Abstract

A drug delivery system based on physically cross-linked poly vinyl alcohol (PVA)/chitosan blend hydrogels for the release of sparfloxacin antibiotic as a model for drugs was described. Eco-synthesis in current work is based on synthesizing a hydrogel without using chemical crosslinking agents like in the conventional method. In addition all materials are used are non- toxic, safe, non-carcinogenic and can be accepted by the human body without danger. The swelling behavior was tested to be dependent on pH as temperature as well as time and number of freezing thawing cycles. The physical properties of the hydrogels, such as swelling percent, dissolution percent, gel fraction and mechanical properties was assessed. The antimicrobial activity of hydrogels having different compositions was evaluated for both gram positive and gram negative bacteria. Furthermore, the release of antibiotic from hydrogels prepared using the freeze—thawed process was studied. Results obtained disclose that the swelling percent of the hydrogels is pH- dependent and increases by increasing the chitosan percent and decreases with increasing the time and number of freezing cycle. With respect to the antimicrobial activity of the prepared hydrogels, display a positive effect for both gram positive and gram negative bacteria. Freeze-thawed hydrogels could serve as drug delivery system to release sparfloxacin in acidic medium. Indeed, the release percent of sparfloxacin relies on both pH and temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels are polymeric materials that do not dissolve in water at physiological temperature and pH but swell considerably in aqueous medium. They have some unique properties that make them highly biocompatible. Firstly, they have a low interfacial tension with surrounding biological fluids and tissues. This minimizes the driving force for protein adsorption and cell adhesion [1, 2]. Secondly, because of its very high water content, the hydrogel surface is highly hydrophilic and able to simulate some properties of natural tissues by virtue of its high water content; this makes them biocompatible [3]. Thirdly, the soft nature of the hydrogels minimizes mechanical and frictional irritation of the surrounding tissues. Many synthetic polymers are available for biomedical applications; poly (vinyl alcohol) (PVA) is one of them.

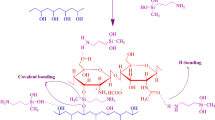

One method of producing a hydrogel, without utilization of chemical crosslinkers, is freeze/thaw processing [4, 5]. PVA hydrogels prepared using freeze/thaw cycling are excellent biomaterials candidates as they exhibit a high degree of swelling in water, a rubbery elastic nature, are non-toxic, non-carcinogenic and can be readily accepted in the body [5]. In aqueous solutions with a polymer concentration of more than 1% entangled aggregates of hydrogen bonded PVA molecules are formed as a consequence of the formation of crystalline regions [6]. Freeze/thawed gels are formed by dissolving polymer in a suitable solvent and freezing the solution.

Upon freezing the solvent, crystals grow until they meet the facets of other crystals. The effect of these crystals is the formation of a porous system upon thawing [7]. This porous structure allows diffusion of solutes of practically any size.

In order to improve the applicability, PVA often combined with other polymers. Pure PVA hydrogels are insensitive to pH changes and the addition of poly acrylic acid in the freeze/thaw process results in pH sensitive gels [8, 9]. The use of natural polymer dosage from design has received considerable attention, especially from the point of view of safety. Among these more recently, hydrogels composed of 75% PVA and 25% poly acrylic acid were prepared by a freeze/thaw treatment of aqueous solutions. The use of natural polymers in dosage form design has received considerable attention, especially from the viewpoint of safety. Among these polymers, chitosan, the N-deacetylated product of the polysaccharide chitin, is gaining increasing importance in the pharmaceutical field owing to its biodegradability [10–12].

In the early 1980s, chitosan was proposed as a useful excipient for either sustaining the release of water—soluble drug [13] or enhancing the bioavailability of poorly water—soluble compounds [8, 14, 15]. More recently, chitosan has been presented as a useful polymer for colon–specific drug delivery because of its specific biodegradability by colonic bacteria.

