Abstract

In this study, a 3D printing process was used to fabricate antibacterial polycaprolactone/graphene scaffolds using short filament sticks. The first part of the work focused on the manufacture of a strong and flexible filament, in the form of sticks for use in the existing FDM system without any hardware or software modification. New filament materials, which can be connected together, containing graphene nanoplatelets have been prepared at three levels of concentration: 0.5, 5 and 10 wt%. The PCL and graphene were processed into filaments using injection molding, and their morphology, FTIR, WAXS, ultrasonic wave propagation, and mechanical properties were measured. WAXS and ultrasonic tests confirmed the even distribution of graphene powder in the sample modified with 0.5 wt% of graphene. The presence of graphene in the samples improved their mechanical properties; however, 10 wt% of addition did not produce further tensile strength enhancement. The filaments were successfully tested in a commercially available 3D printer to evaluate their capacity to produce printed scaffolds for nasal cartilage replacement. Initial cell culture study has shown that printed scaffolds support the proliferation of chondrocytes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The surgical treatment of nasal cartilage injuries is often difficult because of a lack of suitable materials for reconstruction [1]. The most common implants for nasal cartilages are composed of high-density polyethylene (Med-Por), silicone or polytetrafluoroethylene (Gore-Tex) [2]. Synthetic implants are easily carved, decrease surgical time and costs, and are readily available, making multiple surgical procedures unnecessary [3]. Despite the noticeable advantages of using synthetic implants, surgical procedures may be associated with postoperative complications including inflammation, infection, resorption, dislocation, and extrusion [4]. Complications associated with infection are of the greatest concern because the respiratory tract is considered to be potentially exposed to contamination during the procedure [5]. Tissue engineering has the potential to address many of the challenges in nasal cartilage replacement. Different methods have been applied to fabricate porous 3D scaffolds, such as solvent casting, particulate leaching, phase separation, electrospinning, fiber bonding, foaming, molding, and membrane lamination [6, 7].

Biofabrication of scaffolds may allow for the creation of custom, anatomically shaped implants. Moreover, the possibility of incorporating antibacterial components into tissue scaffolds may ensure proper postoperative regeneration of scaffold implantation side. Graphene is an example of a material with antibacterial properties which can be successfully embedded into the polymer matrix of scaffolds or implants [8, 9]. It has high mechanical strength, is flexible, and has excellent electrical conductivity [10]. Graphene also has antibacterial properties and accelerates the healing time of wounds [11, 12].

Fused deposition modeling (FDM) is one of the simplest and most cost-effective 3D printing methods, which is based on layer-by-layer deposition of extruded thermoplastic materials through a nozzle using feedstock filaments from a spool [13]. Numerous degradable polymers such as polycaprolactone (PCL), polylactic acid (PLA), polyglycolic acid, and their copolymers have been used to fabricate 3D scaffolds using the FDM method [14]. In particular, PCL is a currently used biodegradable polymer that has been approved by the FDA for various biomedical applications. PCL is a biocompatible, biodegradable, and non-toxic aliphatic polyester [15]. The effective solubility of PCL, its long-term degradation properties (> 24 months to lose total mass), its low melting point (59–64 °C), and its exceptional blend-compatibility have stimulated extensive research into its potential application in the biomedical field [16]. PCL exhibits more prolonged mechanical strength than other bioresorbable polymeric materials and degrades at a rate compatible with tissue regeneration [17]. In addition, PCL can be processed using 3D printing technology. Moreover, incorporation of particles, fibers, or nanomaterials into PCL permits the fabrication of polymer matrix composites, which are characterized by high biocompatibility, bioactivity, and excellent functionality, depending on their application [18]. Some examples of PCL composite materials for printing include: PCL with β-TCP particles [19], PCL with hydroxyapatite [20], PCL with strontium-containing hydroxyapatite [21]. In the above-mentioned examples, particles were mixed with PCL, either in powder form (and printed using the laboratory-made 3D bioprinting system) or in liquid form. One common drawback of mixing particles in liquid form is that this process is time consuming. The homogeneous solution of PCL and particles must be prepared, then the solution must be quickly poured into the molds, and then the composite raw materials must be exposed to a ventilated place for at least 3 days before the printing process can commence [21]. Recently, graphene and graphene-based polycaprolactone composites have been emerging as better materials to produce scaffolds with enhanced conductivity and biocompatibility [22]. Different methods were used to produce 3D graphene foams as scaffolds for tissue engineering. Electrohydrodynamic jet (EHD-jet) 3D printing allowed to obtain a 3D polycaprolactone/reduced graphene oxide biomimetic, conductive scaffold, which provides the native tissue microenvironment to the cells [23]. Other scientists used an integrated layer-by-layer casting method for the production of 3D porous graphene conduit and they proved that graphene-based PCL scaffold can significantly improve neural expression both in vitro and in vivo [24].

