Abstract

A high-pressure micro-fluidization method is applied to layered cathode materials to obtain few-layered nanosheets for the first time. The effect of the micro-fluidization on Li(Ni0.333Mn0.333Co0.333) (NMC) and LiCoO2 is investigated regarding crystal structure, morphology, and electrochemical properties. Micro-fluidization facilitated the exfoliation of LiCoO2 layers thanks to the high shear force. As a result, the exfoliated LiCoO2 nanosheets exhibited preferred orientations with more intense (003) facets. In addition, the oxygen position in the CoO6 octahedra altered, resulting in a shortened Co–O bond length after micro-fluidization. Research demonstrates that micro-fluidized NMC and LiCoO2 exhibited superior cyclic performance compared to the pristine one. Notably, it was found that micro-fluidized LiCoO2 exhibited an improvement in capacity retention (75%) compared to pristine LiCoO2 (21%) after 100 cycles at 0.1C. The enhanced cyclic performance of micro-fluidized NMC and LiCoO2 is attributed to the surface stabilization due to the surface reconstruction of thin plates after micro-fluidization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Layered structured materials with a chemical formula of LiMO2 where M is a transition metal like Ni, Co, and Mn are the most promising candidates among the cathode active materials for lithium-ion batteries [1]. The crystal model of LiMO2 is similar to the α-NaFeO2 structure with trigonal symmetry (space group: \(R\overline{3 }m\)), where sodium and iron cations occupy different crystallographic octahedral sites within the cubic close-packed oxide array. The resulting rhombohedral structure has alternating NaO2 and FeO2 layers perpendicular to the [111] rock-salt plane in the ABC–ABC-stacking scheme. In LiMO2, Na ions and other possible M ions (Co3+, Ni2+, and Mn4+) were replaced by Li+ and Fe3+ ions, respectively [2, 3]. Among the layered cathode materials, lithium cobalt oxide (LiCoO2) has been the most commonly used positive electrode material in Li-ion batteries for many years thanks to its ease of production, high energy density, high operational voltage, and good cyclic stability [4]. Although the LiCoO2's theoretical capacity is 274 mAh g−1, its practical capacity is limited to 140 mAh g−1 due to the oxygen evolution that starts when around half of the lithiums are de-intercalated from the Li1−xCoO2 structure (1 − x < 0.5). The reason for the oxygen release is the overlap between the Co3+/4+ and the O2−:2p bands at about 4.2 V [5, 6]. This fact limits the use of LiCoO2 only to small devices requiring relatively low energy and power densities, such as mobile phones, cameras, and laptops. Therefore, alternative layered cathode materials were improved for high-energy–density Li-ion battery applications such as electric vehicles and grid energy storage [7]. With the introduction of Ni and Mn elements into the LiCoO2 structure, layered LiNixCoyMnzO2 (where x + y + z ≈ 1) (NMC) cathode materials have been developed. In the NMC structure, Ni3+/4+ and Mn3+/4+ bands do not overlap with the O2−:2p band. Therefore, structural and chemical instability reasons such as electron density removal and oxygen release do not occur in contrast to cobalt. However, due to their low octahedral site stabilization energies, Mn and Ni have less structural instability, which results in spinel transition and associated voltage drop during cycling [8].

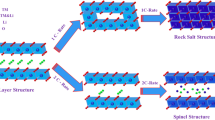

The development of (2D) nanosheets has taken significant attention in the field of materials science. After the invention of graphene in 2004 [9], many types of 2D nanosheets comprising different elements were discovered [10]. Furthermore, researchers have recently shown increased interest in developing 2D nanosheets for Li-ion battery applications to take advantage of their short ion diffusion distance and open charge transport path advantages for fast charge and discharge performance [11]. Particularly on the anode side, researchers improved the electrochemical stability and rate capability of graphene [12], TiS2 [13], and Co3O4 [14]. Several attempts were also made in order to produce 2D cathode materials such as LiFePO4, and improved electrochemical stability was observed [15, 16]. However, little attention has been paid to obtaining 2D nanosheets for layered cathode materials because the exfoliation of layers leads to the extraction of lithium atoms from their sites and the oxidation of transition metals to higher valence states. These problems cause layered to rock-salt transformation, which is a significant concern for layered cathode materials [17, 18]. Recently, Lin et al. suggested that the rock-salt layer could shed light on the possible advantages of functionalizing the surfaces of cathode particles [19]. Besides, Su et al. demonstrated that the rock-salt layer improves the cyclic stability of the cathode due to the prevention of reactions between the active material and liquid electrolyte [20]. Therefore, we believe that 2D layered cathode nanosheets with stable surfaces may exhibit superior cycling performance than bulk cathodes. Although stacked morphologies of the layered cathodes allow producing of them as exfoliated 2D nanosheets theoretically, this is difficult due to the robust electrostatic force between the neighboring layers. Therefore, a suitable and practical top-down methodology are still needed to develop 2D layered cathode nanosheets.

