Abstract

Ferroelectrics are considered as the most promising energy-storage materials applied in advance power electronic devices due to excellent charge–discharge properties. However, the unsatisfactory energy-storage density is the paramount issue that limits their practical applications. In this work, the excellent energy-storage properties are achieved in (1-x)Na0.5Bi0.5TiO3-xSr0.7Nd0.2TiO3 ((1-x)NBT-xSNT) ferroelectric ceramics by a synergistic strategy, where SNT improves breakdown strength and enhances relaxation characteristic simultaneously. A high recoverable energy-storage density of 3.85 J cm−3 and an energy-storage efficiency of 85.3% under an applied electric field of 305 kV cm−1 are acquired in 0.5NBT-0.5SNT ceramic. Moreover, excellent temperature stability and frequency stability were also observed. The change rate of energy density is less than 10%, where the temperature and frequency in the range of 20–120 °C and 20–180 Hz, respectively. Meanwhile, an ultrahigh power density of 175 MW cm−3 together with a fast discharge time of 136 ns is realized at 250 kV cm−1. These excellent performances show that (1-x)NBT-xSNT ceramics have the potential to be used in pulsed power systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the rapid development of new materials and energy conversion as well as storage devices in pulsed power systems, advanced function materials have been brought into focus [1,2,3,4,5,6,7,8,9]. Ceramic-based dielectric materials have been receiving considerable attentions because of fast charge–discharge speed, ultra-high power density and excellent stability [10, 11]. In general, four typical dielectric ceramics are suited for energy-storage application, including linear dielectrics (LDs), ferroelectrics (FEs), antiferroelectrics (AFEs) and relaxation ferroelectrics (RFEs) [4, 5, 12,13,14]. Linear dielectric ceramics have high energy-storage efficiency (η) due to tiny remnant polarization (Pr), but low maximum polarization (Pmax) limits their recoverable energy-storage density (Wrec). For instance, Ca0.5Sr0.5Ti0.9Zr0.1O3 ceramic exhibits a large η (97%), but the Wrec is just 2.05 J cm−3 [15]. Ferroelectric ceramics are another class of attractive candidates for energy-storage due to the high polarization. However, the shortcoming is high Pr, leading to a large energy-storage loss (Wloss) during the phase transition and domain wall motion [16,17,18]. Antiferroelectric ceramics have good energy-storage properties owing to large Pmax and small Pr. Nonetheless, double hysteresis loops and antiferroelectric-paraelectric phase transition led to a small energy-storage efficiency and temperature-sensitive energy-storage, respectively [5, 19,20,21]. Nowadays, relaxor ferroelectric ceramics as the potential energy-storage materials have attracted a lot of interests. Due to the order-disordering of cations and the random electric fields (RFS), long-range domains of relaxation materials are disrupted at the nanoscale and polar nano-regions (PNRs) are created [22], thereby leading to a slender polarization–electric field (P-E) hysteresis loops together with high electric displacement, excellent stability performance, high power density and fast charge–discharge rates [23].

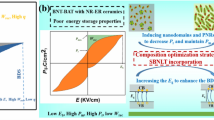

Among relaxor ferroelectric ceramics, Na0.5Bi0.5TiO3 (NBT)-based ceramics are considered to be the most competitive lead-free candidate materials owing to high Pmax (43 μC cm−2). However, low breakdown strength (BDS) and small hysteresis characteristics lead to low Wrec [24,25,26]. Therefore, many studies have been carried out to improve relaxation behavior of NBT-based ceramics, resulting in an enhancement in the energy-storage density. As reported by Yan et al., introducing Sr2+ ion and (Al0.5Nb0.5)4+ complex-ion into BNT ceramic to disrupt the long-range ordering of ferroelectrics and induce the generation of PNRs. The energy-storage properties of (1-x)Bi0.5Na0.5TiO3-xSrNb0.5Al0.5O3((1-x)BNT-xSNA) RFE ceramics were increased via inducing the PNRs to decrease the Pr and decreasing the grain size to submicron scale to improve the relaxation behavior and BDS [27]. Qiao et al. prepared (1-x)Bi0.5Na0.5TiO3-xSr0.7La0.2TiO3 ((1-x)BNT-xSLT) RFE ceramics, exhibiting a large BDS of 338 kV cm−1 due to grain size reduction, in addition to enhanced relaxation behaviors by driving Ts to room temperature. [28]. It is of great significance to combine fined grains and high densification to enhance BDS and relaxation behavior of NBT-based RFEs, resulting in further improved performances for practical applications [29,30,31].

