Abstract

Phthalocyanine (Pc) polymer composites containing multi-walled carbon nanotubes (MWCNTs) were successfully prepared via thermal annealing and their microwave absorption properties were tuned by changing the annealing temperatures from 300 to 500 °C. The effects of the introduction of MWCNTs into Pc polymer matrices and elevated annealing temperature on the electrical conductivity and the permittivity of the composites have been investigated. The results indicated that the synergistic effect of electrical conductivity and the permittivity endowed the composites with excellent microwave absorbing properties. Particularly, the reflection loss peak achieved a minimum value of −59.50 dB at 11.84 GHz when the sample with a thickness of 2.36 mm was annealed at 450 °C. The tuning of electromagnetic parameters of polymer composites by changing annealing temperature provided a simple and effective technical direction for the design of microwave attenuation materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As an engineering thermosetting plastic, phthalocyanine (Pc) polymer has received increasing attention in the past decades. The formation of planar heterocyclic molecule with four fused phenyl and pyrrole subunits through aza brigade renders Pc polymer to become a class of potential structural materials [1–6] and a good polymer matrix for the advanced functional materials [7–10]. Especially, a lot of novel works have been attempted in the field of microwave absorption.

The previously study [11] indicates that adjusting annealing temperature could significantly change the morphology and microstructure of the Pc polymer and effectively enhance the microwave absorbing and electrical conductivity of the Pc polymer. However, the major reason of those properties is primarily attributed to the pyrolysis of Pc polymer, leading to the generation of carbon-Pc polymer composites at higher sintering temperatures. As the result of pyrolysis, the electrical conductivity of the Pc polymer have a dramatic increase with the annealing temperature increasing. And the increased electrical conductivity of the composites could be considered as a dominated factor affecting the imaginary part of permittivity of the composites, leading to the enhanced microwave absorbing performance of the Pc-carbon composites. According to the results of the system, despite the electrical conductivity can be effectively controlled by elevating sintering temperature to meet the impedance matching conditions of microwave-absorption [12–14], the annealing temperature is too high, which will unavoidably result in the catastrophic breakdown between the covalent bonds of Pc polymer [15].

In general, most of the microwave absorbing materials use dielectric materials as the matrices and the latter should meet two functions: one is to provide a channel for the transmission of electromagnetic waves and the other is to meet the impedance matching function. To meet these two functions, the electrical conductivity of the dielectric material must be in the range of 10−18 to 10−4 S/cm. Based on our previous work [8], although the Pc polymer annealed below 550 °C shows strong temperature-dependent electrical conductivity, the value is still too low to fulfill the impedance matching conditions for microwave absorption, which limits their use in the field of electromagnetic absorption. Hence, in order to obtain a high microwave absorbing intensity, introducing high electrical conductivity filler into the Pc polymer would be an effective method to enhance the original electrical conductivity of the Pc resin.

In this paper, we report a facile preparation of Pc conducting composites with multi-walled carbon nanotubes (MWCNTs) by thermal annealing, and the annealing temperature will be controlled below the initial decomposition temperature of 550 °C, to avoid destroying the molecule structure of Pc polymer. The presence of MWCNTs in Pc polymer matrices and elevated annealing temperature endow the composites with high electrical conductivity and dielectric loss, which effectively promotes their microwave absorption properties.

2 Experimental

2.1 Materials

4,4′-Bis(3,4-dicyanophenoxy)biphenyl (BPh), was synthesized in our laboratory. The synthetic procedure and characterization were reported previously [16]. 4,4′-Diaminediphenyl sulfone (DDS, as curing agent) was purchased from Sichuan Dongcai chemicals. Multi-walled carbon nanotubes (MWCNTs) (diameter: 10–30 nm, length: 3–10 μm, purity: >95 %), synthesized via chemical vapor deposition, was supplied by Chengdu Organic Chemicals CO. LTD. Chinese Academy of Science. N-methyl-2-pyrrolidone (NMP) was purchased from Tianjin BODI Chemicals (Tianjin, China). All reagents and solvents were of analytical grade and were used without further purification.

