Abstract

Zinc molybdate rod-like nanostructures have been successfully synthesized by precipitation method process in the presence of different surfactants. This study aimed to investigate the effects of different surfactant such as sodium dodecyl sulfate, polyethylene glycol, and cetyltrimethylammonium bromide and solvent on the morphology and particle size of final products. It was found that the size and morphology of the products could be greatly influenced by the aforementioned parameters. To the best of authors’ knowledge, this is the first report on the synthesis of ZnMoO4 nanostructure with different morphologies in the presence of ethanol as a solvent. The as-synthesized products were characterized by XRD, SEM, UV–Vis, and EDS techniques. To evaluate the photocatalyst properties of nanocrystalline zinc molybdate, the photocatalytic degradation of methyl orange under visible light irradiation was carried out.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been considerable interest in nanocrystalline semiconductor particles, due to increase activity and a large surface-to-volume ratio and special optical and electrical properties as compared to those of the bulk materials [1–4]. Metal molybdates and tungstates have two types of structures, depending on the size of bivalentcations, scheelite (ionic radius >40.99 A: Ca, Sr, Ba, and Pb) and wolframite (ionic radius <0.77 A: Mg, Mn, Fe, Co, Ni, and Zn) [5–8]. They have attracted considerable interest for a number of researchers, due to their promising technological importance in a wide range of applications, including photoluminescence, scintillating materials, humidity sensors, photoelectric devices, photonic crystals, light weight filler materials, photocatalysts, and chemical reactors [9–14]. Several methods have been used to obtain ZnMoO4 powders, such as czochralski and kyropoulos method, hydrothermal synthesis, full-potential linear-augmented-plane-wave method [15–19]. Zinc cations have been reported to be very interesting as ‘inorganic nodes’ in the design of porous inorganic compounds or metal organic framework compounds. Hence, studies on zinc molybdenum compounds are not only for catalytic purposes but also to investigate substances with complex architecture. It is very interesting that zinc molybdate includes monoclinic (ZnMoO4) and triclinic (α-ZnMoO4) structures, and the structure of ZnMoO4 is more complex than that of MMoO4 (M = Mn, Co) [20–23]. Here, we report the synthesis and characterization of ZnMoO4 through the precipitation method. Besides, several experiments were performed in order to investigate the effect of surfactants such as sodium dodecyl sulfate (SDS), polyethylene glycol (PEG), and cetyltrimethylammonium bromide (CTAB) and solvent on the morphology and particle size of final products. The photocatalytic degradation was investigated using methyl orange (MO) under visible light irradiation (λ > 400 nm). The resulting degradation rates of the methyl orange were measured to be as high as 90 % in 6 h.

2 Experimental

2.1 Characterization

X-ray diffraction (XRD) patterns were recorded by a Philips-X’PertPro, X-ray diffractometer using Ni-filtered Cu Kα radiation at scan range of 10 < 2θ < 80. Scanning electron microscopy (SEM) images were obtained on LEO-1455VP equipped with an energy dispersive X-ray spectroscopy. The energy dispersive spectrometry (EDS) analysis was studied by XL30, Philips microscope. UV–Vis diffuse reflectance spectroscopy analysis (UV–Vis) was carried out using shimadzu UV–Vis scanning spectrometer.

2.2 Synthesis of ZnMoO4 nanostructures

The zinc nitrate (Zn(NO3)2·6H2O, (NH4)6Mo7O24·4H2O were purchased from Merck Company and used without further purification. In a typical synthesis, the stoichiometric amount of (NH4)6Mo7O24·4H2O (1 mmol), was dissolved in 20 ml distilled water under stirring to form a homogeneous solution. Afterwards, 7 mmol of Zn(NO3)2·6H2O and SDS as surfactant were dissolved in distilled water and added to the above solution under constant stirring. Subsequently, the system was allowed to cool to room temperature naturally, the obtained precipitate was collected by filtration, then washed with absolute ethanol, and distilled water several times. Finally, the product was dried in vacuum at 90 °C for 2 h. Reaction conditions are listed in Table 1. Schematic diagram of formation of ZnMoO4 nanostructures is depicted in Scheme 1.

2.3 Photocatalytic experimental

The methyl orange (MO) photodegradation was examined as a model reaction to evaluate the photocatalytic activities of the ZnMoO4 nanostructures. The photocatalytic experiments were performed under an irradiation wavelength of λ > 400 nm. The photocatalytic activity of nanocrystalline zinc molybdate obtained from sample no. 5 was studied by the degradation of methyl orange solution as a target pollutant. The photocatalytic degradation was performed with 150 mL solution of methyl orange (0.0005 g) containing 0.05 g of ZnMoO4. This mixture was aerated for 30 min to reach adsorption equilibrium. Later, the mixture was placed inside the photoreactor in which the vessel was 15 cm away from the visible source of 400 W Xeno lamp. The photocatalytic test was performed at room temperature. Aliquots of the mixture were taken at definite interval of times during the irradiation, and after centrifugation they were analyzed by a UV–Vis spectrometer. The methyl orange (MO) degradation percentage was calculated as:

where A0 and A are the absorbance value of solution at A0 and A min, respectively.

