cellulose nanofibrils as a green support of palladium nanoparticles: catalyst evaluation in Suzuki reactions. Cellulose 25(6963):6975

Cherpinski A, Biswas A, Lagaron JM, Dufresne A, Kim S, Buttrum M, Cheng HN (2019) Preparation and evaluation of oxygen scavenging nanocomposite films incorporating cellulose nanocrystals and Pd nanoparticles in poly (ethylene-co-vinyl alcohol). Cellulose 26:7237–7251

Ramírez CA, Rol F, Bras J, Dufresne A, Garcia NL, D'Accorso N (2019) Isolation and characterization of cellulose nanofibers from Argentine tacuara cane (Guadua Angustifolia Kunth). J Renew Mater 7:373–381

Sofla MRK, Brown RJ, Tsuzuki T, Rainey TJ (2016) A comparison of cellulose nanocrystals and cellulose nanofibres extracted from bagasse using acid and ball milling methods. Adv Nat Sci 7(3):035004

Kouadri I, Satha H (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crop Prod 124(787):796

Kouadri I, Layachi A, Makhlouf A, Satha H (2018) Optimization of extraction process and characterization of water-soluble polysaccharide (Galactomannan) from Algerian biomass; Citrullus colocynthis seeds. Int J Polym Anal Charact 23(362):375

Tarraf W, Laquale S, De Mastro G, D'Addabbo T (2019) The potential of Citrullus colocynthis oil as a biocide against phytoparasitic nematodes. Crop Prot 124:104843

Hussain AI, Rathore HA, Sattar MZ, Chatha SA, ud din Ahmad F, Ahmad A, Johns EJ (2013) Phenolic profile and antioxidant activity of various extracts from Citrullus colocynthis (L.) from the Pakistani flora. Ind Crop Prod 416:422

Hussain AI, Rathore HA, Sattar MZ, Chatha SA, Sarker SD, Gilani AH (2014) Citrullus colocynthis (L.) Schrad (bitter apple fruit): a review of its phytochemistry, pharmacology, traditional uses and nutritional potential. J Ethnopharmacol 54:66

Homann C, Bolze J, Haase M (2019) Colloidal crystals of NaYF4 upconversion nanocrystals studied by small-angle X-ray scattering (SAXS). Part Part Syst Charact 36:1800391

Vestena M, Gross IP, Muller CMO, Pires ATN (2016) Isolation of whiskers from natural sources and their dispersed in a non-aqueous medium. Polmeros 327:335

Alves APP, de Oliveira LP, Castro AA, Neumann R, de Oliveira LF, Edwards HC, Sant’Ana AC (2016) The structure of different cellulosic fibers characterized by Raman spectroscopy. Vib Spectrosc 324:330

Gierlinger N (2017) New insights into plant cell walls by vibrational microspectroscopy. Appl Spectrosc Rev 517:551

Agarwal UP, Ralph SA, Reiner RS, Baez C (2016) Probing crystallinity of never-dried wood cellulose with Raman spectroscopy. Cellulose 125:144

Movasaghi Z, Rehman S, Rehman IU (2007) Raman spectroscopy of biological tissues. Appl Spectrosc 493:541

Sun JX, Sun XF, Zhao H, Sun RC (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab 331:339

Hatakeyama H, Tsujimoto Y, Zarubin M, Krutov SM, Hatakeyama T (2010) Thermal decomposition and glass transition of industrial hydrolysis lignin. J Therm Anal Calorim 289:295

Jafarpour G, Dantras E, Boudet A, Lacabanne C (2008) Molecular mobility of poplar cell wall polymers studied by dielectric techniques. J Non-Cryst Solid 3207:3214

Pelissari FM, do Amaral Sobral PJ, Menegalli FC (2014) Isolation and characterization of cellulose nanofibers from banana peels. Cellulose 417:432

Zhang G, Yin Q, Han T, Zhao Y, Su J, Li M, Ling J (2015) Purification and antioxidant effect of novel fungal polysaccharides from the stroma of Cordyceps kyushuensis. Ind Crop Prod 485:491

Tibolla H, Pelissari FM, Menegalli FC (2014) Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT-Food Sci Technol 1311:1318

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg Res 405:415

Altamura D, Pastore SG, Raucci MG, Siliqi D, De Pascalis F, Nacucchi M, Giannini C (2016) Scanning small-and wide-angle X-ray scattering microscopy selectively probes ha content in gelatin/hydroxyapatite scaffolds for osteochondral defect repair. ACS Appl Mater Interface 8728:8736

de Morais TE, Corrêa AC, Manzoli A, de Lima LF, de Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 595:606

Romo-Uribe A, Manzur A, Olayo R (2012) Synchrotron small-angle x-ray scattering study of linear low-density polyethylene under uniaxial deformation. J Mater Res 1351:1359

Towata SI, Ito A, Komiya S, Yamamoto KI, Sugiyama N, Nakanishi Y, Sakuma Y (2019) Rice starch for brewing sake: characterization by synchrotron X-ray scattering. J Cereal Sci 249:255

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Satha, H., Kouadri, I. & Benachour, D. Thermal, Structural and Morphological Studies of Cellulose and Cellulose Nanofibers Extracted from Bitter Watermelon of the Cucurbitaceae Family. J Polym Environ 28, 1914–1920 (2020). https://doi.org/10.1007/s10924-020-01735-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01735-6