This work aims to creating a novel PVA/chitosan hydrogel composite with sparfloxacin incorporated into gel. There is no research reported on the systematic study for preparation of physical cross-linked hydrogels composed of PVA/chitosan to delivery sparfloxacin antibiotic. Thus, PVA solution is mixed blended with chitosan solution as prerequisite for preparation of hydrogels free crosslinking agent by making use of freezing/thawing process. The effect of the blend composition on the structure, swelling, stability and the dissolution of the obtained hydrogel is studied. Detailed characterization of the mechanical and antimicrobial properties of the PVA/chitosan hydrogels along with their drug release ability is also investigated.

Experimental

Material

PVA powder of molecular weight 17 kDa and a saponification degree of 99.85% was supplied by D-MID GEL Co. Koysna, Monfiya, Egypt. Chitosan powder was supplied by Fluka Chemical, and its degree of acetylation was determined and found to be 14% by elementary analysis with average molecular weight 600 KDa. Both powders were used without further purification. Sparfloxacin a synthetic broad-spectrum antimicrobial has a molecular weight of 392.41. It occurs as a yellow crystalline powder and dissolves in dilute acetic acid. All other chemicals were of reagent grade and used as supplied.

Preparation of Chitosan Solution

Chitosan was dissolved in 1% aqueous acetic acid solution at room temperature and left overnight with continuous mechanical stirring to obtain a 1% (w/v) solution. The chitosan solution was filtered through sintered glass crucible to remove any undissolved matter.

Formation of Hydrogel

Ten grams of PVA were added to 100 mL distilled water and dissolved for 1 h at 95 °C to obtain a final concentration of 10% PVA. After cooling to 25 °C, the PVA solution was mixed with chitosan solution by stirring at 25 °C for 2 h in order to obtain a homogenous solution of the two polymers. Solution with differrent PVA/chitosan ratios were prepared by varying component composition (20/80, 40/60, 50/50, 60/40 and 80/20 (w/w) chitosan/PVA ratio). Then, the solutions were poured in peter dishes at 20 °C for depend intervals of time. After the end of the freezing process, they were thawed to 25 °C and kept there for different times.

Swelling Percent

Pre weighed dry samples of the prepared PVA/chitosan hydrogels were immersed in buffer solutions at pH 3, 5 and 7. At 25 °C, the samples were weighed at set intervals 3, 6, 12, 24 h and the changes of weigh were recorded; before samples were weighed they were blotted to remove any excess media from the surface. The swelling percent was calculated using the following equation:

where S (%) is swelling percent, Wd and Ws are the weights of the samples in the dry and swollen states, respectively [16].

Determination of Gel Fraction

Samples of the PVA/chitosan hydrogels were extracted by water in a Soxhlet apparatus for 24 h and then dried to a constant weight in vacuum. The gel fraction was then calculated gravimetrically by the use of the following formula:

where G % is gel fraction percent; Wg and W0 are the weight of sample after and before extraction, respectively [17].

Dissolution Percent

The samples of the PVA/chitosan hydrogels were immersed in water for 3 days and then the samples were removed from water and then the excess of water and degraded polymer were removed from the surface of the hydrogels through blotting. Samples were weighed before and after immersion, and the dissolution percent was calculated from the following equation:

where W2 and W1 the weight of sample after and before extractions [17].

Mechanical Properties

Mechanical measurements were performed in National Institute of Standard Measurements (NIS), Cairo, Egypt employing the parallel plate geometry on samples in their wet state. The plate diameter was 10 mm. Stress scans in the 10±1,000 mN range were performed using a static to dynamic stress ratio of 150% at 1 Hz frequency and at a stress rate of 50 m.N min−1 [18].

Drug Release

Sparfloxacin (0.1 g) was added to 100 mL of the prepared chitosan/PVA blend solution with continuous stirring for 30 min. After the dissolution by freeze/thawing process the antibiotic membrane hydrogel was then dried as mentioned above. To study the release pattern of the antibiotics, hydrogel pieces (250 mg each) were immersed in solution with pH values 3, 5, 7 and 9. At predetermined time points, 1 mL of these solutions was taken out and assayed for released antibiotic using a spectrophotometer (SHIMADZU, UV 2401 PC, UV–VIS Recording spectrophotometer). The percentage of released antibiotic was calculated from standard calibration curves [19].