It is also possible to extrude a PCL composite into printable filaments for FDM processes. Extrusion is a continuous process in which raw plastic is converted into a product of uniform cross sections by pushing it through a die under controlled conditions. There are a large variety of different commercial materials currently used for producing 3D printing filaments, and many of them are modified with graphene. For example, Graphene Laboratories (Graphene 3D lab) created Conductive Graphene-Polylactide Filament and Graphene-High Impact Polystyrene (HIPS-400)—for technical propose. Commercial PCL (medical grade)/graphene filaments are not available in the market yet.

The success of 3D printing is primarily defined by the quality of the filament being used. Impurities lead to poor melted plastic viscosity with debris blocking the extruder nozzle, therefore ideal filament should be defect free. Filament materials are generally supplied in spools which are not entirely used during the production of small implants for cartilage replacement. A filament should maintain an absolutely constant diameter across the whole spool. Another important factor is the consistency of filament roundness across the full length of a spool. Moreover, a large amount of material is necessary for this process, and usually, filaments used for biomedical applications are very expensive, and it is not necessary to use whole spools to produce scaffolds or small implants. Most grafts used in rhinoplasty are less than 25 mm in length, 15 mm in width, and are approximately 1.5 mm thick [25]. For this study, in order to produce filaments without such consumption of biomedical materials, an injection molding (IM) method was applied in this study. IM is one of the most well-known processes of component production from thermoplastic polymers [26]. Polymer granules are fed into a heated barrel, mixed, and then a molten thermoplastic polymer is injected under the influence of high pressure and speed into a mold [27]. The shape of the mold defines the shape of the molded part. It is also possible to mix the polymer with different additives before the introduction into the injection molding machine.

The aim of this work was to fabricate innovative biomedical filaments for 3D printing in the form of short and biodegradable composite sticks. The PCL polymer was modified with graphene nanoparticles in order to obtain antibacterial properties of future nasal cartilage implants. The polymer sticks were produced using an injection molding process.

The advantages of the proposed processes are listed as follows: low biomaterial consumption, the possibility of shaping the implant geometry and adapting it to the shape of the patient’s tissue, plus the ability to set the required number and material selection of individual implant layers. The application of filament in the form of sticks during the printing process of tissue scaffolds will allow production of pure PCL scaffolds or scaffolds modified with graphene, without the necessity of changing the spool, which will make the scaffold production processes more efficient, faster, and more complex. Moreover, the filament sticks are designed to be used in the existing FDM systems without any hardware or software modification. The method of scaffold production presented in this paper offers advantages such as low production cost, high speed, and simplicity.

Materials and methods

Materials

Polycaprolactone (PCL) (Mn 80 kDa) in granular form and graphene nanoplatelets (polycarboxylate chemically modified graphene nanoplatelets, GNP) were purchased from Sigma-Aldrich. The polymer granules were dry-mixed together with GNP powder in order to obtain 0.5, 5 and 10 wt% of graphene addition in the mixture (mechanical stirring for 15 min). A PCL/GNP blend was used for the injection molding process. A Babyplast 6/10P injection molding machine was used to make filaments in the form of sticks. One of the advantages of the screw-plasticizing systems of the injection molding machine is, among others, good thermal homogenization of the polymers. Thermal homogenization of the material occurred through the screw intensive mixing process. Pure PCL granules were also applied as reference material.

Fabrication of filament in the form of sticks

A Babyplast injection molding machine was used to produce composite sticks. Injection molding is a sophisticated process during which molten polymers undergo complex physiochemical changes. It is often hard to stay on top of all the changes which occur during the injection molding process, and the development of a new product is very complex and difficult. This is due mainly to large number of interdependent process parameters that have an influence on the quality of the final product. The most important parameters of the injection process, which ensures a high quality of the manufactured product, include: temperature of the injected material (for PCL polymer the extruder temperatures should be over 60 °C to facilitate the melting of the polymer and less than 295 °C to prevent polymer degradation), injection pressure, time of maintaining the thermoplastic material in the mold under high pressure and temperature of the mold. The parameterization process consists of changing the parameters depending on the current state of the process and quality of the obtained product. In this study, the selection of injection molding process parameters was carried out using literature reports and the authors’ own experience. A series of injection molding experiments were performed to examine the effects of the processing parameters on the final polymer product quality (determined by microscopic evaluation). Finally, the plasticization temperature of around 200 °C and the parameters presented in Table 1 were applied in order to produce composite sticks. Four types of polymer sticks were obtained: PCL, PCL/GNP_0.5, PCL/GNP_5, and PCL/GNP_10 (resulting form 0.5, 5 and 10 wt% of graphene addition to the PCL).

Scaffold fabrication by 3D printing

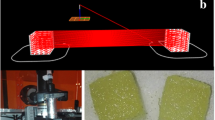

Fused deposition modeling (FDM) technology was used to develop 3D spatial scaffolds made of PCL and PCL/GNPs composite sticks. The FDM process must be controlled by many parameters, which range from filament type to machine settings. FDM is an additive technology building models in a layer-by-layer method. The spatial structure was modeled using computer-aided design (CAD) software and exported to an .stl file. The printer nozzle temperature was kept at 190 °C, and the material left the extruder in a semi-fluid form before being placed in layers with a height of 0.15 mm. To improve adhesion, the fabrication platform temperature was maintained at 50 °C for the duration of the first layer print, while for the remaining layers, the platform heating was turned off. The 3D scaffolds were printed at a speed of 15 mm/s.

