Abstract

Multifunctional bismuth ferrite (BFO) nanoparticles were successfully synthesized using the co-precipitation technique. pH being a key factor in co-precipitation technique was used to optimize the phase pure synthesis of BFO. The undergone structural changes were examined using XRD. The XRD result shows the distortion in rhombohedral structure of the synthesized sample. Under Ultraviolet-visible spectroscopy, the occurrence of d–d transition and C–T transition taking place in BFO sample was investigated. In addition, the band gap values of BFO1, BFO2 and BFO3 were determined using Tauc’s plot and the values are 2.18 eV, 2.18 eV and 2.12eV, respectively. The suppression of modes of vibration in BFO explains the structural distortion caused by reducing agent; these results are consistent with the XRD results. Finally, through electrochemical analysis the redox behavior and the electron hole transport of the samples were analyzed to identify the suitable sample for photocatalytic performance. EIS spectra were carried out to understand the charge transfer resistance of the samples. The electrostatic interaction of catalyst with Fenton reagent and target material was performed at different ranges of pH 3 to 10 which shows enhanced photocatalytic activity toward picric acid (PA).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rhombohedral distorted perovskite bismuth ferrite (BFO) with ferroelectric (Tc=1103K) and ferromagnetic (TN = 643K) property offers a magnetoelectric coupling effect (ME) and plays a leading role in the field of multiferroic. In point to practical applications, BFO promises to serve a wide range of applications such as memory devices, sensors, actuators, water splitting, photocatalytic activity and many more [1, 2].

Therefore, over a few decades researchers have adopted various techniques to address the challenge of (i) phase purity, (ii) leakage current and (iii) weak antiferromagnetic properties. But it is still a challenging one. Due to the presence of secondary phases such as Bi25FeO40 and Bi2Fe4O9, achieving phase purity is a difficult task [3]. In an account with leakage current, the reduction of Fe3+ species to Fe2+ species creates an oxygen vacancy for charge compensation. This leads to the decrease in electrical resistivity of the material reflecting on the ferromagnetic property of BFO. From our literature survey, we have found that the synthesis of BFO was carried out using various techniques such as solid-state, hydrothermal, sol–gel, co-precipitation, autocombustion, etc. [4,5,6,7,8,9,10]. Among these techniques, co-precipitation technique has various control factor like pH, reducing agent, concentration and synthesizing temperature to optimize the compound formation. Therefore, the recent research in understanding the influence of synthesis technique over the property of the material is widely investigated [11].

Allowing various chemical products, particularly nitro compounds, to be disposed of in water poses a risk to human health. 2,4,6-trinitrophenol (PA) is a well-known polynitrated aromatic volatile with explosive materials that has been found to be more lethal than TNT. The ease of solubility of PA in water (12–14 g/L, even at 20 °C) has resulted in a seriously hazardous environmental pollutants [12,13,14]. Recently, the degradation of organic pollutants has been accomplished using advanced oxidation process (AOP) technology, which completely abates the organic contamination into harmless product, creating the conditions for addressing the aforementioned issues. AOPs in general involve the production of highly reactive hydroxyl (OH) radicals (high oxidation potential, 2.8 eV) that promote complete degradation of organic compounds into innocuous products at high reaction rates [15,16,17,18,19]. Bismuth ferrite (BiFeO3) is the hottest photocatalyst among the perovskites that consumes very less energy with lower band gaps of 2.1 eV and has a larger contact area along with rhombohedral phase, chemically stable with low cost. Furthermore, the piezo-electromagnetic characteristics offer ease degradation while completing the process. Very recently, nanostructured BiFeO3 started to be utilized in the areas of degradation of organic pollutants including dyes, organic pesticides, pharmaceutical wastes and other toxic molecules.

In our present work, we have initially optimized the formation of BiFeO3 through a major factor pH involved in the co-precipitation technique. Phase confirmation was carried using X-ray diffraction technique. Raman spectroscopy discusses the modes of vibration undergone by the samples. UV reveals the excitation of electrons leading totransitions. CV discusses the anomalous behavior of redox reaction as an effect of reducing agents. Further, we have performed a detailed study of degradation of picric acid in UV–visible radiation and solar radiation.

2 Experimental details

The synthesizing materials used in the preparation of BiFeO3 were bismuth nitrate Bi (NO3)3 0.5 H2O(CAS No: 10035-06-0), iron nitrate Fe (NO3)3 0.9 H2O(CAS No: 7782-61-8), ammonia hydroxide NH4OH(CAS No: 1336-21-6), sodium hydroxide NaOH(CAS No: 1310-73-2), potassium hydroxide KOH(CAS No: 1310-58-3) which are of analytical grade.