Antimicrobial Activity

The disc diffusion method was used in screening of blended polymer for antimicrobial activity. Nutrient agar or Sabouraud Dextrose agar plates were inoculated with microbial culture. Disc of hydrogels (1 cm diameter) were placed onto the surface of the inoculated plates. The plates were incubated at the appropriate temperature for 18–48 h. The diameter of inhibition zone (mm) was determined for each disc [20].

Five bacterial cultures were used in the present work for assaying the antimicrobial activity of prepared hydrogels. These microorganisms were obtained from the culture collection of the Microbial Chemistry Department, National Research Center, Cairo, Egypt and are shown in Table 1. An inoculum of each bacterial strain was suspended in 5 mL of nutrient broth (5 g/L peptone and 3 g/L beef extract) and incubated for 48 h at 37 °C. The cultures were diluted 1/100 with broth before the use.

Results and Discussion

Effect of Hydrogel Composition of the Freezing Cycle on the Swelling Percent

PVA/chitosan composite membrane were prepared by freezing and thawing of aqueous solutions of the PVA chitosan polymers. They were soft, strong and swelled to equilibrium in a few hours at 25 °C. Figure 1 shows the dependence of the swelling percent of hydrogels on the hydrogel composition and the number of freezing cycles. As is evident increasing the PVA content decreases the swelling percent of the hydrogel. Beside improving the network density of the hydrogel, PVA at the freezing process turn from isotactic structure to syanotactic structure which is able to make hexagonal structure through combination of hydrogen bond with water molecules. As the number of isotactic structures increases a thing called crystalline zone is formed [18]. Crystalline zone exerts very positive effect on mechanical behavior of the hydrogel but adversely affects its swellability.

Figure 1 show that the swelling percent of the hydrogel is highly affected by the number of freezing cycle and practically PVA/chitosan blend with freezing cycle less than 3 cycle numbers could not form hydrogel. The chance to the formation of hydrogel with high elasticity increases with increasing the number of freezing cycles, but at the same time, the swelling percent decreases.

The decrease in the swelling percent at high number of freezing cycle may be attributed to the formation of H—bond between the amino group in chitosan and OH—group in PVA macromolecules.

Figure 2 shows the effect of hydrogel composition and time of freezing cycles on the swelling percent, it is clear that the swelling percent decreases by increasing the time of freezing cycle. This could be interpreted in terms of high probability of H- bond formation between the internal OH- molecules in the PVA at longer time of freezing cycle, which lead to increase in the number of crystalline zone. Increase in the number of crystalline zone leads to increase in the crosslinking area and at the same time decreases the swelling percent.

Effect of Blend Composition on the Gel Fraction Percent

A mixture of PVA/chitosan blend was used to form composite hydrogels by freezing-thawing process with different compositions and different number of cycles and freezing times. Hydrogels so formed were monitored for gel fraction percent. The results obtained are set out in Table 2. Obviously, the gel content increases by increasing the number of freezing cycles, time of freezing as well as the PVA content in the blend. That is, the gel fraction percent increases by factors acting in favour of crosslinking. On the other hand, increasing the chitosan percent in membrane composition is accompanied by a decrease in the percent of gel fraction. This phenomenon may be attributed to degrade a time of the junction zone of the hydrogel as the chitosan percent increase. Previous freezing/thawing studies have indicated that the main reason for the solidification observed during this process is the crystallization of PVA [19, 20]. Results of Table 2 conclude that the different compositions of the hydrogel determine essentially the gel fraction as the latter is taken to indicate the amount of the gel percent crosslinked during the freeze thawing process. That is why the high amount of PVA and high number of cycle results in high percent of gel fraction.

Dissolution Percent

Dissolution refers to the amount of polymer degraded after immersing in water for 3 days. Table 3 shows the effect of composition of hydrogels prepared from PVA/chitosan blends on the gel dissolution percent when the hydrogels were formed under different times of freezing and different number of cycles. Evidently, results of the dissolution percent are inversely related to the results of the gel fraction percent discussed before (Fig. 2) factors with positive impact on the former exert negative effect on the latter. For instance, the dissolution percent decreases by increasing PVA percent whereas the dissolution percent increases by increasing the chitosan percent. This may be explained on the basis that crosslinking occurs only among PVA macromoleculs and not chitosan. Increasing the number of freezing cycles and the long time of freezing lead to more crystalline zone area within hydrogel and, therefore, decrease the destroy percent of the hydrogel.