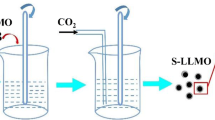

Micro-fluidization is a homogenization technique carried out by passing a fluid through the micro-channels by applying high pressure (207 MPa). It is mainly used to produce nanoparticles and nanosuspensions in pharmaceutical applications. Moreover, it has also been used for the separation and dispersion of carbon nanotubes [21], few-layer graphene [22], graphene quantum dots [23], and hexagonal boron nitride nanosheets [24]. The working principle of this technique was explained elsewhere [24]. Briefly, too-high pressure is generated via the intensifier pump. It accelerates the input powder solution fed into the interaction chamber at high velocities, around 500 m/s. The powders in the solution are exposed to very high shear stresses thanks to the microchannels. Hence, low-energy bands such as Van der Waals can be broken. The most important advantage of this technique is that while applying a high shear force to the entire fluid, the plates can be exfoliated without significantly reducing size in a preferred direction. It is possible to obtain large amounts of materials with preferred orientation because of the semi-continuous nature of the process.

In the present study, we suggest a facile way to obtain the 2D-layered cathode nanosheets with desired thickness by using a micro-fluidization technique for the first time. To this end, we have studied the effect of micro-fluidization on the crystal structure and electrochemical performance. Finally, we correlated the electrochemical measurements via combined X-ray diffraction (XRD), Raman Spectroscopy, and electron microscopy techniques.

Experimental study

Pristine Li(Ni0.333Mn0.333Co0.333)O2 (NMC) (Ecopro) and LiCoO2 (MTI) were used for the micro-fluidization process. Firstly, 1 g cathode powder was sieved through a 63 µm sieve, and 400 mL 2-propanol was added to form a suspension before use. The resulting suspension was mixed using sonication (Sonics, 750 Vef) for one hour. Next, Sonicated LiCoO2 suspension was fed into the high-pressure commercially available micro-fluidizer (Microfluidics Corp.) with 207 MPa constant intensifier pump pressure. After that, the resulting suspension was heated up to 80 °C for 12 h to obtain a dried LiCoO2 powder. The crystallographic structures of all micro-fluidized cathodes were analyzed by the XRD (Rigaku Miniflex 600, Cu-Kα radiation (1.5406 Å), 2θ range of 15°–80°, 0.02 step size and 1°/min scan speed). Rietveld analysis was performed to determine the lattice parameters of cathodes using MAUD software [25]. The morphology of cathode particles was observed using scanning electron microscopy (SEM, Zeiss Supra 50 VP). The thickness of layers was monitored using a transmission electron microscope (TEM, JEOL JEM 2100F). Raman spectroscopy (WITec alpha 300) was carried out on pristine and micro-fluidized samples under 5 mW output power.

The cathode slurry was prepared by mixing 86 wt.% active material with 6 wt.% Super P (Timcal) and 6 wt.% PVdF (MTI) dissolving the mixture into N-Methyl Pyrrolidone (NMP), three times the total solid volume. The slurry prepared was spread uniformly on aluminium foil using a doctor blade (150 µm in thickness) and dried at 80 °C under a vacuum. CR2032 coin cells were fabricated in an Argon-filled glove box. Lithium foil (Alfa Aesar) was used as an anode. The electrolyte was 1 m LiPF6 dissolved in ethylene carbonate and diethyl carbonate (Sigma, EC: DEC = 1:1, v/v). A Celgard 2400 PE/PP membrane separated positive and negative electrodes. The electrochemical tests were performed to analyze the charge–discharge behaviour of cathodes using the BaSyTec GmbH Test System in the 2.75–4.25 voltage range. The electrochemical impedance spectroscopy measurements were performed at 0.1 Hz–1 MHz with a 10 mV AC amplitude. All of the voltage values in this study are given against lithium oxidation potential unless stated otherwise.

