Abstract

Electromagnetic (EM) wave technology has greatly promoted the development of information industry and facilitated human life. At the same time, EM pollution caused by excessive use of EM waves will endanger human health and disrupt the normal operation of instruments. Therefore, compelling immediate action needs to be taken to solve EM pollution and interference problem. One-dimensional carbon has become a potential candidate to solve these problems because of its high dielectric loss, significant thermodynamic stability, high specific surface area, and low density. In this paper, the application of one-dimensional carbon materials and magnetic materials and dielectric materials in absorbing EM waves is introduced, and the future development direction is prospected, which provides some feasible ideas for more scientists.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the commercialization of 5G, electronic devices, which occupy an important position in human's lives, will have a new explosive growth. Exactly as everything has two sides, electromagnetic (EM) wave, as the communication signal of electronic equipment, not only brings convenience to human life but also causes EM pollution caused by EM wave abuse [1,2,3,4,5,6,7]. EM pollution disturbs communication and may damage the instrument in more serious cases. On the other hand, endocrine disorders caused by EM pollution will affect human health. Therefore, whether it is for consideration of property safety or personal safety, it is very necessary to solve the problem of EM pollution [8,9,10,11]. In addition, advanced military weapons such as fighters need to be able to evade enemy detection and attack, and EM stealth technology is an efficient strategy [12,13,14]. EM stealth can be achieved by coating EM wave absorber (EMWA) on military equipment to make enemy radar undetectable. Above all, the study of high-performance EMWA can greatly meet the needs of military and civil.

Based on the above requirements, the EMWA should have the characteristics of small thickness, large absorption bandwidth, strong absorption capacity, and light weight. Many scholars have contributed to the study of ideal absorbing materials [15,16,17].

EM wave-absorbing materials can be classified as dielectric materials and magnetic materials according to the attenuation mechanism. Dielectric material is a kind of dielectric loss absorption mechanism related to electrode, that is, EM energy is transformed into thermal energy consumption and dissipated through the “friction” caused by dielectric repeated polarization. The absorption mechanism of magnetic loss materials is a kind of magnetic loss related to the dynamic magnetization process of ferromagnetic media. This kind of loss mainly comes from domain steering, domain wall displacement, and domain natural resonance similar to the magnetic mechanism.

In the past few decades, magnetic materials, including magnetic metals [18, 19] and ferrites [20], have been widely studied as forceful EMWA benefitting from the ability to prevent EM wave propagation by interacting with magnetic components. In many cases, magnetic metals can even provide compatible dielectric loss mechanisms. Unfortunately, some inherent disadvantages, such as easy corrosion, low Curie temperature, and high density, make them unnecessary in practical applications [21, 22]. As a kind of dielectric materials, carbon materials have attracted a lot of attention because of their light, stable physical and chemical properties and good conductivity [23]. Not only that, carbon materials have many homomorphs, such as graphene [24], carbon nanotubes, CNTs [25], carbon foam [26], porous carbon [27], etc., and are easy to prepare excellent absorbing materials according to needs and different materials [28,29,30]. Among them, like other one-dimensional materials [31]. carbon materials with one-dimensional (1D) morphology have been widely used in the field of microwave absorption because of their aspect ratio, low density, strong dielectric properties, and stable physical and chemical properties [32,33,34]. In addition, 1D carbon materials have been shown to be capable of producing highly efficient EMWA by self-assembling or combining magnetic materials to form three-dimensional interconnect networks.

1D carbon materials widely used in the domain of microwave absorption mainly include CNTs and carbon fibers. In addition to the morphological differences, the former has the properties of strong conductivity, high-temperature resistance, and oxidation resistance, which makes their applications in the field of microwave absorption different. In this paper, the applications of 1D carbon-based materials compounded with magnetic materials and dielectric materials to EM wave absorption are introduced, and the future development direction is prospected.

2 Microwave absorption mechanism

When the EM wave propagates in space and reaches surface of the EMWA, part of it will be reflected on the material surface, the other part will enter the absorber and be converted into other forms of energy, and the last part will propagate through the absorber. In order to achieve EM wave absorption, researchers hope that EM waves will be absorbed into the absorption to the maximum and dissipated almost without reflection and transmission. This behavior is related to the impedance matching and dissipation capacity of the absorber.

Dielectric loss and magnetic loss occupy an important position in the process of EM wave loss. In order to further clarify the attenuation mechanism, the dielectric loss angle and the magnetic loss angle are proposed, which are the parameters to characterize the dielectric loss and the magnetic loss ability.

2.1 Impedance matching

On the basis of the transmission line theory, when impedance matching, the transmission line works in the traveling wave state, and the EM waves do not reflect on the surface of the absorption but directly enter the absorber [9, 35,36,37]. Impedance matching can be achieved by making the input impedance of the transmission line equal to the characteristic impedance of the transmission line.

The characteristic impedance of the absorbing material is calculated as follows [38,39,40,41]:

Among them, Z0 is the impedance of free space, Zin is the characteristic input impedance at the air-coating interface, εr and μr are complex permeability and permittivity, d is the thickness of the prepared composites, c is the velocity of the wave in vacuum, and f is the applied frequency.

When Zin = Z0, EM waves can achieve no reflection on the surface of materials.

The reflection loss (RL) of material is considered as a major parameter to evaluate the microwave absorption performance, which can be expressed as follows [42]:

When RL is less than – 10 dB, it can be considered that more than 90% of the EM wave is absorbed. The frequency range of RL < − 10 dB is called effective absorption bandwidth (EAB).

The attenuation of EM wave by absorber can be characterized by attenuation constant [43,44,45]:

Here, ε' and μ' represent the real parts of the complex permittivity and the complex permeability, respectively. ε" and μ" represent the imaginary part of the complex permittivity and complex permeability, respectively.

2.2 Dielectric loss

The dielectric loss comes partly from the rotation and orientation during the polarization process and partly from the resonance caused by the leakage conductance and the frequency of external electric field consistent with the thermal vibration frequency of molecules or atoms. The polarization of medium mainly includes atomic polarization, ion polarization, dipole polarization, and interface polarization. In general, ion polarization and electron polarization can be easily excluded from microwave absorption because they usually occur in the THz and PHz range [46]. Therefore, the dielectric loss in the absorbing materials should be attributed to various dipole polarization phenomena and interface polarization phenomena [47,48,49]. For dielectrics, relaxation occurs when an electric field is suddenly applied or canceled. A large number of defects and residual groups can be used as polarization centers, in which the dipole cannot move freely like the electron in the external electric field. In the alternating electric field, the positive and negative electric fields are added to the dielectric periodically in turn, which will inevitably cause the dipole to move with direction of electric field. With the increase of electric field frequency, the change of dipole cannot keep up with the change of frequency, and the hysteresis phenomenon appears. The dipole turns repeatedly, which consumes the energy of the electric field. According to Debye's dipole relaxation theory, the relationship between ε' and ε" can be written as follows [50,51,52,53]:

Here, εs, ε∞, and ε0 are constant, which represent the static permittivity, the relative dielectric permittivity at the high frequency limit, and the dielectric constant in vacuum, respectively.

From ε'–ε" curve shown in Fig. 2b, a semicircle in the figure of represents a Debye relaxation process, which is called Cole–Cole semicircular. For the interface polarization and related relaxation, it always appears in heterostructure materials, and the accumulation and distribution of space charge on the interface are uneven, which will produce macroscopic electric moment. In the process of charge separation, the polarization energy of external electric field is converted into the polarization energy of dielectric storage, and the rearrangement of charges requires energy consumption, which leads to the attenuation and loss of EM energy in the conversion process.