Bi (NO3)3.5H2O and Fe (NO3)3.9H2O were used as a precursor and NH4OH, NaOH and KOH as a mineralizer. Bismuth nitrate (0.1 M) and iron nitrate (0.1 M) were taken in a 1:1 stoichiometric ratio and dissolved in water containing 3 ml of concentrated HNO3. The above solution was stirred for about 1 h at room temperature. After 1 h of stirring, NH4OH, NaOH and KOH solution was added dropwise, respectively. Here ammonia hydroxide, sodium hydroxide and potassium hydroxide were used as a reducing agent. The obtained brownish precipitate was filtered, washed with deionized water and dried at 800C overnight. Finally, the dried precursors were annealed at 6000C for 2 h to obtain the required BiFeO3 particles.

2.1 Systematic diagram

The photocatalytic degradation of organic molecules was investigated at room temperature with prepared semiconductor photocatalyst nanostructures in an aqueous solution. The reactor system (100 mL) comprises of photocatalyst (50 mg/L), target pollutant (200 mg/L), oxidants of ferrous sulfate heptahydrate (Fe2SO4 7H2O, 1 mM) and hydrogen peroxide (H2O2, 20 mM). The pH of the above solution was adjusted with sulfuric acid (H2SO4, 2.5 M) and sodium hydroxide (NaOH, 2.5 M) under magnetic stirrer (200 rpm). Three parallel examinations such as UV light (254, 365 and 395 nm), visible light (300 W halogen lamp) and sunlight were carried out to determine the photocatalytic activities of the photocatalysts. The experimented solutions were pipetted out (3 mL) at sequence interval and measured the absorption at the wavelength of 354 nm after removed the photocatalyst by centrifugation (Scheme 1).

2.2 Characterization details

X-ray diffraction pattern of the synthesized sample was recorded on X’Pert Pro PANalytical diffractometer using Cu Kα radiation. The microstructure of the synthesized sample was studied using a Carl ZEISS scanning electron microscope. Ultra-violet visible spectrum study was carried out through the Shimadzu (Model: UV 2600). The electrochemical behavior was recorded using Sinsil instrument. The cell contains the three electrodes: (i) platinum electrode as secondary electrode, (ii) AgCl as a reference electrode and (iii) GCE (glassy carbon electrode) as working electrode.

2.3 Electrochemical characterization

The working electrode, BiFeO3 (BFO1, BFO2, BFO3) nanoparticles were used as an active material. The active material was mixed in the proportion of 80:10:10 (80%—active material, 10%—polyvinylidene difluoride and 10%—carbon black) to form a slurry and coated over the working electrode (glassy carbon electrode). The mass of the active material pasted over the working electrode was 3 mg. This active electrode was then dried at 60 °C for 30 min. The electrochemical properties of nanoparticles were tested using a Sinsil three-electrode cell system in 0.1 M NaOH aqueous electrolyte. The experimental setup consisted of the active materials (3 mg), a platinum wire as secondary electrode and AgCl as reference electrode. The experiment was carried out at a potential range of − 1.5 to 1.5 V for different scan rates of 25, 50, 75, 100 mV/s.

3 Results and discussion

3.1 XRD analysis

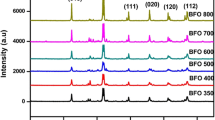

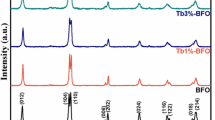

Being pH a major factor involved in the co-precipitation technique, the samples were synthesized using KOH as a reducing agent for different pH values 8, 10 & 12 to understand the optimum pH value for synthesizing a phase pure BFO. Figure 1a shows the XRD pattern of BFO synthesized for different pH which reveals that the sample synthesized at pH = 10 shows a good crystallinity and hinders the growth of the secondary phase (Bi2Fe4O9 and Bi25FeO40) compared to pH = 8 & 12. Hence, the XRD pattern having a good agreement with the JCPDS data (No: 17-2494) pH = 10 seems to be an optimum condition for the chemical reaction to take place in producing phase pure BFO. Therefore, with a fixed parameter pH = 10 different reducing agents (NH4OH, NaOH, KOH) were introduced to understand their effect on the compound formation. Figure 1b illustrates the BFO synthesized using NH4OH, NaOH and KOH, namely BFO1, BFO2 and BFO3, respectively. All three samples show a good agreement with the JCPDS No: 17-2494 having a rhombohedral distorted perovskite structure possessing an R3C space group without any secondary phases. But the observation of characteristic peak at 32° indicates that there is a change in their structural parameters leading to volume expansion [20,21,22,23,24]. These changes in unit cell parameters and volume were determined using unit cell software tabulated [25, 26] in Table 1. Likewise, their particle size was determined using Debye Scherrer formula given in Eq. (1) [27], density using Eq. (2) and surface morphology index using Eq. (3) calculated and tabulated in Table 1 [27,28,29].

