Abstract

Protein expression in E. coli grown in shaker flasks is a routine and pivotal tool in many research laboratories. To maximize protein yields, cells are normally induced in the middle of the linear growth phase, typically at an OD600 of ≤ 1 for cells grown in Luria–Bertani (LB) medium at 37 °C. We recently showed that the E. coli linear growth phase can be extended to higher cell density when cells are cultured under less than optimal conditions such as in minimal medium and/or at lower temperatures. Maximizing the yield of protein per unit volume of culture is important for reducing the costs, especially when isotopically labeling is required. Here, we present a modified minimal medium and a simple protocol that can increase the protein yield up to fourfold in a pH-stabilized LB medium and up to sevenfold in a modified M9+ medium (M9++). When M9++ medium coupled with the high density (OD600 ~ 6) cell growth protocol are used to express uniformly 15N- or 15N/13C-labeled proteins, the amount of 15NH4Cl and 13C6-glucose for a given cell mass is reduced by 50% and ~ 65%, respectively, relative to the traditional low density (OD600 ~ 1) cell growth protocol with M9 medium; the inclusion of 0.1% LB in the minimal medium permits a reduction in the concentration of both the trace element solution and MgCl2, which can cause precipitation. Mass data indicate that inclusion of 0.1% LB does not significantly affect the isotope enrichment level.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

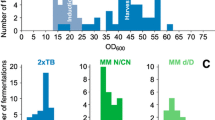

Protein expression in Escherichia coli is routinely employed to produce large quantities of proteins for structural and biochemical studies. E. coli are typically grown in Luria–Bertani (LB) medium for expression of unlabeled proteins, and in M9 minimal medium modified from Anderson’s original recipe (Anderson 1946) and containing 13C (or 13C/2H) glucose and 15NH4Cl as the sole carbon and nitrogen sources, respectively, for expression of isotopically labeled proteins. Typically, cells are grown in shaker flasks and induced at low cell densities (OD600 ≤ 1). By culturing in a fermenter, the pH of the medium, the oxygen level, and other factors can be kept at optimal levels at much higher cell densities and the logarithmic growth phase can be maintained up to an OD600 of 30 (Duff et al. 2015). However, this method is not generally applicable as most laboratories lack access to a fermenter.

There is a therefore a need to improve methods for maximizing the yield of expressed proteins using commonly available equipment, such as air shakers, since the cost of isotopically labelling proteins using common protocols can be prohibitive when cells are induced at low OD. With commonly employed culture protocols for E. coli grown in rich LB medium using air shakers, the linear cell growth phase stops at an OD600 ~ 2 owing to the rate of oxygen consumption exceeding the rate of transfer to the medium, necessitating that protein expression be induced near the middle of the linear growth phase (OD600 ~ 1). This can be mitigated to some extent by increasing the flask volume to medium volume ratio, effectively increasing the surface area (Collins et al. 2013). Decreasing pH and depletion of nutrients can also be limiting factors during growth. In flask cultures, the pH is stabilized by buffering (Cai et al. 2016; Azatian et al. 2019) since continuous adjustments to pH during growth, as can be done automatically in a fermenter, is impractical.

The composition of the medium and temperature also affect the cell doubling time and maximum achievable cell density. For example, E coli can grow to a maximum cell density of OD600 ~ 7 in LB medium (Sezonov et al. 2007). To grow to a cell density with an OD600 > 7 in LB, the medium must be supplemented with glucose and NH4Cl [each gram of glucose and NH4Cl can increase the OD600 by ~ 1.4 and ~ 5.0 respectively (Cai et al. 1998)]. However, the rate of oxygen transfer to the medium and the rate of oxygen consumption by cells in the medium represent the major determinants of how long cells can grow in the linear growth phase.

We have previously described a protocol for achieving high cell densities for isotopically labeling proteins in D2O media expressed in E. coli grown in shaker flasks (Cai et al. 2016). Here, we present a simplified protein expression protocol for cells grown to high density in H2O medium by means of a combination of low growth temperature and the use of a modified minimal medium to reduce the oxygen consumption rate. An improved M9+ medium, referred to here as M9++, including 0.1% LB, dramatically reduces the required concentration of trace element solution and MgCl2, which can cause precipitation due to the high concentration of phosphate salts. Using M9++ and growing E. coli at 30 °C instead of 37 °C reduces oxygen demand and enables cells to reach a much higher cell density in shaker flasks. Using this new protocol, we demonstrate that protein expression levels can be increased up to sevenfold compared to expression using traditional protocols. When 15N is the nitrogen source in the new medium, the 15N enrichment level is the same as when the protein is expressed in M9 medium at low cell density. The new M9++ medium and simplified low temperature growth protocol is therefore applicable for efficient expression of both unlabeled proteins and uniformly 15N or 15N/13C labeled proteins in shaker flasks.