Results and discussion

XRD analyses were used to see the relationship between the micro-fluidization and crystal structure of NMC and LiCoO2 cathode materials. The XRD spectrums and Rietveld refinements of the pristine and micro-fluidized samples are shown in Fig. 1. Each diffraction pattern is normalized by the intensity of the (003) peak. All reflection peaks could be indexed as hexagonal (PDF No.: 01-075-0532) layered oxide structures. The intensity ratios of I(003) and I(104) peaks for each sample are shown in the inset. For the layered cathodes, the most intense Bragg peaks, namely (003) and (104), provide valuable information about crystalline ordering and perfection of crystallization. Kalyani et al. draw attention to the relation between the intensity of the (003) and (104) peaks and the crystalline ordering for LiNiO2. While the (003) peak is diffracted from the layered rock-salt structure, the (104) peak is diffracted from the layered and cubic rock-salt structure. In other words, when the Li+ and Ni2+ ions are entirely mixed, the intensity of (003) peaks completely disappear, and the electrochemical inactive Li2Ni8O10 phase occurs [26, 27]. Figure 1a shows that the relative peak intensity ratios are 2.07 and 3.51 for the pristine and micro-fluidized LiCoO2 samples. It is apparent that the intensity ratios of I(003)/I(104) increase with the micro-fluidization process, which shows that the formation of nanosheets results in excellent layered morphology. The calculated peak intensity ratio of bulk LiCoO2 as 2.07 seems consistent with previous research that found 2.00 [18]. However, the peak intensity ratio of micro-fluidized LiCoO2 calculated as 3.51 is lower than 7.6 in the previous study. This difference may be due to the disorder induction into the LiCoO2 crystal structure during the micro-fluidization process. Another possible explanation for this difference is the thickness differences between nanosheets. On the other hand, the relative peak ratios for the pristine and micro-fluidized NMC samples are calculated as 1.47 and 1.67, respectively (Fig. 1b). Although the relative peak ratio of micro-fluidized NMC is also higher than that of pristine one, it is not as higher as that of LiCoO2 and is still below 2.00. This discrepancy could be attributed to the morphology of NMC powders which is explained in more detail in the SEM results. Crystal structure changes, such as lattice parameters and oxygen positions, were quantified using the Rietveld refinement with LiCoO2 and LiNi0.333Mn0.333Co0.333 phase models (Fig. 1c–f). The results were summarized with weighted (Rwp), expected (Rexp) profiles, and the goodness of fit (χ2 = Rwp/Rexp) in Table 1.

It can be seen from Table 1 that the lattice parameters 'a' and 'c' define the size of the hexagonal lattice. In the case of the NMC particles, the 'c' lattice parameter decreased by micro-fluidization. It seems possible that this reduction is due to induced disorder during the micro-fluidization process [28]. However, the enlargement of the 'c' lattice parameter was observed with micro-fluidization at the LiCoO2 side. This finding shows that the LiCoO2 layers were exfoliated due to the high-shear force effect of the micro-fluidization process [18]. Further data from Table 1 shows that the 'c/a' ratio for all samples is around 4.9 indicating an ideal cubic-close packed oxygen lattice [29]. The refined 'z' parameters showing the oxygen position and are responsible for the deformation of the oxygen octahedron surrounding TM cations [30] are also given in Table 1.

Figure 2 shows the calculated Co–O bond distance and O–Co–O bond angle of the pristine, micro-fluidized, and theoretical LiCoO2 model according to the 'z' parameter. The pristine sample has a lower Co–O bond distance and a higher O–Co–O bond angle (parallel to the c-direction) than the theoretical model. This result suggests that the pristine LixCoO2 sample has less lithium than the nominal amount. Thus, the Co–O bond distance decreased, and the O–Co–O bond angle increased by decreasing 'x' [34]. Furthermore, the micro-fluidized LiCoO2 has the shortest Co–O bond distance and higher O–Co–O bond angle (parallel to the c-direction). It seems possible that this result is due to the partial extraction of Li ions during the exfoliation resulting in spin ordering of the Co ions [31].

