Abstract

Strontium aluminates are important compounds with interesting properties such as long-duration phosphorescence and elastico-deformation luminescence. They have potential application in flexible light emitting panels. Since there are serious discrepancies in available thermodynamic data for these compounds, a redetermination of their Gibbs energies of formation was undertaken using solid-state electrochemical cells incorporating single-crystal SrF2 as the electrolyte in the temperature range from 1000 to 1300 K. However, the measurements were restricted to SrAl12O19 and SrAl4O7 because of the formation of strontium oxyfluoride phase between SrAl2O4 and SrF2. For the reactions, SrO + 6 Al2O3 → SrAl12O19, ΔG o/J mol−1 (± 280) = −83386 − 25.744 (T/K), and SrO + 2Al2O3 → SrAl4O7, ΔG o/J mol−1 (± 240) = −80187 − 25.376 (T/K). The high entropy of SrAl4O7 and SrAl12O19 can be partly related to their complex structures. The results of this study are consistent with calorimetric data on enthalpy of formation of other Sr-rich aluminates and indicate only marginal stability for SrAl4O7 relative to its neighbours, SrAl12O19 and SrAl2O4. The thermodynamic data explain the difficulty in direct synthesis of phase pure SrAl4O7 and the formation of SrAl2O4 as the initial ternary phase when reacting SrO and Al2O3 or crystallizing from amorphous state, irrespective of composition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tertiary oxides belonging to the system SrO–Al2O3 are useful in a variety of applications, most prominently in phosphors. The stable compounds in this system are, Sr4Al2O7, Sr3Al2O6, SrAl2O4, SrAl4O7 and SrAl12O19; Sr4Al2O7 is stable only above 1403 K [1]. Two important metastable phases are Sr4Al14O25 [2] and Sr12Al14O33 [3, 4]. Monoclinic α-SrAl2O4 is unique among strontium aluminates in exhibiting elastico-deformation luminescence which is useful for developing mechano-optical devices [5]. Long-duration phosphorescence has been achieved in Eu2+ and Dy3+ co-doped SrAl4O7 and SrAl12O19 [6]. Organic–inorganic flexible light emitting panels can be made from polystyrene and doped strontium aluminate [7]. Pr3+-activated SrAl12O19 shows photon-cascade emission with the quantum efficiency greater than 100% under vacuum ultraviolet excitation [8].

Thermodynamic data for SrAl2O4 are available in thermodynamic compilations [9, 10]. Ye et al. [11] have estimated thermodynamic data for strontium aluminates by comparison with similar compounds and consistent with the phase diagram for the system SrO–Al2O3. The data for SrAl2O4 from the three sources [9,10,11] differ greatly as shown in Fig. 1. The enthalpy of formation of SrAl2O4, Sr3Al2O6 and Sr4Al2O7 from their binary oxides has been measured by Brisi et al. [12]. The chemical potential of SrO corresponding to a mixture of Sr3Al2O6 and SrAl2O4 was measured by Levitski and Scolis [13] in the temperature range from 1150 to 1375 K using an electrochemical cell incorporating SrF2 as the solid electrolyte. Gibbs energy of formation of SrAl12O19 was measured by Akolis et al. [14] in the temperature range from 1245 to 1380 K using an electrochemical cell. More recently, Ueda et al. [15] have reported the standard Gibbs energies of formation of SrAl4O7 and SrAl12O19 at 1723 K. They equilibrated oxide mixtures with liquid copper contained in a graphite crucible under CO gas atmosphere and measured the equilibrium concentration of strontium in liquid copper. Result of Ueda et al. [15] for SrAl12O19 differs significantly from the extrapolated data of Akolis et al. [14] and estimate of Ye et al. [11] as shown in Fig. 2. The inconsistency in available thermodynamic data on strontium aluminates prompted a redetermination. The most convenient method for measuring Gibbs energies of formation of strontium aluminates at high temperature is the use of solid-state electrochemical cells incorporating SrF2 as the electrolyte. However, in preliminary experiments in this study cells containing SrAl2O4 at the electrode registered time-dependent electromotive force (EMF) suggesting secondary reactions related to the formation of a strontium oxyfluoride phase between SrAl2O4 and SrF2. Hence, the measurements were restricted to SrAl12O19 and SrAl4O7.

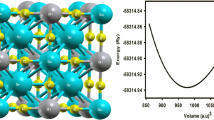

SrAl12O19 crystalizes in the hexagonal system with a magnetoplumbite-type structure, space group P63/mmc (194) [16]. The structure has been characterized by 27Al MAS and MQMAS solid-state NMR. There are five different Al sites; three octahedrally coordinated, one tetrahedrally coordinated, and one having fivefold coordination [17]. Each Sr atom is coordinated by twelve oxygen atoms forming an anticuboctahedron. The crystal structure of SrAl4O7 is monoclinic, space group C12/c1 (15) with four formula units in the unit cell. All the aluminium atoms are tetrahedrally coordinated [18]. Each Sr atom is coordinated by seven oxygen atoms forming a pentagonal bipyramid.