In this study, high energy-storage density and efficiency are achieved in (1-x)Na0.5Bi0.5TiO3-xSr0.7Nd0.2TiO3 ((1-x)NBT-xSNT) ceramics by the addition of SNT. SNT exhibits an obvious effect on decreasing gain size and domain size, leading to the enhancement of BDS and relaxation behavior. And (1-x)NBT-xSNT ceramics were manufactured by the tape-casting method for improving the microstructure and densification of the ceramics, which effectively improves the BDS of ceramics and helps to achieve the desired energy-storage properties [20, 32, 33]. As a result, the excellent energy-storage property is obtained at a high electric filed. These excellent performances confirm the potential of the NBT-based ceramics for dielectric capacitors in advanced power electronic devices and pulsed power systems.

Experimental details

RFE ceramics of the (1-x)NBT-xSNT (x = 0.2, 0.3, 0.4 and 0.5) ceramics were prepared by tape-casting technique and sintered via traditional solid-state reaction method. Firstly, the Na2CO3 (99.8%), Bi2O3 (99.0%), TiO2 (98.0%), SrCO3 (99%) and Nd2O3 (99.9%) were weighted according to the stoichiometric ratio and ball-milled (QM-3SP2, Nanjing University Instrument Factory, China) in ethanol for 24 h as the raw powders. The raw powders were dried and calcined at 850 °C for 4 h. The calcined powders were ball-milled again for 24 h. Secondly, ethyl alcohol, tributyl phosphate, Polyvinyl Butyral (PVB) binder and Plasticiser (Polyethylene glycol, Phthalate) were added to the ceramic powders, then mixture were ball-milled for 18 h to obtain tape-casting slurry. It took 25 min to remove the bubbles from the tape-casting slurry by a vacuum defoaming machine (TP-08, Beijing Orient Sun-Tec Co. Ltd., China). The slurry was cast on a film-belt substrate with the help of a continuous tape-casting machine (LY-150, Beijing Orient SunTec CO. Ltd., China). The obtained thick film was stacked together (DY-30, Tianjin Science and Technology Co. Ltd., China) and disposed under a high pressure to further densify the green-samples via a cold isostatic pressure technique (U150, Shanxi Golden Kaiyuan Co., Ltd. China). The samples were calcined at 500 °C to burn out the binder and sintered at 1170 °C for 3 h in the crucibles. In order to avoid the evaporation of Na+, Bi3+ in the high-temperature sintering process, the samples were embedded in the calcined powders of the same composition. Finally, the ceramic samples were polished to 100 μm and sputtered with an electrode area of 3.14 mm2 before electrical performances tests.

The phase structures of NBT-SNT ceramics were performed by an X-ray diffractometer (Bruker D8 Advanced Diffractometer, German). The surface morphology of the ceramics was observed by a scanning electron microscopy (FE-SEM, ZEISS Supra 55, German). The relative density of the ceramics was calculated by the Archimedes drainage method. The domains and piezoresponse loops were measured by a piezoelectric force microscope (PFM, Bruker, Icon). Temperature dependence of the relative permittivity (εr) and dielectric loss (tanδ) was detected via a computer-controlled LCR meter (TH2828, Tonghui, China). The P-E hysteresis loops at the frequency of 10 Hz were measured by a ferroelectric test system (Radiant Technologies, Inc., Albuquerque, USA). The pulsed discharge current was characterized via the RLC circuit (CFD-001, Guoguo technology, China) and recorded by an oscilloscope (TBS 1102B-EDU, Tektronix CO., China).

Results and discussion

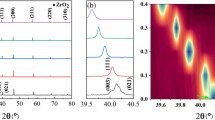

The room-temperature XRD patterns of (1-x)NBT-xSNT ceramics are characterized in Fig. 1a. All ceramics exhibit pure perovskite structure with no apparent trace of the secondary phase [24, 34]. Furthermore, the (111) and (200) peaks gradually move toward the higher angles as the concentration of SNT increases, as depicted in Fig. 1b. It implies a contraction of lattice constant due to the replacement of Na+ (1.02 Å) ions and Bi3+ (1.03 Å) ions by the smaller Nd3+ (0.983 Å) ions [16, 24, 35].

Figure 2 shows the SEM images and the grain size distribution of (1-x)NBT-xSNT ceramics. The relative densities of (1-x)NBT-xSNT ceramics are also calculated, which are 94.9, 96.1, 96.5, 96.7 and 97.3%, respectively. It is found that the ceramic of x = 0.2 exhibits a loose microstructure with a lot of pores. With the content of SNT increasing, the densification of the ceramics increases and the pores disappear. Moreover, based on SEM images, the size of 200 grains is counted by the Nano Measurer software to obtain the grain size distribution [35, 36], the average grain size reduces from 2.53 to 0.96 μm when x increases from 0.2 to 0.6, and the distribution of grain size is more uniform. The small grain size and dense structure are beneficial to gain high BDS verified by previous reported [28, 37].

