Abstract

The ZnO–Nb2O5–xTiO2 (1 ≤ x ≤ 2) ceramics were fabricated by reaction-sintering process, and the effects of TiO2 content and sintering temperature on the crystal structure and microwave dielectric properties of the ceramics were investigated. The XRD patterns of the ceramics showed that ZnTiNb2O8 single phase was formed as x ≤ 1.6 and second phase Zn0.17Nb0.33Ti0.5O2 appeared at x ≥ 1.8. With the increase of TiO2 content and sintering temperature, the amount of the second phase Zn0.17Nb0.33Ti0.5O2 increased, resulting in the increase of dielectric constant, decrease of Q × f value, and the temperature coefficient of resonant frequency (τ f ) shifted to a positive value. The optimum microwave dielectric properties were obtained for ZnO–Nb2O5–2TiO2 ceramics sintered at 1075 °C for 5 h: ε r = 45.3, Q × f = 23,500 GHz, τ f = +4.5 ppm/°C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid growth of satellite and personal mobile communications has resulted in the need for narrow band, temperature-stable materials that operate at high frequencies. To utilize these, low-loss materials with moderate dielectric constant (ε r ) characteristics and near-zero temperature coefficients of resonant frequency (τ f ) are required [1–3].

Among the numerous dielectric materials, the ZnTiNb2O8 ceramics with a fully disordered α-PbO2 structure were first described by Baumgarte and Blachnik [4, 5], and its microwave dielectric properties were investigated by Kim et al. [6] as follows: ε r of 34.3, τ f of −52 ppm/°C, and Q × f of 42,500 GHz sintered at a high temperature (1250 °C). Mei et al. [7] reported that nanosize ZnTiNb2O8 precursors powders could be obtained at 700 °C by an aqueous sol–gel process and the ceramics sintered at 1050 °C showed excellent microwave properties with ε r of 35.3, Q × f value of 66,700 GHz, and τ f of −55.4 ppm/°C. In addition, the large negative temperature coefficient of resonant frequency of ZnTiNb2O8 limited its application. Generally speaking, the adjusting of τ f to near-zero value may be achieved by adding other compounds with positive τ f [8] and TiO2 (τ f = +450 ppm/°C) has been usually used to tune the temperature coefficient [9]. Kim et al. [6, 10] reported that the (1 − x) ZnNb2O6–xTiO2 system with x = 0.58 had a near-zero τ f value and a large ε r (45), however, the quality factor was low (Q × f = 6000 GHz).

Reaction-sintering process is a simple and effective route to synthesize ceramics, which makes the chemical reaction process completed in sintering step which should be done during the calcination step. Reaction-sintering process saves a lot of energy, time, and avoid grinding fine steps after the calcination craft which could introduce impurities, so that it has great application value in the practical production. In this work, the ZnO–Nb2O5–xTiO2 ceramics were fabricated by reaction-sintering process, and the effects of TiO2 on the microstructures, phase compositions, and microwave dielectric properties were investigated.

2 Experimental procedures

All samples in this study were prepared from high-purity oxide powders (≥99 %), appropriate amounts of raw materials for stoichiometric ZnO + Nb2O5 + xTiO2 (1 ≤ x ≤ 2) were milled in ethanol with ZrO2 balls for 12 h. After dried and pulverized the slurry, the powders were then pressed into pellets with 11.5 mm in diameter and 5.5 mm in thickness. The specimens were sintered from 1000 to 1150 °C for 5 h in air with a heating rate of 3 °C/min.

The bulk densities of the sintered ceramics were measured by the Archimedes method. The crystal structures were analyzed using X-ray diffraction (XRD) with Cu Ka radiation (Rigaku D/MAX2550, Japan). Microstructures of the ceramics were performed by scanning electron microscope (FEI Co. Eindhoven, Netherlands). The microwave dielectric properties of the samples at microwave frequency were measured by the TE01δ shielded cavity method with a vector network analysis (ZVB20, Rohde & Schwarz, Germany). The temperature coefficient of resonant frequency (τ f ) were calculated with the following equation:

where f 80 and f 25 were the TE01δ resonant frequency measured at 80 and 25 °C, respectively.

