Abstract

Studies of astromaterials provide valuable insights into the formation and evolution of the solar system. To analyze such astromaterials on a sub-micrometer scale, one of the most useful tools is energy-dispersive X-ray spectroscopy (EDS) in conjunction with scanning transmission electron microscope (STEM). The conventional semiconductor-based EDS system is sometimes insufficient to resolve emission lines at closely adjacent energies. A transition edge sensor (TES) X-ray microcalorimeter is a promising solution to overcome this problem. We developed a 64-pixel TES X-ray microcalorimeter array which had an energy resolution of approximately 7 eV (FWHM) at an energy band from B Kα to Cu Kα. However, the counting rate was only approximately 1000 count/s/array. The distance between the detector and the sample is 30 cm, limited by the stage of the refrigerator. Therefore, an X-ray polycapillary is used to focus the X-ray, which focus size is 5 mm in diameter, resulting in a detection efficiency of only 5%. To increase the effective area, we developed a large size absorber with a large-scale array. A three-dimensional structure was created to fill the dead space between TES pixels. Additionally, an array of 224 elements was made to increase the detection efficiency by a factor of 10. In this paper, we provide more details of design, fabrication process of the overhang absorber, and device performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Studies of astromaterials, including sample return missions such as HAYABUSA2 [1] and OSIRIS-REX [2], provide valuable insights into the formation and evolution of the solar system. Understanding the early phase of the evolutions is critical, and the information may be kept in asteroids and comets because they are considered to be primordial. Thus, meteorites and returned samples from small bodies will give us direct clues to constrain the early phase of the solar system. Those astromaterials are minerals and consist of submicron-scale structures of different materials such as organic matters, silicate and so on. An energy-dispersive X-ray spectroscopy (EDS) on a scanning transmission electron microscope (STEM), which can perform element mapping and quantitative analysis on the nano-scales to micron-scales is an important tool. The conventional semiconductor-based EDS system is sometimes insufficient to resolve emission lines at closely adjacent energies. An example of astromaterials is presolar grains [3]. Presolar grains are known to have formed during supernova explosions and are recommended for analysis to elucidate the process of elemental synthesis. Recent analyses have reported that a large amount of titanium carbides (TiC) is contained in the presolar grains, and it has also been reported that V compounds are contained inside the TiC [4]. The EDS is used for these quantitative analyses. Still, semiconductor-based detectors have difficulty in separating the Ti Kβ line (4931 eV) from the V Kα line (4949 eV), resulting in large systematic errors in the quantitative analysis. The high-energy resolution of a transition edge sensor (TES) X-ray microcalorimeter [5] is a promising solution for quantitative element analysis. Unknown samples such as astromaterials contain numerous elements simultaneously. The TES has a wide energy band (<10 keV) and good energy resolution (<10 eV), making it possible to detect trace elements in such unknown samples. In particular, light metals including Si and Al, which are difficult to detect core-loss in EELS (Electron Energy Loss Spectroscopy), and 3d metal elements can be measured simultaneously with TES-EDS using not only L-line but also K-line, at higher energy levels. The quantitative analysis is also possible because of each element’s high peak separation ability.

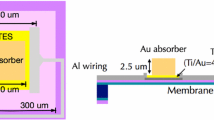

A low maximum counting rate of this type of detector was a significant limitation when we adopt TES-based EDS for material analysis [6]. To satisfy requirement for the material analysis, we had developed an 8 × 8 format 64-pixel TES array and 100 mK stage [7, 8]. A photograph of a 64-pixel TES is shown on the left in Fig.1. Our STEM is a Hitachi HD2700 with a beam scan speed of 10 to 50 ms/frame in TES-EDS. The counting rate was only approximately 1000 count/s/array, which is not enough for astromaterial analysis, as a longer observation time will lead to sample damage [9]. The solid angle of this system is limited by the position of the sample and the X-ray focusing lens, approximately 0.159 steradians (sr), which is ten times smaller than the SDD solid angle (1 sr). In this paper, an effective detection solid angle, which directly correlates with the count rate, is defined as the solid angle of the polycapillary multiplied by the transmission efficiency (which includes the effective area of the TES) obtained from the simulation. The count rate is limited by the effective area of the TES detector. A simple solution to increase the counting rate is to use many pixels and a large absorber. To significantly improve detection efficiency, we designed several hundred pixels and developed a large absorber.