2.3 Magnetic loss

Magnetic loss includes domain wall resonance loss, hysteresis loss, eddy current loss, exchange resonance and natural resonance, commonly stemming from the relaxation process of magnetization. Among them, the domain wall resonance loss usually occurs in the lower frequency range (MHz), while the hysteresis loss can be ignored in the weak magnetic field. Therefore, the magnetic loss can be mainly attributed to resonance loss and eddy current loss. Eddy current loss is the energy loss caused by the current generated in the conductor in a changing magnetic field, which is only related to the conductivity (σ) and thickness (d) of the material, represented as follows [54, 55]:

Assuming that the value of C0 remains constant with the change of frequency, eddy current loss is the only cause of magnetic loss. However, in many cases, the value of C0 often changes, indicating that natural [56] resonance and exchange [57] resonance play a leading role in magnetic loss, while eddy current loss only plays a small part.

Low-frequency resonance is caused by natural resonance, which is attributed to shape anisotropy and magnetic crystal anisotropy, while exchange resonance is the result of energy exchange between particles and surface anisotropy [58].

In order to further clarify the attenuation mechanism, the dielectric loss tangent (tan δμ = μ"/μ') and the magnetic loss (tan δε = ε"/ε') tangent are proposed, which are the parameters to characterize the dielectric loss and the magnetic loss ability [59, 60]. More deeply, ε' and μ' represent the storage capacity of a material for electrical and magnetic energy, respectively. ε" and μ" are related to the material's ability to lose electrical and magnetic energy [61,62,63].

3 1D carbon-based materials for microwave absorption

In order to solve the impedance imbalance caused by high dielectric of 1D carbon materials, magnetic loss materials are often introduced to adjust their impedance matching. In addition, materials with low dielectric can also be introduced to control their dielectric constant to achieve the effect of impedance matching. These two methods are accompanied by structural diversity. Therefore, the microwave absorption performance is improved due to the synergistic effect of EM parameter change and diverse structure.

3.1 Carbon nanotubes-based materials for microwave absorption

CNTs are one-dimensional nanostructures with high specific surface area, quantum effect, strong power dissipation ability, and unique spiral and tubular structures [64, 65]. However, high dielectric constant leads to poor impedance matching between carbon materials and air. Therefore, many scholars have made great efforts to obtain ascendant CNTs-based microwave absorbing materials.

3.1.1 Carbon nanotubes/magnetic materials composites for microwave absorption

Previous study has shown that pure CNTs lack the ability of magnetic loss, so the EMWA performance is not ideal [64]. Magnetic metals, known for their magnetic loss capacity, are often used to composite with CNTs to improve their magnetic loss constant, improve impedance matching, and prepare satisfactory absorbing materials.

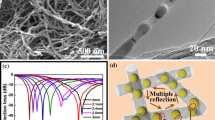

Magnetic metal elements are often filled into CNTs [66,67,68]. As displayed in the transmission electron microscope of Fig. 1, it is intuitive that the magnetic metal is embedded in the CNTs. Interface polarization will occur at the contact between metal and CNT (Fig. 1g), and the magnetic loss is caused by metal introduction. The synergistic effect of the two makes the composite that has good microwave absorption performance. Many scholars have prepared magnetic metal/CNTs with this structure and investigated their microwave absorbing properties.

Using metal organic framework (MOF) as precursor, Qiu et al. [67] compared the effects of different pyrolysis temperatures on the microwave absorbing properties of Ni/CNTs by in situ pyrolysis method. Among the samples they prepared, the samples pyrolyzed at 700 °C had better absorbing performance than the samples pyrolysed at 600 °C, which reached − 65 dB RLmin at only 10 wt% load, with a thickness of 1.9 mm and an EAB of 4.6 GHz. This is because the higher pyrolysis temperature is conducive to improve the catalytic ability of nickel nanoparticles and further improve the degree of graphitization, high degree of graphitization is conducive to conductivity loss.

Coincidentally, the EMWA performance of Fe, Co, and Ni particles composite with CNTs was compared, respectively, by Ning et al. [68] and Wen et al. [69]. The latter achieves better performance with lower content and less thickness because the doping element will introduce a large number of point defects (such as doped atoms or vacancies) into the host material. According to Debye's theory, these defects act as dipoles in EM fields to improve the dielectric properties of the material (Fig. 2a). Significantly, the experimental results show that the wave absorption performance of Fe/CNTs is always higher than that of the other two magnetic metals in both studies (Fig. 2b), indicating that Fe/CNTs have a wider application prospect in the field of EM wave absorption.

Interfacial and dipolar polarization conductive network in paraffin and microwave propagation model in M@NCNTs (a), ε″–ε′ curve (b), and RL curve of 10 wt% Fe@NCNTs, 10 wt% Co@NCNTs, 10 wt% Ni@NCNTs (c) from [68]

Magnetic metal alloy can also be used as a component contributing magnetic loss to composite with CNTs to achieve excellent absorption performance. Among them, the most widely used is iron–nickel (Fe–Ni) alloy [70, 71]. Fe–Ni alloy is a satisfactory choice because of its high permeability and saturation magnetization. The natural resonance frequency of Fe–Ni nanoparticles varies between 2.23 and 6.60 GHz, depending on the anisotropy caused by its shape and size. Not only that, there are many methods for the modification of CNTs with Fe–Ni alloy including wet chemistry, arc discharge, template-assisted method, and organometallic precursor pyrolysis, among which wet chemical method is simple and ensures various metals or metal alloys and other nanophases attached to or encapsulated onto CNTs, involving pretreatment, solution reaction, calcination, and reduction of CNTs. Considering these advantages, Yang et al. employed wet chemistry method to prepare γ-FeNi/CNT composite, reaching RLmin of − 15.4 dB with a thickness of only 1.6 mm with a very low absorbent material content of 2% [70].

Although metallic elemental/CNTs have been used in many scenarios as absorber; however, metal nanoparticles are easily oxidized and corroded, indicating that climate resistance is one of their disadvantages and that such materials need to be suitable for specific working environments, which limits their practical application. Therefore, ferrite with both magnetic and corrosion resistance has attracted the attention of researchers. In recent years, a large number of studies have shown that magnetic spinel ferrite MFe2O4 (M = Fe, Co, Ni, Mn, Zn, etc.) complexation. It is an effective strategy to improve the microwave absorption performance of CNTs to fabricate CNTs/ ferrite hybrid.

In many studies, the modification of CNTs by ferrite only requires a simple hydrothermal method [72,73,74]. A typical method is depicted in Fig. 3.

Firstly, CNTs are treated with acid, during which defects may develop on their surfaces. These defects provide affluent sites for metallic cations deposition. These oxygen-containing groups present on the surface of CNTs are then conducive to the binding of metal cations through electrostatic attraction interactions under alkaline conditions. Finally, a large number of ferrite crystals are formed in situ and fixed on the surface of CNTs, which are further assembled into microspheres during solvothermal processes. As a result, CNTs/ferrite composites were obtained.

What is more attractive is that the element of ferrite and the content of the element are adjustable, which can be slightly changed according to the actual need to obtain the required absorbing materials. Ni–Zn–Co-ferrite synthesized by Dalal et al. not only has EMWA performance with the RLmin of 1-mm-thick MWCNTN3Z4C3–MWCNT nanocomposite being − 22 dB. Due to the increase of Co2 + content caused by the increase of magnetization and magnetic crystal anisotropy, the specific absorption rate of the material increases, so it can be used as an efficient AC-induced heat medium, which is an important part of the treatment of cancer [75].

3.1.2 Carbon nanotubes/dielectric materials composites for microwave absorption

Dielectric materials in addition to carbon materials also include barium titanate [75], silicon carbide [76], conductive polymer [77], and zinc oxide. Due to good conductivity, low density, good stability, and excellent environment characteristics, dielectric materials can also participate in improving the EMWA properties of CNTs. In the recombination with CNTs, the polyvinyl alcohol (PVA) occupies the main position. MWCNT/PVA nanofilms were effectively embedded into PVA matrix by using SDS as effective coating agent [78]. With the change of MWCNT content, the wave absorption performance of the composite changed. For pure PVA, the RLmin was − 12 dB, and when the MWCNT content increased to 10%, the RLmin was − 28 dB. Another polymer, polyaniline (PANI), is also commonly used in combination with CNTs to achieve excellent wave absorption properties.