Figure 3a–e shows the out-of-plane phase PFM images of (1-x)NBT-xSNT ceramics. The clear long-range ordered FE domains can be observed in the x = 0.2 sample (Fig. 3a). The polarization direction of the bright regions is opposite to the dark regions, where the bright regions and the dark regions represent upward and downward polarization, respectively [38]. The complete ferroelectric domain structure of x = 0.2 sample is illustrated by the alternating bright and dark regions. It can be found that the increase of SNT content has made the contrast in PFM images become blurred. FE domains gradually become smaller and more irregular. This is due to the local RFS created by the introduction of SNT in the NBT, which is caused by structural and charge inhomogeneity around the substitution ions. The presence of local RFS has been widely reported to hinder long-range ordering and produce PNRs [39]. It is indicated that the introduction of SNT decreases the size of domains and gives rise to PNRs [39, 40]. To obtain deeper insight into the behavior features of domain structure, the piezo response loops on selected regions of all samples are also carried out. It is found that the FE domains give saturated square-shaped phase loops, whereas the PNRs show pinched loops. In short, the addition of SNT to the NBT matrix indicates that the long-range order of FE domains is disrupted and leads to the appearance of PNRs, thereby resulting in a structure transformation from FE to RFE.

The temperature dependence of εr and tanδ for (1-x)NBT-xSNT ceramics was measured at the different frequencies of 1 kHz-1 MHz is depicted in Fig. 4a–e. The tanδ decreases and then increases at higher temperatures. It is attributed to the oxygen vacancies getting activated at a higher temperature, resulting in increased conductivity [41]. Two dielectric peaks are observed according to the curves, including the absolute maximum dielectric peak (Tm) and a low-temperature peak (Ts). For the NBT-based ceramics, the dielectric anomaly at Ts is attributed to the thermal evolution of the PNRs of rhombohedral (R3c) and tetragonal (P4bm) structured. Tm is related to a mixed contribution from the transition of PNRs from R3c to P4bm structured and a thermal evolution of PNRs [2, 24, 33, 42,43,44]. Furthermore, the εr and tanδ exhibit an obvious frequency dispersion around Ts. Due to the occupation of the (Na0.5Bi0.5)2+ by the Nd3+, the differences in radius and valence of these cations at A-site give rise to enhance RFS. It can produce a competition between the long-range driving dipoles and the translational symmetry, which tends to enhance the RFS. The PNRs generated by local random bonds that will give rise to typical relaxation properties [45]. Ts, Tm and the maximum relative permittivity (εm) gradually decrease with the content of SNT increasing, as shown in Fig. 4f. This result suggests the deformation of local lattice and destruction of ferroelectric long-range order with the content of SNT increasing, inducing the RFS. The RFS resulting in a gradual increase in the dynamics of PNRs and thus can enhance the relaxor behavior [2, 41].

To characterize the BDS of the ceramics, the Weibull distribution is acquired based on eight samples of every ceramic. The Weibull distribution can be calculated by the equations:

where Ei and n represent the values of specimens and the group number of test ceramics, respectively [42]. The results for the Weibull distribution of (1-x) NBT-xSNT ceramics are shown in Fig. 5a. The graph shows a good fit of the data points, and all shape parameters (β) are higher than 13 for each composition [27, 30]. The breakdown data of all samples follow a good agreement with the Weibull distribution. The BDS of the ceramics is shown in Fig. 5b. The BDS increases from 140 to 320 kV cm−1 with the increase of the x from 0.2 to 0.6. The relationship between BDS and grain size (G) is computed by using the following relations:

The higher BDS values are due to their good insulated property, which may be attributed to the decrease of grain size [32].

The total energy-storage density (Wtot), Wrec and η of (1-x)NBT-xSNT ceramics were calculated according to the P–E hysteresis loops. The P-E hysteresis loops of (1-x)NBT-xSNT ceramics as a function of electric field are illustrated in Fig. 6a. Clearly, the Pmax and Pr of (1-x)NBT-xSNT ceramics gradually decrease with the content of SNT increasing. The decrease of Pmax might be ascribed to translation between the weakly polar phase and polar phase [16]. The Pr might be determined the amount of irreversible electric dipoles without external electric field, the amount of irreversible electric dipoles largely depended on the PNRs and grain size [46, 47]. The Wtot, Wrec and η of (1-x)NBT-xSNT ceramics are summarized, as displayed in Fig. 6b. The η of (1-x)NBT-xSNT ceramics increases significantly from 61 to 88%, when the SNT content increases from 0.2 to 0.6. Particularly, the 0.5NBT-0.5SNT ceramic possesses the highest Wtot (4.52 J cm−3) and Wrec (3.85 J cm−3) and maintains a relatively high η (85.2%).