3 Results and discussion

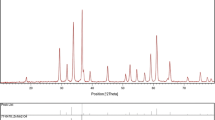

Figure 1 shows a typical XRD pattern (10° < 2θ < 80°) of ZnMoO4 nanostructures (sample 5). Based on the Fig. 1, the patterns agree well with the reported patterns for zinc molybdate (JCPDS No: 28-1475). From XRD data, the crystallite diameter (Dc) of ZnMoO4 nanostructures obtained from sample 5 was calculated to be 35 nm using the Scherer equation [24]:

where β is the breadth of the observed diffraction line at its half intensity maximum, K is the so-called shape factor, which usually takes a value of about 0.9, and λ is the wavelength of X-ray source used in XRD. It is well-known that the presence of surfactant during the production of nano-sized materials has a great effect on the shape and particle size of products. Therefore, much attention has been paid to the study of such supramolecular structures, which can play an important role as both template and microreactore for producing nanomaterials. For example, sodium dodecyl sulfate (SDS) molecules as an anionic surfactant can self-aggregate into cubic, hexagonal and lamellar structures [25, 26].

In recent years, there has been considerable interest in control the shape and particle size of nanostructures through the control reaction parameters thanks to the fact that properties of nanostructures are highly depend on their particle size and shape; therefore, we performed several experiments to investigate the effect of surfactants such as SDS, PEG, and CTAB and solvent on the morphology and particle size of the ZnMoO4 nanostructures. Figure 2a–c shows the SEM images of ZnMoO4 in the presence of water as a solvent and SDS, PEG, and CTAB as surfactants accordance with sample 1–3, respectively. According to the Fig. 2a–c, the products mainly consist of nanosheets; however, use SDS as surfactant causes decrease in the size of nanosheets structure. To investigate the effect of water as a solvent three experiments were performed with ethanol in the presence of same surfactants SDS, PEG, and CTAB accordance with sample 4–6 (Fig. 3a–c), respectively. Based on the Fig. 3a–c, in the presence of ethanol with same surfactant the morphology of products were changed from nanosheets to nano rod structure. Furthermore, ethanol as a solvent causes decrease in particle size of final products. Chemical composition and purity of the as-synthesized ZnMoO4 nanostructures was investigated by EDS analysis. The EDS spectrum of ZnMoO4 obtained from sample 5 is shown in Fig. 4. According to the Fig. 4, Zn, O, and Mo elements are observed in the EDS spectrum. In addition, neither N nor C signals were detected in the EDS spectrum, which means the product is pure and free of any surfactant or impurity. The diffused reflectance spectrum of the as-prepared ZnMoO4 nanostructures (sample 5) is shown in Fig. 5. Using Tauc’s formula, the band gap can be obtained from the absorption data. The energy gap (Eg) of the nanocrystalline ZnMoO4 has been estimated by extrapolating the linear portion of the plot of (αhν)2 against hν to the energy axis. The Eg value of the nanocrystalline ZnMoO4 was calculated to be 2.76 eV. Photodegradation of methyl orange under UV light irradiation (Fig. 6a–c) was employed to evaluate the photocatalytic activity of the as-synthesized ZnMoO4 (sample no. 5). No methyl orange was practically broken down after 6 h without using visible light irradiation or nanocrystalline ZnMoO4. This observation indicated that the contribution of self-degradation was insignificant. The probable mechanism of the photocatalytic degradation of methyl orange can be summarized as follows:

Using photocatalytic calculations by Eq. (1), the methyl orange degradation was about 90 % after 6 h under irradiation of visible light and nanocrystalline ZnMoO4 presented high photocatalytic activity (Fig. 6a). The spectrofluorimetric time-scans of methyl orange solution illuminated at 365 nm with nanocrystalline ZnMoO4 are depicted in Fig. 6b. Figure 6b shows the continuous removal of methyl orange on the ZnMoO4 under visible light irradiation. It is generally accepted that the heterogeneous photocatalytic processes comprise various steps (diffusion, adsorption, reaction, and etc.), and suitable distribution of the pore in the catalyst surface is effective and useful to diffusion of reactants and products, which prefer the photocatalytic reaction. In this investigation, the enhanced photocatalytic activity can be related to appropriate distribution of the pore in the nanocrystalline ZnMoO4 surface, high hydroxyl amount and high separation rate of charge carriers (Fig. 6c) [27].

a Photocatalytic methyl orange degradation of ZnMoO4 nanostructures (sample no. 5) under visible light, b fluorescence spectral time scan of methyl orange illuminated at 365 nm with ZnMoO4 nanostructures and c reaction mechanism of methyl orange photodegradation over ZnMoO4 under visible light irradiation

4 Conclusions

In this work, ZnMoO4 nanostructures were successfully synthesized by a precipitation method. Besides, the effect of preparation parameters such as type surfactants and solvent on the morphology, particle size, and crystal structure of ZnMoO4 nanostructures were studied by SEM. Sodium dodecyl sulfate (SDS), polyethylene glycol (PEG), and cetyltrimethylammonium bromide (CTAB) were used as the surfactant. SEM results indicate that type of solvent as well as surfactants play an important role in the morphology and particle size of ZnMoO4 nanostructures. When as-prepared nanocrystalline ZnMoO4 was utilized as photocatalyst, the percentage of methyl orange degradation was about 90 % after 6 h irradiation under visible light.

