Abstract

Lead-free (0.99 − x)K0.5Na0.5Nb0.96Sb0.04O3-0.01BaZrO3-xBi0.5Na0.5ZrO3 (KNNS–BZ–BNZ) piezoelectric ceramics were fabricated by the conventional solid-state reaction method. The effects of the addition of Bi0.5Na0.5ZrO3 on phase structure, microstructure, and electrical properties were studied in detail. The rhombohedral–tetragonal (R–T) phase boundary was established in the ceramics with 0.03 ≤ x ≤ 0.04. Owing to the both R–T phase boundary and the enhancement of dielectric and ferroelectric properties, an optimal electrical property (e.g., d33 = 450 ± 5 pC/N, kp = 0.50 ± 0.02, and TC = 252 °C) was attained in the ceramics with x = 0.03. As a result, constructing phase boundary is proved to be a good way to improve the electrical properties in KNN-based ceramics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Piezoelectric materials are widely used in kinds of electron devices, such as sensors, actuators and so on, because of their unique properties which can convert mechanical energy into electrical energy and vice versa [1, 2]. Lead zirconate titanate (PZT) family is governing the piezoelectric market due to their superior piezoelectric properties [3]. However, in order to achieve the sustainable development, it is imperative to develop high-performance Pb-free piezoceramics to replace the Pb-based ones because of the high toxicity of Pb element [4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35].

Potassium-sodium niobate (KNN) ceramics, which are the most promising among the Pb-free piezoceramics, have received considerable attentions due to their good peizoelectric properties and high Curie temperature (TC) [5,6,7, 29]. In the past decades, numerous efforts have been carried out to enhance the electrical properties of KNN-based ceramics with the purpose of replacing the Pb-based piezoceramics [5,6,7, 29]. Some approaches are currently employed to improve the electrical properties in KNN-based ceramics, such as constructing phase boundary [5, 9], new sintering methods [8], new preparation method [10]. Constructing phase boundary is the most promising one among these approaches [5, 9, 12,13,14,15, 29, 34]. In particular, a large d33 of 416 pC/N as well as a high TC of 250 °C was obtained in a well-designed textured ceramics [(K0.44Na0.52Li0.04)(Nb0.86Ta0.10Sb0.04)O3, (LF4T)] possessing an orthorhombic–tetragonal (O–T) phase boundary by Saito et al. who adopted the reactive templated grain growth (RTGG) method [10]. Very recently, Wu’s group observed two large d33 values of 490 pC/N and 570 pC/N in (1 − x)(K1−yNa y )(Nb1−zSb z )O3-xBi0.5(Na1−wK w )0.5ZrO3 ceramics and (1 − x − y)(K1−wNa w Nb1−zSb z O3-yBaZrO3-Bi0.5K0.5HfO3) ceramics, respectively [14, 15]. They attributed the superior piezoelectric properties to the appearance of R–T phase boundary. In spite of the high cost of RTGG method and the relatively low TC values (< 250 °C) at the optimal piezoelectric properties in Wu’s ceramics, constructing phase boundary shows a crucial role in the improvement of electrical properties in KNN ceramics. According to previous works, Sb5+, BaZrO3, and Bi0.5Na0.5ZrO3 can effectively affect the phase structure and electrical properties of KNN ceramics [16,17,18,19, 29]. Therefore, these additives are good candidates for constructing phase boundary.

In this work, with the purpose of constructing phase boundary and obtaining high piezoelectric properties, we designed a new formula, (0.99 − x)K0.5Na0.5Nb0.96Sb0.04O3-0.01BaZrO3-xBi0.5Na0.5ZrO3 (KNNS–BZ–BNZ) and then prepared the KNNS–BZ–BNZ ceramics by using the conventional solid-state reaction method. Effects of the addition of Bi0.5Na0.5ZrO3 on the phase structure and electrical properties were systematically studied. Both XRD patterns and the temperature dependence of dielectric constant curves attested the formation of R–T phase boundary in the ceramics with 0.03 ≤ x ≤ 0.04, and their electrical properties were improved. The related physical mechanisms were addressed.