The Raman spectroscopy was conducted further to assess the effect of micro-fluidization on the bonding structure, and results are given in Fig. 3. The Raman analysis showed two characteristic spectra belonging to the layered cathodes. While the Eg band indicates O-Co–O bending in the a–b plane at 485 cm−1, the A1g band shows the Co–O stretching mode along the c-axis at 593 cm−1 [32]. The broad-spectrum nature of NMC due to the different oxidation states of Ni ions is explained in detail elsewhere [33]. It is seen from Fig. 3a, b that Eg and A1g bands broadened and shifted downwards from the pristine state with the micro-fluidization of NMC and LiCoO2, respectively. The polyhedral distortion and motion of the oxygen atoms may result in peak shifts [34]. These results also align with the Co–O bond distance and O–Co–O bond angle measurements in Fig. 2. For the LiCoO2 samples, there is also a minor peak around the 693 cm−1 showing the Co3O4 formation during the micro-fluidization process. The formation of Co3O4 was assigned to the LiCoO2 decomposition into O2 and Co3O4 (Eq. 3) due to the loss of more than 0.50 lithium [35,36,37]. However, since there is no Co3O4 peak detected on XRD patterns, it is believed that Co3O4 content is found only as a thin layer at the LiCoO2 surface.

Secondary electron SEM images of pristine and micro-fluidized cathodes are shown in Fig. 4. The shape of the pristine NMC has a spherical secondary particle nature, and the primary particles are closely packed without apparent gaps in between (Fig. 4a). After micro-fluidization, the secondary particles are disintegrated into the primary particles having loose contact (Fig. 4b). Pristine LiCoO2 particles have the typical smooth bulk morphology consisting of thin layers with approximately 10 µm particle size (Fig. 4c). Moreover, it can be observed that pristine LiCoO2 powders get thinner with micro-fluidization while preserving their characteristic stacked morphology (Fig. 4d).

We performed TEM analysis to assess the layer morphology, elemental distribution, and crystal structure of micro-fluidized LiCoO2 cathodes. It can be seen from the bright-field TEM images that pristine LiCoO2 powder appears as shaded due to being in bulk form (Fig. 5a). As the sample is micro-fluidized, transparent layers stand out by thinning LiCoO2 stacks (Fig. 5b). This finding has important implications for the micro-fluidization process, which helps to reduce the thickness of LiCoO2 layer stacks thanks to the exfoliation effect. Additionally, EDX analyses were done from the edge toward the center of the micro-fluidized LiCoO2 sample (labelled as 1, 2, and 3 in Fig. 5c). The corresponding spectrums are shown in Fig. 5 (d), and chemical compositions are given in Table 2. As a result, the oxygen content increases from edge to inside the sample, pointing out that the edges of LiCoO2 get more oxygen-deficient due to the edge disordering of LiCoO2 nanosheets [38]. These results also support the Raman spectra showing Co3O4 formation with micro-fluidization. HRTEM image of the micro-fluidized LiCoO2 (Fig. 5e) confirms the edge disordering with a few atom thicknesses, which is known for its chemical resistivity against liquid electrolyte reactions [39,40,41]. Although the surface seems to be layered structured (space group \(R\overline{3 }m\)), previous studies showed that a surface reconstruction with a few atom thicknesses occurs along with the (003) facets [42]. This combination of findings provides some support for LiCoO2 nanosheets being more stable against the liquid electrolyte reactions in all directions. However, the nanosheets compromise the battery's rate capability due to the reduced electronic and ionic conductivity [17, 43, 44].

The effect of micro-fluidization on the electrochemical performance of NMC and LiCoO2 materials has been studied in a potential range between 2.75 and 4.25 V under room temperature. The initial charge/discharge capacities of the pristine and micro-fluidized NMC samples were measured at 0.1C, and results are given in Fig. 6a. The pristine NMC delivered a higher charge and discharge capacity (176 and 143 mAh g−1, respectively) than the micro-fluidized NMC (161 and 128 mAh g−1, respectively). The coulombic efficiency of the pristine and micro-fluidized NMC are nearly the same (81% and 80%). In the case of the LiCoO2, the micro-fluidized sample delivered a higher charge capacity (164 mAh g−1) than the pristine LiCoO2 (155 mAh g−1) (Fig. 6b). Besides, discharge capacities are nearly identical (146 mAh g−1 and 145 mAh g−1, respectively). The decrease in coulombic efficiency (93.5% for pristine-LiCoO2 and 89.0% for micro-fluidized LiCoO2) shows that the reversible capacity decreases with micro-fluidization, which may be due to the crystal structure distortion.