(a) P-E loops of (1-x)NBT-xSNT ceramics; (b) energy-storage density and efficiency as a function of x content; (c) P-E loops under an increasing applied electric field of 0.5NBT-0.5SNT ceramics; (d) charge energy density, discharge energy density and energy efficiency as a function of electric field for 0.5NBT-0.5SNT ceramics; (e) Wrec and η of 0.5NBT-0.5SNT ceramic and previously reported NBT-based ceramics

To further clarify the energy-storage performance of 0.5NBT-0.5SNT ceramic, the P-E hysteresis loops of under varying electric fields at RT and 10 Hz are shown in Fig. 6c. As electric field increase from 205 to 305 kV cm−1, Pmax increases from 20 to 29 μC cm−2. The enhanced Pmax and BDS are conducive to achieving large Wrec in 0.5NBT-0.5SNT ceramic. The Wtot, Wrec and η of 0.5NBT-0.5SNT ceramic under different applied electric fields, respectively, shown in Fig. 6d. It can be observed that the Wtot and Wrec increase from 2.1 J cm−3 and 1.9 J cm−3 to 4.52 J cm−3 and 3.85 J cm−3, respectively. The η slightly decreases from 87.5 to 85.2% with the BDS increasing due to the enhanced conductivity. For better evaluation of the energy-storage performance of (1-x)NBT-xSNT, a comparison of the energy-storage performance between 0.5NBT-0.5SNT ceramic and other NBT-based ceramics are given in Fig. 6e [2, 22, 23, 26, 28, 30, 31, 35, 48,49,50,51,52]. We can find that the Wrec and η of most NBT-based ceramics are less than 3 J cm−3 and 80%, respectively.

Figure 7a shows temperature dependence of P-E hysteresis loops for the 0.5NBT-0.5SNT ceramic in the range from 20 to 120 °C at 10 Hz and 200 kV cm−1. All of the P-E hysteresis loops exhibit extremely slim profile. The temperature dependence of Wloss, Wrec and η of the 0.5NBT-0.5SNT ceramic is summarized in Fig. 7b. A satisfactory thermal stability was observed in the 0.5NBT-0.5SNT ceramic, the variation of the Wrec was less than 10% at the test temperature range. Figure 7c shows the P–E hysteresis loops under the applied electric field of 200 kV cm−1 in a frequency range of 20–180 Hz. It can be clearly seen that the P–E hysteresis loops are almost unchanged. Figure 7d shows the changing trend of Wloss, Wrec and η at different frequencies. Correspondingly, the change rates of the Wrec and η are below 10%. According to the above analyses suggests that the 0.5NBT-0.5SNT ceramic exhibits excellent energy-storage performance in a wide temperature and frequency range.

To investigate the actual energy-storage performance of the 0.5NBT-0.5SNT ceramic, a pulsed discharge method is utilized to obtain the discharge energy density. The overdamped discharge current curves under different electric fields are shown in Fig. 8a. The pulsed discharged energy density (Wdis) can be calculated as: [13, 34, 35]

where i(t), R and V are the current, load resistance (200 Ω) and the volume of the ceramic, respectively. The time dependence of Wdis under different applied electric fields is calculated, as shown in Fig. 8b. The Wdis increased from 0.17 J cm−3 at 50 kV cm−1 to 2.03 J cm−3 at 250 kV cm−1. The parameter t0.9 (the discharge time that reaches 90% saturated Wdis value) of 0.5NBT-0.5SNT ceramic is only 136 ns under the condition of 250 kV cm−1, showing an extremely fast discharge speed. Figure 8c shows the pulse discharge current was measured with a load resistance of zero in the underdamped state. It can be found that the amplitude of the first peak current (Imax) gradually increases with the increase of the electric field. The maximum value is 10.6 A when the applied electric field of 250 kV cm−1. It shows that the ceramic has stable discharge behavior.

(a–b) Overdamped discharge current waveform and the electric field strength of 0.5NBT-0.5SNT ceramics under different electric fields; (c–d) underdamped discharge current waveform and the corresponding current density and power density under different electric fields; (e–f) overdamped discharge current waveform and the electric field strength of 0.5NBT-0.5SNT ceramics under different temperature; (g) underdamped discharge current waveform, the corresponding current density and power density under different temperature; (i) contrast of charge–discharge performance of 0.5NBT-0.5SNT ceramic and previously reported NBT-based ceramics

The current density (CD) and power density (PD) of 0.5NBT-0.5SNT ceramic are calculated by the following formulas [23]:

where S and E represent the effective electrode area and the applied electric field, respectively. Related CD and PD also show a similar increasing trend as Imax, as shown in Fig. 8d. CD and PD reach the maximum value of 1401 A cm−2 and 175 MW cm−3, respectively, which are better than many energy-storage ceramics.

