Abstract

Highly stretchable supersensitive sensors represent a new epoch in the field of intelligent medical devices. Applications include the detection of various stimuli of the human body and environmental monitoring around biological surfaces. To provide more accurate measurement results, stretchable sensors must be tightly attached on the skin surface or to clothing. Consequently, stretchable sensors must fulfill many requirements, such as high stretchability, high comfortability, high sensitivity, and long-term wear. To address these challenges, investigators have devoted considerable research effort to the development of technology, and much progress has been achieved. Here, recent developments with stretchable sensors are described, including human motion monitoring sensors, vital sign monitoring sensors, and sensors for environmental monitoring around biological surfaces. The latest successful examples of supersensitive sensors for achieving stretchability by novel materials or structures are reviewed. In the next section, recent advances regarding processing technology innovations are introduced. Future research directions and challenges in developing a highly stretchable supersensitive sensor for wearable biomedical applications are also discussed. With the development of new materials and novel technologies, and given the interdisciplinary nature of the research, the functionalities of stretchable sensors will become more powerful, and stretchable sensor technology will become more mature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

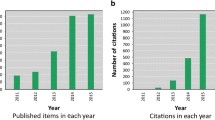

Since their introduction in the early twenty-first century [1], stretchable sensors have attracted substantial attention due to their unique characteristics, such as low modulus, light weight, high flexibility, and stretchability [2]. In addition to these characteristics, stretchable sensors easily flag certain diseases without requiring medical workers to connect to smart devices, thereby not only simplifying diagnostic procedures but also providing health information by monitoring body conditions. Meanwhile, advances in wireless technologies, low-power electronics, and the digital health domain are driving innovations in stretchable sensors for wearable biomedical applications at a tremendous pace. During recent years, stretchable electronic devices for wearable biomedical applications have seen many remarkable achievements, such as the creation of the e-skin [3, 4]. In terms of statistics, the wearable device market reached US$5 billion in 2015 and is predicted to reach US$20.6 billion in 2018.

The main objective of a highly stretchable supersensitive sensor is to measure and quantify physiological signals that are generated by biological activities to provide feedback about physical condition. To carry out its function, a stretchable sensor is generally fixed on the skin surface. Hence, given their nature as interfaces between the skin and the environment, some stretchable sensors also undertake environmental monitoring around a biological surface, such as monitoring the humidity around a wound. The quality of the bio-adhesion between the sensor and skin is the determining factor in achieving signal acquisition results and thus has become a critical issue given that the human epidermal structure is complicated, not flat, and constantly moving.

Generally, electrodes are used to overcome this issue by facilitating attachment to skin via a mechanical clamp, adhesive tape, gel, straps, or penetrating needles. These methods have limitations in terms of comfort, ease of use, long-term wear, and accuracy of health monitoring. Only by possessing the characteristics of high stretchability, flexibility, sensitivity, durability, and fast response/recovery speeds are sensors be suitable for wearable human motion detection, especially for detecting a large range of motion such as that involved in joint movement, which usually results in more than 50% stretchability deformation [5]. However, traditional metallic and semiconducting sensors only withstand very limited stretchability before fracture. Thus, they are not suitable for stretchable applications [6,7,8]. Continued rapid progress with diverse flexible and stretchable substrates [9, 10], novel mechanically durable materials [11,12,13], deformable electrodes and novel processing technology [14,15,16] is promising for the development of stretchable sensors in the near future.

In recent years, the rapid development of new materials and structures [17,18,19,20] has resulted in significant progress in the achievement of highly stretchable supersensitive sensors for wearable biomedical applications. Stretchable sensors have proven to be an important step in achieving a major breakthrough in intelligent healthcare [21, 22]. Highly stretchable supersensitive sensors have been widely used for many wearable biomedical applications, such as human body motion detection [23, 24], human body sign monitoring [25,26,27,28], and environmental monitoring around biological surfaces [29]. Taken a step further, stretchable sensors protect human health in a real-time, safe, and comfortable manner. With the development of materials and processing technology, stretchable sensor technology will become more mature. Undoubtedly, monitoring human health and the environments around biological surfaces will facilitate a healthier lifestyle.

Given the efforts of an increasing number of researchers, there have been many research achievements with stretchable sensors for wearable biomedical applications. The large number of research achievements brings a certain degree of inconvenience for researchers in the process of acquiring relevant information. Several excellent overviews of recent achievements with flexible and stretchable sensors are available [3]. However, a detailed overview of recent progress with highly stretchable supersensitive sensors for wearable biomedical applications has not been reported. Thus, this review focuses on recent developments regarding highly stretchable supersensitive sensors for functional applications and considerations in achieving stretchability. The first section introduces the functions of stretchable sensors, especially recent achievements. In the second section, we review the latest successful examples that have solved the problem of large-range stretchability with technological innovations and material renewal. The third section gives a detailed overview of recent progress regarding processing technology for human activity monitoring and personal health care. Problems and future development trends in the field of stretchable sensors for wearable biomedical applications are discussed in the final section.

Functions of stretchable sensors

To satisfy the requirements of various individuals, the functions of stretchable sensors have gradually trended toward diversification, including body temperature detection [30], heart rate monitoring [31], and muscle movement monitoring [32]. These functions help people fully understand their own physical condition in real time and identify the initial symptoms of diseases in a timely manner to avoid missing optimal treatment windows. In this paper, the functions of stretchable sensors are divided into three categories: human body motion detection, vital sign monitoring, and environmental monitoring around biological surfaces (Fig. 1). Table 1 provides a list of several stretchable sensors attached or laminated to various positions of the human body, along with their corresponding monitored electrophysiological activity and acute physiological responses to improve our understanding of physical condition.

Functional characteristics of recently developed stretchable sensors for wearable biomedical applications. Stretchable sensors for human body motion detection: a voice monitoring [33], b monitoring shoulder movement [34], c monitoring human emotion [35], d monitoring joint movement [10]. Stretchable sensors for environmental monitoring: e monitoring humidity [29], f monitoring perspiration [36], g monitoring gas [37]. Stretchable sensors for personal healthcare: h core body temperature detection [28], i heart pulse monitoring [4], j blood vessel monitoring [38], k pulse monitoring [39]

Stretchable sensors for human body motion detection

Movement is an essential part of people’s daily lives. However, some bad habits have a substantial influence on health. For example, smartphones provide a new approach to studying and entertainment. However, their use has resulted in a high incidence of phubbing, which is a type of spinal cord injury. There is no doubt that human health will improve if such problems are solved properly, and stretchable sensors provide a ray of hope. Moreover, as their application evolves, stretchable sensors will provide people with more quality products and better services.

The measurement mechanism used by stretchable sensors for movement monitoring is based on changes in voltage/current/resistance upon stretching, as shown in Fig. 2. In the context of people’s daily lives, movements are classified into two categories: large-scale motions, which include bending movements of the joints, waist and spine [40], and small-scale motions, which include subtle movements of the face, chest, and neck during emotional expression, swallowing, and speaking. Aiming to monitor motions with different scales, the requirements of stretchable sensors change as different scales of strain are detected. In contrast to large-scale-motion monitoring sensors, small-scale-motion monitoring sensors not only must have sufficiently high sensitivity to detect variations in strain of a few percentage points or less but also must be stretchable to make conformal contact with the skin with high signal quality. Lan Liu fabricated a graphene/silver nanoparticle (NP) synergic sensor with extremely high sensitivity and a detection limit of 0.5%. To solve the problem arising from the addition of rigid fillers into the matrix, which leads to an increase in the stiffness of the composite [41], this sensor employed a sandwich structure that contains two conductive layers on the top and bottom and graphene/sliver nanoparticle/thermoplastic polyurethane as an insulating layer in the middle, ensuring both initial conductivity and stretchability. This sensor accurately captures extremely small strain from muscle motion during speech, and the relative resistance change is presented in Fig. 2b. Lee [35] made progress on a small-strain sensor that detects small strains on the skin of a human face that are induced by the minute movements of muscles related to facial expressions in response to emotions and eyeball movements (Fig. 2c). Experiment showed that the stability of sensor responses was primarily affected by single-wall carbon nanotubes (SWNCTs), and the sensitivity of the stacked nanohybrid strain sensor was primarily determined by the formation of electrical junctions between SWNCTs and PEDOT phases in the polyurethane-poly(3,4-ethylenedioxythiophene) polystyrenesulfonate (PU-PEDOT:PSS) composite. Hence, the PU-PEDOT:PSS (bottom)/SWNCT/PU-PEDOT:PSS (top) structure was selected to guarantee the high sensitivity and stability of the sensor.