Using the chiral helical PANI@CNTs, Meng and colleagues [79] demonstrated that the integration of CNTs and PANI achieves enhanced microwave absorption compared to pure CNTs and PANI with an RL value of − 32.5 dB at 8.9 GHz. Figure 4 reveals the EWMA performance of PANI-CSA@helical CNTs (HCNTs) and the feasible dissipation mechanism. There are π–π and H bond interactions between PANI molecule and HCNT, and the chiral binding of PANI and continuous HCNT of chiral-doped acid at the molecular and nanoscale, respectively, leading to the synergistic effect of two handedness. The cross-polarization of HCNT and chiral PANI main chains enhances the microwave absorption performance, and the cooperation of multiple relaxation from functional groups and interface polarization can synergically benefit the EM absorption characteristics. In order to compare the effects of different polymer morphologies on the microwave absorption of MWCNT, PANI/MWCNT, and PVA/MWCNT composites synthesized by Salimbeygi et al. [80]. In their study, although the nanofibrous sample had an RLmin of − 23 dB, higher than the − 28 dB, which is the RLmin of thin film, its thickness was only 0.1 mm, one tenth of that of the thin-film sample. Such a thin thickness makes it possible to create ultra-thin EMWA materials.

The microstructure of PANI-CSA@HCNTs (a), the RL value of PANI-CSA@HCNTs composites, HCNTs, PANI@CSA, the mixture of PANI@CSA and HCNTs (b), and the schematic of microwave loss mechanism of PANI-CSA@HCNTs (c) from [79]

Among all the non-magnetic metal oxides, titanium dioxide (TiO2) has aroused great concern in EMWA applications because of its strong dielectric loss characteristics [80,81,82]. The low dielectric constant makes it suitable for adjusting the impedance of CNTs. To overcome the high density and processing difficulties of powdered CNTs/TiO2, Mo et al. made a breakthrough in producing a lightweight CNT/TiO2 sponge for microwave absorption using simple hydrolysis and heat treatment methods [83]. The crystal structure and morphology of CNTs/TiO2 sponge can be regulated by changing the experimental conditions. The CNTs/TiO2 sponge has excellent performance in microwave absorption. The RLmin is − 31.8 dB at a thickness of 2 mm.

Some non-magnetic metal oxides have semiconductor properties with adjustable band gaps and are, therefore, used to adjust the conductivity to enhance the microwave absorption properties of mixed materials, such as zinc oxide (ZnO) [84], copper oxide (Cu2O) [85], and alumina (Al2O3) [86]. For instance, copper oxide is deposited on MWCNT by means of the chemical force between the copper atoms of the copper oxide nanoparticles and the C=O associated with MWCNT [85]. Compared with pure MWCNT without absorbing performance, when the Cu2O/MWCNT thickness is 1.5 mm, the optimal RL is − 28.8 dB at 11.9 GHz, and the EAB can reach 2.7 GHz (10.7–13.4 GHz). When the thickness is 2.0 mm, the optimal RL is − 40.5 dB at 8.1 GHz. The mass fraction of Cu2O in Cu2O/MWCNT mixture is about 39.36%. The specific structure of the Cu2O/MWCNT mixture can establish the conductive network and increase the conductive path between the Cu2O and MWCNT. In addition, the immobilized copper oxide nanoparticles on MWCNTs provide the conditions that lead to polarization and capacitor-like structure at the interface between the Cu2O nanoparticles and MWCNTs, and attenuates EM wave energy.

3.2 Carbon fibers-based materials for microwave absorption

As a typical representative of 1D carbon materials, carbon nanofibers (CNFs) have aroused extensive interest in the field of EMWA due to their low density, high aspect ratio, high strength, good dielectric properties and corrosion resistance. Meanwhile, it has demonstrated in experiments that CNFs can prepare efficient EMWA due to three-dimensional networks through self-assembly or combination with magnetic materials. Therefore, in view of the unique ability of CNFs and magnetic metals and the synergistic effect between them, we have studied a large number of CNFs-based composites for microwave absorption.

3.2.1 Carbon fibers/magnetic materials composites for microwave absorption

Among the various technologies to obtain nanofibers, electrospinning is considered as a simple, low-cost, and efficient strategy for large-scale preparation of fibers with controllable size and microstructure [87, 88]. Electrospinning technology is a method of drawing and deforming charged polymer solution or melt under the action of electric field, and then obtaining fiber structure through solvent evaporation/melt cooling and solidification. In theory, any polymer material that can be dissolved or melted can be electrospun at a certain viscosity. This is an electrospinning process in Fig. 5a.

Ni/CNFs with well-controlled structure and morphology were prepared by electrospinning in the study of Shen et al. [89]. They found that the samples calcined at 650 °C could achieve the optimal RL value of − 44.9 dB and EAB of 3.0 GHz at the thickness of 3.0 mm, which is closely related to the impedance matching of magnetic loss optimization caused by magnetic nickel nanoparticles. The enhancement of dielectric loss is originated from the conductivity loss, dipole orientation polarization, and interface polarization caused by the conductive network formed by Ni/CNFs. The dipole orientation polarization and interface polarization result from the charge transfer among NiO, Ni, and carbon, which leads to the formation of electric dipole (Fig. 5c).

Also using electrospinning method, Liu et al. prepared nitrogen-doped CNFs (Co/N-CNFs) with solid and macroporous structure [90]. Compared with microporous Co/N-CNFs, the RLmin value of solid Co/N-CNFs was lower, which was − 25.7 dB, and the absorption bandwidth was wider, which was 4.3 GHz. This may be due to the high Co content.

In addition to electrospinning, the composite can also be obtained by coating thin film on the surface of carbon fiber. The most common thin-film growth processes, such as sputtering [91] and molecular beam epitaxy, require high vacuum or ultra-high vacuum. Electroplating is also accessible to prepare ferromagnetic films, because this method can change the electrodeposition parameters in the experiment and has the advantage of easy control [92]. Based on this, Liu et al. deposited a 2 μm thick Ni–Fe alloy film on the surface of CNFs by electroplating [92]. The magnetic and microwave absorption properties of Ni–Fe/CF composites were studied. The RL of Fe0.45Ni0.55/CF composites is less than − 10 dB in the range of 1.6–2.1 GHz. The lowest RL of Fe0.45Ni0.55/CF composite is − 14.7 dB, and the corresponding thickness is 3.3 mm, realizing at 2.0 GHz.

3.2.2 Carbon fibers/dielectric materials composites for microwave absorption

Silicon carbide (SiC) is best known as a semiconductor material, but it can also be employed as a lightweight, high-temperature EMWA due to its low density, good oxidation resistance, high thermochemical stability, high mechanical strength, and adjustable conductivity [93]. It is important to note that the EM properties of SiC usually change with its morphology. 1D silicon carbide nanofibers (SiCNF) with high surface volume ratio and shape structure effect are considered to have better microwave absorption properties than bulk or micro-silicon carbide particles. Consequently, it is universally accepted that SiCNF-coated CFs can achieve effective and stable EMWA performance. Chemical vapor deposition (CVD) is widely applied to coat SiC on carbon fibers to achieve one-dimensional structure [94]. In the work of Wu et al., large-scale SiC nanowire arrays were directly grown on the surface of carbon fibers (CFs) by CVD at a relatively low temperature (1200 °C). With the growth of SiCNW/CF composites, they have excellent microwave absorption properties, which are mainly caused by dielectric loss. For the composite with 30 wt% SiCNW/CF of 2 mm thickness, the RLmin of 21.5 dB is achieved at 7.7 GHz, and the EAB is 2.4 GHz [95].