2 Experimental procedure

Lead-free KNNS–BZ–BNZ (0.03 ≤ x ≤ 0.04) piezoelectric ceramics were synthesized by the conventional solid-state reaction method. The raw materials were K2CO3 (99%), Na2CO3 (99.8%), Nb2O5 (99.5%), Sb2O3 (99.99%), BaCO3 (99%), Bi2O3 (99.999%), and ZrO2 (99%). All these raw materials were accurately weighed according to the formula by using a high precise electronic balance, and then were ball milled for 20 h with the ethyl alcohol. After drying, the powders were calcined at 850 °C for 6 h, and then were mixed with a binder of 8 wt% polyvinyl alcohol (PVA) and pressed into pellets with a diameter of 10 mm and a thickness of 1 mm. After evaporating PVA, the green disks were sintered at 1080–1125 °C for 3 h. In order to measure the electrical properties, the as-sintered samples were printed with silver paste on the both sides, and then heated at 650 °C for 20 min to form the electrode. Finally, the samples were poled at room temperature for 30 min in a silicon oil bath, by applying a direct current (dc) electric field of 3 kV/mm.

The crystal structure was collected by the X-ray diffraction patterns (Bruker D8 Advanced XRD, Bruker AXS Inc., Madison, WI, CuKα). The surface morphology of the as-sintered samples and their elements distribution were measured by a filed-emission scanning electron microscope (FE-SEM, JSM-7500, Japan) accompanied by Energy Dispersive X-ray (EDX) spectroscopy. The dielectric constant (εr) varying with temperature (− 150 to 200 °C and 25–400 °C) was measured by using an LCR analyzer (HP 4980, Agilent, USA) in connection with a temperature-controlled instrument. The ferroelectric loops of the ceramics were measured by using a ferroelectric tester (Radiant Technologies, Inc., Albuquerque, NM) at 10 Hz. The planar electromechanical coupling coefficient (kp) was measured by a resonance-antiresonance method with an impedance analyzer (Impedance Analyzer, PV70A, Beijing). The piezoelectric constant (d33) of the poled samples was measured by using a quasi-static d33 meter (ZJ-3A, China). In order to measure the thermal stability, the poled samples were heated for 30 min at the scheduled temperatures and then their d33 values were measured.

3 Results and discussion

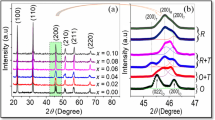

Figure 1a shows the XRD patterns of the KNNS–BZ–BNZ ceramics as a function of x. All samples display a pure perovskite structure without the occurrence of secondary phases, indicating that Bi0.5Na0.5ZrO3 can effectively diffused into KNN ceramics. Figure 1b shows the enlarged XRD patterns of the samples in the 2 theta range of 44°–47°. The phase structure of the samples is strongly dependent on the content of Bi0.5Na0.5ZrO3. For the ceramics with x = 0 and 0.01, a typical orthorhombic (O) phase structure with I202/I020 near to 2:1 [I202 and I020 represent the intensity of diffraction peak (202) and (020), respectively] was observed [20]. As the content of Bi0.5Na0.5ZrO3 increased, I202 decreased and I020 increased. A ratio of 1:1 and 1:2 between I202 and I020 were observed in the ceramics with x = 0.02 and 0.03, respectively, indicating that a tetragonal (T) phase structure was involved [21]. As the content of Bi0.5Na0.5ZrO3 was further increased, a single diffraction peak was observed in the ceramics with x = 0.05, which was regarded as rhombohedral (R) or pseudo-cubic phase [20, 21].

In order to further analyze the phase structure of KNNS–BZ–BNZ ceramics, the temperature (− 150 to 200 °C) dependence of dielectric constant (εr–T) curves were measured, as shown in Fig. 2a–f. From Fig. 2a, two abnormal dielectric peaks were observed, which corresponded to the R–O phase transition (TR−O = − 75 °C) and O–T phase transition (TO−T = 127 °C), respectively. With an increase of x, TR−O increased and TO−T dropped. Then, only one abnormal dielectric peak was observed in the ceramics with x = 0.03 (see Fig. 2d), indicating that both TR−O and TO−T were shifted to the same temperature leading to the formation of R–T phase boundary. As x further increased, TR−T vanished and only one abnormal dielectric peak corresponding to Curie temperature (TC) was observed in the ceramics with x = 0.05 (see Fig. 2f), which can be explained by the small grains (see Fig. 4d), and the similar phenomenon was observed in other lead-free ceramics [31,32,33]. Therefore, combined with XRD patterns and εr–T curves, a conclusion on phase structure can be obtained, that is, the ceramics with x = 0 and 0.01 have an O phase, the ceramics with x = 0.02 possess an O–T coexistence phase, the ceramics with x = 0.03 and 0.04 own a R–T coexistence phase and the ceramics with x = 0.05 are pseudo-cubic phase.