Applications of wearable sensors for human body motion detection. a A small-scale strain sensor is attached to the human neck to monitor muscle motion during speech; b responsive resistance–time curve for the strain sensor under voices saying “Hi, how are you” [33]; c the acquired time-dependent △R/R0 responses of laughing and crying detected via small-scale sensors with high sensitivity, which are attached to the forehead and the skin near the mouth [35]; d digital photograph of a large-scale sensor that is attached to the human knee to monitor motions; e the relative curves for large-scale strain sensors in response to flexing/extending, walking, jogging, jumping, and squatting-jumping motions [8]; f photographs of a bandage strain sensor that is attached onto the knee to monitor large-scale movements; g a bandage strain sensor is applied to monitor small-scale motions, including breathing and phonation [42]

For large-scale movement monitoring sensors, large-scale stretchability, and fast response/recovery speeds are expected. Some remarkable sensors with large-scale stretchability were developed by exploring new materials and novel technologies [42]. Gao [8] fabricated a large-scale strain sensor that easily records and discriminates various knee-related motions, including knee flexing/extending, walking, jogging, jumping, and squatting-jumping, by virtue of the distinctly differentiated patterns of response curves (Fig. 2d, e). However, attaining the combination of high sensitivity to tiny deformations and broad sensing range is a large obstacle. Stretchable sensors have overcome this obstacle through technical progress. Yamada [42] introduced a new type of stretchable electric nanomaterial that consists of aligned single-walled carbon nanotube thin film that deforms when stretched in a manner that is similar to the structural deformation of string cheese when peeled. This stretchable sensor is used not only to precisely monitor large-scale and rapid human motion (Fig. 2f) but also to detect typing and phonation (Fig. 2g). Such progress facilitates the fabrication of a stretchable sensor that realizes the detection of a full range of human activities, from single functions to complex human body movements that involve tensile strain, bending, and twisting. Meanwhile, stretchable sensors for human body motion detection are undergoing constant improvement. The functions of stretchable sensors for human body motion detection play an important role in diagnosing damaged vocal cords, monitoring Parkinson’s disease, determining the degree of change in spinal posture, analyzing facial expression changes, and detecting posture and movement.

Meanwhile, some wearable biomedical sensors about tracking patients with Parkinson’s, epilepsy as well as detecting sudden falls have acquired some outstanding achievements. Son [56] developed a wearable sensor for the Parkinson’s (Fig. 3a–c); this device can measure tremors using silicon nanomembrane strain sensors when Parkinson’s disease patient wears the current multifunctional devices. And then the tremors data will be analyzed and categorized into specific disease mode, and the corresponding feedback therapy, namely drug delivery from mesoporous-silica nanoparticles will proceed transdermally at optimized rates through thermal stimuli (heater). The skin temperature will be simultaneously monitored (temperature sensor) to prevent skin burns during thermal control of the drug delivery rate. Burns [177] used triaxial accelerometer-based fall sensor can accurately sense the movement of the patient’s hands and feet. The specially developed quantitative evaluation algorithm analyzes the severity of the symptoms such as tremor and bradykinesia in real time. It is said that the biggest feature of Parkinson’s disease is the appearance of gait and movement disorders. People will experience dizziness, inability to walk normally, and changes in speech sounds, and these characterizations can be received by sensors such as gyroscopes. So it is very suitable for detection with wearable devices.

Applications of wearable sensors. a Wearable memory array consisting of a TiO2 NM–Au NPs–TiO2 NM switching layer and Al electrodes (top left inset: layer information). The memory array was transfer-printed on the bottom side of an elastomeric hydrocolloid skin patch. The electroresistive heater/temperature sensor was fabricated on the top-side of the patch, with the Si strain sensor on the opposite side. The m-silica NP array was transfer-printed on the hydrocolloid side of the patch; b, c strain sensor is attached to the human skin with stretching and folding [56]; d schematic illustration of a Parkinson’s patients with shaking in the wrists and/or difficulty in walking. e By sewing the two fibers into the routine wrist support, stretching of skins and muscles associated with routine human motions could be monitored in real time and in situ. f The plot of the resistance of IL/fibers as a function of time [178]. g The single pouch cell. h Pictures of wristband-type LIB before (bottom) and after ~ 100% stretching (top). i Temporal changes of the vector sum during various movements of the subject. j A photograph of the ECoG electrode device, clearly showing its flexibility

Guan [178] used the principle of short-chain IL species, and small fiber gaps/liquid volume could yield stretchable liquid bridges with stable TCL, making a wearable stretchable sensors by the way of stretchable conductors attached to curved, textured surfaces of human body and in clothes for strains of muscles and skins to monitor the muscle movement driven (Fig. 3d–f). Sungmook [179] showed wearable fall detector using integrated sensors and energy devices (Fig. 3g–i); this device improves stretchable energy harvesting and storage units based on requirement of integrated systems. The integrated system successfully detects a fall from normal daily motions and sends an immediate alarm wirelessly. Xie [180] reported a wireless ECoG recording system with a flexible and biocompatible electrode device with an array of 32-microelectrodes (Fig. 3j). Based on some epilepsy treatment experiments, ECoG system can record brain activity and perform electric stimulation wirelessly, demonstrating its potential for broad applications.

Stretchable sensors for vital sign monitoring

Vital signs are crucial parameters for evaluating human health [43]. Consider the example of temperature: abnormal body temperature indicates that some system of human body is work improperly because of increased heart burden, physical overdraft, loss of consciousness, and other reasons. Therefore, it is essential to establish an effective system for vital sign monitoring to provide timely information to a doctor and avoid sudden incidents. It is well known that the optimal cure times for various diseases are different, representing a great challenge in the practice of traditional medicine. For example, the optimal rescue time for heart disease patients is 4–6 min. If a patient does not receive treatment within 1 h, they will face serious hazards. However, despite the urgent need, there remains a significant challenge in providing treatment to patients within the confines of traditional medical practice in such a short period of time. Fortunately, stretchable sensors for vital sign monitoring are easily worn by patients for long-term monitoring while remaining comfortable and maintaining high accuracy in real time. In addition, elderly people suffer from a high incidence of disease but dislike medical equipment with complex operations. Stretchable sensors, which are characterized by their simplicity of use, are highly suitable for elderly people. The major monitoring objects of stretchable sensors are body temperature, heart rate, respiration rate, blood pressure, pulse oxygenation, and blood glucose [44]. Vital signs do not include pulse oxygenation and blood glucose, but these parameters are widely used in medical diagnosis. Therefore, pulse oxygenation and blood glucose will also be discussed in this section.

Temperature

Temperature, the first vital sign, provides important information about human health. Flexible and stretchable temperature-monitoring sensors are attracting increased attention for biomedical applications because they provide real-time monitoring in a comfortable manner on wrinkled and stretchable skin. Usually, body temperature is measured via pyroelectric temperature detectors [45], resistive temperature detectors (RTD) [46], and thermistors temperature detectors [47], which are shown in Fig. 4. The measurement mechanism of pyroelectric temperature detectors is as follows: two different components of the conductor are inserted into the circuit at both ends of the circuit, and electromotive force is produced in the loop when their temperatures at the joint point are different. This electromotive force, which is called the thermoelectric potential, along with generated thermoelectricity is used to measure the temperature. Making use of this measurement mechanism, pyroelectric devices with a metal/insulator/metal (MIM) structure based on poly(vinylidene fluoride) (PVDF) or poly(vinylidenefluoride-co-trifluoroethylene) (P(VDF-TrFE)) have been developed in recent decades. However, these devices are fabricated on rigid substrates and thus do not meet the requirements for a high degree of comfort. Sang-Woo Kim [45] fabricated a highly stretchable hybrid nanogenerator that includes three layers: PDMS-CNT acts as the bottom electrode, P(VDF-TrFE) as the piezoelectric and pyroelectric material, and graphene as the top electrode (Fig. 4a). The hybrid device is designed with a microline patterning architecture to increase the flexibility, stretchability, stability, durability, and robustness of the pyroelectric temperature detectors. The materials and structure that are used to construct the pyroelectric temperature sensor to avoid the metal electrodes have very low stretchability/flexibility. The working mechanism was discussed in which a heating process is applied to the device, thereby leading to decreases in the electric dipoles and voltage (Fig. 4c–e). The remarkable robustness of this device, even after stretching, is demonstrated by the experimental results (Fig. 4f).