Filaments and scaffolds characterization

Pure PCL and PCL/GNP filaments in the form of sticks and obtained using 3D-printed structures were observed with Stereomicroscope (SN) from the OPTA-TECH company, equipped with a CMOS 3 camera and OptaViewIS software. The samples were also evaluated using a scanning electron microscope (Nova NanoSEM 200, FEI) equipped with EDS analysis. The samples were coated with carbon before observation.

The FTIR spectra of the PCL and PCL/GNPs filaments were measured using a Bio-Rad FTS60V spectrometer (KBr pellet method). The FTIR spectra registered in the wavenumber range of 600–4000 cm−1.

Tests of the mechanical properties of the filaments were performed on a Universal Testing Machine (Hegewald & Peschke, Nossen, Germany) set in tensile mode, at a cross-head speed of 5 mm/min. Five sticks for each type of sample (1.75 mm diameter x 50 mm length) were analyzed. Young’s modulus was calculated as the slope of the curve between 0.05 and 0.25% strain using a chord slope calculation. The tensile strength, Young’s modulus, and strain at break were given as the average value ± standard deviation. All tests were conducted at room temperature (approximately 20 °C).

Measurements of the longitudinal waves’ velocity were performed using a CT-3 materials tester along the sample length. For measuring the velocity of longitudinal ultrasonic waves, the transducers with a frequency of f = 1 MHz were used. Adhesive tape was used as a coupling medium. Each measurement series was performed on five independent measurements of the transmission times of longitudinal ultrasonic waves, and the mean values of velocity and its standard deviations were calculated.

The wide-angle X-ray scattering (WAXS) measurements were carried out on a Seifert URD6 diffractometer, equipped with an ISO-DEBYEFLEX 3003 high voltage generator and a secondary graphite monochromator. A cooper target sealed X-ray tube operated at: U = 40 kV and I = 30 mA was used as the radiation source (λ = 0.1542 nm). The step scanning measurement mode was employed over 2θ scattering angles, ranging from 2.5° to 60°, with a step-size of 0.05°.

Cell culture study

The Primary Human Chondrocytes, isolated from normal human articular cartilage from the knee and hip joints (HCH, PromoCell, USA), were used during preliminary assessment of the scaffold’s cytocompatibility. The Chondrocyte Growth Medium, (PromoCell, USA) with the addition of 10% of a serum containing growth factors of Chondrocyte Growth Medium SupplementMix (PromoCell, USA), was used for HCH cultures. Cells were cultured at 37 °C in a humidified incubator with 5% CO2. After the first passage, cells were detached using TrypLE Express reagent (Gibco, USA), counted and prepared for the scaffold seeding. 3D-printed PCL and PCL/GNP_0.5 scaffolds in the form of disks with a diameter matching the size of the wells of the 96-well culture plate were sterilized using 70% pure ethanol and also by means of UV radiation (half an hour each side). Sterile biomaterial samples were placed on the bottom of the culture plate. An empty polystyrene well served as a positive control (TCPS). The cells were seeded onto the 3D-printed scaffolds at a concentration of 5 × 103 cells/200 µl. The cultured medium was renewed every 3 days.

Sterile biomaterials samples were placed in the culture plate wells. HCHs were seeded onto the scaffolds at the concentration of 5 × 103 cells/200 µl. The culture medium was half renewed every 3 days.

Cytotoxicity and cell proliferation were determined after 7 and 14 days. Cytotoxicity was measured in the supernatant collected from above cells cultured with biomaterials. Cells that were grown on the surface of examined samples were lysed with ToxiLight 100% lysis reagent (Lonza, USA). With the use of ToxiLight Bioassay Kit (Lonza, USA) AK enzyme (Adenosine Kinase) released from the dead or lysed cells catalyzes the reaction that gives the luminescence. Its intensity corresponds to the cytotoxicity or cells number, respectively. Chondrocyte differentiation was assessed by measuring collagen type II production with the aid of ELISA Kit for Collagen Type II (Cloud-Clone Corp., USA). All measurements were taken with a microplate reader PolarStar Omega (BMG Labtech, Germany).

The results were expressed as mean ± standard deviation (SD) from 6 samples for each experimental group. The ANOVA was used to determine the differences among the evaluated series of samples. The results were considered statistically significant when p < 0.05.

Results

PCL and PCL/GNP filaments characterization

The influence of the injection molding conditions on the final geometry and surface of the stick filaments was investigated using macro- and microscopic observations. The macroscopic images of the molded final products are presented in Fig. 1. The shape of the mold (Fig. 1a) has been properly reproduced in the case of PCL and PCL/GNP (Fig. 1b, c). When the polymer is molded using an injection molding process, there are gates and channels that allow the compound to pass through the mold cavities. As can be observed in Fig. 1, the excess of materials mapping mentioned channels is presented and must be cut off and removed in order to obtain pure PCL or PCL/GNP sticks.