Materials and methods

E. coli and plasmids

All proteins were expressed in E coli BL21(DE3). Genes for Neisseria gonorrhoeae (ng) MinE (full-length and the ∆14-ngMinE N-terminal 14 amino acids deletion) and ngMinD(D40A/∆18) (18 residue C-terminal deletion and a D40A mutation) were synthesized by Genescript. ∆14-ngMinE and ngMinE(∆18/D40A) were cloned into pET11a and expressed as C-terminal His-tagged proteins. Full length ngMinE was cloned (untagged) into pET24a. ngMinE and ngMinD(D40A/∆18) were transfected simultaneously into BL21 cell and co-expressed, with ampicillin (for pET11a) or kanamycin (for pET24a) as antibiotics. HIV-1 Sso7d integrase (Li et al. 2014) and prototype foamy virus (PFV) integrase (Yin et al. 2012) were cloned into pET15b.

∆14-ngMinE used for mass analysis was purified using a Ni-column in buffer containing 50 mM Tris HCl, pH 7.5 and 300 mM NaCl with a 40 mM to 1 M imidazole gradient, followed by gel filtration using a Superdex 75 column with 50 mM Tris HCl, pH 7.5 and 300 mM NaCl as running buffer. Mass measurements were carried out by electrospray mass spectrometry using a q-TOF MS/MS mass spectrometer, model Xevo Gs-XS (Waters). Intact proteins were ionized by electrospray at a capillary voltage of 2.8 kV with a mobile phase of water (0.2% w/v formic acid/0.1% w/v trifluoroacetic acid) and acetonitrile (0.2% w/v formic acid/0.1% w/v trifluoroacetic acid). The mass spectrometer was operated in positive ion mode at a resolution of 25 K. The charge envelope was deconvoluted using the MAX ENT II software.

Relative protein yields were estimated based on SDS-PAGE (sodium dodecylsulphate polyacrylamide gel electrophoresis) gel band intensities determined using the Li-COR OYSSEY CLx system (Li-COR Bioscienses-US).

Growth medium

The final medium, M9++, used in the current studies is a modified M9+ medium (Cai et al. 2016). The compositions of M9, M9+ and M9++ media are provided in Table 1. LB medium was either purchased commercially or prepared by dissolving LB capsules (MP Biochemicals, Catalog Number 113002031) in deionized water, and sterile filtered or autoclaved. pH-stabilized LB medium was made up by mixing 200 ml LB medium with 50 ml M9++ medium. Note that if autoclaving is used for sterilization, sterile MgCl2 should be added last after the medium has cooled to avoid precipitation of magnesium phosphate. (Note that precipitation of MgCl2 can preclude accurate measurement of optical density as well as potentially interfere with the initial column step of purification).

Growth protocols

Agar plates and growth media contained appropriate antibiotics for plasmid selection. All experiments were carried out in air shakers, shaken/rotated at a speed of 200 rpm in 2.8 l baffled bottom PYREX flasks (VWR Catalog Number: 22877-168) with the culture volume equal to or less than 280 ml (unless otherwise specified).

The general protocol for expression in M9++ medium is as follows. Start a 1 ml LB culture from multiple fresh colonies or from a glycerol stock in a 15 ml culture tube and allow it to grow at 37 °C for 2 to 3 h; if a fresh colony is used it is advisable to take an aliquot at this stage and check for induction of expression and keep a glycerol stock for future use. Inoculate 10 ml M9++ medium preculture in a 125 ml culture flask with 100 µl of the above LB culture; allow the preculture to grow at 37 °C overnight; inoculate 250 ml M9++ culture with the 10 ml preculture and allow this culture to grow to an OD600 between 2 and 3 at 37 °C. Lower the culture temperature to 30 °C and continue growth until the OD600 reaches between 6 and 6.5. Lower the temperature to 20 °C and induce expression with 1.0 mM isopropyl β-d-1-thiogalactopyranoside (IPTG) and allow cells to express for 20 h before harvesting the cells by centrifugation.