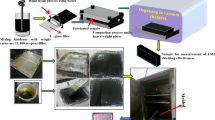

2.2 Synthesis of MWCNTs/Pc polymer composites

The preparation process of the MWCNTs/Pc polymer composite was carried out as follows. Firstly, BPh (10 g) was dissolved in NMP with a mechanical stirrer. The mixture was refluxed at 180 °C for few minutes to be dissolved sufficiently. Then, DDS (0.2 g, 2 wt%) was added slowly and stirred vigorously for several minutes, giving a light green solution. Then the solution was cooled to room temperature and MWCNTs (0.5 g 5 wt%) was added to the bottle with vigorous stirring. The mixture was refluxed at 200 °C for 4 h. Finally, dark green solution was obtained. Then the prepolymer solution was poured to water to precipitate the prepolymer with the vigorous mechanical stirring and then dried at 60 °C for 12 h. The samples were subsequently cured following a sequential program of 250 °C for 4 h, 280 °C for 4 h, 300 °C for 60 h, and then the samples were annealed at different higher temperature of 350, 400, 450 and 500 °C for 24 h under the nitrogen atmosphere, respectively. For comparison, the Pc polymers without MWCNTs loading were prepared using the same procedure.

2.3 Characterizations

The morphology of the fracture surfaces of the MWCNTs/Pc polymer was observed with scanning electron microscope (JEOL JSM-5900LV). Fourier transform infrared (FTIR) spectra were recorded on a Shimadzu 8000S spectrophotometer. The dc electrical conductivity of the MWCNTs/Pc polymer composites was determined using the standard four-point contact method on rectangular sample slabs in order to eliminate contact-resistance effects. The samples used for electromagnetic measurements were prepared by homogeneously mixing the Pc polymer with wax in a mass ratio of 3:1. The mixture was made into O-ring shaped samples with an outer diameter of 7.0 mm, inner diameter of 3.0 mm, and thickness of 2–4 mm. The complex permittivity and permeability of the samples were measured using a vector network analyzer (Agilent 8720ET) in the 0.5–18.0 GHz region.

3 Results and discussions

3.1 Structure and morphology

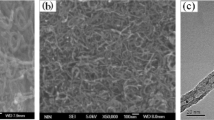

In order to investigate the influence of MWCNTs on the properties of composite, 5 wt% MWCNTs is mixed with BPh to form MWCNTs/Pc polymer composite. The scanning electron microscope (SEM) is usually employed to observe the fracture surface of the Pc polymer and its composites as shown in Fig. 1. In Fig. 1a, the fracture surface of the Pc polymer annealed at 400 °C for 24 h appears a smooth, glassy and homogenous microstructure without any plastic deformation. It is obvious that the smooth surface indicates the cured Pc polymer has a high degree of crosslinking attributed to the effective polymerization after annealing [17]. The SEM image in Fig. 1b indicates homogeneous dispersion of the MWCNTs and a compact structure within the Pc polymer, which confirms that MWCNTs is successfully dispersed into the matrices.

3.2 Electrical conductivity

The dc electrical conductivity (σ) of the Pc polymer and its composites with 5 wt% MWCNTs annealed at different annealing temperatures is measured. As shown in Fig. 2, the dc electrical conductivity of the Pc polymers and its composites with 5 wt% MWCNTs can be varied and controlled as a function of annealing temperature in a linear relation. It is worth noting that the measurable range of electrical conductivity in our experimental set-up is limited to values above 10−11 S/cm. Therefore, the electrical conductivity of the Pc polymers without MWNCTs annealed at 300 and 350 °C is out of the validation range. However, it is clear that the electrical conductivity of the composites displays a dramatic increase compared with that of annealed Pc polymers. Specifically, as the annealing temperature is elevated from 300 to 500 °C, the electrical conductivity of the composites exhibits an increase of electrical conductivity from 10−10 S/cm to approximately 10−3 S/cm, being about 7 orders of magnitude bigger than the electrical conductivity annealed at 300 °C. Especially, when the annealing temperature is above 400 °C, the samples exhibit excellent electrical conductivity, which effectively meet the impedance matching conditions of microwave-absorption.