In addition, it is necessary to consider the stability of charge–discharge performances at different working temperatures. Figure 8e–f displays the discharge current curves of the 0.5NBT-0.5SNT ceramic at 150 kV cm−1 from 30 to 120 °C. It is obvious that the Wdis was no significant change and t0.9 fluctuates between 37 and 43 ns from 30 to 120 °C. Thus, the 0.5NBT-0.5SNT ceramic has a fast discharge speed and an extremely temperature stability over a wide temperature range. Figure 8g shows the underdamped discharge waveforms of the 0.5NBT-0.5SNT ceramic under the different working temperatures. The variation of CD and PD is less than 10% over a broad temperature range from 20 to 120 °C. To further describe the advancement of charge–discharge properties, this work and other reported NBT-based ceramics are performed in Fig. 8i. The 0.5NBT-0.5SNT ceramic possesses high CD and PD, which is which is superior to most previously reported results [16, 27, 28, 30, 31, 33, 53, 54]. Therefore, 0.5NBT-0.5SNT ceramic has an excellent charge–discharge performance with fast discharge rate, large CD and PD, which also indicates that it has great potential in practical applications.

Conclusions

In summary, the lead-free (1-x)NBT-xSNT ceramics were fabricated by the tape-casting method, and the energy-storage properties and charge–discharge characteristics of the ceramics were studied. The (1-x)NBT-xSNT ceramics exhibit pure perovskite structure and dense structure. It is found that SNT plays a key role in decreasing grain size and domain size, leading to the enhanced BDS and relaxation characteristics. The 0.5NBT-0.5SNT ceramic obtained the highest Wrec of 3.85 J cm−3 together with a high η of 85.2%. Moreover, the 0.5NBT-0.5SNT ceramic exhibits good temperature stability and frequency stability. In addition, an ultrahigh PD of 175 MW cm−3 and a giant CD of 1401A cm−2 are acquired in the ceramic. These excellent performances prove the great potential of the studied ceramics for dielectric capacitors, promoting the development of advanced power electronic devices and pulsed power system.

References

Palneedi H, Peddigari M, Hwang G-T, Jeong D-Y, Ryu J (2018) High-performance dielectric ceramic films for energy storage capacitors: progress and outlook. Adv Funct Mater. https://doi.org/10.1002/adfm.201803665

Pan Z, Hu D, Zhang Y, Liu J, Shen B, Zhai J (2019) Achieving high discharge energy density and efficiency with NBT-based ceramics for application in capacitors. J Mater Chem C 7:4072–4078. https://doi.org/10.1039/c9tc00087a

Wang D, Fan Z, Zhou D, Khesro A, Murakami S, Feteira A, Zhao Q, Tan X, Reaney IM (2018) Bismuth ferrite-based lead-free ceramics and multilayers with high recoverable energy density. J Mater Chem A 6:4133–4144. https://doi.org/10.1039/c7ta09857j

Zhang H, Wei T, Zhang Q, Ma W, Fan P, Salamon D, Zhang S-T, Nan B, Tan H, Ye Z-G (2020) A review on the development of lead-free ferroelectric energy-storage ceramics and multilayer capacitors. J Mater Chem C 8:16648–16667. https://doi.org/10.1039/d0tc04381h

Zhao L, Liu Q, Gao J, Zhang S, Li JF (2017) Lead-free antiferroelectric silver niobate tantalate with high energy storage performance. Adv Mater. https://doi.org/10.1002/adma.201701824

Chen H, Cong TN, Yang W, Tan C, Li Y, Ding Y (2009) Progress in electrical energy storage system: a critical review. Prog Nat Sci 19:291–312. https://doi.org/10.1016/j.pnsc.2008.07.014

Cao MS, Wang XX, Zhang M, Shu JC, Cao WQ, Yang HJ, Fang XY, Yuan J (2019) Electromagnetic response and energy conversion for functions and devices in low-dimensional materials. Adv Funct Mater. https://doi.org/10.1002/adfm.201807398

Zhang M, Cao M-S, Shu J-C, Cao W-Q, Li L, Yuan J (2021) Electromagnetic absorber converting radiation for multifunction. Mater Sci Eng R Rep. https://doi.org/10.1016/j.mser.2021.100627

Cao M, Wang X, Cao W, Fang X, Wen B, Yuan J (2018) Thermally driven transport and relaxation switching self-powered electromagnetic energy conversion. Small. https://doi.org/10.1002/smll.201800987

Jo W, Dittmer R, Acosta M, Zang J, Groh C, Sapper E, Wang K, Rödel J (2012) Giant electric-field-induced strains in lead-free ceramics for actuator applications – status and perspective. J Electroceram 29:71–93. https://doi.org/10.1007/s10832-012-9742-3

Veerapandiyan V, Benes F, Gindel T, Deluca M (2020) Strategies to improve the energy storage properties of perovskite lead-free relaxor ferroelectrics: a rev. Mater (Basel). https://doi.org/10.3390/ma13245742