Using the same CVD method (Fig. 6a, b), Zhou et al. adopted nickel nanoparticles as a catalyst to grow SiC nanofibers (SiCNFs) in situ on the surface of CFs [96]. The minimum RL of this composite can reach − 19.9 dB, and the RL of SiCNFs-coated CFs is less than − 10 dB in the frequency range of 9.2 to 11.7 GHz. Compared with the pure CFs, the RL in the range of 2 and 18 GHz is higher than − 2.1 dB, and the absorbing performance of this composite shows a significant improvement. As shown in Fig. 6d, they believe that the short carbon fibers are considered to act as micro-capacitors due to the electron accumulation on the surface of the short carbon fibers and the internal defects of the short carbon fibers under the external electric field. Under the electric field action of the SiCNFs-coated CFs, there is also a jump migration between the neighboring SiCNFs. Therefore, compared with pure CFs, the superior microwave absorption characteristics of SiCNFs-coated CFs are mainly attributed to the improved impedance matching and the dissipation caused by jump migration. The results of thermogravimetric analysis (TGA) show that the initial and final oxidation temperatures of SiCNFs-coated CFs are higher (Fig. 6g), which indicates that the oxidation resistance of oxygen is improved at high temperature. Therefore, SiCNFs-coated CFs can be used as a candidate of EMWA in harsh environment.

Dielectric materials such as zinc oxide (ZnO) and alumina (Al2O3) are widely used as necessary components of absorbers because of their dielectric behavior and dipole relaxation polarization.

Zhao et al. produced a specially designed CNFs coated with a gradient multilayer nanofilm [97]. This experiment applies atomic layer deposition (Fig. 7a, b) to precisely control the proportion of Al2O3 and ZnO contents in the nanofilm to regulate the electrical conductivity. A multifunctional gradient film with increasing electrical conductivity can be used as an intermediate layer to regulate the impedance matching between the air and the CNFs surface (Fig. 7c). By adjusting the thickness of the gradient film reasonably, the optimal RL of − 58.5 dB was attained, and the absorption layer thickness was only 1.8 mm.

Schematic of the synthesis process of the gradient films/CNFs via ALD (a), TEM images of the cross section of 5 × 45(Al + Zn)/CNFs (b), microwave absorption properties of the CNFs and coated CNFs (c), schematic of the interaction of an electromagnetic wave with gradient films/CNFs and possible absorption mechanisms (d) from [97], RL values verse frequency of granular ZnO/CFs and flocculent ZnO/CFs (e), and scanning electron microscope of different microstructure ZnO/CFs (f) from [99]

The release energy of internal stress in copper film caused by atomic diffusion makes the growth of CuO/CFs composites possible. Based on this, Zeng et al. synthesized CuO/CFs composites by annealing at 400 °C [98]. The ferromagnetism and microwave absorption properties of CuO/CF composites were studied. In the 1.8 mm layer, the strongest RL is further enhanced to − 29.6 dB at 7.8 GHz. Strong absorption (RL < − 10 dB and – 20 dB) ranges from 2.7 to 15.9 GHz and 3.0 to 9.4 GHz, with thickness of 1.0–4.0 mm, respectively. CuO/CF composite is considered to be an ideal material for manufacturing light, strong absorption, and multifrequency microwave absorption materials.

The change of microstructure, which is beneficial to multiple scattering and multiple polarization, is another strategy to optimize the absorbing performance besides changing the composition (Fig. 7f). The microwave absorbing properties of ZnO with flocculent structure on the surface of carbon fiber have been proved by Luo et al. [99] to be better than that of granular and flat plate. The flocculent ZnO/CFs synthesized by them have the RLmin of − 46.6 dB at 17.8 GHz, and the thickness is only 1.21 mm. However, the RLmin of granular ZnO/CFs at 16.6 GHz is − 46.4 dB with the thickness of 1.52 mm (Fig. 7e). They claimed that the special geometry of ZnO nanotrees with isotropic tangent network framework can be explained, which is consistent with the view in other studies [100,101,102]: fillers with high aspect ratio show better microwave absorption performance than those with low aspect ratio.

3.3 Other 1D carbon-based materials for microwave absorption

There are other one-dimensional carbon materials such as carbon nanowires (CNWs) and carbon nanorods to absorb EM waves.

Liu et al. [103] successfully prepared CNWs/SiC/SiOC composite ceramics including two types of nanowires, which have large specific surface area, more interfaces, and polarization loss is significantly higher than conductivity loss. Consequently, the RLmin of the composite ceramics is about − 24.5 dB at the thickness of 1.8 mm, and the EAB is 4.8 GHz at the thickness of 1.9 mm.

In order to obtain a novel absorber with high absorption, small reflection, and wide absorption band, Pan et al. prepared lithium carbonate nanowire reinforced silicon nitride composite ceramics (CNW/Si3N4) by catalytic CVD (Fig. 8a) [104]. The RLmin of the composite is − 50.21 dB, reaching at 10.8 GHz, and the maximum effective absorption bandwidth is 4.2 GHz, covering the whole X-band. The impressive absorption performance of CNW/Si3N4 originates from the contribution of the unique hierarchical porous structure to impedance matching, as well as the strong conductive loss and various dipole polarization effects (Fig. 8b).

Schematic illustration of the synthesis of hierarchically porous and polycrystalline CNW by CCVD (a), schematic illustration of the interaction of electromagnetic wave with the wires and possible EM absorption mechanisms in CNW/Si3N4 composite ceramics (b) from [104], schematic illustrations for a synthesis of rod-like Ni@C composites (c), and mechanism of microwave absorption in the rod-like Ni@C composites (d) from [17]

Instead of using CVD to embed magnetic nanomaterials into one-dimensional carbon materials, Li et al. [17] prepared heterogeneous rod-like Ni@C by a convenient hydrothermal reaction and subsequent calcination. The Ni@C nanorods have an RLmin of − 58.7 dB, at a thickness of 1.66 mm, and an effective absorption bandwidth of 4.4 GHz. Under the synergistic effect of conductive loss, dielectric loss, and magnetic loss, the Ni@C composite has a powerful EMWA ability. In addition, due to the high specific surface area and abundant heterogeneous interfaces of Ni@C composites, the multiple reflection and scattering of microwave are significantly increased. Moreover, the hybrids are suitable for practical applications because carbon matrix on the surface of nickel nanoparticles effectively prevents its aggregation and oxidation.

A series of rod-like composites containing ferromagnetic nanoparticles (Fe3O4, Fe3C, and Fe nanoparticles) embedded in porous carbon (Fig. 8d) were demonstrated and synthesized by Wu et al. [105]. The composition of the hybrids has a significant effect on the magnetic properties, and the fluctuation of dielectric constant depends greatly on the degree of graphitization with the change of pyrolysis temperature. Improvement of impedance matching results from multicomponent synergistic effect, conduction loss, and highly pore structure (Fig. 8e), which is conducive to good EM wave absorption performance. Finally, the magnetic nanorods obtained at the pyrolysis temperatures of 600 and 700 °C show the most significant EMWA properties, with a strong reflection loss of − 52.9 dB and a wide EAB of 4.64 GHz at 3.07 mm. The thickness of the magnetic nanorods at 600 °C is 3.5 mm, and EAB covers the whole X-band from 7.92 to 12.48 GHz.

4 Conclusion and perspectives

In this paper, we mainly take CNTs and carbon fibers as examples to summarize one-dimensional carbon-based materials as microwave absorbing materials. Due to its light weight, high dielectric, and high specific surface area, one-dimensional carbon materials can obtain excellent microwave absorption properties through composite and morphology design with other materials. This can be attributed to the synergistic effect of impedance matching and loss capability enhancement. The idea of modification mainly includes the combination with other materials and changing the structure to improve impedance matching and enrich the loss mechanism. In addition, the preparation of one-dimensional carbon matrix composites is also the focus of this paper.

Although the development of EM microwave absorption technology is constantly updated, the preparation of composites with different forms and components and excellent EM absorption effect have been obtained, there are still obvious defects in the practical application of related materials, and the further improvement is still facing great challenges.