It is further noted that the gel dissolution percent is very high in the first three freezing cycles provided that chitosan percent in the blend with PVA is 50% or above. This could be ascribed to the low attraction between PVA and chitosan; meanwhile the crosslinking between the hydroxyl groups of PVA macromolecules is low.

Mechanical Properties of PVA/Chitosan Hydrogels

PVA/Chitosan hydrogels varied in both composition and swelling was crosslinked using freezing-thawing process and examined for mechanical properties in the wet state. Table 4 shows the mechanical properties of PVA/Chitosan hydrogels with different swelling percent. It is obvious that the tensile strength of the PVA/Chitosan hydrogel in the form of membrane is improved by crosslinking. The latter is directly reflected on the swelling percent. Increasing crosslinking percent causes further increase in tensile strength of the hydrogel. It is also seen that tensile strength of the hydrogel membrane increases by increasing concentration of PVA percent in blend with chitosan; a point which could be associated with increased crosslinking of PVA. Maximum value for tensile strength is observed at 80% PVA. The remarkable increase in tensile strength of these blend hydrogels emphasizes the relation between mechanical properties and PVA percent in the hydrogel. In addition, results of Table 4 signify a gradual increase in the breaking elongation of the crosslinked hydrogel at low swelling percent.

Young’s modulus was determined from the initial portion of the stress/strain curve in tensile tests carried out to failure at a constant crosshead displacement rate of 5 mm/min. Six samples were tested for each swelling value investigated. A mean value of Young’s modulus was calculated from this set of data and is indicated with a data point in Table 4, while error bars denote the standard deviation within each data set. Young’s modulus was calculated from the slope of the stress–strain curve within the region of 10% strain, where axial strains were determined from crosshead position.

All strain measurements were calculated from the initial, stress-free state the gel assumes after reaching equilibrium with its respective swelling percent. The effectiveness of the theory to predict changes in modulus with swelling, and the implications of mechanical constraint on swelling are considered. Results of Table 4 make it evident that young modulus decreases by increasing the percent of swelling and decreasing PVA percent, which relates to the mechanical property. A volume change occurred due to interstitial in compression; whereas little or no such volume change occurred in the highest amount of PVA, reaches (0.32 N/mm2) because of crosslinking improve the hardness of the membrane. By increasing the percent of chitosan these forces decreases followed improving elasticity of membrane reaching (0.32 N/mm2) which increasing the change in surface to the original state of the object decreasing the E-modulus in the same time.

Low percent of young modulus indicates that the hydrogel is elastic, whereas the high percent of young modulus implies that the hydrogel is hard. It is as well to report that even if swelling percent increases the hydrogel becomes elastic and acquires low mechanical properties.

Antimicrobial Activity

Chitosan has been studied in terms of bacteriostatic/bactericidal activity to control growth of algae and to inhibit viral multiplication [21, 22]. Moreover, Chitosan has several advantages over other type of disinfectants because it possesses a higher antibacterial activity, a broader spectrum of activity, a higher killing rate, and a lower toxicity toward mammalian cells.

Table 5 shows the effect of PVA/Chitosan with different compositions on the antimicrobial activity for gram positive and gram negative bacteria. It is clear that the blend with low content of chitosan has no antibacterial effect for all bacteria under test. At the same time, the antimicrobial activity of the blended composition increases with increasing the content of chitosan in the polymer blends. This phenomenon may be related to the presence of a lot amount of net positively charge in the chitosan macromolecules.

Drug Release of PVA/Chitosan Hydrogels

Hydrogels are generally considered as biocompatible materials because of their high water content [23]. They have been used in a variety of biomaterials and biotechnology applications, such as tissue engineering, artificial organs, and drug delivery.