To further determinate the influence of annealing temperature on the changing electrical conductivity, Fourier transform infrared spectrophotometer (FTIR) is employed to characterize the chemical structures of the Pc polymer annealed at different temperatures. As shown in Fig. 3, the absorption bands at 2230 and 1010 cm−1 are attributed to cyano groups and phthalocyanine cycles, respectively. Meanwhile, it is obvious that the weak absorption peak of cyano groups remains after a series of curing process and finally disappears between 450 and 500 °C. It can be attributed to the further polymerization of the residual and unreacted cyano groups at the high post-curing temperature of 300–400 °C, leading to extension of the polymeric chains and improvement of crosslinking degree, which effectively promote the transmission of an electrical disturbance or carriers along the backbone of the Pc polymer [18].

Moreover, the vaporization of any unreacted monomer or oligomers at high annealing temperature results in volume shrinkage of the Pc polymer. The reduction of the free volume of the polymer network will effectively decrease the distance of the Pc polymer chains, facilitating overlapping of π orbits. Therefore, for the polymer system, the reduction of the free volume of the Pc polymer network is of paramount importance so that the individual polymeric macromolecule can be packed in an array to transport the charge carriers through the π orbits of the polymeric domains, which move from one ring system to another, thus the electrical conductivity of Pc polymer is consequently elevated [18]. On the other hand, due to the special electrical transport structures of one-dimensional MWCNTs, the introduction and the formation of conductive network of MWCNTs provide many migration channels for charge carriers when the filler concentration is controlled at 5 wt%, which is high enough to connect the individual fillers in the composites [10, 19]. Compared with the Pc polymers, the introduction of MWCNTs successfully and effectively enhances the initial electrical conductivity of the composite, and the formation of conductive network of MWCNTs promotes the transmission of charge carriers along the network. For the composites, the synergistic enhancing effect of the conductive network of MWCNTs and the elevated annealing temperature endows the composites with high electrical conductivity, which effectively meets the impedance matching conditions of microwave-absorption.

3.3 Absorption properties

The composites used for microwave electromagnetic measurements are prepared by homogeneously mixing with wax in a mass ratio of 3:1. Figure 4a, b show the real and imaginary parts of the complex permittivity of the samples with excellent electrical conductivity. It can be obviously observed that the introduction of MWCNTs effectively enhances the real and imaginary parts of permittivity of the samples, and the real part of the permittivity increase with the rising annealing temperature. It may be attributed to the interfacial polarization [20, 21], which plays a dominant role in the increase of the real part of permittivity. Interfacial polarization arises from electrical heterogeneous materials such as a MWCNTs/Pc polymer composite in which the conductivity of the Pc polymer matrices and the MWCNTs are different. In these materials, the motion of the charge carriers may occur more easily through one phase and therefore are constricted at phase boundaries. The motion of virtual charge trapped at the interface of the multiphase material with different conductivity results in an increase in the permittivity [22]. When the electrical conductivity of the composites is increased with the rising annealing temperature, the real part of permittivity is greatly enhanced. It is caused by facilitated interfacial polarization as a result of the increased mismatch in conductivity between the two phases of MWCNTs and Pc polymer [20]. Moreover, it is worth noting that the abrupt decreases and the sharp peaks are found in the higher frequency range 9–13 GHz as shown in Fig. 4a, which could potentially be ascribed to an increase in the conductive and skin effect [23, 24].

On the other hand, it can be also observed that ε″ increases with rising annealing temperature, as shown in Fig. 4b. And the dramatic increasing peaks arise at the frequency range 9–12 GHz. From the Debye theory of dielectric, free electrons play an important role in the imaginary part, due to the good electrical conductivity of the composites [25]. According to the free electric theory [26], ε″ could be obtained to be

As shown in equation, it indicates that the temperature-dependent electrical conductivity σ plays the dominating role in ε″.

Based on the data in Fig. 4a, b, the dielectric loss of the Pc polymer and the composites annealed at different temperatures is calculated as shown in Fig. 4c. For the Pc polymer annealed at 400 °C for 24 h, a single and weak dielectric loss peak arises at the high frequency of ~13.0 GHz, which may be originated from dielectric relaxation process, due to numerous delocalized electrons in Pc ring [27]. When MWCNTs is introduced into the Pc matrices and the composite is annealed at high temperatures, a visible peak appears at lower frequency, which may be mainly attributed to interfacial polarization. The dielectric losses of three samples are almost equal, and the maximum dielectric losses gradually increase from 0.38 to 0.82, which may be ascribed to the enhanced interfacial polarization at the MWCNTs/Pc polymer interfaces as the annealing temperature increases from 400 to 500 °C. Therefore, the introduction of MWCNTs and the elevating annealing temperature result in an enhancement of the dielectric loss of the composites (Fig. 5).