In the work, we summarized that the effective absorption bandwidth of one-dimensional carbon-based microwave absorbing materials is concentrated in high frequency, which limits its application and is still difficult to be put into the civil range dominated by low-frequency EM waves.

Most studies are only guided by experience and lack of early simulation, and it is difficult to predict the experimental results. In this way, the time cost and material cost of work are high, which are not conducive to the efficient production of satisfactory results. In the future, the combination of simulation and experiment will greatly improve the work efficiency of researchers and prepare microwave absorbing materials with excellent performance.

However, some problems still exist in the calculation of microwave absorption properties. The existing formulas and theories cannot quantitatively analyze the contribution of each component and loss mechanism to the overall absorption characteristics of materials, which is not conducive to controlling the absorption characteristics of materials by adjusting components. Therefore, more work can be considered to study the absorption mechanism.

On the whole, one-dimensional carbon is more compounded with magnetic materials to improve the microwave absorbing performance, which is not conducive to the production of lightweight microwave absorbing materials. However, when developing airborne structures such as fighter aircraft, in addition to microwave absorbing performance, it is also important to consider weight. In conclusion, in future research, we must seriously consider looking for lightweight microwave absorbing materials with sufficient microwave attenuation.

Most of the preparation methods are only feasible in the laboratory and are difficult to generalize to industrial production. For example, in the preparation of carbon fiber tube ferrite, the solution thermal method is widely used in the preparation of EM wave electricity in the laboratory. It is only suitable for the preparation of a small amount of powder absorbent, which is difficult to realize large-scale industrialization. The method of preparing mass-produced microwave absorbing materials will become another challenge.

References

Z.J. Qu, Y. Wang, W. Wang, D. Yu, Hierarchical FeCoNiOx-PDA-rGO/WPU layers constructed on the polyimide fabric by screen printing with high microwave absorption performance. Appl. Surf. Sci. 562, 150190 (2021)

F. Chen, S.S. Zhang, R.D. Guo, B.B. Ma, Y. Xiong, H. Luo, Y.Z. Cheng, X. Wang, R.Z. Gong, 1D magnetic nitrogen doped carbon-based fibers derived from NiFe Prussian blue analogues embedded polyacrylonitrile via electrospinning with tunable microwave absorption. Composites B 224, 109161 (2021)

Z.H. Zhao, K.C. Kou, L.M. Zhang, H.J. Wu, Optimal particle distribution induced interfacial polarization in bouquet-like hierarchical composites for electromagnetic wave absorption. Carbon 186, 323–332 (2022)

J.L. Liu, L.M. Zhang, H.J. Wu, D.Y. Zang, Boosted electromagnetic wave absorption performance from vacancies, defects and interfaces engineering in Co(OH)F/Zn0.76Co0.24S/Co3S4 composite. Chem. Eng. J. 411, 128601 (2021)

D. Lan, Z.G. Gao, Z.H. Zhao, K.C. Kou, H.J. Wu, Application progress of conductive conjugated polymers in electromagnetic wave absorbing composites. Compos. Commun. 26, 100767 (2021)

G.Z. Wang, Z. Gao, S.W. Tang, C.Q. Chen, F.F. Duan, S.C. Zhao, S.W. Lin, Y.H. Feng, L. Zhou, Y. Qin, Microwave absorption properties of carbon nanocoils coated with highly controlled magnetic materials by atomic layer deposition. ACS Nano 6, 11009–11017 (2012)

M. Zhang, M.S. Cao, J.C. Shu, W.Q. Cao, L. Li, J. Yuan, Electromagnetic absorber converting radiation for multifunction. Mater. Sci. Eng. R 145, 100627 (2021)

H.S. Liang, H. Xing, Z.H. Ma, H.J. Wu, Tailoring high-electroconductivity carbon cloth coated by nickel cobaltate/nickel oxide: a case of transition from microwave shielding to absorption. Carbon 183, 138–149 (2021)

M.T. Qiao, X.F. Lei, Y. Ma, L.D. Tian, X.W. He, K.H. Su, Q.Y. Zhang, Application of yolk-shell Fe3O4@N-doped carbon nanochains as highly effective microwave-absorption material. Nano Res. 11, 1500–1519 (2018)

G. Chen, L.M. Zhang, B.C. Luo, H.J. Wu, Optimal control of the compositions, interfaces, and defects of hollow sulfide for electromagnetic wave absorption. J. Colloid Interface Sci. 607, 24–33 (2022)

M. Qin, L.M. Zhang, X.R. Zhao, H.J. Wu, Defect induced polarization loss in multi-shelled spinel hollow spheres for electromagnetic wave absorption application. Adv. Sci. 8, 2004640 (2021)

H.T. Guan, Q.Y. Wang, X.F. Wu, J. Pang, Z.Y. Jiang, G. Chen, C.J. Dong, L.H. Wang, C.H. Gong, Biomass derived porous carbon (BPC) and their composites as lightweight and efficient microwave absorption materials. Composites B 207, 108562 (2021)

D. Lan, Z.H. Zhao, Z.G. Gao, K.C. Kou, H.J. Wu, Novel magnetic silicate composite for lightweight and efficient electromagnetic wave absorption. J. Mater. Sci. Technol. 92, 51–59 (2021)

J.L. Liu, H.S. Liang, Y. Zhang, G.L. Wu, H.J. Wu, Facile synthesis of ellipsoid-like MgCo2O4/Co3O4 composites for strong wideband microwave absorption application. Composites B 176, 107240 (2019)

X.H. Liang, Z.M. Man, B. Quan, J. Zheng, W.H. Gu, Z. Zhang, G.B. Ji, Environment-stable CoxNiy encapsulation in stacked porous carbon nanosheets for enhanced microwave absorption. Nano–Micro Lett. 12, 102 (2020)

Y. Song, F.X. Yin, C.G. Zhang, W.B. Guo, L.Y. Han, Y. Yuan, Three-dimensional ordered mesoporous carbon spheres modified with ultrafine zinc oxide nanoparticles for enhanced microwave absorption properties. Nano–Micro Lett. 13, 76 (2021)

J.J. Li, F. Zhang, H.B. Lu, W.B. Guo, X.D. He, Y. Yuan, Heterogeneous rod-like Ni@C composites toward strong and stable microwave absorption performance. Carbon 181, 358–369 (2021)

L. Wang, X.F. Yu, X. Li, J. Zhang, M. Wang, R.C. Che, MOF-derived yolk-shell Ni@C@ZnO Schottky contact structure for enhanced microwave absorption. Chem. Eng. J. 383, 123099 (2020)

S.S. Wang, Y.C. Xu, R.R. Fu, H.H. Zhu, Q.Z. Jiao, T.Y. Feng, C.H. Feng, D.X. Shi, H.S. Li, Y. Zhao, Rational construction of hierarchically porous Fe–Co/N-doped carbon/rGO composites for broadband microwave absorption. Nano–Micro Lett. 11, 76 (2019)

X. Meng, Y.Q. Liu, G.H. Han, W.W. Yang, Y.S. Yu, Three-dimensional (Fe3O4/ZnO)@C double-core@shell porous nanocomposites with enhanced broadband microwave absorption. Carbon 162, 356–364 (2020)

L.R. Cui, X.J. Han, F.Y. Wang, H.H. Zhao, Y.C. Du, A review on recent advances in carbon-based dielectric system for microwave absorption. J. Mater. Sci. 56, 10782–10811 (2021)

X. Li, W.Q. Dong, C. Zhang, W.C. Guo, C.S. Wang, Y.M. Li, H.Y. Wang, Leaf-like Fe/C composite assembled by iron veins interpenetrated into amorphous carbon lamina for high-performance microwave absorption. Composites A 140, 106202 (2021)