Simple path of X-rays from the sample to the detector. The size of the input side of the X-ray polycapillary optics is 4.5 mm in diameter, the output side is 12 mm in diameter, and the overall size is 50 mm, with a distance of 10 mm from the sample. From the exit of the polycapillary to the detector is about 300 mm. On the left is an optical micrograph of an 8 × 8 pixel TES detector, showing one pixel

2 Simulation and Design

A distance between the TES detector and the STEM’s sample is approximately 300 mm, maintained under vacuum conditions. The vacuum between the STEM and the dilution refrigerator is separated by an X-ray window, with optical blocking filters installed at 40 K, 4 K, and 1 K of the dilution refrigerator, respectively. As X-ray intensity attenuates with distance from the sample, we have adopted X-ray polycapillary optics positioned at a 10-mm distance from the sample. The positioning of the STEM sample, polycapillary, and the detector is shown in Fig.1 By using this configuration, the X-rays can be concentrated, which enhances the solid angle and improves detection efficiency. According to specifications, the focal spot size on the output side is 2 mm and the focal distance is 220 mm, but the focal spot is defocused because the detector is placed at 300 mm due to the geometry of the refrigerator and STEM. The X-ray transmission of the polycapillary and the spread of X-rays on the detector surface are highly dependent on the incident energy, which should be considered in the detector design.

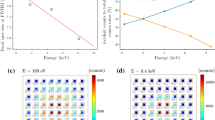

A Monte Carlo simulation of the X-ray polycapillary optics created by A.Takano et al. [10] was used to design the number and position of pixels. The Monte Carlo simulation was used to generate 100000 events at each energy, varying the energy in 10 eV increments, and ray-tracing the photons. The resulting effective area from 0.1 to 15 keV and photon maps at the 1740 eV and 8040 eV detector surfaces are shown in Fig.2 (a) and (b). Based on the simulation results, we adopted a 224-pixel TES array and a mushroom-type absorber to cover a 5-mm diameter. This design consists of a 16 × 16 layout within a 5-mm square, excluding 8 pixels in the corners. An absorber size, pitch, and gap are 260 μm, 300 μm, and 40 μm, respectively, and a filling factor is 70%. The absorber and TES are thermally connected at two locations, and columns to support the structure are connected to the membrane at four corners. These conditions were chosen for ease of demonstration. A diagram comparing the structure and size of the absorber of the old-type and new-type TES and a schematic diagram from the cross section of the mushroom-type absorber are shown in Fig.3. Based on the designs of the conventional absorber and the mushroom-type absorber, the transmission efficiency of the polycapillary was calculated by simulating the number of photons entering the absorber region of the TES. The transmission efficiencies multiplied by the solid angle from the sample is shown in Fig.2 (c). The simulation results show that the new design improves the solid angle by about 10 times compared to the old design.

Pixel map of counts and comparison of old and new solid angles. (a) and (b) are photon maps at the detector surface for incident energies of 1740 eV and 8040 eV, respectively. The simulation results depict a 5 mm × 5 mm area; one tile corresponds to one pixel of TES. The red boxes in the four corners represent pixel areas that were not included in the design. The color map indicates high counts in red and low counts in blue. (c) is a comparison of the effective detection solid angle between old and new designs. The black represents the old design of the solid angle, while the red represents the new design of the solid angle