Stretchable temperature sensor. Pyroelectric temperature detectors: a schematic illustration of the device, which includes three layers (from top to bottom): the graphene layer, the P(VDF-TrFE) layer, and the PDMS-CNT layer. b Schematic diagram of the pyroelectric process under a thermal gradient. c Responsive voltage–time curve under a thermal gradient (heating and cooling). d, e Schematic illustration of electric signal under the application of release and a heating gradient due to dipole movement from the equilibrium position, with the application of heating and compressive strain due to dipole fluctuations from the equilibrium position. f Simulation results of temperature fluctuation for the original-state device and a 30%-strained device [45]. Resistive temperature detectors: g, h Schematic illustration of a 4 × 4 RTD sensor array with a serpentine that is laminated on human skin under relaxation and deformation states. i Infrared image of a 4 × 4 RTD sensor array that is adhered to the palm. j, k The temperature changes of the palm were measured using an infrared camera (blue) and a sensor array (red) under applied mental (j) and physical stimuli (k) [46]. Thermistor temperature detectors: l, m schematic illustration of stretchable graphene thermistors under relaxed and twisted states. n Optical images of a stretchable graphene thermistor under applied 0% and 50% strains. o Responsive voltage–current relationship of the thermistor under a relaxed state in the temperature range of 30–100 °C. p Resistance variation with temperature, which shows a nonlinear relationship. q Dependence of ln(R) on 1000/T, which shows a linear relationship [47]

The RTD senses the change in electrical resistance of the conductive metal as the temperature changes. Several common pure metal materials are applied during the construction of the RTD, including copper, platinum, and nickel [46]. John A. Roger [46] introduced a precision RTD with an ultra-thin, compliant, skin-like array, which is pliably laminated onto the epidermis to provide continuous, accurate thermal characterizations. This device is mounted directly onto the skin and follows skin deformations. High flexibility and stretchability are essential features of this device. To achieve these features, Cr and Au, with thicknesses of 5 nm and 50 nm, respectively, were selected together as the resistive material of the noninvasive RTD sensor. The resistive material was designed as a filamentary serpentine mesh to improve flexibility and stretchability (Fig. 4g, h). The precision of this device was explored by comparing different numbers of devices. Experimental results show that when the number of devices was 222 and 50, the corresponding precision was 12 Mk and 8 Mk, respectively, demonstrating that the precision of this device was dependent on the number of devices. A 4 × 4 RTD sensor array was applied on the palm to explore the relationship between the distribution of skin temperature of the human body and mental/physical stimuli (Fig. 4i). Figure 4j, k shows the variations in skin temperature during the application of mental and physical stimuli. Based on Fig. 4j, k, the results obtained with this device are nearly identical to the averaged data from a neighboring region in the infrared image. The results proved that an RTD sensor array with high precision and mapping capability was capable of monitoring of cardiovascular health, cognitive state, malignancy, and many other important aspects of human physiology.

The thermistor temperature detector is similar to RTD: the sensing mechanism of the thermistor is also based on the change in the electrical resistance of the sensing material with temperature. However, a thermistor is a semiconductor material, which usually has a negative temperature coefficient; that is to say, the resistance decreases with increasing temperature. Lee [47] fabricated a stretchable graphene thermistor temperature sensor using a lithographic filtration method. Three-dimensional (3D) crumpled graphene was used for the thermal detection channels, and highly conductive silver nanowires were used as electrodes (Fig. 4l, m). To achieve stretchability, all electrodes and detection channels with serpentine were fully embedded inside a polydimethylsiloxane (PDMS) matrix, and this device maintained thermal sensing properties when the stretchable strain reached 50% (Fig. 4n). In addition, the stretchable sensors demonstrated mechanical robustness and strain-dependent resistance (Fig. 4o–q). Nickel oxide and nickel microparticles also have been demonstrated to qualify as thermistor materials [48].

In summary, flexible and stretchable body temperature sensors have been investigated by researchers all over the world, and many achievements have been made in this field. Undeniably, certain urgent problems remain to be solved to meet the requirements of high accuracy and timeliness for body temperature monitoring. These problems include the response and relaxation times of pyroelectric temperature detectors, the large-scale stretchability of the RTD, and the strain dependence of thermistor temperature detectors. In addition to temperature sensors used for the three applications described methods, there are other temperature sensors with high sensitivity, such as the diode temperature sensor and the polar groups of the dielectric-induced charge-trapping temperature sensor [49].

Body temperature sensors are usually positioned on the arm and chest. Hence, there is a gap between the recorded temperature and the body-core temperature because body surface temperature changes with the temperature of the environment. For example, the body-core temperature is approximately 37 °C under normal conditions, while the body surface temperature is only 32 °C in a room with a temperature of 25 °C. Therefore, in the field of temperature research, measurement and monitoring of body-core temperature are prioritized. Rogers [28] proposed a method based on a theoretical approach together with a modeling algorithm, yielding a core body temperature from multiple differential measurements from temperature sensors that are separated by different effective distances from the skin. This method greatly contributes to the determination of body-core temperature using flexible sensors and provides potential future research areas.

Heart rate

Heart rate (HR) or pulse is defined as the frequency of the cardiac cycle and is expressed in beats per minute (b.p.m.). HR is a necessary item in physical examinations, and its importance is self-evident because abnormal HR indicates that something is wrong with the human body, such as heart disease or myocardial infarction. Therefore, there is an urgent need to fabricate a wearable heart monitoring sensor that monitors HR accurately and in a timely manner. The measurement part of a stretchable sensor is normally fixed on the radial artery at the wrist or carotid artery at the neck or chest. Electrocardiography (ECG) [50,51,52,53], a conventional method for measuring HR, has been applied widely. As a key bio-signal, ECG requires constant monitoring via a connection with a bioelectrode that consists of a durable skin adhesive and a stretchable circuit [54,55,56]. In general, the bioelectrode that is connected to the ECG device to monitor HR is a gel-type silver/silver chloride (Ag/AgCl) electrode. While Ag/AgCl electrodes have been widely used, their use has been limited by skin irritations such as itching or erythema. Moreover, people only feel comfortable with human motion in daily life at a bioelectrode deformation of less than 30% [42]. Hence, the Ag/AgCl electrode does not satisfy the requirements for long-term wear. The Ag/AgCl electrode also dries over time, resulting in a sharp drop in signal quality. To overcome this problem, Jeon [57] fabricated a single stretchable and conductive dry adhesive to replace the Ag/AgCl electrode, which combines a gecko-inspired hierarchical structure and an elastomeric carbon nanocomposite. The conductive dry adhesive pad also employs gecko-inspired structures that consist of micro- and nanopillars (Fig. 5a) to repeatedly adhere to and detach from the rough surface of human skin (Fig. 5b). Then, a 1D–2D carbon hybrid filler system is introduced to enhance the electrical percolation. Figure 4c shows that the conductive dry adhesive pad is highly stretchable and bendable due to the conductive elastomer, which is composed of carbon nanofillers and PDMS. Unlike the conventional ECG electrode, this electrode is self-cleaning, which makes it semipermanently reusable by simply washing off the dust on its surface without pattern damage. Figure 5d–f shows the obtained ECG signals under different conditions and movement states using this electrode to connect to the ECG device. Lee [58] fabricated a carbon nanotube (CNT)/polydimethylsiloxane (PDMS) composite-based dry ECG electrode that is readily connected to conventional ECG devices and demonstrated its long-term wearable monitoring capability. The effects of the mixing ratio of CNT and PDMS, diameter and thickness were investigated to achieve CNT/PDMS prepolymer dispersion with excellent properties. This group demonstrated that a larger electrode measured ECG signals better than a smaller electrode. Unlike the significant effects of CNT wt% and diameter, the effects of thickness were low, which is consistent with the conductivity tests (Fig. 5f). In addition to the CNT/PDMS composite-based dry ECG electrode, other similar wearable ECG configurations have been used with flexible capacitive electrodes [59], metal ink electrodes [53], and embroidered textile electrodes to solve the problems of the gel-type Ag/AgCl electrode in terms of skin irritation and inaccuracy after drying.