Results and discussion

To test the effect of temperature on linear grown phase and protein expression, pH-stabilized LB medium was used to check protein expression levels at different cell densities. (The impact of temperature on growth rate and maximum cell density was discussed previously in Cai et al. 2016). After E. coli cells were grown to an OD600 ~ 1 at 37 °C, the growth temperature was lowered to 30 °C to reduce oxygen demand and the cells were induced at 20 °C for 16 h after reaching different cell densities. As examples, we expressed HIV-1 and PFV integrase and ngMinE. SDS-PAGE gel electrophoresis indicated that maximum protein yield was obtained when cells were induced at OD600 ~ 4 and that the protein yield was roughly quadruple that obtained when cells were induced at OD600 ~ 1 (Fig. 1). Figure 2 shows that induction at OD600 ~ 4 in pH-stabilized LB at 20 °C for 16 h results in the same expression level as induction at OD600 = 1 in LB at 37 °C for 3 h when normalized for cell mass.

Protein expression levels of HIV-1 integrase, ngMinE and PFV integrase with induction at the indicated OD600 in pH-stabilized LB medium. a SDS-PAGE of samples induced at the different OD600 values (indicated at the bottom of each lane) after induction for 16 h at 20 °C. The bands corresponding to each protein are indicated by an arrow on the right hand side of the gel. Sample loading was normalized for cell mass. b Expressed protein yields were estimated on the basis of the band intensities and normalized to the band intensity with induction at OD600 = 1

SDS-PAGE comparison of protein expression levels for PFV integrase, ngMinE and HIV-integrase. Lane 1: E. coli cells grown in LB medium to OD600 = 1 at 37 °C before induction. Lane 2: E. coli cells grown in LB medium at 37 °C and induced at OD600 = 1 at 37 °C for 3 h. Lane 3: E. coli cells grown in pH-stabilized LB medium at 30 °C and induced at OD600 = 4 at 20 °C for 16 h. Sample loading was normalized for cell mass

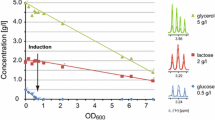

Optimal protein yield was obtained using the new M9++ medium containing 0.1% LB (see Table 1) with induction for 20 h at 20 °C at which time the OD600 reached a value of ~ 7 (Fig. 3). The results of SDS-PAGE analysis are shown in Fig. 3a: Lane 1 is before induction at OD600 = 1; lane 2, 3 h after induction at 37 °C in LB; lane 3, uninduced cells in M9++ medium; and lanes 4 to 11 show the results of induction at the indicated OD600 in M9++ medium. The expressed protein yield per cell mass remained constant up to induction at OD600 = 7, and decreased slightly between OD600 values of 7 to 8.9. Finally, inclusion of 0.1% LB in the M9++ medium (containing 15NH4Cl with glucose at natural isotopic abundance) does not affect the 15N isotope enrichment level of the expressed protein compared to expression in M9 medium in the absence of 0.1% LB, as demonstrated by mass spectrometry analysis of expressed ∆14-ngMinE shown in Fig. 4.

Comparison of protein expression levels for ∆14-ngMinE and ngMinD (D40A/∆18) induced at different cell densities. a SDS-PAGE of samples induced at the OD600 indicated at the top of each lane. Cells were grown at 30 °C in M9++ medium (14NH4Cl and 12C glucose were used for this experiment) and induced at the indicated OD600 with 1 mM IPTG for 20 h at 20 °C (lanes 4 to 11). The bands corresponding to ngMinE and ngMinD are indicated by arrows on the right-hand side of the gel. Lanes 1 (before induction) and 2 (after induction) show expression in LB when induced at OD600 = 1 for 3 h at 37 °C. Sample loadings were normalized for cell mass. b Plot of relative protein yields as a function of OD600 at the time of induction based on the band intensities measured using a Li-COR OYSSEY CLx system. The data are normalized relative to the yield obtained with induction at OD600 = 1. In the case of MinE, all protein is in the soluble fraction and the average yield is 30–40 mg per 250 ml culture after Ni column and gel filtration purification