Pristine and micro-fluidized NMC and LiCoO2 cathodes were cycled for 100 cycles between 2.75 and 4.25 V at 0.1 C-rate. Figure 7 displays the cyclic performance of pristine and micro-fluidized NMC electrodes. The capacities of pristine and micro-fluidized NMC are 76 and 88 mAh g−1, respectively, after the 100th cycle. Even having a lower initial discharge capacity, the micro-fluidized sample retained more than 68% of its capacity after 100 cycles (Fig. 7b). This value is limited to 53% for pristine-NMC (Fig. 7a). It seems possible that the improved cyclic stability of micro-fluidized NMC is due to the surface reconstruction of disintegrated primary particles, which were shielded in secondary particles before [45, 46]. The cyclic stabilities of pristine and micro-fluidized LiCoO2 samples at 0.1 C are shown in Fig. 8. Pristine LiCoO2 preserved its discharge capacity of only 31 mAh g−1 after 100 cycles representing 21% of its initial discharge capacity (146 mAh g−1). This capacity retention rate of pristine LiCoO2 is similar to previous studies [47,48,49]. Such a high capacity fade can be attributed to mechanical failure because of the structural changes during cycling above 4.25 V [50]. Although the pristine and micro-fluidized LiCoO2 have the same discharge capacity at the first cycle, the micro-fluidized sample shows faster capacity decay during the first ten cycles and then is stabilized. This rapid and irreversible capacity loss confirms the association between the surface reconstruction layer formation and the surface stabilization of exfoliated LiCoO2 nanosheets [51, 52]. However, compared to the pristine LiCoO2 electrode, micro-fluidized LiCoO2 showed much better capacity retention than the pristine LiCoO2 with 75%. Therefore, the primary outcome of the LiCoO2 nanosheet cathode material, as confirmed in relevant literature based on the exfoliation process [21]. The stable, protective layer nature of the disordered surface and edges of LiCoO2 nanosheets resulted in the retention of the reaction between liquid electrolyte and active material.

Rate performances of pristine and corresponding micro-fluidized NMC and LiCoO2 at different charge/discharge C-rates from 0.1C, 0.2 C, 0.5 C, and 1C between 2.75 to 4.25 V were also examined. Figure 9 shows the rate capabilities of pristine and micro-fluidized NMC cathodes. Micro-fluidization's clear benefit in enhancing discharge capacity at high C-rates could not be identified for the NMC cathode (Fig. 9a). This result may be explained because disintegrated primary particles with micro-fluidization have loose contact leading to longer Li-ion pathways and impedance. In the case of LiCoO2, pristine and micro-fluidized samples exhibited almost the same discharge capacity at a 0.1C rate (Fig. 8b). However, the difference between the discharge capacities of the two samples increased with higher C rates. The decreased rate capability of micro-fluidized LiCoO2 may be attributed to the worsened Li-ion conductivity of particles due to the surface rock-salt layer, according to recent studies [44].

We conducted electrochemical impedance spectroscopy (EIS) at room temperature under the same conditions to analyze the micro-fluidization effect on charge transfer kinetics. The Nyquist plots of pristine and micro-fluidized electrodes are presented in Fig. 10. The spectra included a high-frequency semi-circle associated with the ohmic resistance (Rs), medium frequency semi-circle related to the solid-electrolyte interface and charge transfer (Rct), and a low-frequency tail was a clue of Warburg-type lithium-ion migration. We calculated the Rs and Rct values from Nyquist curves fitting with corresponding equivalent circuit models presented as an inlet in Fig. 10 and gave results in Table 3. Notably, the charge transfer resistance of pristine NMC (Fig. 10a) and LiCoO2 (Fig. 10b) was decreased due to the micro-fluidization process. This increase in the Rct value was attributed to the evolution of a resistive layer that impedes ionic transport due to the surface reconstruction of micro-fluidized samples [53].

Conclusion

This study aimed to exfoliate NMC and LiCoO2 cathode particles using a novel micro-fluidization technique inspired by 2D materials such as graphene. The results show that the micro-fluidized cathode samples have better cyclic stability than that pristine samples. Notably, LiCoO2 showed superior capacity retention with 78% after 100 cycles. The exfoliated cathode layers having more (003) facets are more stable against the liquid electrolyte reactions due to the surface reconstruction (Co3O4 formation), confirmed by XRD, Raman, and TEM analysis. The study's primary limitation is reducing rate capability due to the looser contact of particles with fragmentation and surface reconstruction after exfoliation with the micro-fluidization process. The electrochemical impedance spectroscopy results show increasing charge transfer resistance with micro-fluidization correlated with this limitation of both layered cathodes.

Notwithstanding these limitations, this study offers valuable insight into exfoliated layered cathodes for long-lasting lithium-ion batteries. A greater focus on reproducing secondary particles with controlled shape and heat treatment could produce interesting findings that account for more enhanced rate capability.