Flexible and stretchable dry electrodes, connected to ECG. a Photograph illustration of the gecko-inspired hierarchical structure of the conductive dry adhesive and its application to ECG electrodes. b Digital image of a conductive dry adhesive with high adhesion that handles 1 kg of weight. c Digital images of conductive dry adhesives with high stretchability and bendability. d ECG signals using conductive dry adhesives under normal conditions and an immersed condition (red box inset: magnified view of the measured ECG wave, with the P, QRS, and T waves identified). e Series of ECG signals obtained using conductive dry adhesives under various movement conditions (i.e., wrist curl, squat, and writing) [57]. f ECG signals that were measured using 36 types of CNT/PDMS electrodes. The control parameter is CNT concentration: 1.0, 1.5, 2.0, and 4.5 wt%. For each case, the thickness and the diameter of the CNT/PDMS electrodes were modulated as follows: thickness (1, 2, and 3 mm) and diameter (20, 30, and 40 mm) [58]

In the above ECG monitoring system, the sensors are only flexible and stretchable in the electrode section, and flexibility and stretchability of the entire system is not achieved. Due to great advances in flexible and stretchable materials and technology, an ECG monitoring system with flexibility and stretchability has been successfully developed. Rogers [60] fabricated an ECG system composed of electrodes, circuits, and radios for wireless communication in a soft microfluidic assembly. This complete ECG system consists of a novel structure in which all components are connected by serpentine-shaped metal (Fig. 6d) and suspended in the surrounding fluid. Due to this structure, the complete system is flexible and stretchable (Fig. 6a–c). This device measured the ECG signal that is shown in Fig. 6e, f.

Flexible and stretchable complete ECG system. a Image of a complete ECG system with colored dashed boxes that identify various subsystems. b, c Images of this system under b stretched and c twisted conditions. d Image of the serpentine-shaped metal that is used to connect all subsystems. e, f ECG signal that was acquired using a device mounted on the sternum. The graph on the right provides a detailed view that shows the expected Q, R, and S waveforms [60]

Plethysmography is another effective method for monitoring HR and has the advantages of simplicity, reliability, and low cost. Plethysmography methods include photoplethysmography (PPG) [61] and the piezoelectric effect [62]. The principle of PPG is to optically detect changes in the blood flow volume in the microvascular bed of tissue via reflection from or transmission through the tissue. Techniques for PPG require hard photoelectric modules, which are tightly attached to the skin, e.g., on the fingers, with a specified penetration depth. For reasons that are stated above, this HR monitoring system is not appropriate for long-term ordinary daily use due to the inconvenience of the user experience, especially at night. Some researchers revealed that the principle of plethysmography applies equally well to stretchable pressure sensors [62]. The principle underlying the use of pressure sensors to monitor HR is that the pressure sensor records the waveform of blood pressure when it is attached on the radial artery or carotid artery, and HR is calculated from the number of signal periods. Unlike PPG, a hard photoelectric module is not essential for pressure sensors. Pressure sensors are tightly attached to the skin in a flexible and stretchable manner for HR monitoring. Bao [62] used a pressure-sensitive polymer transistor as a stretchable pressure sensor to continuously monitor the radial artery pulse wave (Fig. 7a–c). The HR is determined from the calculated pulse waveform. Similarly, Pan [63] presented a novel droplet-based pressure sensor that uses elastic and capacitive electrode–electrolyte interfaces to record the blood pressure wave of the carotid artery under the application of a gentle contact force (Fig. 7d, e). In addition to recording the blood pressure waveform, the pressure sensor is attached to the chest to record the pressure waveform of the heartbeat. Sun [8] developed a graphene-based composite fiber with a “compression spring” architecture to capture the heart beat signal (Fig. 7f, h).

Stretchable sensors for monitoring HR. a Continuously recorded blood pressure of radial artery variations on the skin surface. b Averaged signal from 16 periods (separate measurements). c Photograph of a sensor attached to the radial artery of a person to monitor HR [62]. d Photograph of a droplet-based ultra-high-sensitivity sensor attached to the carotid artery. e The waveform signal from a real-time transient of the carotid artery [63]. f Wearable sensor attached to the chest to monitor HR. h Response curves of a wearable sensor on the chest under relaxation and exercise conditions [8]

Respiration rate

Respiration is defined as the process of gas exchange between the body and the external environment. During the process of respiration, oxygen is inhaled and carbon dioxide is released. The optimum frequency of respiration of an adult is approximately 6.4 s during relaxation. The respiration rate during exercise is accelerated to a variable extent, and the respiration intensity is increased compared the respiration rate during relaxation. An abnormal respiration rate may indicate that the human body is sickened by respiratory disease, coronary heart disease, myocarditis, or pericarditis. The sensors are placed next to the nose or mouth to detect the respiratory airflow signal. Then, the respiration rate is determined based on changes in air temperature, humidity, airflow pressure, or carbon dioxide concentration during respiration [64, 65]. Li [64] used a stretchable humidity sensor that is based on a large-area polycrystalline few-layer WS2 film, which was synthesized by metal sulfurization, to monitor human respiration in real time. This device efficiently followed relatively fast (~ 1 s) or slow (∼ 5 s) breathing (Fig. 8b), which suggests its potential application for mask-free monitoring of the respiration rate. Ko [66] designed flexible electronic skins that are based on composite elastomer films that contain interlocked microdome arrays and display very large tunneling piezoresistance (Fig. 8c). This electronic device, which demonstrates high sensitivity to pressure, sensitively monitors airflow pressure during breathing. Figure 8d shows that this electronic device was attached to the front of the nostrils, and periodic breathing generated reliable and stable changes in resistance (Fig. 8e). Although these sensors accurately measure respiration rate when placed near the nose and mouth, they are limited by being conspicuous and less comfortable. In general, few people are willing to use these sensors to monitor their respiration rate for a long period of time.

Sensors placed near the mouth for monitoring respiration rate. a Sensor is attached under the nose to monitor respiration by detecting moisture in the breath. b Sensor responses to relatively slow and fast respiration rates of the volunteer when the device is attached under the volunteer’s nose [64]. c Schematic diagram of the working principle of respiration monitoring. When air flows through the surface of the sensor, the external pressure concentrates stress at the contact spots, thereby deforming the microdomes, which in turn causes increases in the contact area and the tunneling currents. d Image of the sensor attached to the front of a volunteer’s nostrils to monitor HR. e Response curves of resistance from human breathing [66]

To investigate a comfortable method to monitor respiration rate, researchers focused the placement of the sensor on the torso rather than the face. An important feature of respiration is the expansion and contraction of the chest and abdomen (Fig. 9a) [67, 68], which provides a means for the change in volume to be transduced into an electrical signal. Based on the periodic deformations of the chest wall during the physiological movements of respiration, Khine [69] presented a wrinkled platinum strain sensor with tunable strain sensitivity (Fig. 9b). The possibility of using such a sensor for real-time respiratory monitoring by measuring chest wall displacement and correlating it with lung volume has been demonstrated (Fig. 9c, d). Wang [70] reported a new membrane-based triboelectric sensor (M-TES) as a self-powered approach. This sensor generates a voltage that is induced by surface triboelectric charges in response to air pressure changes. This system, which includes a wireless security system, is built by integrating an M-TES, an air bag, and a processing circuit (Fig. 9e). The air bag is placed on the abdomen. The M-TES checks the air pressure change in the air that follows the expansion and contraction of the abdomen and obtains respiration rate signals in real time, as shown in Fig. 8f, g. Wang [71] fabricated a belt that embedded a stretchable conductive polypyrrole/polyurethane (PPy/PU) elastomer. The conductivity of this elastomer changes when stretched. Abdominal expansion and contraction during respiratory activity results in PPy/PU elastomer elongation. When being stretched, the conductivity of this elastomer changes. Hence, the respiration rate is determined from the resistive change waveform. The elongation and sensitivity of the waistband-like human breath detection sensor are shown in Fig. 8i. In addition to volume changes of the chest or abdomen, changes in the trachea during respiration have attracted attention. Lee [72] developed a new type of transparent, stretchable, and ultrasensitive strain sensor that is based on a AgNW/PEDOT:PSS/PU nanocomposite. This sensor is placed on the neck to detect changes in the trachea (Fig. 9j). There were significant differences between the signals that were generated during inhalation and exhalation, as shown in Fig. 9k. These sensors are attached on the body directly. Hence, the comfort of the wearable device is crucially important for users.