K.W. Pan, T.L. Leng, J. Song, C.Y. Ji, J.W. Zhang, J.S. Li, K.S. Novoselov, Z.R. Hu, Controlled reduction of graphene oxide laminate and its applications for ultra-wideband microwave absorption. Carbon 160, 307–316 (2020)

J.Q. Wang, H.Y. Yu, Z.T. Yang, A.B. Zhang, Q.Y. Zhang, B.L. Zhang, Tubular carbon nanofibers: synthesis, characterization and applications in microwave absorption. Carbon 152, 255–266 (2019)

J.X. Wang, J.F. Yang, J. Yang, H. Zhang, An Ni–Co bimetallic MOF-derived hierarchical CNT/CoO/Ni2O3 composite for electromagnetic wave absorption. J. Alloys Compd. 876, 160126 (2021)

H.Q. Zhao, J. Zhu, Y. Cheng, Z.C. Xu, G.B. Ji, Green synthesis of hierarchically porous carbons with tunable dielectric response for microwave absorption. Ceram. Int. 46, 15447–15455 (2020)

G.J. Gou, F.B. Meng, H.G. Wang, M. Jiang, W. Wei, Z.W. Zhou, Wheat straw-derived magnetic carbon foams: in situ preparation and tunable high-performance microwave absorption. Nano Res. 12, 1423–1429 (2019)

L. Kong, J. Qi, M.H. Li, X.Y. Chen, X.Y. Yuan, T. Wang, J. Yang, J.F. Huang, X.M. Fan, Electromagnetic wave absorption properties of Ti3C2Tx nanosheets modified with in situ growth carbon nanotubes. Carbon 183, 322–331 (2021)

M. Zhu, X.X. Yan, H.L. Xu, Y.J. Xu, L. Kong, Ultralight, compressible, and anisotropic MXene@Wood nanocomposite aerogel with excellent electromagnetic wave shielding and absorbing properties at different directions. Carbon 182, 806–814 (2021)

M.H. Li, X.M. Fan, H.L. Xu, F. Ye, J.M. Xue, X.Q. Li, L.F. Cheng, Controllable synthesis of mesoporous carbon hollow microsphere twined by CNT for enhanced microwave absorption performance. J. Mater. Sci. Technol. 59, 164–172 (2020)

X. Li, M.H. Li, X.K. Lu, W.J. Zhu, H.L. Xu, J.M. Xue, F. Ye, Y.S. Liu, X.M. Fan, L.F. Cheng, A sheath-core shaped ZrO2–SiC/SiO2 fiber felt with continuously distributed SiC for broad-band electromagnetic absorption. Chem. Eng. J. 419, 129414 (2021)

Z.H. Zhao, K.C. Kou, H.J. Wu, 2-Methylimidazole-mediated hierarchical Co3O4/N-doped carbon/short-carbon-fiber composite as high-performance electromagnetic wave absorber. J. Colloid Interface Sci. 574, 1–10 (2020)

M. Zhang, C. Han, W.Q. Cao, M.S. Cao, H.J. Yang, J. Yuan, A nano–micro engineering nanofiber for electromagnetic absorber, green shielding and sensor. Nano–Micro Lett. 13, 27 (2021)

M.S. Cao, W.L. Song, Z.L. Hou, B. Wen, J. Yuan, The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon 48, 788–796 (2010)

M. Qin, Q. Shuai, G.L. Wu, B.H. Zheng, Z.D. Wang, H.J. Wu, Zinc ferrite composite material with controllable morphology and its applications. Mater. Sci. Eng. B 224, 125–138 (2017)

H.S. Liang, H. Xing, M. Qin, H.J. Wu, Bamboo-like short carbon fibers@Fe3O4@phenolic resin and honeycomb-like short carbon fibers@Fe3O4@FeO composites as high-performance electromagnetic wave absorbing materials. Composites A 135, 105959 (2020)

Z.G. Gao, Y.H. Song, S.J. Zhang, D. Lan, Z.H. Zhao, Z.J. Wang, D.Y. Zang, G.L. Wu, H.J. Wu, Electromagnetic absorbers with Schottky contacts derived from interfacial ligand exchanging metal–organic frameworks. J. Colloid Interface Sci. 600, 288–298 (2021)

J.P. Chen, H. Jia, Z. Liu, Q.Q. Kong, Z.H. Hou, L.J. Xie, G.H. Sun, S.C. Zhang, C.M. Chen, Construction of C–Si heterojunction interface in SiC whisker/reduced graphene oxide aerogels for improving microwave absorption. Carbon 164, 59–68 (2020)

Z.G. Gao, Z.H. Zhao, D. Lan, K.C. Kou, J.Q. Zhang, H.J. Wu, Accessory ligand strategies for hexacyanometallate networks deriving perovskite polycrystalline electromagnetic absorbents. J. Mater. Sci. Technol. 82, 69–79 (2021)

J.B. Cheng, Y.Q. Wang, A.N. Zhang, H.B. Zhao, Y.Z. Wang, Growing MoO3-doped WO3 nanoflakes on rGO aerogel sheets towards superior microwave absorption. Carbon 183, 205–215 (2021)

D. Lan, Z.G. Gao, Z.H. Zhao, G.L. Wu, K.C. Kou, H.J. Wu, Double-shell hollow glass microspheres@Co2SiO4 for lightweight and efficient electromagnetic wave absorption. Chem. Eng. J. 408, 127313 (2021)

J.L. Liu, L.M. Zhang, D.Y. Zang, H.J. Wu, A competitive reaction strategy toward binary metal sulfides for tailoring electromagnetic wave absorption. Adv. Funct. Mater. 31(45), 2105018 (2021)

H.P. Zhu, H.Y. Zhang, Y.M. Chen, Z.H. Li, D.F. Zhang, G.X. Zeng, Y.X. Huang, W.G. Wang, Q.B. Wu, C.Y. Zhi, The electromagnetic property and microwave absorption of wormhole-like mesoporous carbons with different surface areas. J. Mater. Sci. 51, 9723–9731 (2016)

R.X. Xu, D.W. Xu, Z. Zeng, D. Liu, CoFe2O4/porous carbon nanosheet composites for broadband microwave absorption. Chem. Eng. J. 427, 130796 (2022)

X.J. Zeng, L.Y. Zhu, B. Yang, R.H. Yu, Necklace-like Fe3O4 nanoparticle beads on carbon nanotube threads for microwave absorption and supercapacitors. Mater. Des. 189, 108517 (2020)

P.B. Liu, C.Y. Zhu, S. Gao, C. Guan, Y. Huang, W.J. He, N-doped porous carbon nanoplates embedded with CoS2 vertically anchored on carbon cloths for flexible and ultrahigh microwave absorption. Carbon 163, 348–359 (2020)

M. Qin, L.M. Zhang, X.R. Zhao, H.J. Wu, Lightweight Ni foam-based ultra-broadband electromagnetic wave absorber. Adv. Funct. Mater. 31(30), 2103436 (2021)

Y. Li, Y.C. Qing, Y.F. Zhou, B. Zhao, Q. Zhi, B.B. Fan, R. Zhang, Unique nanoporous structure derived from Co3O4–C and Co/CoO–C composites towards the ultra-strong electromagnetic absorption. Composites B 213, 108731 (2012)

C. Jin, Z.C. Wu, R.X. Zhang, X. Qian, H.L. Xu, R.C. Che, 1D electromagnetic-gradient hierarchical carbon microtube via coaxial electrospinning design for enhanced microwave absorption. ACS Appl. Mater. Interfaces 13, 15939–15949 (2021)

B.L. Wang, Q. Wu, Y.G. Fu, T. Liu, A review on carbon/magnetic metal composites for microwave absorption. J. Mater. Sci. Technol. 86, 91–109 (2021)

C.Q. Hong, X.K. Wang, H. Sun, Nd-doped Ni–Zn ferrite/multi-walled carbon nanotubes composites with effective microwave absorption properties. Ceram. Int. 47, 10545–10554 (2021)