References

Nitta N, Wu F, Lee JT, Yushin G (2015) Li-ion battery materials: present and future. Mater Today 18:252–264. https://doi.org/10.1016/j.mattod.2014.10.040

Delmas C, Fouassier C, Hagenmuller P (1980) Structural classification and properties of the layered oxides. Physica B+C 99:81–85. https://doi.org/10.1016/0378-4363(80)90214-4

Chakraborty A, Kunnikuruvan S, Kumar S et al (2020) Layered cathode materials for lithium-ion batteries: review of computational studies on LiNi1−x−yCoxMnyO2 and LiNi1−x−yCoxAlyO2. Chem Mater 32:915–952. https://doi.org/10.1021/acs.chemmater.9b04066

Kim H, Kong M, Kim K et al (2009) Electrochemical characteristics of LiFeP4/LiCoO2 mixed electrode for Li secondary battery. J Electroceram 23:219–224. https://doi.org/10.1007/s10832-007-9403-0

Radin MD, Hy S, Sina M et al (2017) Narrowing the gap between theoretical and practical capacities in Li-Ion layered oxide cathode materials. Adv Energy Mater 7:1602888–1602921. https://doi.org/10.1002/aenm.201602888

Venkatraman S, Shin Y, Manthiram A (2003) Phase relationships and structural and chemical stabilities of charged Li1 − xCoO2 − δ and Li1 − x Ni0.85Co0.15O2 − δ Cathodes. Electrochem Solid-State Lett 6:A9–A12. https://doi.org/10.1149/1.1525430

Ohzuku T, Makimura Y (2001) Layered lithium insertion material of LiCo1/3Ni1/3Mn1/3O2 for lithium-ion batteries. Chem Lett 30:642–643

Manthiram A (2020) A reflection on lithium-ion battery cathode chemistry. Nat Commun 11:1550–1559. https://doi.org/10.1038/s41467-020-15355-0

Novoselov KS, Geim AK, Morozov Sv et al (2004) Electric field effect in atomically thin carbon films. Science 1979(306):666–669. https://doi.org/10.1126/science.1102896

Kim NY, Blake S, De D et al (2020) Two-dimensional nanosheet-based photonic nanomedicine for combined gene and photothermal therapy. Front Pharmacol 10:1573–1587. https://doi.org/10.3389/fphar.2019.01573

Xiong P, Peng L, Chen D et al (2015) Two-dimensional nanosheets based Li-ion full batteries with high rate capability and flexibility. Nano Energy 12:816–823. https://doi.org/10.1016/j.nanoen.2015.01.044

Wu Z-S, Ren W, Xu L et al (2011) Doped graphene sheets as anode materials with superhigh rate and large capacity for lithium ion batteries. ACS Nano 5:5463–5471. https://doi.org/10.1021/nn2006249

Liu SH, Jia HP, Han L et al (2012) Nanosheet-constructed porous TiO2-B for advanced lithium ion batteries. Adv Mater 24:3201–3204. https://doi.org/10.1002/adma.201201036

Wang X, Wu XL, Guo YG et al (2010) Synthesis and lithium storage properties of Co3O4 nanosheet-assembled multishelled hollow spheres. Adv Funct Mater 20:1680–1686. https://doi.org/10.1002/adfm.200902295

Ren MM, Zhou Z, Gao XP et al (2008) LiVOPO4 hollow microspheres: one-pot hydrothermal synthesis with reactants as self-sacrifice templates and lithium intercalation performances. J Phys Chem C 112:13043–13046

Rui X, Zhao X, Lu Z et al (2013) Olivine-type nanosheets for lithium ion battery cathodes. ACS Nano 7:5637–5646. https://doi.org/10.1021/nn4022263

Yan P, Zheng J, Zheng J et al (2016) Ni and Co segregations on selective surface facets and rational design of layered lithium transition-metal oxide cathodes. Adv Energy Mater 6:1502455–1502464. https://doi.org/10.1002/aenm.201502455

Tai Z, Subramaniyam CM, Chou S-L et al (2017) Few atomic layered lithium cathode materials to achieve ultrahigh rate capability in lithium-ion batteries. Adv Mater 29:1700605–1700613. https://doi.org/10.1002/adma.201700605

Lin F, Markus IM, Nordlund D et al (2014) Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat Commun 5:3529–3538. https://doi.org/10.1038/ncomms4529

Su Y, Yang Y, Chen L et al (2018) Improving the cycling stability of Ni-rich cathode materials by fabricating surface rock salt phase. Electrochim Acta 292:217–226. https://doi.org/10.1016/j.electacta.2018.09.158