Respiration rate monitoring sensors based on volume changes: a Image of volume changes in the chest and abdomen in response to inhalation and exhalation [67]. b Flexible wPt sensor attached to the intercostal muscles to measure chest wall displacement caused by respiration. c The sensor signal that is generated by chest wall displacement during respiration. d Comparison of sensor data to spirometer reading; the similarity reaches 95% [69]. e A complete system for respiration monitoring, which includes a processing circuit, an alarm apparatus, the M-TES and an air bag. f An image of respiration detection by utilizing the M-TES. g Output voltage signals of the M-TES at a breathing rate of 32 breaths per minute [70]. h Schematic diagram of the waistband-like human breath detection sensor, which was built from the PPy/PU elastomer. i Elongation and sensitivity of the waistband-like human breath detection sensor [71]. j Stretchable and transparent strain sensor for monitoring breathing via attachment to the neck. k Resistance change (ΔR/R0) from the nanocomposite strain sensor during inhalation and exhalation [72]

Based on the volume changes in the chest and abdomen during breathing, many respiration rate sensors take advantage of conductive textile technology to build the sensing elements directly into the textile. Kennon [73] used a textile-based strain sensor to create a respiration belt. This device was realized by bringing together a knitted sensor and a relatively inelastic textile strap. As the textile is stretched, the contact area between the conductive fibers is reduced, and the resistance increases. Figure 10a shows knitted loops of conductive fibers and highlights the contact areas, and Fig. 10b shows a belt that contains the resistive sensor. The changes in resistance during respiration are shown in Fig. 10c. Zhu [23] fabricated electronic skin, which was constructed from graphene woven fabrics, PDMS, and medical tape. This device, which is highly sensitive, detects weak respiratory activity (Fig. 10d). Moreover, the device is sufficiently wearable and biomedically compatible for placement inside clothing around human skin without causing any irritation. Guo [74] designed a garment-based sensing system for the long-term monitoring of breathing rhythm (Fig. 10e). To overcome posture artifacts, this garment was integrated with two piezoresistive sensors placed on two different moving parts of the body. Figure 10f shows the respiration waveform. Tao [75] fabricated notched POF fabric strain sensors and integrated them into a belt for respiration monitoring (Fig. 10g). Min [67] proposed a simplified structural textile capacitive respiration sensor for a respiration monitoring system, which was composed of conductive textile and polyester (Fig. 10h, i). Figure 10j shows the experimental setup. During the monitoring process, respiration rate is determined by the distance changes between two textile plates in the TCRS, which measures the force from abdominal diameter changes with respiratory movement. The obtained breathing signals are shown in Fig. 10k. This textile sensor achieves excellent performance for monitoring respiration rate. However, some problems persist, such as cleaning methods and manufacturing for different people. However, we believe that these problems will be properly addressed in the future.

Textile respiration rate sensors: a Photograph of a sensor, which shows the geometry of the conductive yarn. b Image of a subject wearing a respiration belt to detect volume changes in the abdomen. c Signal waveform from a sensor in the following respiration scenarios: normal breathing, low-rate breathing, high-rate breathing, and apnea [73]. d Relative changes in the resistance of a respiratory sensor that is attached to the chest under a relaxed state and an exercise state [23]. e Photograph of a prototype garment for an electronic unit that is used to monitor breathing. f The recorded breathing signal from a normal young subject. From top to bottom: signal from the reference belt; signals from sensors that are placed in the chest and abdominal positions, and the difference between the signals [74]. g Human respiration monitoring system detecting volume changes in the chest [75]. h Fabricated BCTFS with snap button. i Plating structure of the electro-conductive fabric. From top to bottom: polyester, Ni, Cu, and Ni. j Textile experimental setup for respiration monitoring. k Comparison of measured respiratory signals. From top to bottom: measured respiration from nasal thermocouple and measured respiration from BTCRS; moving-average-filtered nasal thermocouple signal and moving-average-filtered BTCRS signal; results of inflection-point detection (nasal), and results of inflection-point detection (BTCRS) [67]

Blood pressure

Blood pressure is one of the most important health indices of the human body. The normal range for systolic pressure is between 90 and 140 mmHg, and the normal range for diastolic pressure is between 60 and 90 mmHg. Blood pressure is inherently variable, and ambulatory measurement of blood pressure is the best way to predict clinical outcomes, especially during the night. Sphygmomanometers cannot be carried by people. Thus, they do not meet the requirements for ambulatory measurement. A pressure sensor is placed on the artery via the finger to measure the blood pressure, and the measurement result is displayed as a waveform. Peak and trough values correspond to systolic and diastolic pressures, respectively. Another function of the complete pulse pressure waveform of blood pressure is that it provides valuable information for the diagnostics and therapy of cardiovascular diseases such as arteriosclerosis, hypertension, and left ventricular systolic dysfunction [76, 77]. A sensor with high stretchability is necessary since it will be deformed and wrinkled with the skin. Many breakthroughs have been made regarding highly stretchable sensors for monitoring blood pressure with ease, and new milestones are reached as new materials are developed. Some achievements have been made with high-sensitivity capacitive [77], piezoelectric [78], and piezoresistive [79] sensors. For capacitive pressure sensors, compressible capacitive strain sensors are constructed by sandwiching a robust dielectric material between two flexible electrodes. When the dielectric is compressed from externally applied pressure, the capacitance of the device changes accordingly. Sang Ouk Kim fabricated a capacitive pressure sensor with a thin, stretchable, and skin-conformal sensor array, in which microtopography-guided, graphene-based, conductive patterns are embedded without any complicated processes [38]. This sensor is capable of creating an intimate relationship between the rough skin and the device via a structure-assisted approach (Fig. 11a). The measured pulse pressure waveform is shown in Fig. 11b. When pressure is applied to the piezoelectric material, the voltage signal changes. This sensing mechanism is in line with the development and utilization of the pressure sensor. Based on this mechanism, Rogers [80] presented a noninvasive sensor for measuring subtle changes in arterial pressure. This sensor consists of PZT and MOSFET. The piezoelectric voltage response of the PZT is converted to a current output via capacitance coupling. Figure 11e–g shows the measured position and pulse pressure waveform. Choong [81] fabricated a novel stretchable resistive pressure sensor. To enhance the pressure sensitivity, this sensor employs micro-pyramid PDMS arrays with spring-like compressible platforms that are deposited to form a base for a conductive electrode, which has a sensitivity of up to 10.3 kPa−1. This sensor is attached on the radial artery to demonstrate its bio-monitoring capabilities, and a monitored blood pressure waveform is shown in Fig. 11g, h.