Here,

D is crystallite size, k is Scherrer’s constant (0.9) [28], λ is the X-ray wavelength, β is the full width at half maximum (FWHM) [29], θ is the position of the Bragg diffraction angle

Here,

M is the molecular weight of BiFeO3, n is the number of formula units in the unit cell taken as n = 6 for BiFeO3, a and c are the lattice constants of the unit cell.

Here, S is the specific surface area, Dp is the size, and ρ is the density of BiFeO3.

These results clearly illustrate that the type of reducing agent used in the synthesis influences over the compound formation, nature of the compound and property of the material.

3.2 UV spectra

In general, the absorption spectra were used to understand the optical property of the material. As the light incident on the sample, the electrons were energized leading to the transition in states. Figure 2a shows the UV absorption spectra of the synthesized samples. The excitation taking place at ~ 1.92 eV indicates the presence of d–d transition caused due to Fe3+ ion which is forbidden for the change in a total spin, but the relaxation in the spin selection rule led by the spin–orbital coupling gives rise to this transition [30, 31]. The other two charge transfer transitions around ~ 2.59 eV and ~ 3.4 eV were due to the intersite electron transfer and interatomic electron transfer between Fe 3d atoms and Fe 3d–O2p atoms, respectively. Also, the redshift of this transition goes following the XRD result that the shift may be caused due to the tilt in the octahedral environment (FeO6) which is also a phenomenon explaining the reason for distortion of crystal structure [32,33,34]. Figure 2b shows the band gap values determined using Tauc’s plot. The estimated band gap values were 2.18 eV, 2.18 eV, 2.12 eV for BFO1, BFO2 & BFO3, respectively. These results show that the tuning of optical bandgap can also be done using various reducing agent without altering the crystal system of the compound. Further to understand the structural property, Raman spectroscopy was carried out.

3.3 Raman spectroscopy

Figure 3 shows the Raman spectra of the synthesized samples. According to group theory, the material with R3C space group has 13 active modes  = 4A1 + 9E. Here, the A1 modes take place due to Bi–O vibrations that normally occur in the region of lower frequencies up to 167 cm−1, whereas the E(TO) modes are due to Fe–O vibration, which lies in the region of higher frequencies 152 cm−1–262 cm−1 [35]. Since the ferroelectric and ferromagnetic behavior of BFO was employed by the Bi–O and Fe–O, respectively, the small variation in these values would reflect toward the property of the material. Usually the change in Bi-O covalent bonds observed in the A1, A2, A3, E1 and E2 modes takes place along c-axis which corresponds to the Bi lone pair electrons responsible for the ferroelectric property of BFO. Similarly, the changes in ferromagnetic behavior were caused by Fe–O1 mode at around 556 cm−1 and Fe–O2 mode at around 604 cm−1 along with the a and b-axis. These two modes E(TO) at 79 cm−1 and A1 at 130 cm−1 clearly show the displacement of lone pair electron in Bi. The suppression of A1 mode indicates the distortion in the unit cell without any structural transformation [36,37,38,39].

= 4A1 + 9E. Here, the A1 modes take place due to Bi–O vibrations that normally occur in the region of lower frequencies up to 167 cm−1, whereas the E(TO) modes are due to Fe–O vibration, which lies in the region of higher frequencies 152 cm−1–262 cm−1 [35]. Since the ferroelectric and ferromagnetic behavior of BFO was employed by the Bi–O and Fe–O, respectively, the small variation in these values would reflect toward the property of the material. Usually the change in Bi-O covalent bonds observed in the A1, A2, A3, E1 and E2 modes takes place along c-axis which corresponds to the Bi lone pair electrons responsible for the ferroelectric property of BFO. Similarly, the changes in ferromagnetic behavior were caused by Fe–O1 mode at around 556 cm−1 and Fe–O2 mode at around 604 cm−1 along with the a and b-axis. These two modes E(TO) at 79 cm−1 and A1 at 130 cm−1 clearly show the displacement of lone pair electron in Bi. The suppression of A1 mode indicates the distortion in the unit cell without any structural transformation [36,37,38,39].

3.4 Microstructural analysis

Scanning electron microscopy was used to examine the shape of the synthesized nanomaterials. Figure 4a, b, c shows the morphology of BFO1, BFO2, BFO3 samples. It was found that all the samples were uniformly distributed and cuboid in shape.

3.5 Electrochemical studies

To study the contribution of the precipitant in the formation of BiFeO3, the cyclic voltammetry studies were carried out and the results were found to be quite interesting that there is a remarkable change in the oxidation and reduction step in the redox reaction [40,41,42].