The quality of the filament has a huge influence on the success of 3D printing. Any defects present on the surface of the filament can lead to the blocking of the printer’s nozzle. Therefore, an ideal filament should be defect-free. Obtained samples differed in color. A black color observed on the PCL/GNP samples was related to the graphene content in the polymer blends. The results of microscopic evaluation are presented in Fig. 2. The surface of pure PCL sticks was smooth and uniform, in the case of PCL/GNP sticks, some irregular spots or grains were observed on the filament surface, proving that graphene nanoplatelets were successfully incorporated into the sample structure.

Figure 3a shows the FTIR spectra of PCL and PCL/GNPs samples. In the FTIR, the spectra of PCL characteristic bands were observed at a range between 1727 cm−1 (C=O stretching), 1293 cm−1 (C–O and C–C stretching), 1240 cm−1 (C–O–C asymmetric stretching) and 1175 cm−1 (C–O–C symmetric stretching) [28]. The bands appeared at 2945, 2867 cm−1 are attributed to asymmetric CH2 stretching and symmetric CH2 stretching. Overall, the FTIR spectra of PCL/GNP_0.5 do not provide evidence that the incorporated GNP strongly interacts with PCL chains. Only after 10 wt% of graphene incorporation did the characteristic very small band situated at 1560 cm−1 appear. These bands may be attributed to the C–C stretching vibration of the carbon backbone (unoxidized graphitic domains).

The WAXS diffraction patterns of the samples investigated are presented in Fig. 3b. Diffraction curves of the pure PCL sticks and the PCL/GNP sticks reveal that supermolecular structure of those sticks is semicrystalline. This is indicated by the detection of the sharp PCL crystalline diffraction peaks at: 2θ ≈ 21.35°, 21.95° and 23.60° [29] superimposed on the broad amorphous diffraction halo centered at 2θ ≈ 20.50°. The diffraction pattern of the pure GNPs is characterized by three main diffraction peaks detected at: 2θ ≈ 8.40°, 26.55°, and 27.55° as it should be observed for that Sigma-Aldrich product. Note, that those GPNs diffraction peaks don’t appear on the diffraction curve of the PCL/GNP_0.5 sticks. For samples PCL/GNP_5 and PCL/GNP_10, the presence of trace amounts of GNP agglomerates reveals the very weak diffraction maximum indicated by the arrow, which corresponds to the diffraction peaks at 26.55 and 27.55.

Figure 4a shows the longitudinal (VL) ultrasonic wave velocity propagation in the PCL and PCL/GNPs filament sticks. The highest velocity values are for the pure PCL and PCL modified with 0.5 wt. % addition of graphene. A similar value of the wave velocity indicates the even distribution of graphene powder in the PCL polymer matrix. The lowest VL value was observed for PCL/GNP_5 sample.

Figure 4b shows representative stress–strain curves of polymer sticks under tensile loading. It was observed that the addition of graphene could improve the strain ability of filaments. Mean values of Young’s modulus, tensile strength, and strain at break of the filaments in the form of sticks are presented in Table 2 and Fig. 4c. Among the four sample types, the highest tensile strength was observed for PCL/GNP_5 sample. The addition of 10 wt% graphene into the sticks decreased their tensile strength to about 15 MPa, probably due to the formation of graphene agglomerates. Compared to pure PCL samples, strain at the break of PCL/GNPs samples increased when graphene was added. The highest strain at break was observed for PCL/GNP_5 sample. As illustrated in Table 2, tensile strength and strain at break start decreasing with the increase in graphene content from 5 to 10%. Young’s modulus of the samples modified with 10 wt% graphene addition was 19% higher than Young’s modulus of pure PCL polymer sticks.

Based on the WAXS measurements, the ultrasonic through-transmission method and mechanical tests PCL/GNP_0.5 sticks were chosen for fused deposition modeling as the graphene particles were well distributed in this samples.

Filament application in 3D FDM printing

Fused deposition modeling (FDM), a rapid prototyping technology, was used to produce scaffolds from obtained polymer filaments. In order to produce 3D-printed scaffolds, a scaffold pattern was designed (Fig. 5) based on previous results [5]. The spacing between filling bars was set at 0.7 mm. The structure consisted of 3 layers, each 1 mm in height, arranged in at a 90° angle with respect to the previous layer (Fig. 5a). To characterize the designed scaffold, the volume of PCL, porosity, and the total area of the obtained structure with respect to a reference cuboid (21.4 mm × 19.7 mm, 3 mm height) were calculated and presented in Fig. 5e. Pure PCL and PCL/GNP_0.5 filaments were tested using a commercially available 3D printer to evaluate their capacity to produce printed scaffolds. The morphology of a 3D-printed scaffold is presented in Fig. 5f–i. The porous structure of scaffolds with a pore size less than 0.7 mm could be observed. Small GNP powder agglomerates are visible on the surface of printed PCL/GNP scaffolds, indicating a successful incorporation of graphene into the final scaffold (Fig. 5g, i).