3 Fabrication Process and Results

We fabricated a TES microcalorimeter at the ISAS/JAXA and NAOJ facilities [11]. The 3-inch sized, 300 \(\upmu\)m thick Si wafer was prepared, and thermal oxide film (500 nm) and a nitride film (1 μm) were deposited on both sides. The nitride film was deposited using a low-pressure chemical vapor deposition (LPCVD) method. For laboratory evaluation, a 5 × 5-pixel evaluation chip was placed on the wafer along with a 224-pixel chip. Reactive-ion etching (RIE) was used to scrape several hundred nanometers of the nitride film as an alignment mark on the surface of the wafer and remove the nitride film from the membrane area on the backside of the wafer. The oxide film on the rear side of the wafer was wet etched using hydrofluoric acid. The TES thermometer used a Ti and Au bilayer that was deposited using a dedicated electron-beam (EB) and resistance-heated (RH) evaporation system. In this system, the film was deposited within 1 minute from Ti deposition to Au deposition, with a vacuum of ~ 2 × 10−5 Pa during deposition. The thicknesses of the Ti and Au layers were 50 nm and 155 nm, respectively. Nb was adopted for the wiring process, and the wiring was formed using a lift-off process. A two-layer photoresist process was adopted to improve lift-off yield. This method involved the application of a lift-off-only resist (LOR-10B) to the lower layer of an ordinary positive resist. The LOR-10B resist was side-etched using tetramethylammonium hydroxide (TMAH) during development. The etching rate of the side etching can be adjusted by adjusting the temperature and duration of the soft bake process, which, in our case, was set to 130°C for 150 seconds to prevent excessive heating of the TES. The positive resist on the upper layer was processed under normal conditions, with a development time of 10 seconds and a side-etching of ~ 5 μm on the lower layer. The LOR-10B resist is a solvent that does not dissolve in acetone and can only be removed using a dedicated remover. After the wiring process, we fabricated a mushroom-type Au X-ray absorber by electroplating in combination with a double photoresist layer process. For large absorbers, the residual resistivity ratio (RRR) is an indicator of thermal diffusion and limits the TES performance. We introduced an electroplating environment of gold and obtained an RRR of approximately 23 [12]. As shown in Fig.4, the absorber was fabricated using nine separate processes, culminating in the final chip fabrication. During formation of the membrane structure, the wafer was carried to the equipment on an aluminum stand. To protect the surface, LOR-10B resist was applied, followed by a positive resist. This enabled the wafer to be removed from the aluminum stand without damaging its surface. Figure5 (a), (b) and (c) depicts a photograph of the completed chip, a micrograph of one element, and an SEM image of the mushroom-shaped absorber.

4 Results of Developing Mushroom-Type Absorber

We confirmed the structure of the mushroom-type absorber and verified that it maintains its three-dimensional structure. The results are shown in Fig.5. We characterized a 5 × 5-array chip to evaluate the fabrication process. Based on the current-voltage relationship in the TES and common impedance measurements, the parameters at the TES operating point were found to be: transition temperature (\(T_\textrm{c}\)) ~ 155 mK, resistance (R) ~ 33.1 m\(\Omega\), thermal conductance (G) ~ 112 pW/K, heat capacity (C) ~ 2.12 pJ/K, and thermometer sensitivity (\(\alpha\)) ~ 114. X-ray irradiation tests were performed to evaluate energy resolution. \(^{55}\)Fe isotopes were used as the X-ray source and positioned directly above the TES chip. The TES chip absorber was voltage-biased and connected to Superconducting Quantum Interference Device (SQUID) readout. The bath temperature was set to 120 mK, with a TES bias current of 150 μA. We obtained an X-ray pulse at this operating point and measured the pulse decay time (\(\tau _\textrm{eff}\)) ~ 200 μs, energy resolution (\(\Delta E_\textrm{FWHM}\)) 8.23 ± 0.64 eV at 5.9 keV and baseline resolution 8.19 eV (Fig.5 (d) and (e)). The difference between the baseline resolution and the energy resolution is suggested by electrothermal simulations to be due to waveform variations, and the degradation due to waveform variations is less than 1 eV [13].

Photograph of the completed device and performance results. (a) is photograph of the completed chip. The chip size is 15 mm × 19 mm, and the 224-element TES array is placed in the center with a diameter of 5 mm. (b) is optical micrograph viewed from above. The absorber size, pitch, and gap are 260 μm, 300 μm, and 40 μm, respectively, and a filling factor is 70%. The absorber is supported by six stems and is thermally connected to the TES by two stems in the center. (c) is SEM image of the absorber observed from a 45-degree oblique angle. (d) is baseline resolution, denoting the energy resolution at 0 eV. (e) is energy resolution at MnK\(\alpha\) (5980 eV), where \(\Delta E\) ~ 8.23 eV. Baseline resolution and energy resolution differ by less than 1 eV, and energy resolution is limited by the superconducting transition temperature

5 Summary

Conventional STEM-TES-EDS systems have difficulty analyzing materials that are weak against electron beams, such as meteorites, due to insufficient count rates. To improve the counting rate, Monte Carlo simulations of the X-ray polycapillary optics were performed to generate photon maps. Based on the simulation results, we adopted a 224-pixel TES array and a mushroom-type absorber to cover a 5-mm diameter. In the fabrication process, Nb was introduced in the wiring, and a special LOR10B resist for lift-off was utilized to perform the lift-off process. When releasing wafers, LOR10B resist is applied for surface protection, leveraging its property of not dissolving in acetone. This enabled release without damaging the surface. The fabricated device was evaluated and found to have a transition temperature of 155 mK and an energy resolution of 8.23 ± 0.64 eV, which is below the STEM requirement of 10 eV (Fig.5 (e)). The waveform variation, which is a problem unique to the mushroom absorber, was not confirmed due to an RRR of 23. In the future, we plan to introduce a microwave multiplexing system, which is a basic technology for reading out large TES arrays, to our group’s refrigerator.