Figure 3a depicts the εr–T curves measured at the temperature range of 25–400 °C. It is found that TC gradually dropped as the content of Bi0.5Na0.5ZrO3 increased. In addition, a relatively high TC value of 252 °C was obtained in the ceramics with x = 0.03 which possessed the optimal piezoelectric properties, as discussed later. After deriving TR−O, TO−T, TR−T, and TC from Figs. 2 and 3a, the phase diagram of the KNNS–BZ–BNZ ceramics was established, as shown in Fig. 3b. According to previous references [19], the addition of Bi0.5Na0.5ZrO3 can elevate TR−O and drop TO−T and TC, which is also attested in this work. As the content of Bi0.5Na0.5ZrO3 increased, both TO−T and TC decreased and TR−O increased. Increasing TR−O and decreasing TO−T compressed and even vanished the zone of O phase, leading to the formation of R–T phase boundary.

Figure 4 shows the SEM surface morphology of the KNNS–BZ–BNZ ceramics as a function of x. For the ceramic with x = 0, an inhomogeneous grain size distribution, which was that the large grains were surrounded by the small ones, was observed. As the x increased from 0 to 0.03, the grain size gradually increased, suggesting that an appropriate content of Bi0.5Na0.5ZrO3 can promote the grain growth [22]. As the x was further increased from 0.03 to 0.05, the grain size sharply dropped, indicating that high doping content of Bi0.5Na0.5ZrO3 greatly inhibits the grain growth. When the content of Bi0.5Na0.5ZrO3 is high, a small amount of Bi0.5Na0.5ZrO3 aggregates at the grain boundary and then inhibits the grain growth [22]. Considering that eight elements (i.e., K, Na, Nb, Sb, O, Zr, Bi, Ba) are involved in this work, therefore it is necessary to figure out the distribution of these elements. Figure 5 shows the elements mappings of the ceramics with x = 0.03. It is found that a homogeneous distribution is observed for all elements, indicating a good chemical homogeneity.

Figure 6a shows the ferroelectric loops of the KNNS–BZ–BNZ ceramics as a function of x. All ceramics, except for x = 0.05, display a classical ferroelectric loops. The deteriorative ferroelectric loop of the ceramics with x = 0.05 mainly attributed to the pseudo-cubic phase. As we know, a material with high symmetry possesses a poor ferroelectricity and vice vers [23]. Therefore, the high symmetry of pseudo-cubic phase is responsible for the deteriorative ferroelectricity in the ceramics x = 0.05. Figure 6b shows Pr and EC values of the KNNS–BZ–BNZ ceramics as a function of x. As the x increased, Pr first increased and then decreased, while EC sostenuto decreased, which was consist with the previous study [24].

Figure 7 shows the dielectric constant (εr) and dielectric loss (tanδ) of the KNNS–BZ–BNZ ceramics varying with x values. For all ceramics, εr decreased and tan δ increased as the frequency increased, indicating a typical ferroelectricity [23]. For all frequencies, εr first increased and then decreased as the x increased, reaching the optimal value in the ceramics with x = 0.03 possessing an R–T coexistence phase. As for tanδ, a sostenuto increasing tendency was observed in all frequencies.