Graphene composites have been used in cartilage tissue engineering applications and have been shown to support chondrogenic differentiation and proliferation of chondrocytes [30]. The preliminary results of cell culture study on the 3D-printed PCL and PCL/GNP_0.5 scaffolds are presented in Fig. 6. The number of chondrocytes growing on the 7th and 14th day of cell culture in wells with 3D-printed scaffolds was significantly higher compared to the TCPS control material (Fig. 6a). This effect is achieved mainly due to the larger surface area of printed biomaterials. A large specific surface area of the porous spatial scaffolds supports cell proliferation. A smaller number of cells cultured on TCPS may indicate differentiation of cells. As cells differentiate, their rate of proliferation usually decreases. Cytotoxic effect of biomaterials on chondrocyte cells was also evaluated (Fig. 6b). No statistically significant differences were observed between modified and unmodified graphene samples. Also similar expression of the type II collagen occurred after 7 and 14 days of the cell culture on both PCL and PCL/GNP_0.5 biomaterials (Fig. 6c). The addition of graphene into samples did not alter the expression level of collagen type II.

a Relative number of intact adherent HCH cells. RLUs—relative luminescence units. Results are expressed as a mean ± SD. Statistically significant differences (p < 0.05) between each material and TCPS after 7 and 14 days of cell culture are indicated by uppercase and lowercase letters, respectively. No statistically significant differences (p < 0.05) between materials were observed. b Cytotoxic effect of biomaterials on HCH cells. RLUs—relative luminescence units. Results are expressed as mean ± SD. No statistically significant differences (p < 0.05) between materials were observed. c Secretion of collagen II by HCH cells after 7 and 14 days of culture. The sample concentrations were calculated based on the standard curve. Results are expressed as mean ± SD. No statistically significant differences (p < 0.05) between materials were observed

Discussion

Temperatures during the injection process have a significant impact on the properties of the final product. Too high of a temperature during the process causes numerous defects. If the melt temperature is too low, the polymer might not be completely melted or it might be too viscous to flow. The molten plastic, for some reason, does not fully occupy the mold cavity or cavities, resulting in a portion where there is no plastic. The finished product becomes deficient because it is incomplete. Aside from that, some surface delamination may also occur or weld lines may appear on the surface of molded element. If the melt temperature is too high, the polymer can degrade. Heat decomposition of the material may occur and discoloration or dark reddish brown streaks may appear in the molded product. The most important parameter is the first injection pressure, which is responsible for the correct mapping of the shape of the mold. The injection pressure should be as low as possible to reduce internal stress on the product. If the pressure is too low, the materials will not be dispersed correctly. Not enough material will enter the mold and incomplete molded parts will be produced (short shot defect). If the pressure is too high, the material will flow outside of the mold cavity (flash defect). A high, first-stage pressure is followed by a lower, second stage pressure. Another important parameter is cooling time. Polycaprolactone has high ductility at elevated temperatures and a long cooling time. A defect called ‘sink marks’ may occur when the cooling time or the cooling mechanism is insufficient for the polymer to fully cool and cure while in the mold. Sink marks are small craters or depressions that develop in molded samples when shrinkage occurs in the inner portions of the finished product. In the case of PCL, the long cooling time (60 s) allowed for sufficient cooling of the manufactured parts and no defects were observed on the surface of polymer sticks. The cooling time for PCL/GNP blends was reduced to 45 s and the material cooled faster due to the excellent heat conductivity of graphene.

FTIR spectra of PCL/GNP_0.5 do not provide evidence that the incorporated GNP strongly interact with PCL chains. On the other hand, the PCL/GNP_0.5 sticks are dark gray due to the graphene additive. Consequently, one can conclude that graphene nanoplatelets underwent exfoliation during the fabrication of the sticks and that graphene sheets are homogeneously dispersed within the amorphous phase of the semicrystalline PCL matrix (which was also confirmed by a WAXS examination in the case of PCL/GNP_0.5 sample).