Karagiannidis PG, Hodge SA, Lombardi L et al (2017) Microfluidization of graphite and formulation of graphene-based conductive ınks. ACS Nano 11:2742–2755. https://doi.org/10.1021/acsnano.6b07735

Baskut S, Cinar A, Seyhan AT, Turan S (2018) Tailoring the properties of spark plasma sintered SiAlON containing graphene nanoplatelets by using different exfoliation and size reduction techniques: Anisotropic electrical properties. J Eur Ceram Soc 38:3787–3792. https://doi.org/10.1016/j.jeurceramsoc.2018.04.066

Buzaglo M, Shtein M, Regev O (2016) Graphene quantum dots produced by microfluidization. Chem Mater 28:21–24. https://doi.org/10.1021/acs.chemmater.5b03301

Yurdakul H, Göncü Y, Durukan O et al (2012) Nanoscopic characterization of two-dimensional (2D) boron nitride nanosheets (BNNSs) produced by microfluidization. Ceram Int 38:2187–2193. https://doi.org/10.1016/j.ceramint.2011.10.064

Lutterotti L, Bortolotti M, Ischia G et al (2007) Rietveld texture analysis from diffraction images. Zeitschrift fur Kristallographie 2007:125–130. https://doi.org/10.1524/9783486992540-020

Kalyani P, Kalaiselvi N (2005) Various aspects of LiNiO2 chemistry: a review. Sci Technol Adv Mater 6:689–703. https://doi.org/10.1016/j.stam.2005.06.001

Morales J, Pérez-Vicente C, Tirado JL (1990) Cation distribution and chemical deintercalation of Li1−xNi1+xO2. Mater Res Bull 25:623–630. https://doi.org/10.1016/0025-5408(90)90028-Z

Pan T, Alvarado J, Zhu J et al (2019) Structural degradation of layered cathode materials in lithium-ion batteries induced by ball milling. J Electrochem Soc 166:A1964–A1971. https://doi.org/10.1149/2.0091910jes

Broussely M, Perton F, Biensan P et al (1995) LixNiO2, a promising cathode for rechargeable lithium batteries. J Power Sources 54:109–114. https://doi.org/10.1016/0378-7753(94)02049-9

Molenda J (2019) Cathode electronic structure impact on lithium and sodium batteries parameters. In: Lithium-ion batteries - thin film for energy materials and devices. London, United Kingdom: IntechOpen, 2019 [Online]. https://www.intechopen.com/chapters/65700. https://doi.org/10.5772/intechopen.83606

Zheng X, Chen Y, Zheng X et al (2019) Electronic structure engineering of LiCoO2 toward enhanced oxygen electrocatalysis. Adv Energy Mater 9:1803482–1803492. https://doi.org/10.1002/aenm.201803482

Rao MC (2010) Raman investigations on laser ablated LiCoO2 and LiTixCo1−xO2 thin film cathodes. Optoelectron Adv Mater Rapid Commun 4:2088–2091

Flores E, Novák P, Berg EJ (2018) In situ and Operando Raman spectroscopy of layered transition metal oxides for Li-ion battery cathodes. Front Energy Res 6:82–98. https://doi.org/10.3389/fenrg.2018.00082

Wang X, Loa I, Kunc K et al (2005) Effect of pressure on the structural properties and Raman modes of LiCoO2. Phys Rev B: Condens Matter Mater Phys 72:224102–224110. https://doi.org/10.1103/PhysRevB.72.224102

Julien C (2000) Structure and electrochemistry of LiCoO2 from disordered to microcrystalline materials. In: Proceedings of the 3rd France-Japan Meeting on Lithium Batteries, Chamonix, May 26–27, 2000

Santana IL, Moreira TFM, Lelis MFF, Freitas MBJG (2017) Photocatalytic properties of Co3O4/LiCoO2 recycled from spent lithium-ion batteries using citric acid as leaching agent. Mater Chem Phys 190:38–44. https://doi.org/10.1016/j.matchemphys.2017.01.003

Yamaki JI, Baba Y, Katayama N et al (2003) Thermal stability of electrolytes with LixCoO2 cathode or lithiated carbon anode. J Power Sour 119–121:789–793

Pokle A, Ahmed S, Schweidler S et al (2020) In situ monitoring of thermally induced effects in nickel-rich layered oxide cathode materials at the atomic level. ACS Appl Mater Interfaces 12(51):57047–57054. https://doi.org/10.1021/acsami.0c16685