Stretchable pressure sensor for blood pressure monitoring. a Schematic illustration of a capacitive pressure sensor with microlines for monitoring blood pressure signals. A cross-sectional diagram shows that the microstructured sensor, with high conformity, tightly attaches on the surface near the blood vessel. b A signal waveform of blood pressure from the radial artery [38]. c A photograph of the flexible and stretchable piezoelectric sensor, mounted on the wrist, for measuring fast transient changes in the pressure, which are associated with the flow of blood through near-surface arteries. d I DS–time wave curves from a pressure sensor that is placed on the wrist. e I DS–time plot for data in the region that is indicated by the dashed box in (d) [80]. f Demonstration of blood pressure monitoring using a pressure-resistive sensor. g A plot of eleven real-time arterial pulse waves, which were captured within 10 s. h The plot shows distinct systolic and diastolic peaks for each pulse [81]

Pulse oxygenation

Oxygen saturation is the percentage of oxygen-bound oxygenated hemoglobin in the blood relative to the total amount of hemoglobin. In other words, oxygen saturation is the concentration of blood oxygen in the blood, which is an important physiological parameter of the respiratory cycle. In a healthy adult, pulse oxygenation should be maintained at 98%, and vein oxygenation should be maintained at 75%. Abnormal oxygen saturation is one important factor that hinders proper organ function. Therefore, monitoring oxygen saturation is important for protecting human health. Using two different wavelengths of LED lights as the incident light source, the intensity of the light through the tissue bed is measured to calculate the oxygen saturation. In general, the sensors are mounted on the finger, earlobe, forehead, or wrist. Conventional pulse oximeters are limited by their bulk, rigidity, and area-scaling complexity. Ana C. Arias introduced a pulse oximeter sensor that is composed of organic LEDs (OLEDs) and a flexible organic polymer photodiode (OPD) [82] (Fig. 12). Unlike commercially available inorganic oximetry sensors, this device uses red (532 nm) and green (626 nm) organic light-emitting diodes. The main reason for this is that oxy-hemoglobin and deoxy-hemoglobin have different absorptivities at red and green wavelengths (Fig. 12c). Moreover, green OLEDs overcome the disadvantages of instability and lower overall efficiencies of near-infrared OLEDs. These results demonstrate the use of organic sensors to measure pulse rate and oxygenation with high accuracy.

Stretchable sensor for monitoring pulse oxygenation. a Pulse oximetry sensor composed of two OPDs and two OLED arrays. b A schematic illustration of a model for the pulse oximeter’s light transmission path through pulsating arterial blood, non-pulsating arterial blood, venous blood, and other tissues over several cardiac cycles. c Orange solid line and blue dashed line represent the absorptivities of oxygenated and deoxygenated hemoglobin in arterial blood, which are functions of the wavelength. The wavelengths that correspond to the peak OLED electroluminescence (EL) spectra are highlighted to show that there is a difference in the deoxy- and oxy-hemoglobin absorptivities at the wavelengths of interest. d The black dashed line represents OPD EQE at the short circuit, and the red solid line and green dashed line represent the EL spectra of red and green OLEDs, respectively [82]

Blood glucose

The rising incidence of diabetes all over the world is attributed to unhealthy lifestyles. Daily glucose monitoring in diabetes is vital for maintaining health and quality of life. Blood glucose is determined by the glucose levels in the blood. The traditional blood glucose measurement method causes substantial distress to diabetics because of painful blood sampling from the fingertip. Moreover, blood glucose is inherently variable, and a difference between fasting and postprandial levels is observed. Therefore, there is an urgent need to fabricate a noninvasive stretchable sensor that is capable of monitoring variations in blood glucose in real time. Available noninvasive glucose sensors main rely on optical, spectroscopic, ultrasound, heat, electrical, or electrochemical techniques [83]. Among these, electrochemical techniques have been shown to possess great potential for monitoring blood glucose. Wang [84] presented a proof-of-concept demonstration of an all-printed temporary-tattoo-based glucose sensor for noninvasive glycemic monitoring. The tattoo-based platform for noninvasive glucose sensing is composed of tattoo-based paper, Ag/AgCl electrodes, Prussian Blue electrodes, a transparent insulating layer and hydrogel (Fig. 13a). The stretchability and flexibility of this sensor are the same as those of the tattoo (Fig. 13b). To measure glucose levels, reverse iontophoresis is performed, which involves applying a mild current to the epidermis, thereby causing ions to transport interstitial glucose from the skin to the electrodes. Then, ISF glucose is detected via an enzymatic electrochemical glucose sensor (Fig. 13c). Based on this approach, post-meal and pre-meal blood glucose measurements are obtained, as shown in Fig. 12d. Seo [85] fabricated a flexible glucose sensor using a CVD-grown graphene-based field-effect transistor (FET). The function of CVD-grown graphene is to immobilize the enzymes that induce the catalytic response of glucose. Glucose sensing is achieved through that reaction, which produces gluconic acid and H2O2. Then, H2O2 reacts with the graphene channel of the FET, thereby changing its conductance (Fig. 13e), which results in the shifting of the Dirac point of the graphene. Although glucose oxidase has made substantial achievements as an enzyme-based electrochemical sensor, the long-term stability of the enzyme has always been a challenge. To solve this problem, Pak [86] presented a CVD graphene FET enzymatic glucose biosensor that utilizes silk protein as both a device substrate and for enzyme immobilization (Fig. 13f, g). The CVD graphene FET structure is built by depositing Au/Ti (500 nm/100 nm) at the two opposite ends of the graphene channel to fabricate source (S) and drain (D) electrodes. The glucose oxidase (GOx) enzyme is attached to the graphene channels on the silk substrates. The subsequent reaction is the same as that described in the above example. There are also certain methods for maintaining enzyme stability; these include covalent attachment to sensing surfaces [87] and physical entrapment in a porous material matrix [88]. However, although these methods improve enzyme stability to some extent, there is a long way to go before solving this problem completely.

Flexible sensor for monitoring blood glucose. a Schematic diagram of the printable iontophoretic-sensing system, including the Ag/AgCl electrodes (silver), tattoo-based paper (purple), Prussian Blue electrodes (black), transparent insulating layer (green), and hydrogel layer (blue). b Photograph of a glucose iontophoretic-sensing tattoo device placed on the surface of the skin. c Schematic diagram of the time frame of a typical on-body study and the different processes that are involved in each phase. d Post-meal and pre-meal blood glucose measurements by the printable iontophoretic-sensing system [84]. e Schematic diagram of the solution-gated CVD graphene sensor [85]. f Image of silk-based graphene FET biosensors applied on the wrist. g Magnified view of the schematic illustration of the silk-based graphene FET biosensors, from top to bottom: silk film, drains, graphene channels, silk/GOx film, and gates [86]. h Photograph of working and counter electrodes of the glucose sensor with concentric rings. i Measured sensor response to continuous glucose flow [89]

In addition to sensors that are attached to the skin, Liao [89] fabricated an enzyme sensor that directly accesses tear fluid to monitor glucose levels. Wireless health monitoring is achieved using an active contact lens. This system includes a glucose sensor, an antenna, a communication interface, and readout circuitry on a polymer lens substrate. The glucose sensor is composed of working, counter and reference electrodes. The working and counter electrodes are fabricated as concentric rings (Fig. 13h), and the Ti/Pd/Pt reference electrode is obtained by evaporation. The exposed Ti/Pd/Pt sensor surface is used to immobilize GOD, and it is handled with a GOD/titania sol–gel membrane. To prevent the interference of ascorbic acid, lactate, and urea, Nafion is applied to promote random protein absorption [90]. The glucose level is measured based on the current that is generated in the glucose solution when the working and reference electrodes apply a voltage, and the measurement result is shown in Fig. 13i.