Comparison of masses of ∆14-ngMinE expressed in regular M9 medium induced at OD600 = 1 and in M9++ medium induced at OD600 = 6, both using 15NH4Cl and unlabeled glucose (natural isotopic abundance) as nitrogen and carbon sources, respectively. The calculated molecular mass for 100% uniformly 15N-labeled ∆14-ngMinE is 9523.79. The protocol employed for M9++ medium is described in the Methods section. For M9 medium growth, cells were grown to OD600 = 1 at 37 °C, and induced with 1 mM IPTG at 37 °C for 3 h. The inclusion of 0.1% LB in the M9++ medium has no effect on 15N enrichment relative to M9 medium. We did not perform the equivalent pair of experiments using 13C6-glucose (with NH4Cl at natural isotope abundance) as no difference would be expected with regard to 13C enrichment given that LB is present in only trace quantities (0.1% v/v) in M9++ medium, and all natural isotope abundance carbon and nitrogen nutrients from LB are used up prior to induction (Cai et al. 1998). In our hands, typical 13C enrichment levels of ~ 98% are obtained using the current protocol with M9++ medium

Concluding remarks

Culturing E. coli under optimal conditions of temperature (37 °C) and medium (LB) increases the cell growth rate and decreases the required growth time. Increasing cell growth rate, however, increases the oxygen demand beyond what can be provided in an air shaker, except at low cell density. Here we have shown that growing E. coli cells at lower than optimal temperature and in the new M9++ minimal medium containing 0.1% LB extends the linear growth phase and allows growth to higher cell density without compromising the efficiency of protein expression. It should also be noted that the amount of protein produced per bacterial cell is not increased; rather the total cell mass is increased and hence the distribution of expressed protein in the soluble fraction versus inclusion bodies is not expected to be affected by the growth protocol described here. Compared to previous protocols, the new protocol provides a simple method of significantly decreasing usage of 15NH4Cl and 13C6-glucose for expressing proteins in E. coli in an air shaker at relatively high density without compromising the efficiency of isotopic labeling. Thus, the cell mass harvested from a 250 ml culture with M9++ medium using the new protocol is approximately 1.5-fold higher than that from a 1 l culture with M9 medium using the standard protocol, for the same amount of 13C6-glucose and 25% less 15NH4Cl (Table 1).

References

Anderson EH (1946) Growth requirements of virus-resistant mutants of Escherichia coli Strain-B. Proc Natl Acad Sci USA 32:120–128

Azatian SB, Kaur N, Latham MP (2019) Increasing the buffering capacity of minimal media leads to higher protein yield. J Biomol NMR 73:11–17

Cai M, Huang Y, Sakaguchi K, Clore GM, Gronenborn AM, Craigie R (1998) An efficient and cost-effective isotope labeling protocol for proteins expressed in Escherichia coli. J Biomol NMR 11:97–102

Cai M, Huang Y, Yang R, Craigie R, Clore GM (2016) A simple and robust protocol for high-yield expression of perdeuterated proteins in Escherichia coli grown in shaker flasks. J Biomol NMR 66:85–91

Collins T, Azevedo-Silva J, da Costa A, Branca F, Machado R, Casal M (2013) Batch production of a silk-elastin-like protein in E. coli BL21 (DE3): key parameters for optimization. Microb Cell Fact 12:21

Duff AP, Wilde KL, Rekas A, Lake V, Holden PJ (2015) Robust high-yield methodologies for 2H and 2H/15N/13C labeling of proteins for structural investigations using neutron scattering and NMR. Meth Enzymol 565:3–25

Li M, Jurado KA, Lin S, Emgelman A, Craigie R (2014) Engineered hyperactive integrase for concerted HIV-1 DNA integration. PLoS ONE 9:e105078

Sezonov G, Joseleau-Petit D, D’Ari R (2007) Escherichia coli physiology in Luria–Bertani broth. J Bacteriol 189:8746–8749

Yin Z, Lapkowski M, Yang W, Craigie R (2012) Assembly of prototype foamy virus strand transfer complexes on product DNA bypassing catalysis of integration. Protein Sci 21:1849–1857

Acknowledgements

This work was supported by the Intramural Program of the National Institute of Diabetes and Digestive Diseases of the National Institutes of Health (to G.M.C. and R.C.).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cai, M., Huang, Y., Craigie, R. et al. A simple protocol for expression of isotope-labeled proteins in Escherichia coli grown in shaker flasks at high cell density. J Biomol NMR 73, 743–748 (2019). https://doi.org/10.1007/s10858-019-00285-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10858-019-00285-x