Zhou M, Liang R, Zhou Z, Dong X (2018) Novel BaTiO3-based lead-free ceramic capacitors featuring high energy storage density, high power density, and excellent stability. J Mater Chem C 6:8528–8537. https://doi.org/10.1039/c8tc03003k

Qi H, Zuo R (2019) Linear-like lead-free relaxor antiferroelectric (Bi0.5Na0.5)TiO3–NaNbO3 with giant energy-storage density/efficiency and super stability against temperature and frequency. J Mater Chem A 7:3971–3978. https://doi.org/10.1039/c8ta12232f

Yang H, Liu P, Yan F, Lin Y, Wang T (2019) A novel lead-free ceramic with layered structure for high energy storage applications. J Alloys Compd 773:244–249. https://doi.org/10.1016/j.jallcom.2018.09.252

Wang W, Pu Y, Guo X, Ouyang T, Shi Y, Yang M, Li J, Shi R, Liu G (2019) Enhanced energy storage properties of lead-free (Ca0.5Sr0.5)1–1.5xLaxTiO3 linear dielectric ceramics within a wide temperature range. Ceram Int 45:14684–14690. https://doi.org/10.1016/j.ceramint.2019.04.188

Zhang L, Pu Y, Chen M, Wei T, Peng X (2020) Novel Na0.5Bi0.5TiO3 based, lead-free energy storage ceramics with high power and energy density and excellent high-temperature stability. Chem Eng J. https://doi.org/10.1016/j.cej.2019.123154

Chen L, Wang H, Zhao P, Zhu C, Cai Z, Cen Z, Li L, Wang X (2019) Multifunctional BaTiO3-(Bi0.5Na0.5)TiO3-based MLCC with high-energy storage properties and temperature stability. J Am Ceram Soc 102:4178–4187. https://doi.org/10.1111/jace.16292

Wang G, Lu Z, Li J, Ji H, Yang H, Li L, Sun S, Feteira A, Yang H, Zuo R, Wang D, Reaney IM (2020) Lead-free (Ba, Sr)TiO3-BiFeO3 based multilayer ceramic capacitors with high energy density. J Eur Ceram Soc 40:1779–1783. https://doi.org/10.1016/j.jeurceramsoc.2019.12.009

Qu N, Du H, Hao X (2019) A new strategy to realize high comprehensive energy storage properties in lead-free bulk ceramics. J Mater Chem C 7:7993–8002. https://doi.org/10.1039/c9tc02088h

Meng X, Zhao Y, Li Y, Hao X (2021) Simultaneously achieving ultrahigh energy density and power density in PbZrO3-based antiferroelectric ceramics with field-induced multistage phase transition. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.159149

Liu X, Zhao Y, Sun N, Li Y, Hao X (2021) Ultra-high energy density induced by diversified enhancement effects in (Pb0.98−xLa0.02Cax)(Zr0.7Sn0.3)0.995O3 antiferroelectric multilayer ceramic capacitors. Chem Eng J. https://doi.org/10.1016/j.cej.2020.128032

Li J, Li F, Xu Z, Zhang S (2018) Multilayer lead-free ceramic capacitors with ultrahigh energy density and efficiency. Adv Mater 30,1802155:1-7. https://doi.org/10.1002/adma.201802155

Wu Y, Fan Y, Liu N, Peng P, Zhou M, Yan S, Cao F, Dong X, Wang G (2019) Enhanced energy storage properties in sodium bismuth titanate-based ceramics for dielectric capacitor applications. J Mater Chem C 7:6222–6230. https://doi.org/10.1039/c9tc01239g

Butnoi P, Manotham S, Jaita P, Randorn C, Rujijanagul G (2018) High thermal stability of energy storage density and large strain improvement of lead-free Bi0.5(Na0.40K0.10)TiO3 piezoelectric ceramics doped with La and Zr. J Eur Ceram Soc 38:3822–3832. https://doi.org/10.1016/j.jeurceramsoc.2018.04.024

Le PG, Fisher JG, Moon WJ (2019) Effect of composition on the growth of single crystals of (1–x)(Na1/2Bi1/2)TiO3-xSrTiO3 by solid state crystal growth. Mater (Basel). https://doi.org/10.3390/ma12152357

Hu D, Pan Z, Zhang X, Ye H, He Z, Wang M, Xing S, Zhai J, Fu Q, Liu J (2020) Greatly enhanced discharge energy density and efficiency of novel relaxation ferroelectric BNT–BKT-based ceramics. J Mater Chem C 8:591–601. https://doi.org/10.1039/c9tc05528b

Yan F, Zhou X, He X, Bai H, Wu S, Shen B, Zhai J (2020) Superior energy storage properties and excellent stability achieved in environment-friendly ferroelectrics via composition design strategy. Nano Energy. https://doi.org/10.1016/j.nanoen.2020.105012