In order to further and roundly indentify the factors contributing to the permittivity property of the samples, the plotting of ε″ versus ε′ exhibits several semicircles, which are generally denoted as Cole–Cole semicircle. Each semicircle corresponds to a Debye dipolar relaxation. However, some slight differences exist in their shapes of these curves as shown in Fig. 6, and several semicircles in each curve imply that other kinds of relaxation occur in the MWCNTs/Pc polymer composites, such as Maxwell–Wagner relaxation and electron polarization. In composites, the existence of interfaces gives rise to interfacial polarization or the Maxwell–Wagner effect [28–31]. The interfacial relaxation is dependent on the good electrical conductivity and permittivity of the components of the composites, which plays the dominating role in dielectric loss. The accumulation of charges at the interfaces and the formation of large dipoles on MWCNTs with the elevated annealing temperature result in those slight differences in the shapes of ε′–ε″ curves. Meanwhile, the electron polarization also contributes to the synergistic effect. According to the free-electron theory, the electrical conductivity of the composites annealed at rising temperatures could result in strong dielectric loss. Under the alternating electromagnetic field, polarization relaxation would be established due to the delay of the induced charges which counters the external applied field and the electromagnetic energy is dissipated subsequently as heat energy, so the microwave is attenuated. Therefore, we can conclude that the synergistic effect between MWCNTs and Pc polymer is caused by Debye relaxation, Maxwell–Wagner relaxation and electron polarization together, which result a profound effect on the loss of microwave, as shown in Fig. 7.

For the complex permeability as shown in Fig. 5, both the real part (μ′) and imaginary part (μ″) of the annealed Pc polymer and composites are very low due to the weak magnetic characteristic. The μ″ and μ′ share the similar frequency dispersion as the ε″ and ε′ of the samples in the frequency range of 0.5–18 GHz, but the maximum value of µ′ and µ″ are less than 1.35 and 0.55, respectively. In general, the synergistic effect of the complex permittivity and permeability of the electromagnetic absorbing materials results in the abilities of the microwave absorption. Particularly, appropriate dielectric loss and magnetic loss are favorable to the improvement of the microwave absorption properties [32]. For the MWCNTs/Pc polymer composites, microwave absorption in these materials originates from the combination of magnetic loss of the composites and the dielectric loss caused by the MWCNTs, Pc ploymer and MWCNTs/Pc polymer interfaces. According to the results of Figs. 4c and 5c, we can conclude that the microwave absorption of composites is mainly attributed to the dielectic loss rather than magnetic loss due to the lower value of µ″ than that of ε″ which are used to manifest the energy loss.

To further study the electromagnetic microwave absorption properties of the annealed MWCNTs/Pc polymer composites, reflection loss (RL) as a function of frequency and thickness is calculated on the basis of electromagnetic data by transmission line theory, as shown in Fig. 8. The calculating details are as follows:

where μ r and ɛ r are the measured relative complex permeability and permittivity, respectively, c is the speed of light, f is the frequency of microwaves and d is the thickness of the absorber. The microwave reflection loss of the Pc polymer and composites with different annealing temperatures for a layer thickness of 2.5 mm is shown in Fig. 8a. It is obvious that the reflection loss properties of the Pc polymer can be effectively tuned by introducing high conductive MWCNTs and controlling the annealing temperature. While only one peak is detected for Pc polymer, two peaks are observed for the Pc/MWCNTs polymer composites, and the peaks shift to a lower frequency with increasing annealing temperature.