Figure 5a, b, c shows the cyclic voltametric graph explaining the redox reaction of BFO1, BFO2, BFO3. From the anodic peak, the changes in the oxidation of the elements present in the compound are addressable as shown in Fig. 6a, b, c. In comparing the compound BiFeO3 made of NH4OH, NaOH and KOH, we can conclude that the transition of Bi metal to Bi3+ state and Fe2+ to Fe3+by losing the electron which is stable during the time of charging in NH4OH than compare toward the other two precipitants (NaOH and KOH) which exhibits a peak split during charging this phenomenon shows that there is no complete oxidation of Bi and Fe metals which would affect the charging of the material. From the cathodic peak, the changes in the reduction in the elements present in the compound are addressable. The transition of Bi metal to Bi3+ state and Fe2+ to Fe3+by gaining the electron is stable during the time of discharging in NaOH and KOH when compared toward the NH4OH which exhibits a peak split during discharging this phenomenon shows that there is no complete reduction of Bi and Fe metals which would lead to the longer duration of discharging which can benefit the battery applications.

Figure 7 shows the fit between peak current density vs scan rate of BFO1, BFO2 and BFO3, respectively. The linearity in the anodic peak current density (ipa) and cathodic peak current density (ipc) describes the electron transfer taking place in a controlled manner in BFO1 than compared to that of BFO2 and BFO3 which would significantly affect their specific capacitance value. Figure 7 shows the plot between scan rate vs specific capacitance. From the graph, we can observe that the BFO1 tends to have a higher specific capacitance value than BFO2 and BFO3 relatable to the current density behavior. Hence, through these analyses, it is clear that the NH4OH is not only a suitable reducing agent but also has a better pseudo capacitance behavior. Due to this excellent electrochemical property exhibited by BFO1, it is further subjected to photocatalytic activity [43,44,45].

Figure 8a, b, c represents the EIS spectra of BFO1, BFO2, BFO3 revealing the charge transfer resistance of the samples. The sample having smallest semi-circle offers a lower charge transfer resistance benefiting the photocatalytic process. Hence, from the spectra BFO1 has a smallest semi-circle than BFO2, BFO3 which means BFO1 tends to have a better electron–hole charge carrier transportation for the effective degradation of pollutants. So, from the conclusion of these electrochemical behavior BFO1 sample was subjected to photocatalytic activity [46].

3.6 Photocatalytic activity

3.6.1 Photocatalytic performances under UV radiations

Figure 9a replicates the impact of pH (3–10) on the developed BiFeO3–Fenton reagent's photocatalytic activity toward PA degradation under UV radiation of 254 nm and links it to the result obtained from UV radiation of 365. The maximal rate of PA degradation (100%) was achieved at pH 3.0 (39 min), compared to pH 7.0 (61%) and 10.0 (51%) in that time, showing that an acidic medium is preferable for this degradation. It is envisaged that the partially negatively charged oxygen moiety of the PA molecule and the partially positively charged (protonated) surface of the BiFeO3 will interact electrostatically to cause the degrading phenomena (Eq. 4). The BiFeO3 valance band (VB) electrons are driven to the conduction band (CB) in addition to the Fenton processes, and when exposed to UV radiation, they create holes in the VB [47,48,49]. The superoxide radical ions (O2-) were produced by the reduction process between the excited electrons in CB and Fenton's reagent (Eq. 5). In the meantime, the VB holes directly oxidize organic pollutants or generate hydroxyl radicals (OH) (Eq. 6). The breakdown of the PA into the mild products is caused by the harvested radicals of O2 and OH. [50]. Owing to the negatively charged surface of BiFeO3 nanoparticles, overall % degradation of the PA is slower at pH 7.0 and 10.0 than it is at pH 3.0.

a Photocatalytic activity of prepared BiFeO3 toward the degradation of PA with effect of pH ranges from 3.0 to 10.0 under the UV radiation of 254 nm. b Photocatalytic activity of prepared BiFeO3 toward the degradation of PA with effect of pH ranges from 3.0 to 10.0 under the UV radiation of 365 nm. c Photocatalytic degradation of picric acid at various time intervals in the presence of BiFeO3 (pH 3 and UV254)

Similar to this, Fig. 9b shows how the photocatalytic activity of PA has been expanded for the 365 UV rays. The properties of BiFeO3-Fenton reagents are responsible for the trend's permanence as seen at 254 nm. Under acidic conditions, the UV radiation of 365 increased the maximal PA degradation rate by 36 min, respectively (pH 3.0). When compared to UV light at a wavelength of 254 nm, PA degradation was substantially same at pH values of 7.0 and 10.0. The photocatalytic degradation of picric acid at various time intervals in the presence of BiFeO3 (pH 3 and UV254) is represented in Fig. 9c.

Figure 10 depicts the degradation profiles of PA using various methods such as photo-Fenton catalyst (PFC, BiFeO3-Fenton reagent), photocatalyst (PC, BiFeO3), Fenton's reagent (F) and hydrogen peroxide (H2O2) under UV radiation of 254 nm (pH 4.0). It is clearly evident that the photodegradation efficiency of PA was found to be 100, 11, 37 and 27% for PFC-, PC-, F- and H2O2-based methods, respectively. It is indicating that Fenton’s reagent encompasses with photocatalyst of BiFeO3 possessed maximum activity toward PA degradation than other methods. As a result, the increased electron production of BiFeO3-reagent Fenton's has influenced the free radicals responsible for PA mineralization in acidic suspensions.