Zou L, He Y, Liu Z et al (2020) Unlocking the passivation nature of the cathode–air interfacial reactions in lithium ion batteries. Nat Commun 11:3204–3212. https://doi.org/10.1038/s41467-020-17050-6

Myung ST, Maglia F, Park KJ et al (2017) Nickel-rich layered cathode materials for automotive lithium-ıon batteries: achievements and perspectives. ACS Energy Lett 2:196–223. https://doi.org/10.1021/acsenergylett.6b00594

Hwang S, Chang W, Kim SM et al (2014) Investigation of changes in the surface structure of LixNi0.8Co0.15Al0.05O2 cathode materials induced by the initial charge. Chem Mater 26:1084–1092. https://doi.org/10.1021/cm403332s

Zhang H, May BM, Serrano-Sevillano J et al (2018) Facet-dependent rock-salt reconstruction on the surface of layered oxide cathodes. Chem Mater 30:692–699. https://doi.org/10.1021/acs.chemmater.7b03901

Aricò AS, Bruce P, Scrosati B et al (2005) Nanostructured materials for advanced energy conversion and storage devices. Nat Mater 4:366–377

Mohanty D, Dahlberg K, King DM et al (2016) Modification of Ni-Rich FCG NMC and NCA cathodes by atomic layer deposition: preventing surface phase transitions for high-voltage lithium-ion batteries. Sci Rep 6:26532–26548. https://doi.org/10.1038/srep26532

Zou L, Zhao W, Jia H et al (2020) The role of secondary particle structures in surface phase transitions of Ni-Rich cathodes. Chem Mater 32(7):2884–2892. https://doi.org/10.1021/acs.chemmater.9b04938

Zhu J, Sharifi-Asl S, Garcia JC et al (2020) Atomic-level understanding of surface reconstruction based on Li[NixMnyCo1−x−y]O2 single-crystal studies. ACS Appl Energy Mater 3(5):4799–4811. https://doi.org/10.1021/acsaem.0c00411

Zuo D, Tian G, Chen D et al (2015) Comparative study of Al2O3-coated LiCoO2 electrode derived from different Al precursors: uniformity, microstructure and electrochemical properties. Electrochim Acta 178:447–457. https://doi.org/10.1016/j.electacta.2015.08.039

Daxian Z (2017) Comparative study of the electrochemical behaviors for LiCoO2 electrode coated with two different Al2O3 coating layer. Int J Electrochem Sci 12:5044–5057. https://doi.org/10.20964/2017.06.70

Sheng S, Chen G, Hu B et al (2017) Al2O3-surface modification of LiCoO2 cathode with improved cyclic performance. J Electroanal Chem 795:59–67. https://doi.org/10.1016/j.jelechem.2017.04.026

Wang H (1999) TEM study of electrochemical cycling-induced damage and disorder in LiCoO2 cathodes for rechargeable lithium batteries. J Electrochem Soc 146:473–480. https://doi.org/10.1149/1.1391631

Wen JW, Liu HJ, Wu H, Chen CH (2007) Synthesis and electrochemical characterization of LiCo1/3Ni1/3Mn1/3O2 by radiated polymer gel method. J Mater Sci 42:7696–7701. https://doi.org/10.1007/s10853-007-1673-z

Yan P, Zheng J, Zhang J-G, Wang C (2017) Atomic resolution structural and chemical imaging revealing the sequential migration of Ni Co, and Mn upon the battery cycling of layered cathode. Nano Lett 17:3946–3951. https://doi.org/10.1021/acs.nanolett.7b01546

Park J-H, Cho J-H, Kim J-S et al (2012) High-voltage cell performance and thermal stability of nanoarchitectured polyimide gel polymer electrolyte-coated LiCoO2 cathode materials. Electrochim Acta 86:346–351. https://doi.org/10.1016/j.electacta.2012.04.073

Acknowledgements

The authors would like to acknowledge the Eskişehir Technical University Scientific Research Projects Unit with Grant Number 1803F057. Thanks are also to Prof. Dr. A. Tuğrul Seyhan for using micro-fluidization equipment, Prof. Dr. Feridun Ay and Dr. Ayberk Özden for Raman Analysis, and A. Furkan Buluç for technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Mark Bissett.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Engün, S., Dermenci, K.B., Savacı, U. et al. A novel scalable thinning route to enhance long-term stability of layered cathode materials for Li-ion batteries. J Mater Sci 58, 864–879 (2023). https://doi.org/10.1007/s10853-022-08057-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08057-z