3 Results and discussions

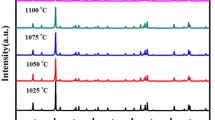

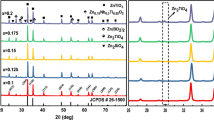

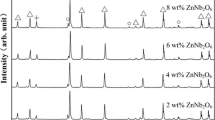

The XRD patterns of ZnO–Nb2O5–xTiO2 (x = 1, 1.4, 1.6, 1.8, 2) ceramics sintered at 1075 °C are shown in Fig. 1. As x ≤ 1.6, a single-phase ZnTiNb2O8 (JCPDS #88-1973) is obtained. As shown in the insert of Fig. 1, the main peak (111) shift slightly toward higher angles with the increase of TiO2 content and almost no longer move for x ≥ 1.6, indicating a decrease of unit-cell volume due to the substitution of Ti4+ ions (0.605 Å) for Nb5+ ions (0.640 Å) of ZnTiNb2O8 [11]. Thus, the solid solution is supposed to be formed for x ≤ 1.6. The chemical reaction happens between excess TiO2 and ZnTiNb2O8, resulting in a new phase Zn0.17Nb0.33Ti0.5O2 (ICDD–PDF#39-0291) [11] for the samples with x ≥ 1.8. Figure 2 shows the XRD patterns of ZnO–Nb2O5–2TiO2 sintered at temperatures from 1000 to 1150 °C. Regardless of sintering temperature, two types of phase are obtained in all samples and the peak intensities of Zn0.17Nb0.33Ti0.5O2 phase gradually enhance with increasing sintering temperature. This indicates that both TiO2 content and sintering temperature affect the generation of Zn0.17Nb0.33Ti0.5O2 phase, which ultimately affect the dielectric properties of the composite ceramics.

Figure 3 shows the bulk densities of ZnO–Nb2O5–xTiO2 (1 ≤ x ≤ 2) ceramics sintered at different temperatures. The bulk densities of ZnTiNb2O8 (x = 1) ceramic increase initially and reach a maximum (5.23 g/cm3) at 1075 °C (relative density corresponding to 98.05 %), then slightly decrease with the increase of temperature, which means ZnTiNb2O8 have a nearly full density sintered at 1075 °C for 5 h, 175 °C lower than that by a conventional solid-state method [6]. As shown in Fig. 3, at the fixed temperature (≥1025 °C), the bulk densities of the ceramics decrease with addition of TiO2 since TiO2 and Zn0.17Nb0.33Ti0.5O2 have lower densities (4.25 and 4.90 g/cm3, respectively) than that of ZnTiNb2O8 (5.33 g/cm3).

Figure 4 shows the SEM images of ZnO–Nb2O5–xTiO2 (1 ≤ x ≤ 2) ceramics sintered at 1075 °C. In order to obtain the average grain size, the statistics of grain size were calculated on the more than 300 particles in each sample. It can be seen that all samples exhibit a compact microstructure, while the average grain size increase from 3.42 to 7.23 μm (Fig. 2a, b) and then decrease to 2.81 μm for x = 2(Fig. 2e). It was suggested that excess TiO2 promote the grow of the grains, but the second phase Zn0.17Nb0.33Ti0.5O2 restrain the crystal move that led the decrease of grain size [12, 13].

Figure 5 demonstrates the dielectric constant of ZnO–Nb2O5–xTiO2 (1 ≤ x ≤ 2) ceramics sintered at different temperatures. As is well known, the dielectric constant is dependent on the density, secondary phases, and the crystal structure in microwave frequency [14]. The variation trend of ε r values of the samples are in accordance with that of the corresponding density for x ≤ 1.4. Furthermore, ε r values increase with increasing TiO2 content and sintering temperatures. It is suggested that the Zn0.17Nb0.33Ti0.5O2 (ε r = 95) [15] content is the dominating factor to control dielectric constant which is consistent with the logarithmic mixing rule [16]:

where ε r1 and ε r2 are the dielectric constant of ZnTiNb2O8 and Zn0.17Nb0.33Ti0.5O2; ν1 and ν2 are their volume fraction.

Figure 6 presents the Q × f values of ZnO–Nb2O5–xTiO2 (1 ≤ x ≤ 2) ceramics sintered at different temperatures. The relationships between Q × f values and sintering temperatures follow the similar trend to those between density and sintering temperature for x = 1. While the Q × f values of ZnO–Nb2O5–xTiO2 seem to decrease firstly and then increase for 1.4 ≤ x ≤ 1.6, owing to the increase of the TiO2 content that cause the increase in lattice defects, but higher sintering temperature is beneficial to promote the densification and crystallizability of the ceramics which ultimately make the Q × f values increase. However, the Q × f value of all samples exhibits the same tendency of decline when x ≥ 1.8, because the raising in TiO2 content and sintering temperature would be helpful to the generation of Zn0.17Nb0.33Ti0.5O2 phase, which have an imponderable impact on crystal structure. Furthermore, the Zn0.17Nb0.33Ti0.5O2 phase have a relatively lower Q × f value (15,000 GHz) [15] than that of ZnTiNb2O8 ceramics (Q × f value of 56,900 GHz) [17].