M. Qin, H.S. Liang, X.R. Zhao, H.J. Wu, Glycine-assisted solution combustion synthesis of NiCo2O4 electromagnetic wave absorber with wide absorption bandwidth. Ceram. Int. 46, 22313–22320 (2020)

J.L. Liu, M. Wang, L.M. Zhang, D.Y. Zang, H. Liu, L.F. Liotta, H.J. Wu, Tunable sulfur vacancies and hetero-interfaces of FeS2-based composites for high-efficiency electromagnetic wave absorption. J. Colloid Interface Sci. 591, 148–160 (2021)

R.Y. Tan, J.T. Zhou, Z.J. Yao, B. Wei, J.Q. Zu, H.Y. Lin, Z. Li, Ferrero Rocher® chocolates-like FeCo/C microspheres with adjustable electromagnetic properties for effective microwave absorption. J. Alloys Compd. 857, 157568 (2021)

P.P. Zhou, X.K. Wang, Z. Song, M. Wang, W.T. Huang, M.X. Yu, L.X. Wang, Q.T. Zhang, Multi-dimensional ordered mesoporous carbon/silica@Ni composite with hierarchical nanostructure for strong and broadband microwave absorption. Carbon 176, 209–218 (2021)

S. Dong, P.T. Hu, X.T. Li, C.Q. Hong, X.H. Zhang, J.C. Han, NiCo2S4 nanosheets on 3D wood-derived carbon for microwave absorption. Chem. Eng. J. 398, 125588 (2020)

B. Qu, C.L. Zhu, C.Y. Li, X.T. Zhang, Y.J. Chen, Coupling hollow Fe3O4−Fe nanoparticles with graphene sheets for high-performance electromagnetic wave absorbing material. ACS Appl. Mater. Interfaces 8, 3730–3735 (2016)

Y. Gao, Z. Wang, Microwave absorption and electromagnetic interference shielding properties of Li–Zn ferrite–carbon nanotubes composite. J. Magn. Magn. Mater. 528, 167808 (2021)

X.Y. Zhu, H.F. Qiu, P. Chen, G.Z. Chen, W.X. Min, Graphitic carbon nitride (g-C3N4) in situ polymerization to synthesize MOF-Co@CNTs as efficient electromagnetic microwave absorption materials. Carbon 176, 530–539 (2021)

Z. Xiang, C. Huang, Y.M. Song, B.W. Deng, X. Zhang, X.J. Zhu, D. Batalu, O. Tutunaru, W. Lu, Rational construction of hierarchical accordion-like Ni@porous carbon nanocomposites derived from metal–organic frameworks with enhanced microwave absorption. Carbon 167, 364–377 (2020)

J.Q. Wang, F. Wu, Y.H. Cui, A.B. Zhang, Q.Y. Zhang, B.L. Zhang, Efficient synthesis of N-doped porous carbon nanoribbon composites with selective microwave absorption performance in common wavebands. Carbon 175, 164–175 (2021)

Y. Wu, R.W. Shu, J.B. Zhang, Z.L. Wan, J.J. Shi, Y. Liu, G.M. Zhao, M.D. Zheng, Oxygen vacancies regulated microwave absorption properties of reduced graphene oxide/multi-walled carbon nanotubes/cerium oxide ternary nanocomposite. J. Alloys Compd. 819, 152944 (2020)

Q. Chang, H.S. Liang, B. Shi, H.J. Wu, Sodium oxalate-induced hydrothermal synthesis of wood-texture-column-like NiCo2O4 with broad bandwidth electromagnetic wave absorption performance. J. Colloid Interface Sci. 600, 49–57 (2021)

X.J. Chen, H.Y. Liu, D.C. Hu, H.Q. Liu, W.S. Ma, Recent advances in carbon nanotubes-based microwave absorbing composites. Ceram. Int. 64, 6481–6489 (2021)

T. Zhang, B. Zhong, J.Q. Yang, X.X. Huang, G. Wen, Boron and nitrogen doped carbon nanotubes/Fe3O4 composite architectures with microwave absorption property. Ceram. Int. 41, 8163–8170 (2015)

K.Y. Li, H. Sun, H.R. Yuan, S. Zhang, X. Zhang, C.L. Zhu, X.T. Zhang, Y.J. Chen, Three-dimensional architectures assembled with branched metal nanoparticle-encapsulated nitrogen-doped carbon nanotube arrays for absorption of electromagnetic wave. J. Alloys Compd. 821, 153267 (2020)

Y. Qiu, H.B. Yang, B. Wen, L. Ma, Y. Lin, Facile synthesis of nickel/carbon nanotubes hybrid derived from metal organic framework as a lightweight, strong and efficient microwave absorber. J. Colloid Interface Sci. 590, 561–570 (2021)

M.Q. Ning, J.B. Li, B.Y. Kuang, C.Z. Wang, D.Z. Su, Y.J. Zhao, H.B. Jin, M.S. Cao, One-step fabrication of N-doped CNTs encapsulating M nanoparticles (M = Fe Co, Ni) for efficient microwave absorption. Appl. Surf. Sci. 447, 244–253 (2018)

F.S. Wen, F. Zhang, Z.Y. Liu, Investigation on microwave absorption properties for multiwalled carbon nanotubes/Fe/Co/Ni nanopowders as lightweight absorbers. J. Phys. Chem. C 115, 14025–14030 (2011)

F.S. Wen, F. Zhang, J.Y. Xiang, W.T. Hu, S.J. Yuan, Z.Y. Liu, Microwave absorption properties of multiwalled carbon nanotube/FeNi nanopowders as light-weight microwave absorbers. J. Magn. Magn. Mater. 343, 285 (2013)

Q.X. Yang, L. Liu, D. Hui, M. Chipara, Microstructure, electrical conductivity and microwave absorption properties of γ-FeNi decorated carbon nanotube composites. Composites B 87, 256–262 (2016)

R.W. Shu, Y. Wu, Z.Y. Li, J.B. Zhang, Z.L. Wan, Y. Liu, M. Zheng, Facile synthesis of cobalt–zinc ferrite microspheres decorated nitrogen-doped multi-walled carbon nanotubes hybrid composites with excellent microwave absorption in the X-band. Compos. Sci. Technol. 184, 107839 (2019)

H.F. Pang, R.P. Sahu, Y.P. Duan, I.K. Puri, MnFe2O4-coated carbon nanotubes with enhanced microwave absorption: effect of CNT content and hydrothermal reaction time. Diam. Relat. Mater. 96, 31–43 (2019)

Z.F. Liu, H.L. Xing, Y. Liu, H. Wang, H.X. Jia, X.L. Ji, Hydrothermally synthesized Zn ferrite/multi-walled carbon, nanotubes composite with enhanced electromagnetic-wave absorption performance. J. Alloys Compd. 731, 745–752 (2018)

M. Dalal, A. Das, D. Das, R.S. Ningthoujam, P.K. Chakrabarti, Studies of magnetic, Mössbauer spectroscopy, microwave absorption and hyperthermia behavior of Ni–Zn–Co-ferrite nanoparticles encapsulated in multi-walled carbon nanotubes. J. Magn. Magn. Mater. 460, 12–27 (2018)

Q.Q. Ni, Y.F. Zhu, L.J. Yu, Y.Q. Fu, One-dimensional carbon nanotube@barium titanate@polyaniline multiheterostructures for microwave absorbing application. Nanoscale Res. Lett. 10, 174 (2015)

J.L. Kuang, X.J. Hou, T. Xiao, Y. Li, Q. Wang, P. Jiang, W.B. Cao, Three-dimensional carbon nanotube/SiC nanowire composite network structure for high-efficiency electromagnetic wave absorption. Ceram. Int. 45, 6263–6267 (2019)

G. Salimbeygi, K. Nasouri, A.M. Shoushtari, Fabrication of homogeneous multi-walled carbon nanotube/poly (vinyl alcohol) composite films using for microwave absorption application. Fibers Polym. 15, 583–588 (2014)