An ultrasound through-transmission method can be used to determine the elastic properties of the filament sticks, which are linked to their material properties and provide some information about changes occurring within higher concentrations of graphene nanoparticles. In the through-transmission method, a transmitter sends an ultrasonic signal through one surface and a separate receiver detects the amount that has reached it on another surface after traveling through the sample [31]. Ultrasonic wave propagation is influenced by the microstructure of the material through which it propagates. Defects, pores or agglomerates in the sample placed between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. A higher concentration of graphene in the sample PCL/GNP_5 causes an increase in particle agglomeration. The empty spaces (voids) created by the particle agglomerates decrease the wave velocity. In the case of PCL/GNP_10 samples, the graphene particles are more packed and less voids are present in the filament, which is why the velocity of the ultrasonic wave increases. Due to the alignment of graphene nanoplatelets (GNPs), the filament sticks showed also a higher elastic modulus in the case of PCL/GNP_10 samples. Moreover, the addition of GNP powder resulted in increased crystallinity of the composites. The mechanical properties of polymer nanocomposite sticks depend strongly on filler dispersion state. Excessive addition of nanofillers does not produce further mechanical enhancement. An aggregated filler acts as a stress concentrator and severely deteriorates the mechanical properties [32]. In the sample PCL/GNP_0.5 the graphene particles were evenly distributed, no agglomerate and no voids between agglomerates were present. Increasing the graphene concentration to 5 wt%, the ultrasonic wave velocity decreases, but tensile strength and strain at yield increases significantly. The presence of defects, pores or agglomerates in the sample reduced the speed of propagation of the ultrasonic wave. However, graphene agglomerates are randomly distributed increasing the tensile strength and the strain at yield. In the case of the PCL/GNP_10 sample, graphene particles are more alignment and packed, which reduces the number of voids, and the speed of the ultrasonic wave increases. Moreover, agglomerates of graphene are more oriented and polymer has higher crystallinity. Therefore, higher Young’s modulus but lower tensile strength and lower strain at yield were observed.

Fused deposition modeling (FDM) was successfully applied to produce scaffolds from obtained polymer filaments. The microscopic observations confirmed the presence of graphene in the printed samples.

Initial cell culture study has shown that printed scaffolds support the proliferation of chondrocytes. The three-dimensional structure of these materials seems to have a greater impact on cell proliferation than the addition of graphene. The addition of graphene to the three-dimensional printed scaffolds does not increase the cellular toxicity of the materials. Also the expression of collagen type II was on a similar level for both PCL and PCL/GNP_0.5 materials.

Advantages of produced filaments

The endings of the sticks are not flat, but they have a shape that is similar to a single dovetail joint. The fitting of two sticks is performed in such a way that the pin cut of the first stick is fitted in a tail cut in the next stick (Fig. 7). Short sticks made of material with different additives and required length can be combined into one filament, which can be used in a standard 3D printer. Once a few sets of sticks have been fabricated, it is possible to connect them in an arbitrary way and obtain a filament that can be used in standard or mid-range FDM 3D printer. The only important requirement to considered regarding the 3D printer is its ability to adjust to a wide range of printing parameters (in particular, the temperature of the nozzle is crucial for the success of the entire process). The possibility of combining different sticks during the printing process enables the production of diverse scaffolds without the necessity of changing the spool, as it is in the traditional fused deposition modeling process. For example, the outer layer of the implant can be augmented with antibacterial ingredients and be stronger, while the inner layer can contain ingredients that facilitate the growth of cells. One additional routine during the CAD model generation process is the estimation of the volumes of all designed layers of the nasal implant. Fortunately, volume computation is now a standard feature of 3D CAD software. The lengths of subsequent sticks which, after bonding the other elements together, produce the whole filament, can be calculated using the following formula:

where Vi the volume of the subsequent stick; d = 1.75 mm—the standard diameter of the filament; K contraction coefficient, in preliminary experiments it can be assumed its value is equal to 1.

By using short filament sticks, as proposed in this paper, cheaper scaffold production is possible. The presented strategy allows one to obtain the desired results with no waste of materials. Moreover, the surgeon will also have the option of designing the composition of each scaffold from different sticks (pure or modified), without the necessity of changing the spool, as it is in the traditional fused deposition modeling process.

Conclusions

In this work, we evaluated the possibility of preparing 3D scaffolds from composite polycaprolactone/graphene filament in the form of sticks obtained using an injection molding process. The parameterization process was performed, along with microscopic evaluation, to examine the effects of the processing parameters on the final quality of filament sticks. The process parameters were slightly different for pure PCL and PCL/GNPs blends. The cooling time for PCL/GNPs blends was shorter, as the material cooled faster due to the excellent heat conductivity of graphene. Microscopic observations, and the FTIR study, indicate that graphene was successfully incorporated into the polymer filament structure. The velocity of the ultrasonic waves was influenced by the amount of various phases (like pores, additives) presented in the material. The highest velocity values were measured for the pure PCL and PCL modified with 0.5 wt% addition of graphene. Higher concentrations of graphene in samples causes an increase in particle agglomeration and decreases wave velocity. Furthermore, the WAXS results confirmed that graphene nanoplatelets underwent exfoliation during the fabrication of the sticks, and in the case of 0.5 wt% graphene addition, graphene sheets are homogeneously dispersed within the amorphous phase of the semicrystalline PCL matrix. The presence of graphene in the samples improved their mechanical properties, however, 10 wt% of addition did not produce further tensile strength enhancement. Fused deposition modeling (FDM) was successfully applied to produce scaffolds from obtained polymer filaments. Microscopic observation confirmed the presence of graphene in the printed samples. Initial cell culture study has shown that printed scaffolds support proliferation of chondrocytes. Similar results of cytotoxicity and collagen type II expression were attained after 7 and 14 days of cultivation on porous 3D scaffold without and with incorporated graphene present. This indicates that graphene is not adversely affecting cellular behavior in vitro. The positive results of the preliminary investigation on the composite sticks will allow for the development of novel sets of sticks modified with various additives. Therefore, in the future, instead of buying a whole spool filament of one type of modified polymer, the surgeon will be able to buy a set of differently modified sticks (e.g., graphene, hydroxyapatite, drugs) and combine them depending on the patient’s needs, using a commercially available 3D printer The possibility of combining different sticks during the printing process will enable the production of diverse scaffolds without the necessity of changing the spool, as it is in the traditional fused deposition modeling process. For example, the outer layer of the implant can be augmented with antibacterial ingredients and be stronger (graphene addition), while the inner layer can contain ingredients that facilitate the growth of cells (calcium phosphate additives). The filaments developed during this project are designed to be used in the existing FDM systems without any hardware or software modification. The method of scaffold production presented in this paper offers advantages such as low production cost, high speed, and simplicity.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