References

S. Watanabe et al., Science (2019). https://doi.org/10.1126/science.aav8032

D.S. Lauretta et al., Space Sci Rev. 212, 925–984 (2017). https://doi.org/10.1007/s11214-017-0405-1

T.J. Bernatowicz, R. Cowsik, in Astrophysical Implications of the Laboratory Study of Presolar Materials, eds. by T.J. Bernatowicz, E.Zinner. AIP Conf. Proc., vol. 402 (1997), pp. 451–474.

T.K. Croat, T. Bernatowicz, S. Amari, S. Messenger, F.J. Stadermann, Geochimica et Cosmochimica Acta. 67(24), 0016–7037 (2003). https://doi.org/10.1016/S0016-7037(03)00463-0

K.D. Irwin, G.C. Hilton, Topics Appl. Phys. 99, 63–152 (2005). https://doi.org/10.1007/10933596_3

K. Maehata, T. Hara, K. Mitsuda, M. Hidaka, K. Tanaka, Y. Yamanaka, J. Low Temp. Phys. (2015). https://doi.org/10.1007/s10909-015-1361-3

H. Muramatsu, K. Nagayoshi, T. Hayashi, K. Sakai, R. Yamamoto, K. Mitsuda, N.Y. Yamasaki, K. Maehata, T. Hara, J. Low Temp. Phys. (2016). https://doi.org/10.1007/s10909-016-1547-3

T. Hayashi, K. Ryohei, N.Y. Yamasaki, K. Mitsuda, K. Maehata, T. Hara, J. Low Temp. Phys. (2020). https://doi.org/10.1007/s10909-019-02326-z

T. Hayashi, H. Muramatsu, K. Maehisa, N.Y. Yamasaki, K. Mitsuda, A. Takano, S. Yoshimoto, K. Maehata, M. Hidaka, H. Yamamori, T. Hara, J. Low Temp. Phys. (2018). https://doi.org/10.1007/s10909-018-2013-1

A. Takano, K. Maehata, N. Iyomoto, T. Hara, K. Mitsuda, N. Yamasaki, K. Tanaka, IEEE Trans. Nuclear Sci. 65(2), 758–765 (2018). https://doi.org/10.1109/TNS.2017.2786703

R. Miyagawa, Master thesis in University of Tokyo (2022)

Y. Yagi, T. Hayashi, K. Tanaka, R. Miyagawa, R. Ota, N.Y. Yamasaki, K. Mitsuda, N. Yoshida, M. Saito, T. Homma, IEEE Trans. Appl. Supercond. 33(5), 1–5 (2023). https://doi.org/10.1109/TASC.2023.3254488

R. Ota, K. Tanaka, T. Hayashi, R. Miyagawa, Y. Yagi, N.Y. Yamasaki, K. Mitsuda, J. Low Temp. Phys. (2024). https://doi.org/10.1007/s10909-024-03190-2

Acknowledgements

This work was partly supported by SENTAN, Japan Science and Technology Agency (JST). T. Hayashi is partially supported by JSPS Grant-in-Aid for Young Scientists No.20K14548 and Grant-in-Aid for Transformative Research Areas (A) No.21H05444. We fabricated the TES microcalorimeter partly using the nano-electronics fabrication facility of JAXA and the advanced technology center (ATC) of NAOJ. The SQUID array amplifier was fabricated by CRAVITY of AIST.

Author information

Authors and Affiliations

Contributions

T. Hayashi designed the TES. T. Hayashi, R.M., Y.Y., K.T., and R.O. produced the TES device. K. Mitsuda, N.Y.Y., K. Mitsuda and T. Hara provided ideas for the STEM-TES-EDS system. T. Hara performed the STEM operation. T. Hayashi wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hayashi, T., Miyagawa, R., Yagi, Y. et al. Design and Development of a 224-pixel TES X-Ray Microcalorimeter System for Microanalysis with STEM. J Low Temp Phys (2024). https://doi.org/10.1007/s10909-024-03175-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10909-024-03175-1