As x changes from 1 to 2, τ f values varied from −70 to 30 ppm/°C in Fig. 7. A near-zero τ f value is obtained at x = 2. For a given temperature (such as 1075 °C), it can be seen that the τ f values almost have no change with x varies from 1 to 1.6 but dramatically shift to a positive value when x ≥ 1.8, and the phenomenon support the transformation process of phases as indicated in the XRD patterns: x ≤ 1.6, Ti4+ ions have entered the lattice of ZnTiNb2O8 leading to the decrease of actual TiO2 content thus have no obvious contribution to the adjustment of τ f value. While when x ≥ 1.8, the τ f values are observed to increase with increasing TiO2 content and sintering temperature is reasonable when considering the difference in reported τ f values of ZnTiNb2O8 and Zn0.17Nb0.33Ti0.5O2 (−56 and +237 ppm/°C [15], respectively) on the basis of the mixing rule for composite materials. The good microwave dielectric properties of ε r = 45.3, Q × f = 23,500 GHz, τ f = +4.5 ppm/°C were obtained for ZnO–Nb2O5–2TiO2 specimen sintered at 1075 °C for 5 h.

4 Conclusion

The crystal structure and microwave dielectric properties of ZnO–Nb2O5–xTiO2 ceramics (x = 1, 1.4, 1.6, 1.8, 2) synthesized by reaction-sintering process. The superior microwave dielectric properties were obtained for ZnTiNb2O8 ceramics sintered at 1075 °C for 5 h: ε r = 34.1, Q × f = 53,300 GHz, τ f = −59.3 ppm/°C. While with increasing TiO2 content and sintering temperature, the content of the second phase Zn0.17Nb0.33Ti0.5O2 gradually increased, which was helpful to increase the dielectric constant and τ f value. The excellent microwave dielectric properties were obtained for ZnO–Nb2O5–2TiO2 ceramics sintered at 1075 °C for 5 h: ε r = 45.3, Q × f = 23,500 GHz, τ f = +4.5 ppm/°C.

References

H.W. Lee, J.H. Park, J.S. Nahm, D.W. Kim, J.G. Park, Mater. Res. Bull. 45, 21 (2010)

H. Jantunen, R. Rautioaho, A. Unsimäki, S. Leppävuori, J. Eur. Ceram. Soc. 20, 2331 (2000)

L. Fang, Q. Yu, C. Hu, H. Zhang, Mater. Lett. 61, 4140 (2007)

A. Baumgarte, R. Blachnik, Mater. Res. Bull. 27, 1287 (1992)

A. Baumgarte, R. Blachnik, J. Alloys Compd. 210, 75 (1994)

D.W. Kim, D.Y. Kim, K.S. Hong, J. Mater. Res. 15(6), 1331 (2000)

Q.J. Mei, C.Y. Li, J.D. Guo, H.T. Wu, J. Alloys Compd. 626, 217 (2015)

M.P. Seabra, A.N. Salak, V.M. Ferreira, J.L. Ribeiro, L.G. Vieira, J. Eur. Ceram. Soc. 24, 2995 (2004)

J. Ortiz-Landeros, M.E. Contreras-Garcia, C. GomezYanez, J. Solid State Chem. 184, 1304 (2011)

D.W. Kim, K.H. Ko, D.K. Kwon, J. Am. Ceram. Soc. 85(5), 1169 (2002)

S.P. Wu, J. Ni, J.H. Luo, X.H. Ding, Mater. Chem. Phys. 117, 307 (2009)

Y.-C. Liou, C.-Y. Shiue, J. Eur. Ceram. Soc. 29, 1165 (2009)

T.K. Chen, W.B. Ma, R. Li, J. Mater. Sci.: Mater. Electron. 25, 2494 (2014)

H.F. Zhou, X.B. Liu, X.L. Chen, L. Fang, H. Wang, J. Mater. Sci.: Mater. Electron. 23, 238 (2012)

D.W. Kim, J.H. Kim, J.R. Kim, K.S. Hong, Jpn. J. Appl. Phys. 40, 5994 (2001)

K.P. Surendran, N. Santha, P. Mohanan, Eur. Phys. J. B 41, 301 (2004)

Q.W. Liao, L.X. Li, X. Ren, Mater. Lett. 89, 351 (2012)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant Nos: 51272150 and 51572162) and Specialized Research Fund for the Doctoral Program of Higher Education (No. 20120202110004) and the Fundamental Research Funds for the Central Universities (GK201401003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruan, P., Liu, P., Guo, Bc. et al. Microwave dielectric properties of ZnO–Nb2O5–xTiO2 ceramics prepared by reaction-sintering process. J Mater Sci: Mater Electron 27, 4201–4205 (2016). https://doi.org/10.1007/s10854-016-4283-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4283-1