Rajzer I, Menaszek E, Bacakova L, Orzelski M, Błażewicz M (2013) Hyluronic acid-coated carbon nonwoven fabrics as potential material for repair of osteochondral defects. Fibres Text East Eur 99(3):102–107

Patel K, Brandstetter K (2016) Solid implants in facial plastic surgery: potential complications and how to prevent them. Facial Plast Surg 32:520–531. https://doi.org/10.1055/s-0036-1586497

Lavernia L, Brown WE, Wong BJF, Hua JC, Athanasiou KA (2019) Toward tissue-engineering of nasal cartilages. Acta Biomater. https://doi.org/10.1016/j.actbio.2019.02.025

Ottoline AC, Tomita S, Marques MP, Felix F, Ferraiolo PN, Laurindo RS (2013) Antibiotic prophylaxis in otolaryngologic surgery. Int Arch Otorhinolaryngol 17(1):85–91. https://doi.org/10.7162/S1809-97772013000100015

Rajzer I, Kurowska A, Jabłoński A, Jatteau S, Śliwka M, Ziąbka M, Menaszek E (2018) Layered gelatin/PLLA scaffolds fabricated by electrospinning and 3D printing- for nasal cartilages and subchondral bone reconstruction. Mater Des 155:297–306. https://doi.org/10.1016/j.matdes.2018.06.012

Jia A, Ee J, Teoh M, Suntornnond R, Chua CK (2015) Design and 3D printing of scaffolds and tissues. Engineering 1(2):261–268. https://doi.org/10.15302/J-ENG-2015061

Bogun M, Mikolajczyk T, Kurzak A, Blazewicz M, Rajzer I (2006) Influence of the as-spun draw ratio on the structure and properties of PAN fibres including montmorillonite. Fibres Text East Eur 14(2):13–16

Gomes RN, Borges I, Pereira AT, Maia AF, Pestana M, Magalhães FD, Pinto AM, Gonçalves IC (2018) Antimicrobial graphene nanoplatelets coatings for silicone catheters. Carbon 139:635–647. https://doi.org/10.1016/j.carbon.2018.06.044

Chaudhuri B, Mondal B, Kumar S, Sarkar SC (2016) Myoblast differentiation and protein expression in electrospun graphene oxide (GO)-poly(ε-caprolactone, PCL) composite meshes. Mater Lett 182:194–197. https://doi.org/10.1016/j.matlet.2016.06.107

Ionita M, Vlasceanu GM, Watzlawek AA, Voicu SI, Burns JS, Iovu H (2017) Graphene and functionalized graphene: extraordinary prospects for nanobiocomposite materials. Compos B 121:34–57. https://doi.org/10.1016/j.compositesb.2017.03.031

Shin SR, Li YC, Jang HL, Khoshakhlagh P, Akbari M, Nasajpour A, Zhang YS, Tamayol A, Khademhosseini A (2016) Graphene-based materials for tissue engineering. Adv Drug Deliv Rev 105:255–274. https://doi.org/10.1016/j.addr.2016.03.007

Pang L, Dai C, Bi L, Guo Z, Fan J (2017) biosafety and antibacterial ability of graphene and graphene oxide in vitro and in vivo. Nanoscale Res Lett 12(1):564. https://doi.org/10.1186/s11671-017-2317-0

An J, Teoh JEM, Suntornnond R, Chua CK (2015) Design and 3D printing of scaffolds and tissues. Engineering 1(2):261–268. https://doi.org/10.15302/J-ENG-2015061

Zhang B, Seong B, Nguyen V, Byun D (2016) 3D printing of high-resolution PLA-based structures by hybrid electrohydrodynamic and fused deposition modeling techniques. J Micromech Microeng 26(2):025015. https://doi.org/10.1088/0960-1317/26/2/025015

Fereshteh Z, Fathi M, Bagri A, Boccaccini AR (2016) Preparation and characterization of aligned porous PCL/zein scaffolds as drug delivery systems via improved unidirectional freeze–drying method. Mater Sci Eng C 68:613–622. https://doi.org/10.1016/j.msec.2016.06.009