In order to investigate the effect of Bi0.5Na0.5ZrO3 on the piezoelectric properties of KNN ceramics, both d33 and kp were measured, as shown in Fig. 8a. It is found that both d33 and kp first increased and then dropped as the x increased, with the optimal value of 450 ± 5 pC/N and 0.50 ± 0.02 reached at x = 0.03 possessing an R–T phase boundary. According to previous work, both polarization rotation and domain wall motion are facilitated in the vicinity of R–T phase boundary during poling [25, 26, 34], which leads to the improved piezoelectric properties. Therefore, the enhanced piezoelectric property in this work is mainly attributed to the R–T phase boundary. In addition, the piezoelectric properties of a ferroelectric material can be evaluated by the following equation, d33 ~ αεrPr [23, 27, 28]. Where α is the electrostrictive coefficient. Figure 8b plots d33 and εrPr of the KNNS–BZ–BNZ ceramics as a function of x. It is found that both d33 and εrPr should display a similar change tendency, which is well consistent with the equation. Therefore, except for the R–T phase boundary, the enhancement of εr and Pr plays a part role in the improved piezoelectric properties [23, 27, 28].

For practical applications, the thermal stability is an important factor. Figure 9a, b show d33 and normalized d33 values of the KNNS–BZ–BNZ ceramics against the annealing temperature (Ta). It was found that d33 and normalized d33 values of all ceramics first decreased slightly before Ta reached to TC, and then dropped sharply when Ta exceeded TC. Despite the decreasing d33 values, a relatively high d33 of 362 pC/N was still observed when Ta reached to 180 °C in the ceramic with x = 0.03, indicating a well thermal stability.

4 Conclusions

In the present work, the KNNS–BZ–BNZ lead-free piezoelectric ceramics were prepared by the conventional solid-state reaction method. The effects of Bi0.5Na0.5ZrO3 on the phase structure, microstructure and electrical properties were systematically investigated. The results show that the addition of Bi0.5Na0.5ZrO3 can elevate TR−O and drop TO−T, leading to the formation of R–T phase boundary in the ceramics with x = 0.03 and 0.04. The ceramics with x = 0.03 show the optimal piezoelectric properties, that is, d33 = 450 ± 5 pC/N, kp = 0.50 ± 0.02. Both R–T phase boundary and the enhancement of dielectric and ferroelectric properties are attributed to the improvement of piezoelectric properties in this work. In addition, a well thermal stability is observed in the ceramics with x = 0.03, with a high d33 value of 362 pC/N as Ta reached to 180 °C. Therefore, we believe that the material system is promising for applications.

References

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics (Academic, New York, 1971)

J. Rödel, K.G. Webber, R. Dittmer, W. Jo, M. Kimura, D. Damjanovic, J. Am. Ceram. Soc. 35(6), 1659 (2015)

T.R. Shrout, S. Zhang, J. Electroceram. 19, 111 (2007)

J. Rödel, W. Jo, K.T. Seifert, E.M. Anton, T. Granzow, D. Damjanovic, J. Am. Ceram. Soc. 92(6), 1153 (2009)

J.G. Wu, D.Q. Xiao, J.G. Zhu, Chem. Rev. 115, 2559 (2015)

J.G. Wu, D.Q. Xiao, J.G. Zhu, J. Mater. Sci. Mater. Electron. 26(12), 9297 (2015)

J.F. Li, K. Wang, F.Y. Zhu, L.Q. Cheng, F.Z. Yao, J. Am. Ceram. Soc. 96(12), 3677 (2013)

M. Feizpour, H.B. Bafrooei, R. Hayati, T. Ebadzadeh, Ceram. Int. 40(1), 871 (2014)

B. Wu, J.G. Wu, D.Q. Xiao, J.G. Zhu, Dalton Trans. 44(48), 21141 (2015)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432(7013), 84 (2004)

D. Lv, R. Zuo, J. Alloys Compd. 560, 62 (2013)

F.Z. Yao, K. Wang, W. Jo, J.F. Li, Adv. Funct. Mater. 26, 1217 (2016)

M.H. Zhang, K. Wang, Y.J. Du, G. Dai, W. Sun, G. Li, D. Hu, H.C. Thong, C.L. Zhao, X.Q. Xi, Z.X. Yue, J.F. Li, J. Am. Chem. Soc. 139(10), 3889 (2017)

X.P. Wang, J.G. Wu, D.Q. Xiao, J.G. Zhu, X.J. Cheng, T. Zheng, B.Y. Zhang, X.J. Lou, X.J. Wang, J. Am. Chem. Soc. 136, 2905 (2014)