3.6.2 Photocatalytic performances under visible light

The photocatalytic performance of the BiFeO3-reagent Fenton's was also evaluated for the photodegradation of PA under visible light irradiation with the effect of pH (Fig. 11). The complete degradation was completed in 42 min for pH 3.0, which is significantly faster than the degradation achieved for pH 7.0 (60%, 42 min) and 10.0 (50 percent, 42 min). As a result, the same photo-Fenton reactions mechanism that was explained in the photodegradation by UV radiation could occur on the surface of the catalyst under visible light. A comparison table for BFO-based materials employed in photocatalytic activity is tabulated in Table 2.

3.6.3 Photocatalytic performances under sunlight

Figure 12 shows the results of an evaluation of the PA degradation efficiency with BiFeO3 nanoparticles in a sunlight system using the same pH ranges. It eventually showed that the BiFeO3 was photoactive even when exposed to sunlight. The PA was degraded to 100%, 61% and 56% by BiFeO3 nanoparticles with pH values of 3.0, 7.0 and 10.0, respectively. However, the degradation time of this reaction condition is extremely similar to that of the above-mentioned visible light reaction. As a result, inhibition efficiency for PA degradation in acidic medium is higher than in neutral and basic medium. Furthermore, UV illumination at 365 nm provided more accessible and effective results, and BiFeO3 nanoparticles in combined application with Fenton's regent acted as an efficient photocatalysis toward PA degradation.

4 Conclusion

From the above results and discussions, it is clear that the reducing agent is playing a vital role in not only the compound formation but also in the property of the materials. UV-spectrum shows the existence of d–d transition, C–T transition and tuning of band gap by reducing agent. Raman spectrum indicates the suppression of modes explaining the reason for structural distortion as per the XRD spectrum. Furthermore, photocatalytic activity of UV illumination at 365 nm, sun light, and UV all provided more accessible and effective results. Finally, BiFeO3 nanoparticles acted as an efficient photocatalysis toward PA degradation when combined with Fenton's regent. Because it is uncommon to see catalysts active at all rays, it is advantageous to use Fenton-based multifunctionalized bismuth ferrite nanoparticles to degrade organic pollutants.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

N.A. Spaldin, R. Ramesh, Advances in magnetoelectric multiferroics. Nat. Mater. 18, 203–212 (2019). https://doi.org/10.1038/s41563-018-0275-2

A. Nicola Hill, Why are there so few magnetic ferroelectrics? J. Phys. Chem. B 104, 6694–6709 (2000). https://doi.org/10.1021/jp000114x

S.M. Abdul Kader, D.E. Jain Ruth, M.V. Gajendra Babu, M. Muneeswaran, N.V. Giridharan, B. Sundarakannan, Investigations on the effect of Ba and Zr co-doping on the structural, thermal, electrical and magnetic properties of BiFeO3 multiferroics. Ceram. Int. 43, 15544–15550 (2017). https://doi.org/10.1016/j.ceramint.2017.08.104

J.C. Chen, W. Jenn-Ming, Dielectric properties and ac conductivities of dense single-phased BiFeO3 ceramics. Appl. Phys. Lett. (2007). https://doi.org/10.1063/1.2798256

Y. Wang, X. Gang, Z. Ren, X. Wei, W. Weng, D. Piyi, G. Shen, G. Han, Low temperature polymer assisted hydrothermal synthesis of bismuth ferrite nanoparticles. Ceram Int 34, 1569–1571 (2008). https://doi.org/10.1016/j.ceramint.2007.04.013

S. Ghosh, S. Dasgupta, A. Sen, H.S. Maiti, Low-temperature synthesis of nanosized bismuth ferrite by soft chemical route. J. Am. Ceram. Soc. 88, 1349–1352 (2005). https://doi.org/10.1111/j.1551-2916.2005.00306.x

D.P. Dutta, A.K. Tyagi, Effect of Sm3+ and Zr4+ codoping on the magnetic, ferroelectric and magnetodielectric properties of sonochemically synthesized BiFeO3 nanorods. Appl. Surf. Sci. 450, 429–440 (2018)

M. Sakar, S. Balakumar, P. Saravanan, S.N. Jaisankar, Annealing temperature mediated physical properties of bismuth ferrite (BiFeO3) nanostructures synthesized by a novel wet chemical method. Mater. Res. Bull. 48, 2878–2885 (2013). https://doi.org/10.1016/j.materresbull.2013.04.008