PVA/Chitosan sample (40/60 ratio v/v) prepared from an initial aqueous concentration of 10 wt% PVA and 1 wt% Chitosan in presence 0.01 g of sparfloxacin with and exposed to four cycles of freezing and thawing, was used as the model system. It was determined that this system initially contained swelling percent of 400. The effect of the pH and time on the release of sparfloxacin antibiotics from the model sample are examined and the results are shown in Fig. 3. the latter show that, the release percent increases by increasing the time, meanwhile the release in acidic medium pH3 is larger than pH5 and follows the order pH3> pH5>pH7>pH9. polymer networks containing chitosan can form hydrogen bond complex that are strongly dependent on the environment pH and ionic strength. The pH-sensitive nature of these hydrogels is due to presence of NH2 within hydrogel structure. The ionizable chitosan leads to high swelling which permits drugs to get out from the hydrogels. By time the dissolution of hydrogel increases and permits more amount of drug to release by long duration. In contrast alkaline medium causes the membrane to collapse and as a result drug release decreases significantly in pH9.

Effect of Membrane Thickness

PVA/Chitosan (60/40w/w) was blended in presence of sparfloxacin to form hydrogel with 400% swelling percent at different thickness (thickness I; 1.2 mm, II; 0.85 mm, III; 0.35 mm). The effect of thickness membrane on the release of loaded drugs was investigated. Figure 4 shows the release of drug from the hydrogel loaded sparfloxacin. It is noticed that the polymer diffusibility inversely proportional with thickness of the polymer membrane and directly proportional with the time. Hickly and Peppas[24] in their investigation of drug release from PVA found that the reputed freezing/thawing cycles lead to a denser crystalline structure with the changes in crystallinity having little effect on the mechanism of release.

The percent of drug released from the hydrogels increases by increasing both the thickness of the hydrogels and duration of drug release. The relatively fast release may be attributed to the high water content of the hydrogel (400%).

Effect of Heat on Drug Release

Figure 5 shows the effect of heat and duration on the release of sparfloxacin when PVA/chitosan hydrogel was loaded with 0.02 g sparfloxacin. The release test was preformed at temperatures ranging from 30 to 60 °C using deionized water at pH7.

Figure 5 shows that the sparfloxacin release percent increases by increasing the temperature from 30 to 60 °C.

At 60 °C the polymer chains of the hydrogels is flexible and its flexibility increases with increasing temperature which causes breaking of secondary interactions, creating more space for water within the matrix of the gel and permitting water which carries drug molecule from the membrane to the medium. This indicates that chitosan/PVA membranes structure is becoming mechanically very fragile and easily unfold.

The temperature responsive release behavior of the PVA/chitosan hydrogel membrane can be explained on the bores of association/dissociation of hydrogel bonding occurring between the amino groups within chitosan chains. Dissociation of hydrogen bond leads to increase the amount of free water present in the hydrogel network.

Conclusion

The system devised in current work for drug release is characterized by the following: (1) it is based on a through systematic investigation carried out for the first time;(2) synthesis of the membrane hydrogel is based soley on eco-friendly ingredient; (3) the use of the membrane as bactericidal as well as for wound healing is rather innovative as it is preformed for the first time.

Chitosan and PVA were physically crosslinked by making innovative use of physical process to give hydrogels with different degrees of swelling percent.

Results obtained disclose that the swelling percent and gel fraction percent increases with increasing the percent of chitosan and decreases by increasing the percent of PVA and number of freeze thaw cycles. On the other hand, gel destroy percent increases by increasing chitosan percent and decreasing the time and number of cycles. Antibacterial test shows the high killing and high efficacy against the two types of bacteria (gram positive and gram negative). The efficacy and effectiveness of the hydrogel composition towards antibacterial test increases by increasing the percent of chitosan. The Freeze—thawed hydrogels could serve as drug delivery systems to release Sparfloxacin antibiotics. The latter is affected by the thickness membrane, pH and temperature of the medium.