Domalik-Pyzik P, Morawska-Chochół A, Chłopek J, Rajzer I, Wrona A, Menaszek E, Ambroziak M (2016) Polylactide/polycaprolactone asymmetric membranes for guided bone regeneration. E-Polymers 16(5):351–358. https://doi.org/10.1515/epoly-2016-0138

Rajzer I (2014) Fabrication of bioactive polycaprolactone/hydroxyapatite scaffolds with final bilayer nano-/micro-fibrous structures for tissue engineering application. J Mater Sci 49(16):5799–5807. https://doi.org/10.1007/s10853-014-8311-

Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017) 3D printing of polymer matrix composites: a review and prospective. Compos B 110:442–458. https://doi.org/10.1016/j.compositesb.2016.11.034

Park JS, Lee SJ, Jo HH, Lee JH, Kim WD, Lee JY, Park SA (2017) Fabrication and characterization of 3D-printed bone-like β-tricalcium phosphate/polycaprolactone scaffolds for dental tissue engineering. J Ind Eng Chem 46:175–181. https://doi.org/10.1016/j.jiec.2016.10.028

Qu X, Xia P, He J, Li D (2016) Microscale electrohydrodynamic printing of biomimetic PCL/nHA composite scaffolds for bone tissue engineering. Mater Lett 185:554–555. https://doi.org/10.1016/j.matlet.2016.09.035

Liu D, Nie W, Li D, Wang W, Zheng L, Zhang J, Zhang J, Peng C, Mo X, He C (2019) 3D printed PCL/SrHA scaffold for enhanced bone regeneration. Chem Eng J 362(15):269–279. https://doi.org/10.1016/j.cej.2019.01.015

Chaudhuri B, Bhadra D, Moroni L, Pramanik K (2015) Myoblast differentiation of human mesenchymal stem cells on graphene oxide and electrospun graphene oxide–polymer composite fibrous meshes: importance of graphene oxide conductivity and dielectric constant on their biocompatibility. Biofabrication 7(1):015009. https://doi.org/10.1088/1758-5090/7/1/015009

Vijayavenkataraman S, Thaharah S, Zhang S, Lu WF, Fuh JYH (2019) 3D-printed PCL/rGO conductive scaffolds for peripheral nerve injury repair. Artif Organs 43(5):515–523. https://doi.org/10.1111/aor.13360

Qian Y, Zhao X, Han Q, Chen W, Li H, Yuan W (2018) An integrated multi-layer 3D-fabrication of PDA/RGD coated graphene loaded PCL nanoscaffold for peripheral nerve restoration. Nat Commun 9(1):323. https://doi.org/10.1038/s41467-017-02598-7

Kim JS, Khan NA, Song HM, Jang YJ (2010) Intraoperative measurements of harvestable septal cartilage in rhinoplasty. Ann Plast Surg 65(6):519–523. https://doi.org/10.1097/SAP.0b013e3181d59f95

Giboz J, Copponnex T, Mele P (2009) Microinjection molding of thermoplastic polymers: morphological comparison with conventional injection molding. J Micromech Microeng 19(2):1–12. https://doi.org/10.1088/0960-1317/19/2/025023

Mavridis H, Hrymak AN, Vlachopoulos J (1986) Finite element simulation of fountain flow in injection molding. Polym Eng Sci 26(7):449–454. https://doi.org/10.1002/pen.760260702

Gautam S, Dinda AK, Mishra NC (2013) Fabrication and characterization of PCL/gelatin composite nanofibrous scaffold for tissue engineering applications by electrospinning method. Mater Sci Eng, C 33:1228–1235. https://doi.org/10.1016/j.msec.2012.12.015

Bittiger H, Marchessault RH, Niegisch WD (1970) Crystal structure of poly-ε-caprolactone. Acta Crystallogr A B26:1923–1927. https://doi.org/10.1107/S0567740870005198

Lee WC, Lim CH, Su C, Loh KP, Lim CT (2015) Cell-assembled graphene biocomposite for enhanced chondrogenic differentiation. Small 11:963–969. https://doi.org/10.1002/smll.201401635

Rajzer I, Piekarczyk W, Castaño O (2016) An ultrasonic through-transmission technique for monitoring the setting of injectable calcium phosphate cement. Mater Sci Eng C 67:20–25. https://doi.org/10.1016/j.msec.2016.04.083

Atif R, Inam F (2016) Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J Nanotechnol 7:1174–1196. https://doi.org/10.3762/2Fbjnano.7.109

Acknowledgements

This work was supported by the National Science Centre, Poland in the framework of the project: “Layered scaffolds for nasal cartilages reconstruction fabricated by 3D printing and electrospinning” 2015/18/E/ST5/00189 (Sonata Bis 5).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajzer, I., Kurowska, A., Jabłoński, A. et al. Scaffolds modified with graphene as future implants for nasal cartilage. J Mater Sci 55, 4030–4042 (2020). https://doi.org/10.1007/s10853-019-04298-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04298-7