X. Tian, F.B. Meng, F.C. Meng, X.G. Chen, Y.F. Guo, Y. Wang, W.J. Zhu, Z.W. Zhou, Synergistic enhancement of microwave absorption using hybridized polyaniline@helical CNTs with dual chirality. ACS Appl. Mater. Interfaces 9, 15711–15718 (2017)

G. Salimbeygi, K. Nasouri, A.M. Shoushtari, R. Malek, F. Mazaheri, Microwave absorption properties of polyaniline/poly(vinyl alcohol)/multi-walled carbon nanotube composites in thin film and nanofiber layer structures. Macromol. Res. 23, 741–748 (2015)

T.H. Elagib, E.M. Hassan, B.H. Liu, K.Q. Han, M.H. Yu, Evaluation of composite PAN fibers incorporated with carbon nanotubes and titania and their performance during the microwave-induced pre-oxidation. Carbon Lett. 30, 235–245 (2020)

S. Benjedim, J.C. Quiben, E.B. García, Francisco Carrasco-Marín A, Activated carbon-based coloured titania nanoparticles with high visible radiation absorption and excellent photoactivity in the degradation of emerging drugs of wastewater. Carbon 178, 753–766 (2021)

Z.C. Mo, R.L. Yang, D.W. Lu, L.L. Yang, Q.M. Hu, H.B. Li, H. Zhu, Z.K. Tang, X.C. Gui, Lightweight, three-dimensional carbon nanotube@TiO2 sponge with enhanced microwave absorption performance. Carbon 144, 433–439 (2019)

L.L. Yan, L.L. Li, X.X. Ru, D.N. Wen, L. Ding, X.Y. Zhang, H.P. Diao, Y. Qin, Core–shell, wire-in-tube and nanotube structures: carbon-based materials by molecular layer deposition for efficient microwave absorption. Carbon 173, 145–153 (2021)

S.T. Gao, H.L. Xing, Y.F. Li, H. Wang, Synthesis of Cu2O/multi-walled carbon nanotube hybrid material and its microwave absorption performance. Res. Chem. Intermed. 44, 3425–3435 (2018)

S. Bi, X.J. Su, G.L. Hou, C.H. Liu, W.L. Song, M.S. Cao, Electrical conductivity and microwave absorption of shortened multi-walled carbon nanotube/alumina ceramic composites. Ceram. Int. 39, 5979–5983 (2013)

T. Baykara, G. Taylan, Coaxial electrospinning of PVA/Nigella seed oil nanofibers: processing and morphological characterization. Mater. Sci. Eng. B 265, 115012 (2021)

Y.S. Fan, X.K. Tian, L.B. Zheng, X. Jin, Q.S. Zhang, S.Y. Xu, P.F. Liu, N. Yang, H.H. Bai, H.Q. Wang, Yeast encapsulation in nanofiber via electrospinning: shape transformation, cell activity and immobilized efficiency. Mater. Sci. Eng. C 120, 111747 (2021)

Y.Q. Shen, Y.P. Wei, J.Q. Ma, Q.L. Li, J. Li, W.J. Shao, P.Z. Yan, G.W. Huang, X.Y. Du, Tunable microwave absorption properties of nickel–carbon nanofibers prepared by electrospinning. Ceram. Int. 45, 3313–3324 (2019)

H.H. Liu, Y.J. Li, M.W. Yuan, G.B. Sun, H.F. Li, S.L. Ma, Q.L. Liao, Y. Zhang, In situ preparation of cobalt nanoparticles decorated in N-doped carbon nanofibers as excellent electromagnetic wave absorbers. ACS Appl. Mater. Interfaces 10, 22591–22601 (2018)

B. Huang, J.L. Yue, Y.S. Wei, X.Z. Huang, X.Z. Tang, Z.J. Du, Enhanced microwave absorption properties of carbon nanofibers functionalized by FeCo coatings. Appl. Surf. Sci. 483, 98–105 (2019)

Y. Liu, C.W. Qiang, Magnetic properties and microwave absorption properties of short carbon fibres coated by Ni–Fe alloy coatings. Bull. Mater. Sci. 38, 1673–1678 (2015)

L. Long, Y. Li, W. Zhou, Dielectric response and microwave absorption properties of SiC whisker-coated carbon fibers. J. Mater. Sci. Mater. Electron. 30, 15075–15083 (2019)

X.L. Ye, Z.F. Chen, M. Li, T. Wang, J.X. Zhang, C. Wu, Q.B. Zhou, H.Z. Liu, S. Cui, Reticulated SiC coating reinforced carbon foam with tunable electromagnetic microwave absorption performance. Composites B 178, 107479 (2019)

R.B. Wu, Z.H. Yang, M.S. Fu, K. Zhou, In situ growth of SiC nanowire arrays on carbon fibers and their microwave absorption properties. J. Alloys Compd. 687, 833–838 (2016)

W. Zhou, L. Long, P. Xiao, Y. Li, H. Luo, W.D. Hua, R.M. Yin, Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties. Ceram. Int. 43, 5628–5634 (2017)

S.C. Zhao, L.L. Yan, X.D. Tian, Y.Q. Liu, C.Q. Chen, Y.Q. Li, J.K. Zhang, Y. Song, Y. Qin, Flexible design of gradient multilayer nanofilms coated on carbon nanofibers by atomic layer deposition for enhanced microwave absorption performance. Nano Res. 11, 530–541 (2018)

J. Zeng, J.C. Xu, P. Tao, W. Hu, Ferromagnetic and microwave absorption properties of copper oxide–carbon fiber composites. J. Alloys Compd. 487, 304–308 (2009)

H.L. Luo, G.Y. Xiong, X.Q. Chen, Q.P. Li, C.Y. Ma, D.Y. Li, X.B. Wu, Y.Z. Wan, ZnO nanostructures grown on carbon fibers: morphology control and microwave absorption properties. J. Alloys Compd. 593, 7–15 (2014)

M. Oyharcabal, T. Olinga, M.P. Foulc, S. Lacomme, E. Gontier, V. Vigneras, Influence of the morphology of polyaniline on the microwave absorption properties of epoxy polyaniline composites. Compos. Sci. Technol. 74, 107–112 (2013)

Y. Huang, N. Li, Y.F. Ma, F. Du, F.F. Li, X.B. He, X. Lin, H.J. Gao, Y.S. Chen, The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 45, 1614–1621 (2007)

Q.C. Liu, Z.F. Zi, D.J. Wu, Y.P. Sun, J.M. Dai, Controllable synthesis and morphology-dependent microwave absorption properties of iron nanocrystals. J. Mater. Sci. 47, 1033–1037 (2012)

X.L. Liu, J.M. Xue, F.Y. Ren, F. Ye, X.M. Fan, Y.S. Liu, L.F. Cheng, Enhanced microwave-absorption properties of polymer-derived SiC/SiOC composite ceramics modified by carbon nanowires. Ceram. Int. 46, 20742–20750 (2020)

H.X. Pan, X.W. Yin, J.M. Xue, L.F. Cheng, L.T. Zhang, In situ synthesis of hierarchically porous and polycrystalline carbon nanowires with excellent microwave absorption performance. Carbon 107, 36–45 (2016)

N.N. Wu, D.M. Xu, Z. Wang, F.L. Wang, J.R. Liu, W. Liu, Q. Shao, H. Liu, Q. Gao, Z.H. Guo, Achieving superior electromagnetic wave absorbers through the novel metal–organic frameworks derived magnetic porous carbon nanorods. Carbon 145, 433–444 (2019)

Acknowledgements

Financial support was provided by the National Science Foundation of China (Grant Nos. 52074227 and 51801186).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, J., Liang, H., Chen, G. et al. A review on one-dimensional carbon-based composites as electromagnetic wave absorbers. J Mater Sci: Mater Electron 33, 567–584 (2022). https://doi.org/10.1007/s10854-021-07363-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07363-7