N. Arpan Kumar, Bismuth-Based Materials for Environmental Remediation (IOP Publishing, 2022)

A. Puhan, B. Bhushan, S.S. Meena et al., Surface engineered Tb and Co co-doped BiFeO3 nanoparticles for enhanced photocatalytic and magnetic properties. J Mater Sci: Mater Electron 32, 7956–7972 (2021). https://doi.org/10.1007/s10854-021-05520-6

M. Muneeswaran, P. Jegatheesan, N.V. Giridharan, Synthesis of nanosized BiFeO3 powders by co-precipitation method. J Exp. Nanosci. 8, 341–346 (2011). https://doi.org/10.1080/17458080.2012.685954

M. Ismail, M.I. Khan, S.B. Khan, K. Akhtar, M.A. Khan, A.M. Asiri, Catalytic reduction of picric acid, nitrophenols and organic azo dyes via green synthesized plant supported Ag nanoparticles. J Mol Liq 268, 87–101 (2018). https://doi.org/10.1016/j.molliq.2018.07.030

S. Senapati, K.K. Nanda, MgO nanocubes as self-calibrating optical probes for efficient ratiometric detection of picric acid in the solid state. ACS Sustain. Chem. Eng. 6, 13719–13729 (2018). https://doi.org/10.1021/acssuschemeng.8b01330

A. Hakonen, F.C. Wang, P.O. Andersson, H. Wingfors, T. Rindzevicius, M.S. Schmidt, V.R. Soma, S. Xu, Y. Li, A. Boisen, H. Wu, Hand-held femtogram detection of hazardous picric acid with hydrophobic Ag nanopillar SERS substrates and mechanism of elasto-capillarity. ACS Sens 2, 198–202 (2017). https://doi.org/10.1021/acssensors.6b00749

R. Chakraborty, K. Vilya, M. Pradhan, A.K. Nayak, Recent advancement of biomass-derived porous carbon-based materials for energy and environmental remediation applications. J. Mater. Chem. A 10, 6965–7005 (2022). https://doi.org/10.1039/D1TA10269A

A.K. Nayak, Nanostructured materials for visible light photocatalysis. Mater. Sci. Solid. 10, 135–151 (2022)

N. Chnadel, K. Sharma, A. Sudahiak, P. Raizada, A. Hosseini-Bandegharaei, V. Thakur, P. Singh, Magnetically separable ZnO/ZnFe2O4 and ZnO/CoFe2O4 photocatalysts supported onto nitrogen doped graphene for photocatalytic degradation of toxic dyes. Arab J Chem (2019). https://doi.org/10.1016/j.arabjc.2019.08.005

V. Pawar, S. Gawande, An overview of the Fenton process for industrial wastewater. IOSR J Mech Civil Engg 2015, 127–136 (2015)

F. Duan, Y. Ma, P. Lv, J. Sheng, L. Shuanglong, H. Zhu, D. Mingliang, X. Chen, M. Chen, Oxygen vacancy-enriched Bi2O3/BiFeO3 p-n heterojunction nanofibers with highly efficient photocatalytic activity under visible light irradiation. Appl. Surf. Sci. 562, 150171 (2021). https://doi.org/10.1016/j.apsusc.2021.150171

W. Xing, Y. Ma, Y. Bai, S. Zhao, Enhanced ferromagnetism of Er-doped BiFeO3 thin films derived from rhombohedral-to-orthorhombic phase transformations. Mater. Lett. 161, 216–219 (2015). https://doi.org/10.1016/j.matlet.2015.08.098

T.H. Le, N.V. Hao, N.H. Thoan, N.T.M. Hong, P.V. Hai, N.V. Thang, P.D. Thang, L.V. Nam, P.T. Tho, N.V. Dang, X.C. Nguyen, Origin of enhanced magnetization in (La, Co) codoped BiFeO3 at the morphotropic phase boundary. Ceram. Int. 45, 18480–18486 (2019). https://doi.org/10.1016/j.ceramint.2019.06.066

M. Rangi, S. Sanghi, S. Jangra, K. Kaswan, S. Khasa, A. Agarwal, Crystal structure transformation and improved dielectric and magnetic properties of La substituted BiFeO3 multiferroics. Ceram. Int. 43(2017), 12095–12101 (2017). https://doi.org/10.1016/j.ceramint.2017.06.065

D. Rout, M. Kyoung-Seok, L.K. Suk-Joong, Temperature-dependent Raman scattering studies of polycrystalline BiFeO3 bulk ceramics. J. Raman Spectrosc. 40, 618–626 (2009). https://doi.org/10.1002/jrs.2172

D. Singh, T. Tabari, M. Ebadi, M. Mateusz Trochowski, B. Yagci, W. Macyk, Efficient synthesis of BiFeO3 by the microwave-assisted sol-gel method: “A” site influence on the photo electrochemical activity of perovskites. Appl. Surf. Sci. 471(2019), 1017–1027 (2019). https://doi.org/10.1016/j.apsusc.2018.12.082