K. Xu, J. Li, X. Lv, J.G. Wu, X.X. Zhang, D.Q. Xiao, J.G. Zhu, Adv. Mater. 28(38), 8519 (2016)

R. Zuo, J. Fu, D. Lv, Y. Liu, J. Am. Ceram. Soc. 93(9), 2783 (2010)

J. Wu, H. Tao, Y. Yuan, X. Lv, X. Wang, X. Lou, RSC Adv. 5(19), 14575 (2015)

J. Gao, S. Ren, L. Zhang, Y. Hao, M. Fang, M. Zhang, Y. Dai, X. Hu, D. Wang, L. Zhong, J. Appl. Phys. 107(3), 032902 (2015)

Z. Wang, D. Xiao, J. Wu, M. Xiao, F. Li, J. Zhu, J. Am. Ceram. Soc. 97(3), 688 (2014)

Y. Wang, Q. Zhang, J. Alloys Compd. 611, 351 (2014)

H. Tao, J. Wu, T. Zheng, X. Wang, X. Lou, J. Appl. Phys. 118(4), 044102 (2015)

T. Zheng, J. Wu, X. Cheng, X. Wang, B. Zhang, D. Xiao, J. Zhu, X. Wang, X. Lou, J. Mater. Chem. C 2(41), 8796 (2014)

J. Li, L. Fei, S. Zhang, J. Am. Ceram. Soc. 97(1), 1 (2014)

X. Wang, J. Wu, D. Xiao, X. Cheng, T. Zheng, B. Zhang, X. Lou, J. Zhu, J. Mater. Chem. A 2(12), 4122 (2014)

J. Gao, L. Zhang, D. Xue, T. Kimoto, M. Song, L. Zhong, X. Ren, J. Appl. Phys. 115(5), 054108 (2014)

W. Liu, X. Ren, Phys. Rev. Lett. 103(25), 257602 (2009)

F. Rubio-Marcos, R. López-Juárez, R.E. Rojas-Hernandez, A. Del Campo, N. Razo-Pérez, J.F. Fernandez, Acs Appl. Mater. Inter. 7(41), 23080 (2015)

C. Zhao, Y. Feng, H. Wu, J. Wu, J. Alloys Compd. 666, 372 (2016)

B. Wu, H.J. Wu, J.G. Wu, D.Q. Xiao, J.G. Zhu, S.J. Pennycook, J. Am. Chem. Soc. 138, 15459 (2016)

J. Wu, Z. Fan, D. Xiao, J. Zhu, J. Wang, Prog. Mater Sci. 84, 335 (2016)

B. Wu, J. Ma, W. Wu, M. Chen, Y.C. Ding, H.B. Tian, J. Alloys Compd. 710, 130 (2017)

Z. Zhao, V. Buscaglia, M. Viviani, M.T. Buscaglia, L. Mitoseriu, A. Testino, M. Nygren, P. Johnsson, Nanni, Phys. Rev. B 70, 024107 (2004)

V. Buscaglia, M.T. Buscaglia, M. Viviani, L. Mitoseriu, P. Nanni, V. Trefiletti, P. Piaggio, I. Gregora, T. Ostapchuk, J. Pokorny, J. Petzelt, J. Eur. Ceram. Soc. 26, 2889 (2006)

Y. Wang, L. Hu, Q. Zhang, H. Yang, Dalton Trans. 44(30), 13688 (2015)

T. Zheng, H.J. Wu, Y. Yuan, X. Lv, Q. Li, T. Men, C.L. Zhao, D.Q. Xiao, J.G. Wu, K. Wang, J.F. Li, Y.L. Gu, J.G. Zhu, S.J. Pennycook, Energy Environ. Sci. 10, 528 (2017)

Acknowledgements

Authors gratefully acknowledge the National Science Foundations of China (NSFC Nos. 51702028 and 51702029), and the supports of the Scientific Research Foundation of CUIT (Grant No. 376815).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, J., Wu, B., Wu, W. et al. Structure and electrical properties of (0.99 − x)K0.5Na0.5Nb0.96Sb0.04O3-0.01BaZrO3-xBi0.5Na0.5ZrO3 lead-free piezoelectric ceramics. J Mater Sci: Mater Electron 29, 12323–12329 (2018). https://doi.org/10.1007/s10854-018-9345-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9345-0