References

M. Ramezani, A. Davoodi, A. Malekizad, S.M. Hosseinpour-Mashkani, J. Mater. Sci. Mater. Electron. 26, 3957 (2015)

A. Javidan, S. Rafizadeh, S.M. Hosseinpour-Mashkani, Mater. Sci. Semicond. Process. 27, 468 (2014)

S.M. Hosseinpour-Mashkani, M. Ramezani, Mater. Lett. 130, 259 (2014)

F. Davara, M. Salavati-Niasari, J. Alloys Compd. 509, 2487 (2011)

W.S. Wang, L. Zhen, C.Y. Xu, W.Z. Shao, Z.L. Chen, J. Alloys Compd. 529, 17 (2012)

D. Li, Y.F. Zhu, Cryst. Eng. Commun. 14, 1128 (2012)

H.W. Liu, L. Tan, Ionics 16, 57 (2010)

L. Zhen, W.S. Wang, C.Y. Xu, W.Z. Shao, M.M. Ye, Z.L. Chen, Scripta Mater. 58, 461 (2008)

L. Zhou, W. Wang, H. Xu, S. Sun, Cryst. Growth Des. 8, 3595 (2008)

W.S. Wang, L. Zhen, C.Y. Xu, W.Z. Shao, Cryst. Growth Des. 9, 1558 (2009)

A. Phuruangrat, N. Ekthammathat, T. Thongtem, S. Thongtem, J. Phys. Chem. Solids 72, 176 (2011)

D. Zhu, K. Ki, X. Chen, T. Ying, J. Optoelectron. Adv. Mater. 5, 403 (2011)

Q.L. Dai, G.G. Zhang, P. Liu, J. Wang, J.K. Tang, Inorg. Chem. 51, 9232 (2012)

X. Jiang, J. Ma, B. Lin, Y. Ren, J. Liu, X. Zhu, J. Tao, J. Am. Ceram. Soc. 90, 977 (2007)

G. Zhanga, S. Yua, Y. Yanga, W. Jianga, S. Zhanga, B. Huang, J. Cryst. Growth 312, 1866 (2007)

L. Gironi, C. Arnaboldia, J.W. Beeman, O. Cremonesi, F.A. Danevich, V.Y. Degoda, L.I. Ivleva, L.L. Nagornaya, M. Pavan, G. Pessina, S. Pirro, V.I. Tretyak, I.A. Tupitsyna, J. Instrum. 5, 11007 (2010)

L. Lv, W. Tong, Y. Zhang, Y. Su, X. Wang, J. Nanosci. Nanotechnol. 11(11), 9506 (2011)

D.A. Spassky, A.N. Vasil’ev, I.A. Kamenskikh, V.V. Mikhailin, A.E. Savon, Y.A. Hizhnyi, S.G. Nedilko, P.A. Lykov, J. Phys. Condens. Matter 23(36), 365501 (2011)

L.I. Ivleva, I.S. Voronina, L.Y. Berezovskaya, P.A. Lykov, V.V. Osiko, L.D. Iskhakova, Crystallogr. Rep. 53, 1087 (2008)

G. Zhang, S. Yu, Y. Yang, W. Jiang, S. Zhang, B. Huang, J. Cryst. Growth 312, 1866 (2010)

S.C. Abrahams, J. Chem. Phys. 46, 2052 (1967)

M. Grzywa, W. Lasocha, W. Surga, J. Solid State Chem. 180, 1590 (2007)

S.M. Hosseinpour-Mashkani, M. Ramezani, M. Vatanparast, Mater. Sci. Semicond. Process. 26, 112 (2014)

Z. Shahri, M. Bazarganipour, M. Salavati-Niasari, Superlattices Microstruct. 63, 258 (2013)

K. Vinodgopal, Y. He, M. Ashokkumar, F. Grieser, J. Phys. Chem. B 110, 3849 (2006)

Y. Xie, X. Zheng, X. Jiang, J. Lu, L. Zhu, Inorg. Chem. 41, 387 (2002)

J. Zhong, J. Li, F. Feng, Y. Lu, J. Zeng, W. Hu, Z. Tang, J. Mol. Catal. A Chem. 357, 101 (2012)

Acknowledgments

Authors are grateful to council of University of Arak for providing financial support to undertake this work.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramezani, M., Hosseinpour-Mashkani, S.M., Sobhani-Nasab, A. et al. Synthesis, characterization, and morphological control of ZnMoO4 nanostructures through precipitation method and its photocatalyst application. J Mater Sci: Mater Electron 26, 7588–7594 (2015). https://doi.org/10.1007/s10854-015-3395-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3395-3