L. Hongping, L. Shuhui, W. Zhongchang, X. Yanjie, B. Yijia, L. Xiaojuan, M. Jian, Mechanism of A-B inter site charge transfer and negative thermal expansion in A-site ordered perovskite LaCu3Fe4O12. J Appl Phys 111, 103718 (2012). https://doi.org/10.1063/1.4721408

T. Durga Rao, T. Karthik, S. Asthana, Investigation of structural, magnetic and optical properties of rare earth substituted bismuth ferrite. J Rare Earths 31, 370–375 (2013). https://doi.org/10.1016/S1002-0721(12)60288-9

P. Scherrer, Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr. Ges. Wiss. Göttingen 26, 98 (1918)

J.I. Langford, A.J.C. Wilson, Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J. Appl. Cryst. 11, 102 (1978)

V. Uvarov, I. Popov, Metrological characterization of X-ray diffraction methods for determination of crystallite size in nano-scale materials. Mater. Charac. 85, 111 (2013)

R.V. Pisarev, A.S. Moskvin, A.M. Kalashnikova, Th. Rasing, Charge transfer transitions in multiferroic BiFeO3 and related ferrite insulators. Phys. Rev. B 79, 235128–235216 (2009). https://doi.org/10.1103/PhysRevB.79.235128

M.O. Ramirez, A. Kumar, S.A. Denev, N.J. Podraza, X.S. Xu, R.C. Rai, Y.H. Chu, J. Seidel, L.W. Martin, S.-Y. Yang, E. Saiz, J.F. Ihlefeld, S. Lee, J. Klug, S.W. Cheong, M.J. Bedzyk, O. Auciello, D.G. Schlom, R. Ramesh, J. Orenstein, J.L. Musfeldt, V. Gopalan, Magnon sidebands and spin-charge coupling in bismuth ferrite probed by nonlinear optical spectroscopy. Phys. Rev. B 79, 224106–224109 (2009). https://doi.org/10.1103/PhysRevB.79.224106

S. Chaturvedi, R. Bag, V. Sathe, S. Kulkarnia, S. Singh, Holmium induced enhanced functionality at room temperature and structural phase transition at high temperature in bismuth ferrite nanoparticles. J Mater Chem C 4, 780–792 (2016). https://doi.org/10.1039/C5TC02941D

G. Dong, G. Tan, Y. Luo, W. Liu, A. Xia, H. Ren, Charge defects and highly enhanced multiferroic properties in Mn and Cu co-doped BiFeO3 thin films. Appl Surf Sci 305, 55–61 (2014). https://doi.org/10.1016/j.apsusc.2014.02.159

R. Tadisetti Durga, S. Bhumireddi, A. Saket, Predicting high magneto-electric coupling in Gd substituted BiFeO3. Phys. Status Solidi B 256, 1900097–1900098 (2019). https://doi.org/10.1002/pssb.201900097

M. Muneeswaran, P. Jegatheesan, M. Gopiraman, N.V. Ick-Soo Kim, Giridharan, Structural, optical, and multiferroic properties of single phased BiFeO3. Appl. Phys A 114, 853–859 (2014). https://doi.org/10.1007/s00339-013-7712-5

S.K. Singh, H. Ishiwara, K. Maruyama, Room temperature ferroelectric properties of Mn-substituted BiFeO3 thin films deposited on Pt electrodes using chemical solution deposition. Appl. Phys. Lett. 88, 262908–262913 (2006). https://doi.org/10.1063/1.2218819

J. Sharma, D. Basandrai, A.K. Srivastava, Ce Co-doped BiFeO3 multiferroic for optoelectronic and photovoltaic applications. Chin. Phys. B 26, 116201–116206 (2017). https://doi.org/10.1088/1674-1056/26/11/116201

R. Anlin Golda, A. Marikani, E. John Alex, Enhancement of dielectric, ferromagnetic and electrochemical properties of BiFeO3 nanostructured films through rare earth metal doping. Ceram Int 46, 1962–1973 (2020). https://doi.org/10.1016/j.ceramint.2019.09.175

J. Khajonrit, U. Wongpratat, P. Kidkhunthod, S. Pinitsoontorn, S. Maensiri, Effects of Co doping on magnetic and electrochemical properties of BiFeO3 nanoparticles. J Magn Magn Mater 449, 423–434 (2018). https://doi.org/10.1016/j.jmmm.2017.10.092

M. Kaur, P. Chand, H. Anand, Facile synthesis of NiCo2O4 nanostructure with enhanced electrochemical performance for supercapacitor application. Chem Phys Lett. 786, 139181 (2022). https://doi.org/10.1016/j.cplett.2021.139181