References

Wicherle O, Lim D (1960) Hydrophilic gels for biological use. Nature 185:117

John MS, Andrade JD (1973) Water and hydrogels. J Biomed Master Res 7:509

AS Hoffman, RL Kronenthal et al (1975) Polymers in medicine and surgery. Plenum Press, New York, p 33

Stauffer SR, Peppas NA (1992) Polyvinyl alcohol hydrogels prepared by freezing thawing cyclic processing. J Polym 33:3932–3936

Hassan CM, Peppas NA (2000) Structure and applications of poly(vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. J Adv Polym Sci 153:37–65

Hernández R, Sarafian A, López D, Mijangos C (2004) Viscoelastic properties of poly(vinyl alcohol) hydrogels and ferrogels obtained through freezing–thawing cycles. Polymer 46:5543–5549

Lozinsky VI, Galaev IY, Plieva FM, Savina IN, Jungvid H, Mattiasson B (2003) Polymeric cryogels as promising materials of biotechnological interest. Trends Biotechnol 21:445–451

Geresh S, Gdalevsky GY, Gilboa I, Voorspoels J, Remon JP, Kost J (2004) Biodhesive grafted starch copolymers as platforms for peroral drug delivery: a study of theophylline release. J Control Release 94:391–399

Lozinsky VI, Zubov AL, Titova EF (1997) Poly (vinyl alcohol) cryogels employed as matrices for cell immobilization. 2. Entrapped cells resemble porous fillers in their effects on the properties of PVA cryogel carrier. Enzy Microb Technol 20:182–190

Hirano S (1999) Chitin and chitosan as novel biotechnological materials. Polym Int 48(8):732–734

Dodane V, Vilivalam VD (1998) Pharma Appl Chitosan PSTT 1(6):246–253

Gann MJ, Higginbotham LC, Geever LM, Nugen MJD (2009) Int J Pharm 372:154–161

Sawayangi Y, Nmbu N, Nagai T (1982) Enhancement of dissolution properties of griseofulvin from ground mixtures with chitin and chitosan. Chem Pharm Bull 30:4464–4467

Yang X, Liu Q, Chen X, Zhu Z (2008) Investigation on the formation mechanisms of hydrogels made by combination of γ -ray irradiation and freeze thawing. J Appl Polym Sci 108:1365–1372

Yumiin H, Jiahui DV, Hang R, Zhang L (2001) Preparation and characterization of chitosan/poly(vinyl alcohol) blend fibers. J Appl Polym Sci 80:2558–2565

Singh B (2007) Psyllium as therapeutic and drug delivery agent. Int J Pharm 334:1–14

Moosdeen F, Williams JD, Secker A (1987) Standardization of inoculum size for disc susceptibility testing: a preliminary report of a spectrophotometric method. J Antimicrob Chemother 21:439–443

Peppas NA (1975) Hydrogels for synthetic articular cartilage applications. Makromol Chem 176:3433

Shiga T, Hirose Y, Okada A, Kurauchi T (1993) Bending of ionic polymer gel caused by swelling under sinusoidally varying electric fields. J Appl Polym Sci 47:113

Shiga T, Fukumori K, Hirose Y, Okada A, Kurauchi T (1994) Pulsed NMR study of the structure of poly(vinyl alcohol)-poly(sodium acrylate) composite hydrogel. J Polym Sci Polym Phys 32:85

Cuero R, Lilleho E (1990) N-carboxymethylchitosan: algistatic and algicidal properties. J Biotechnol Lett 4:275

Muzzarelli RAA, Tarsi R, Filippini O, Giovanetti E, Biagini G, Varaldo PE (1990) Antimicrobial properties of N-carboxybutyl chitosan. Antimicrob Agents Chemother 34:2019

Bell CL, Peppas NA (1994) Poly (MAA-g-EG) hydrogels as pH responsive, biomedical materials. Mat Res Soc Symp Proc 331:199–204

Hickey AS, Peppas NA (1995) Peppas, Mesh size and diffusion characteristics of semicrystalline PVA membranes prepared by freezing thawing techniques. J Membr Sci 107:229–237

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdel-Mohsen, A.M., Aly, A.S., Hrdina, R. et al. Eco-Synthesis of PVA/Chitosan Hydrogels for Biomedical Application. J Polym Environ 19, 1005–1012 (2011). https://doi.org/10.1007/s10924-011-0334-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0334-0