Stretchable sensor for environmental monitoring around a biological surface

As an interface between the environment and the body, stretchable sensors analyze the surface environment and offer constructive guidance to maintain people in a healthy condition. Due to the joint efforts of certain researchers, many studies have obtained results on wearable medical devices that contribute to healthier lives, such as a stretchable gas sensor [91,92,93,94] and a stretchable humidity sensor [29, 64, 95]. The stretchable gas sensor has two functions: to monitor harmful gasses in the environment and avoid injuries inflicted by noxious gasses to humans, especially colorless and tasteless harmful gasses, and to detect the gas content of the body, which will help people fully understand their health. The gas sensor absorbs gas molecules, leading to changes in its electrical conductivity, which are attributed to changes in the local carrier concentration that is induced by the surface adsorbates. Different materials have different electrical conductivities and surface functional groups, which are utilized by a gas-sensing mechanism for gas detection. Before the development of nanotechnology, gas sensors suffered from problems with long-term stability and limited measurement. With the development of nanotechnology, especially the appearance of graphene, gas sensors have made many critical breakthroughs, such as ultra-high sensitivity at extremely low concentrations, high specificity, fast response and recovery, low power consumption, room-temperature operation, and good reversibility, by employing novel nanostructures as sensing elements. Hyung-Kun Lee fabricated bendable and washable electronic textile gas sensors with high mechanical strength, flexibility, and fast response, which are composed of reduced graphene oxides using commercially available yarn and molecular glue through electrostatic self-assembly [93]. Sun [94] fabricated a transparent chemical gas sensor with highly sensitivity. This device is assembled from a transparent conducting film of hierarchically nanostructured polyaniline (PANI) networks, which are fabricated on a flexible PET substrate by coating silver nanowires (AgNWs), followed by the in situ polymerization of aniline near the sacrificial AgNW template. This sensor provides a potential method to detect disease using exhaled breath samples [96]. At present, diseases that are detected from breath samples include cancer, multiple sclerosis, Parkinson’s disease, tuberculosis, and diabetes. However, some techniques for detecting volatile organic compounds in exhaled breath, such as gas chromatography [97], mass chromatography [98], ion mobility spectrometry [99], and selected ion flow tube mass spectrometry [100], are not widely used due to the large size of the required equipment, the complexity of operation and the high cost. A stretchable gas sensor that is comfortable and easy to use has gradually emerged. Detecting exhaled breath using a gas sensor involves a complex multistep process [101]. Figure 14a shows the process for breath testing. The process includes sample collection, measurement, and data analysis. IL-Doo Kim [102] fabricated a gas sensor for detecting exhaled breath that has a superior detection capacity and an appreciable response. Due to the morphological characteristics of dense and porous SnO2 fibers, this sensor significantly increases the accessibility of all sensing layers to exhaled breath gas (Fig. 14b, c). In addition, catalytic Pt NP decoration enhances the sensor’s ability to sense acetone and toluene in exhaled breath. Figure 14d shows the detection results.

Stretchable sensor for gas monitoring. a Schematic diagram of the processes that are involved in breath testing, including exhaled breath, sample collection, measurement, data analysis, and prediction [101]. b Schematic illustration of the morphological evolution of as-spun and calcined SnO2 fibers. c Photograph of Pt-decorated thin-wall assembled SnO2 fibers. d The acetone response plot of pure SnO2 fibers in 80% relative humidity at 400 °C [102]

Stretchable humidity sensors are typically used to determine the amount of water vapor that is present in a gas or mixture of gases. Such sensors have been increasingly applied in the environmental control and medical fields. For example, a humidity sensor that is used to monitor the moisture level on a wound would also provide information on wound healing [103, 104]. In the past several years, stretchable humidity sensors, which were crippled by difficulties associated with performance (e.g., in terms of responsivity, response time, relaxation time, and stability) and materials, have not demonstrated outstanding achievements. To address these problems, several transduction mechanisms, such as a humidity-sensitive resistor [105, 106] and a humidity-sensitive capacitor [107], have been explored to improve the performance of stretchable humidity sensors. The humidity-sensitive resistor contains polyelectrolytes that respond to water vapor variations by changing their resistivity, while the humidity-sensitive capacitor senses variations in the dielectric constant of the polymer dielectrics and, therefore, changes in capacitance. Many different properties were explored as outputs, such as optical and electrical characteristics (resistance, capacitance, the gate effect in field-effect transistors, and small mass changes). Similarly, to improve the performance of stretchable humidity sensors, numerous materials have been employed as active components, such as carbon-based materials, polymers and composites. Stretchable humidity sensors have already demonstrated some achievements by positively exploiting the transduction mechanism and materials. Chun Li presented an e-skin-compatible resistor humidity sensor that is based on a large-area polycrystalline few-layer WS2 film, which is synthesized by metal sulfurization [64]. The water molecules that are adsorbed onto the WS2 induce changes in concavity; then, the resistor also changes. Meanwhile, patterned graphene was used for the electrodes, and a thinner PDMS membrane was used as a substrate to obtain the stretchable sensor. This sensor not only has a rapid response time of a few seconds but also a sensitivity of up to 2357 (for 90% humidity). Bi [107] fabricated a microscale capacitive humidity sensor that uses graphene oxide (GO) films as humidity-sensing materials. Water molecules are attached to the surface of the GO film via double hydrogen bonding to form a physical adsorption layer of water. The hopping transfer of protons between adjacent hydroxyl groups in the physical adsorption layer of water requires substantial energy due to the strength of double hydrogen bonding. In this scenario, GO films exhibit strong electrical resistance. The protons in GO films are minimal in quantity and restricted by discontinuous mobile layers. These characteristics are crucial for leak conduction, which essentially increases the capacitance at low RH.

Design considerations for stretchable sensors

Stretchable sensors are mainly placed on non-planar skin or clothing. Due to the unevenness, a stretchable sensor must satisfy many requirements, such as ultra-thinness, low modulus, high transparency, high durability, light weight, high flexibility, and high stretchability. Among these requirements, stretchability is a crucial factor in monitoring human body motion (especially large-scale body motion), the environment, and vital signs. Researchers have done substantial work with stretchable sensors and made some achievements in terms of materials and strategies. The following section will discuss some of the materials and strategies that are frequently used to satisfy these requirements.

Materials

To achieve a highly stretchable supersensitive sensor for wearable biomedical applications, the choice of materials is critical. Technological advancements in stretchable sensors have been made largely via the development of new materials for the fabrication of stretchable devices. Generally, the materials that are used to fabricate stretchable sensors fall into three categories according to the function of the stretchable sensor: substrate materials, nanocomposite materials, and liquid metal materials. Below, several of the most commonly used materials for the fabrication of stretchable sensors are investigated.

Materials for flexible substrates

Substrates play an important role in stretchable sensors because the stretchability of the vast majority of sensors is achieved by embedding, depositing, and printing the conductive material and the substrate. For stretchable materials, adhesion and radius of curvature are regarded as the most important factors. Various materials are used for stretchable sensors. Polydimethylsiloxane (PDMS) [64, 108,109,110] has been widely applied for the fabrication of stretchable sensors since it is generally considered to be transparent, chemically inert, nonflammable, and non-toxic. Moreover, it has variable mechanical properties, is of low cost, and has outstanding adhesion with silicon wafers, which is important for bonding electronic materials to its surface. However, PDMS has a large coefficient of thermal expansion and a low Young’s modulus, thus resulting in poor thermal and mechanical stability. When a metal film is sputtered or thermally evaporated on the PDMS surface, the metal film is subjected to thermal stress, which produces wrinkles or cracks [111]. To solve this problem, some NPs are doped into PDMS to enhance the mechanical, thermal, and thermal expansion coefficients [112]. Polyurethane (PU) [113,114,115] is another popular substrate that has been used in many applications, such as stretchable printed circuit board technologies [116]. PU possesses many advantages, including high mechanical strength, excellent wearability, and long life. In addition, there are also certain flexible and stretchable substrates, such as poly ethylene terephthalate (PET) [117, 118], polyimide (PI) [119, 120], and Ecoflex [121, 122]. These substrates have gradually received recognition due to their outstanding mechanical properties, good flexibility, and high stretchability.