M. Kaur, P. Chand, H. Anand, Effect of different synthesis methods on morphology and electrochemical behavior of spinel NiCo2O4 nanostructures as electrode material for energy storage application. Inorg. Chem. Commun. 134, 108996 (2021). https://doi.org/10.1016/j.inoche.2021.108996

K.P. Remya, D. Prabhu, R. JustinJoseyphus, A. ChandraBose, C. Viswanathan, N. Ponpandian, Tailoring the morphology and size of perovskite BiFeO3 nanostructures for enhanced magnetic and electrical properties. Mater. Design. 192, 108694 (2020). https://doi.org/10.1016/j.matdes.2020.108694

H. Zhe, L. Wang, K. Zhang, J. Wang, F. Cheng, Z. Tao, J. Chen, MoS2 nanoflowers with expanded interlayers as high-performance anodes for sodium-ion batteries. Angew. Chem. Int. Ed. 53, 12794–12798 (2014). https://doi.org/10.1002/anie.201407898

C.J. Ma, Y. Chen, C. Zhu, Q. Chen, W.L. Song, S. Jiao, H. Chen, D. Fang, Bismuth ferrite: an abnormal perovskite with electrochemical extraction of ions from A site. J. Mater. Chem. A 7, 12176–12190 (2019). https://doi.org/10.1039/C9TA02569C

J. Zou, J. Jiang, Y. Zhang, J. Ma, Q. Wan, A comparative study of the optical, magnetic and electrocatalytic properties of nano BiFeO3 with different morphologies. Mater. Lett. 72, 134–136 (2012). https://doi.org/10.1016/j.matlet.2011.12.091

A. Sarkar, K. Gobinda Gopal, Synthesis of BiFeO3 nanoparticle anchored TiO2-BiFeO3 nano hetero structure and exploring its different electrochemical aspects as electrode. Mater. Today: Proc. 5, 10177–10184 (2018). https://doi.org/10.1016/j.matpr.2017.11.016

Q. Wang, P. Wang, P. Xu, Y. Li, J. Duan, G. Zhanga, L. Hu, X. Wang, W. Zhang, Visible-light-driven photo-Fenton reactions using Zn1-1.5xFexS/g-C3N4 photocatalyst: degradation kinetics and mechanisms analysis. Appl Catal B Environ 266, 118653 (2020). https://doi.org/10.1016/j.apcatb.2020.118653

P.K. Malik, S.K. Saha, Oxidation of direct dyes with hydrogen peroxide using ferrous ion as catalyst. Sep Purif Technol 31, 241–250 (2003). https://doi.org/10.1016/S1383-5866(02)00200-9

Q. Wang, P. Xu, G. Zhang, W. Zhang, L. Hu, P. Wang, Characterization of visible-light photo-Fenton reactions using Fe-doped ZnS (Fex-ZnS) mesoporous microspheres. Phys Chem Chem Phys 20, 18601–18609 (2018). https://doi.org/10.1039/c8cp02609b

M. Bhushan, R. Jha, R. Bhardwaj, Reduced band gap and diffusion controlled spherical n-type ZnS nanoparticles for absorption of UV-Vis region of solar spectrum. J Phys Chem Solids (2019). https://doi.org/10.1016/j.jpcs.2019.05.018

F. Mushtaq, X. Chen, M. Hoop, H. Torlakcik, E. Pellicer, J.S. Chiara Gattinoni, B.J. Nelson, S. Pané, Piezoelectrically enhanced photocatalysis with BiFeO3 nanostructures for efficient water remediation. Iscience 4, 236–246 (2018). https://doi.org/10.1016/j.isci.2018.06.003

O.V. Nkwachukwu, M. Charles, B.O. Ojo, B.N. Zwane, B.A. Koiki, B.O. Orimolade, D. Nkosi, N. Mabuba, O.A. Arotiba, Photoelectrochemical degradation of organic pollutants on a La3+ doped BiFeO3 perovskite. Catalysts 11(9), 1069 (2021). https://doi.org/10.3390/catal11091069

S.M. Lam, Z.H. Jaffari, J.C. Sin, A.R. Mohamed, IOP Conf. Series: Earth. Environ. Sci. 151, 012021 (2018). https://doi.org/10.1088/1755-1315/151/1/012021

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by RMM, RDD, and PMYA. The first draft of the manuscript was written by RMM, RDD, and project administration SMAK, TS, supervision SMAK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

Ethical approval

This is an observational study; no ethical approval is required.

Informed consent

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muthukrishnan, R.M., Devee, D.R., Ansari, P.M.Y. et al. Investigating the structural, optical and electrochemical performance of bismuth ferrite (BiFeO3) nanoparticles toward photocatalytic activity: as an effect of reducing agent. J Mater Sci: Mater Electron 34, 486 (2023). https://doi.org/10.1007/s10854-023-09877-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-09877-8