Qiao X, Zhang F, Wu D, Chen B, Zhao X, Peng Z, Ren X, Liang P, Chao X, Yang Z (2020) Superior comprehensive energy storage properties in Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramics. Chem Eng J. https://doi.org/10.1016/j.cej.2020.124158

Yang Y, Wang H, Bi L, Zheng Q, Fan G, Jie W, Lin D (2019) High energy storage density and discharging efficiency in La3+/Nb5+-co-substituted (Bi0.5Na0.5)0.94Ba0.06TiO3 ceramics. J Eur Ceram Soc 39:3051–3056. https://doi.org/10.1016/j.jeurceramsoc.2019.04.031

Lin Y, Li D, Zhang M, Yang H (2020) (Na0.5Bi0.5)0.7Sr0.3TiO3 modified by Bi(Mg2/3Nb1/3)O3 ceramics with high energy-storage properties and an ultrafast discharge rate. J Mater Chem C 8:2258–2264. https://doi.org/10.1039/c9tc06218a

Qiao X, Sheng A, Wu D, Zhang F, Chen B, Liang P, Wang J, Chao X, Yang Z (2021) A novel multifunctional ceramic with photoluminescence and outstanding energy storage properties. Chem Eng J. https://doi.org/10.1016/j.cej.2020.127368

Liu X, Yang T, Gong W (2021) Comprehensively enhanced energy-storage properties in (Pb1−3x/2Lax)(Zr0.995Ti0.005)O3 antiferroelectric ceramics via composition optimization. J Mater Chem C. https://doi.org/10.1039/d1tc02972j

Yan F, Huang K, Jiang T, Zhou X, Shi Y, Ge G, Shen B, Zhai J (2020) Significantly enhanced energy storage density and efficiency of BNT-based perovskite ceramics via A-site defect engineering. Energy Stor Mater 30:392–400. https://doi.org/10.1016/j.ensm.2020.05.026

Li Q, Wang J, Liu Z, Dong G, Fan H (2015) Enhanced energy-storage properties of BaZrO3-modified 0.80Bi0.5Na0.5TiO3–0.20Bi0.5K0.5TiO3 lead-free ferroelectric ceramics. J Mater Sci 51:1153–1160. https://doi.org/10.1007/s10853-015-9446-6

Shi P, Zhu L, Gao W, Yu Z, Lou X, Wang X, Yang Z, Yang S (2019) Large energy storage properties of lead-free (1–x)(0.72Bi0.5Na0.5TiO3-0.28SrTiO3)-xBiAlO3 ceramics at broad temperature range. J Alloys Compd 784:788–793. https://doi.org/10.1016/j.jallcom.2019.01.077

Qiao X, Wu D, Zhang F, Niu M, Chen B, Zhao X, Liang P, Wei L, Chao X, Yang Z (2019) Enhanced energy density and thermal stability in relaxor ferroelectric Bi0.5Na0.5TiO3-Sr0.7Bi0.2TiO3 ceramics. J Eur Ceram Soc 39:4778–4784. https://doi.org/10.1016/j.jeurceramsoc.2019.07.003

Zheng P, Zhang JL, Tan YQ, Wang CL (2012) Grain-size effects on dielectric and piezoelectric properties of poled BaTiO3 ceramics. Acta Mater 60:5022–5030. https://doi.org/10.1016/j.actamat.2012.06.015

Li Y, Sun N, Du J, Li X, Hao X (2019) Stable energy density of a PMN–PST ceramic from room temperature to its Curie point based on the synergistic effect of diversified energy. J Mater Chem C 7:7692–7699. https://doi.org/10.1039/c9tc02172h

Sun N, Li Y, Liu X, Hao X (2020) High energy-storage density under low electric field in lead-free relaxor ferroelectric film based on synergistic effect of multiple polar structures. J Power Sour. https://doi.org/10.1016/j.jpowsour.2019.227457

Zhang L, Wang Z, Li Y, Chen P, Cai J, Yan Y, Zhou Y, Wang D, Liu G (2019) Enhanced energy storage performance in Sn doped Sr0.6(Na0.5Bi0.5)0.4TiO3 lead-free relaxor ferroelectric ceramics. J Eur Ceram Soc 39:3057–3063. https://doi.org/10.1016/j.jeurceramsoc.2019.02.004

Xu Q, Lanagan MT, Huang X, Xie J, Zhang L, Hao H, Liu H (2016) Dielectric behavior and impedance spectroscopy in lead-free BNT–BT–NBN perovskite ceramics for energy storage. Ceram Int 42:9728–9736. https://doi.org/10.1016/j.ceramint.2016.03.062