Reflection loss (a) of Pc polymer and the composites with different annealing temperatures for a layer thickness of 2.5 mm. Three-dimensional representations of RL in (b) Pc polymer annealed at the temperature of 400 °C and the composites with annealing temperature of 400 °C (c), 450 °C (d) and 500 °C (e)

Moreover, in order to further explore the influence of thickness and frequency on the reflection loss, the three-dimensional presentations of the reflection loss (Fig. 8b–d) show the calculated theoretical reflection loss of the composites with elevating annealing temperatures in the frequency range of 0.5–18 GHz. It can be observed that the annealing temperature has a great influence on the microwave absorption properties. With increasing annealing temperature, the bandwidth of reflection losses lower than −10 dB (over 90 % microwave absorption) are increased and the minimum reflection losses corresponding to the maximum absorptions gradually decrease and shift towards lower frequency. It is worth noting that when the annealing temperature is elevated above 400 °C, the dual-frequency reflection loss peaks arise and the samples exhibit lower reflection loss, corresponding to the better impedance matching degree. The composites annealed at rising temperature with excellent microwave absorption are contributed to the match between the higher dielectric loss and suitable magnetic loss which can fulfill the impedance matching characteristic and attenuation characteristic. Moreover, the reflection loss peak achieved a minimum value of −59.50 dB at 11.84 GHz when the sample with a thickness of 2.36 mm is annealed at 450 °C, which is obviously larger than previously reports [33–38]. As described above, it indicates that the excellent microwave absorbing properties of the composites can be tuned by controlling the annealing temperature and the thickness of the absorbers.

4 Conclusions

In summary, phthalocyanine (Pc) polymer composites with multi-walled carbon nanotubes (MWCNTs) were successfully prepared and investigated for electrical conductivity and microwave absorption by elevating the annealing temperatures from 300 to 500 °C. The introduction of MWCNTs into Pc polymer matrices and elevated annealing temperature endowed the composites with high electrical conductivity. Meanwhile, the facilitated interfacial polarization as a result of the mismatch in conductivity between the two phases of MWCNTs and Pc polymer would contribute to enhance the real part of the permittivity with the rising annealing temperature, and the increasing temperature dependent electrical conductivity could be considered as a dominating factor for enhancing imaginary part of the permittivity. Therefore, the composites exhibited excellent absorption properties in the frequency range of 0.5–18 GHz, which can be varied and controlled as a function of the annealing temperature. Particularly, for the sample annealed at 450 °C, the reflection loss peak achieved a minimum value of −59.50 dB at 11.84 GHz when the thickness was 2.36 mm. These high-performance microwave attenuation behaviors of MWCNTs/Pc polymer composites made it possible to have enormous potential to be used in microwave absorbing area.

References

S.B. Sastri, T.M. Keller, J. Polym, Sci: Part A Polym. Chem. 36, 1885 (1998)

T.M. Keller, D.D. Dominguez, Polymer 46, 4614 (2005)

T.M. Keller, Polymer 34, 952 (1993)

S.B. Sastri, J.P. Armistead, T.M. Keller, Polym. Compos. 17, 816 (1996)

S.B. Sastri, T.M. Keller, J. Polym. Sci., Part A: Polym. Chem. 37, 2105 (1999)

G.P. Cao, W.J. Chen, X.B. Liu, Polym. Degrad. Stab. 93, 739 (2008)

F.B. Meng, R. Zhao, Y.Q. Zhan, Y.J. Lei, J.C. Zhong, X.B. Liu, Mater. Lett. 65, 264 (2011)

K. Jia, R. Zhao, J.C. Zhong, X.B. Liu, Chem. Mater. Sci. 21, 708 (2011)

Y.J. Lei, G.H. Hu, R. Zhao, H. Guo, X. Zhao, X.B. Liu, J. Phys. Chem. Solid 73, 1335 (2012)

Z.C. Wang, X.L. Yang, J.J. Wei, M.Z. Xu, L.F. Tong, R. Zhao, X.B. Liu, J. Polym. Res. 19, 9969 (2012)

Z.C. Wang, X.L. Yang, M.Z. Xu, J.J. Wei, X.B. Liu, J. Mater. Sci.: Mater. Electron. 24, 2610 (2013)

M.S. Cao, R.R. Qin, C. Qiu, J. Zhu, Mater. Des. 24, 391 (2003)

M.S. Cao, J. Yuan, H.T. Liu, X.Y. Fang, J. Zhu Mater. Des. 24, 31 (2003)