Graphene-based active materials

Graphene is film with a honeycomb structure that consists of an atomically thin layer of sp2-hybridized carbon atoms, which is a quasi-2D material with a thickness of only one atomic layer. It was discovered by Andre Geim and Konstantin Novoselov and was successfully separated from graphite by micro-mechanical stripping. The main preparation methods include bulk growth with CVD [123] and chemical exfoliation [124] from bulk graphite. Graphene is regarded as an outstanding material that is used as an active material in stretchable sensors because of its high mechanical strength, high electrical conductivity, high specific surface area, low Johnson noise, and low number of defects for low 1/f noise [125]. Although graphene possesses many advantages, it might not suitable for stretchable sensors. For example, the stretchability of a graphene-based strain sensor is less than 5% because of the brittleness of graphene sheets. Some highly sensitive stretchable sensors have been fabricated by using graphene sheets on flexible substrates to achieve stretchability [121, 126, 127]. To improve the tensile properties of graphene, researchers have employed various methods, including the use of graphene sheets of giant sizes, optimization of the spinning process, and the introduction of divalent ion cross-linking [128, 129]. However, when stretchability is increased by using the above methods, new problems arise. For example, graphene fibers in spiral form achieve stretchability to some extent but are limited by low electrical conductivity (4.1 × 104 S/m) due to their structural defects and the oxygen-containing groups in the constituent CRG sheets [130, 131]. Hence, further work is required before graphene is used to obtain stretchable materials for various stretchable sensor applications.

Carbon nanotube (CNT)-based active materials

CNTs [132, 133], as a 1D nanomaterial, have unique characteristics, such as light weight, perfectly hexagonal connectivity, an exceptionally high aspect ratio (> 106), Young’s modulus (~ 1 TPa), tensile strength (~ 100 GPa), current carrying ability (109 A/cm2), and thermal conductivity (3500 W/Mk) [132]. Sumio Iijima developed CNTs from the carbon fiber that is produced by the arc discharge method using high-resolution transmission electron microscopy in January 1991 [134, 135]. In addition to arc discharge [136], there are high-volume, low-purity techniques for producing CNTs, such as laser ablation [137] and chemical vapor deposition [138]. For wearable stretchable sensors, a reliable and scalable facile fabrication technique is of the utmost importance. CNTs are directly deposited onto flexible or stretchable substrates to acquire stretchability via vacuum filtration [139], spin-coating [140], spray-coating [141], or inkjet printing [142]. Selecting the appropriate structure for CNT, such as yarn or a sheet, is another effective method for achieving stretchability. For example, Nae-eung Lee reported the construction of transparent, stretchable, ultrasensitive, and tunable strain sensors from a novel stacked nanohybrid structure of single-wall CNTs and a conductive elastomer consisting of poly and a polyurethane dispersion [35].

Nanowire (NW)-based materials

Among metal nanostructures, metallic NWs are very promising candidates for stretchable sensors [143]. A NW is defined as a 1D structural material with a width of 100 nm in the transverse direction and unlimited width in the portrait direction. There are many types of NW materials, some of which are well suited to be active materials of stretchable sensors, such as Si, zinc oxide (ZnO), gallium arsenide (GaAs), and selenide (CdSe). AgNW, as one of the most important conductive materials, has attracted substantial attention for its potential application as transparent and flexible electrodes. Stretchable sensors with AgNWs are made through the lithographic deposition of electrodes. However, negative characteristics of AgNWs seriously affect the stretchable sensor, including weak adhesion of AgNWs on flexible polymer substrates and surface buckling/wrinkling of the AgNW thin film on the substrate, which leads to a permanent loss of contact between adjacent AgNWs [144]. To solve these problems, AgNW stretchable sensors have adopted a novel structure and new technology [145]. Other NWs have acquired excellent results for stretchable sensors. To meet the requirements of highly stretchable sensors, some noble metal NWs have been designed; these NWs change the architecture of the Pt-coated polymeric nanofiber interlocking structure [79]. However, problems such as complex processes or high cost may be encountered during the fabrication of these structures. These problems will be solved in the near future.

NP-based materials

The application of stretchable sensors relies on NPs with diameters that range from 10 to 100 nm and diverse shapes, including sphere, rectangle, hexagon, cube, triangle, star, and branch-like outlines. It is feasible to synthesize nearly any type of NP. Control NP types include pure metals (e.g., Au, Ag, Ni, Co, Pt, Pd, Cu, Al), metal alloys (e.g., Au/Ag, Au/Cu, Au/Ag/Cu, Au/Pt, Au/Pd, and Au/Ag/Cu/Pd, PtRh, Ni–Co, Pt–Ni–Fe), metal oxides, and semiconducting materials (e.g., Si, Ge) [146]. This is quite helpful for stretchable sensors in terms of material selection. Another possibility is to cap the NPs with a wide variety of molecular ligands and prepare NP films with controllable porous properties, which will improve the sensitivity of the stretchable sensor. Stretchable NP sensors facilitate easier and more affordable fabrication compared to other stretchable sensors requiring complicated and multistep processes. Various combinations of NP methods and flexible substrates are possible. For example, NPs may be deposited on flexible substrates and integrated into the composite of a flexible material [147]. NPs are excellent materials that solve the problem that arises when incorporating 1D materials into the polymer matrix, which increases the stiffness and decreases the stretchability of the resultant composite [33]. These advantages have attracted substantial attention. However, NPs are still limited by their small gauge factor, which makes them unsuitable for sensing small strains. Hence, stretchable NP sensors cannot currently be used in industrial applications.

Liquid metal material

In recent years, researchers have invested significant effort into increasing composite material strength. However, material delamination and/or local fracture in rigid electronic components is frequently observed in stretchable sensors. The main reason for the poor durability is that there is an intrinsic difference in the Young’s modulus between the rigid conductors and the soft support material. To solve the problem of Young’s modulus mismatch, many materials have been explored. Liquid conductors have attracted substantial attention, due to their advantages of low Young’s modulus and high durability, which are maintained even under a large strain. Awareness has grown among researchers that using softer liquid materials to generate stretchable conductors is a promising method to fabricate high-performance stretchable sensors. Wenlong Cheng fabricated reliable and long-term stretchable sensors using ionic liquids, which overcome the mechanical mismatch problem [148]. Meanwhile, the method of injecting liquid metal into the flexible substrate has drawbacks. For example, significant hysteresis has been observed. The main reasons for this hysteresis are the viscoelastic characteristics and the retarded reaggregation between filler–filler bonds under a relaxed state [16]. Hence, large-scale hysteresis is inevitable. Hye Moon Lee found that ionic liquid-based wavy sensors have the ability to improve hysteresis performance compared to normal ionic liquid-based flat strain sensors. These devices are based on an ionic liquid consisting of ethylene glycol and sodium chloride, which is encapsulated within a symmetric wavy channel [13]. In addition, masked deposition, direct nozzle writing, and vacuum-induced patterning were applied and yielded outstanding effects [149,150,151,152].

The performances of stretchable sensors according to their sensing materials and sensing mechanisms are listed in Table 2.

Strategies for achieving stretchability

An important characteristic of a stretchable sensor is its ability to stretch with bodily movements without incurring damage, especially when monitoring large-scale movements. That is, it is essential to fabricate a strain sensor with high stretchability (∼ 50% strain) and high sensitivity (a gauge factor of above 100). The problem of sensor stretchability has been addressed by investigating shape design. We will introduce the latest research results and disadvantages in detail in the following section of this article.

Geometric structuring

Plane shape design is an important pathway for achieving stretchability of a stretchable sensor. To improve large-scale stretchability such that a sensor more closely fits on the skin, many types of patterns have been designed by researchers. These patterned electrodes adhere to a compliant substrate to promote continuous plastic deformation. As described above, stretchability is an important factor when monitoring human body signals. Another factor, conductivity, also plays an indispensable role in the process. The final effects of these methods depend on the pattern geometry and material properties to a large extent. Lee [46] fabricated a serpentine stretchable sensor, which stretches to strains of up to 50% before cracking (Fig. 15a). Wei [161] demonstrated that CNT mesh with a macroscopic grid and a microscopic network structure achieves large-scale stretchability (Fig. 15b). Although a stiff-island sensor fabricated by Rogers [80] with small-scale stretchability was used to evaluate subtle motions of the throat that are associated with speech, it stretches up to 30% (Fig. 15c). The feasibility of achieving stretchability by geometric structuring has been demonstrated. Hence, investigators have invested a great deal of effort in optimizing geometric structure to achieve better performance. Horseshoes (Fig. 15d, e), which are serpentine microstructures that were originally developed for interconnections in stretchable electronics, exhibit a wide range of desired mechanical responses [18].