Li Q, Yao Z, Ning L, Gao S, Hu B, Dong G, Fan H (2018) Enhanced energy-storage properties of (1–x)(0.7Bi0.5Na0.5TiO3-0.3Bi0.2Sr0.7TiO3)-xNaNbO3 lead-free ceramics. Ceram Int 44:2782–2788. https://doi.org/10.1016/j.ceramint.2017.11.018

Yang H, Yan F, Lin Y, Wang T (2018) Enhanced energy-storage properties of lanthanum-doped Bi0.5Na0.5TiO3-based lead-free ceramics. Energy Technol 6:357–365. https://doi.org/10.1002/ente.201700504

Gao F, Dong X, Mao C, Liu W, Zhang H, Yang L, Cao F, Wang G, Jones J (2011) Energy-storage properties of 0.89Bi0.5Na0.5TiO3-0.06BaTiO3-0.05K0.5Na0.5NbO3 lead-free anti-ferroelectric ceramics. J Am Ceram Soc 94:4382–4386. https://doi.org/10.1111/j.1551-2916.2011.04731.x

Liu X, Shi J, Zhu F, Du H, Li T, Liu X, Lu H (2018) Ultrahigh energy density and improved discharged efficiency in bismuth sodium titanate based relaxor ferroelectrics with A-site vacancy. J Mater 4:202–207. https://doi.org/10.1016/j.jmat.2018.05.006

Jin L, Li F, Zhang S, Green DJ (2014) Decoding the fingerprint of ferroelectric loops: comprehension of the material properties and structures. J Am Ceram Soc 97:1–27. https://doi.org/10.1111/jace.12773

Zhang L, Zhao C, Zheng T, Wu J (2020) Large electrocaloric effect in (Bi0.5Na0.5)TiO3-based relaxor ferroelectrics. ACS Appl Mater Inter 12:33934–33940. https://doi.org/10.1021/acsami.0c09343

Cui C, Pu Y (2018) Effect of Sn substitution on the energy storage properties of 0.45SrTiO3–0.2Na0.5Bi0.5TiO3–0.35BaTiO3 ceramics. J Mater Sci 53:9830–9841. https://doi.org/10.1007/s10853-018-2282-8

Zhang L, Pu Y, Chen M, Liu G (2018) Antiferroelectric-like properties in MgO-modified 0.775Na0.5Bi0.5TiO3-0.225BaSnO3 ceramics for high power energy storage. J Eur Ceram Soc 38:5388–5395. https://doi.org/10.1016/j.jeurceramsoc.2018.08.010

Yang L, Kong X, Cheng Z, Zhang S (2019) Ultra-high energy storage performance with mitigated polarization saturation in lead-free relaxors. J Mater Chem A 7:8573–8580. https://doi.org/10.1039/c9ta01165j

Yan F, Yang H, Lin Y, Wang T (2017) Dielectric and ferroelectric properties of SrTiO3-Bi0.5Na0.5TiO3-BaAl0.5Nb0.5O3 lead-free ceramics for high-energy-storage applications. Inorg Chem 56:13510–13516. https://doi.org/10.1021/acs.inorgchem.7b02181

Wang C, Yan F, Yang H, Lin Y, Wang T (2018) Dielectric and ferroelectric properties of SrTiO3-Bi0.54Na0.46TiO3-BaTiO3 lead-free ceramics for high energy storage applications. J Alloys Compd 749:605–611. https://doi.org/10.1016/j.jallcom.2018.03.195

Li D, Lin Y, Zhang M, Yang H (2020) Achieved ultrahigh energy storage properties and outstanding charge–discharge performances in (Na0.5Bi0.5)0.7Sr0.3TiO3-based ceramics by introducing a linear additive. Chem Eng J. https://doi.org/10.1016/j.cej.2019.123729

Liu G, Hu L, Wang Y, Wang Z, Yu L, Lv J, Dong J, Wang Y, Tang M, Guo B, Yu K, Yan Y (2020) Investigation of electrical and electric energy storage properties of La-doped Na0.3Sr0.4Bi0.3TiO3 based Pb-free ceramics. Ceram Int 46:19375–19384. https://doi.org/10.1016/j.ceramint.2020.04.280

Acknowledgements

This work was supported by the Major Program for Science and Technology of Inner Mongolia Autonomous Region (grant No. 2019ZD12), the Program for “Grassland Talents” Innovation Team of Inner Mongolia (Rare Earth Modified Lead-free Ferroelectric Multilayer Ceramic Capacitors Innovative Talent Team) and Scientific and Technological Development Foundation of the Central Guidance Local (2021ZY0008)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Z., Su, Q., Zhu, J. et al. Optimization of energy-storage properties for lead-free relaxor-ferroelectric (1-x)Na0.5Bi0.5TiO3-xSr0.7Nd0.2TiO3 ceramics. J Mater Sci 57, 217–228 (2022). https://doi.org/10.1007/s10853-021-06684-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06684-6