C.S. Dong, X. Wang, P.H. Zhou, T. Liu, J.L. Xie, L.J. Deng, J. Magn. Magn. Mater. 354, 340 (2014)

T.M. Keller, J. Polym, Sci: Part A Polym. Chem. 26, 3199 (1988)

X.L. Yang, Y.J. Lei, J.C. Zhong, R. Zhao, X.B. Liu, J. Appl. Polym. Sci. 119, 882 (2011)

A.W. Snow, J.R. Griffith, N.P. Marullo, Macromolecules 17, 1614 (1984)

T.M. Keller, Polym. Chem. 25, 2569 (1987)

M.M. Lu, J. Yuan, B. Wen, J. Liu, W.Q. Cao, M.S. Cao, Chin. Phys. B 22, 037701 (2013)

B.D. Chin, Y.S. Lee, O.O. Park, J. Coll. Interface Sci. 201, 172 (1998)

Y.C. Qing, W.C. Zhou, F. Luo, D.M. Zhu, Carbon 48, 4074 (2010)

S.E. San, Y. Yerli, M. Okutan, F. Yilmaz, O. Gunaydin, Y. Hames, Mater. Sci. Eng., B 138, 284 (2007)

A.N. Lagarkov, A.K. Saruchev, Phys. Rev. B. 53, 6318 (1996)

Y.H. Wu, M.G. Han, Z.K. Tang, L.J. Deng, J. Appl. Phys. 115, 163902 (2014)

D.D.L. Chung, Carbon 39, 279 (2001)

S. Ramo, J.R. Whinnery, T.V. Duzer, Fields and waves in communication electronics (Wiley, New York, 1984)

Y.J. Lei, R. Zhao, G.H. Hu, X.L. Yang, X.B. Liu, J. Mater. Sci. 47, 4473 (2012)

P.K. Mandal, A. Lapanik, R. Wipf, B. Stuehn, W. Haase, Appl. Phys. Lett. 100, 072112 (2012)

J.K. Nelson, J.C. Fothergill, Nanotechnology 15, 586 (2004)

X.G. Huang, J. Zhang, S.R. Xiao, T.Y. Sang, G.S. Chen, Mater. Lett. 124, 126 (2014)

X.G. Huang, Y.Y. Chen, J.H. Yu, J. Zhang, T.Y. Sang, G.X. Tao, H.L. Zhu, J. Mater. Sci: Mater. Elect. 26, 3474 (2015)

X.L. Shi, M.S. Cao, J. Yuan, Q.L. Zhao, Y.Q. Kang, X.Y. Fang, Y.J. Chen, Appl. Phys. Lett. 93, 183118 (2008)

X.G. Huang, J. Zhang, S.R. Xiao, T.Y. Sang, G.S. Chen, J. Am. Ceram. Soc. 97, 1363 (2014)

Z.F. Liu, G. Bai, Y. Huang, F.F. Li, Y.F. Ma, T.Y. Guo, X.B. He, X. Lin, H.J. Gao, Y.S. Chen, J. Phys. Chem. C 111, 13696 (2007)

X.G. Huang, J. Zhang, M. Lai, T.Y. Sang, J. Alloy. Comp. 627, 367 (2015)

L.B. Zhang, P.H. Zhou, H.B. Zhang, L.J. Lu, G.R. Zhang, H.Y. Chen, H.P. Lu, J.L. Xie, L.J. Deng, IEEE Trans. Magn. 50, 1 (2014)

T.H. Ting, Y.N. Jau, R.P. Yu, Appl. Surf. Sci. 258, 3184 (2012)

Z.J. Song, J.L. Xie, P.H. Zhou, X. Wang, T. Liu, L.J. Deng, J. Alloy. Comp. 551, 677 (2013)

Acknowledgments

The authors wish to thank for financial support of this work from the National Natural Science Foundation (Nos. 51173021, 51373028, 51403029) and “863” National Major Program of High Technology (2012AA03A212).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Z., Jia, K. & Liu, X. Temperature dependent electrical conductivity and microwave absorption properties of composites based on multi-wall carbon nanotubes and phthalocyanine polymer. J Mater Sci: Mater Electron 26, 8008–8016 (2015). https://doi.org/10.1007/s10854-015-3455-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3455-8