Materials and methods

Materials

Aluminium nitrate nonahydrate (Al(NO3)3·9H2O) and strontium nitrate (Sr(NO3)2), both of 99.995% purity on the basis trace metal analysis, obtained from Sigma-Aldrich were used as starting materials. Two strontium aluminates, SrAl12O19 and SrAl4O7, were prepared by spray drying a mixture of nitrates in the appropriate molar ratio. To decompose the nitrates, the dry powders were heated at ~ 0.1 K s−1 to 1073 K. The resulting products were amorphous. The powders were then ground in agate mortar and subsequently heat treated for crystallization at 1823 K. XRD confirmed the formation of phase pure aluminates. XRD pattern for white SrAl12O19 was almost identical to that in ICSD file number 01-080-1195. The hexagonal lattice parameters calculated from the ten major peaks are a = b = 0.5569 nm and c = 2.2012 nm. XRD pattern for SrAl4O7 was very close to that in ICSD file number 01-072-1252. The lattice parameters of the monoclinic crystal structure, calculated using the ten major peaks are a = 1.304 nm, b = 0.9011 nm, c = 0.5536 nm and β = 106.24°. Transparent single crystals of SrF2 in the form of disc, 1.5 cm in diameter and 0.3 cm thick, were used as the solid electrolyte.

High-purity premixed (Ar + O2) gas from a cylinder with oxygen partial pressure (P O2/P°) = 0.0276 was used in this study. It was first passed through columns containing sodium hydroxide to remove traces of CO2. The gas was then dried by passing through columns containing silica gel and anhydrous magnesium perchlorate and over boats containing phosphorous pentoxide.

Apparatus and procedure

The electromotive force (EMF) of the following solid-state electrochemical cells was measured as a function of temperature from 1000 to 1300 K.

Since Pt forms ternary oxides with SrO at higher oxygen pressures, a gas mixture with reduced oxygen partial pressure was employed. The reference electrode pellet was prepared by heating a compacted equimolar mixture of SrO and SrF2 at 1300 K. The working electrodes were prepared in a similar manner by initially taking an equimolar mixture of SrF2 and two neighbouring phases in the SrO–Al2O3 system (SrAl12O19 + Al2O3 in Cell 1 and SrAl4O7 + SrAl12O19 in Cell 2). The presence of SrF2 in each electrode was required to generate fluorine potential.

Since the apparatus used in this study for electrochemical measurements was similar to that described earlier [19, 20], only a brief description is given here. The electrode pellets were spring loaded on either side of a transparent SrF2 single crystal. A Pt gauze attached to a Pt lead was inserted between each electrode and the electrolyte. A system of alumina tubes and rods was used to hold the pellets together under spring pressure. Platinum foils were used to prevent direct contact between electrode pellets and the alumina tubes or rods. The cell was assembled inside an outer alumina tube fitted with brass end caps, which had provision for gas inlet/outlet and electrical connections. The entire cell assembly was suspended inside a vertical resistance furnace with good temperature control (± 1 K). The temperature of the cell was initially raised to 573 K. The moisture adsorbed on the ceramic tubes was removed by repeated evacuation of the outer alumina tube and refilling with dry premixed (Ar + O2) gas of known composition from a cylinder. The oxygen partial pressure in the (Ar + O2) mixture was \( \left( {{{P_{{{\text{O}}_{2} }} } \mathord{\left/ {\vphantom {{P_{{{\text{O}}_{2} }} } {P^\circ }}} \right. \kern-0pt} {P^\circ }}} \right) \) = 0.0276, where P° = 1.013 × 105 Pa is the standard pressure. The same gas mixture was passed over both electrodes.

The EMF was measured using a digital voltmeter with the internal impedance greater than 1012 Ω and sensitivity of 0.1 mV. To avoid the pickup of induced EMF on cell leads from furnace winding, a stainless steel foil was wrapped around the outer alumina tube and earthed. The time required to attain steady EMF varied from ~ 40 ks at the lowest temperature to ~ 15 ks at intermediary temperatures and ~ 2 ks at the highest temperature used in this study. To check reversibility small currents (~ 10 μA) were passed in either direction through the cell and the EMF observed as a function of time. Gradual return of the EMF to the same value after successive displacements in opposite directions ensured electrochemical reversibility. The EMF was independent of the flow rate of (Ar + O2) mixture through the cell from 1 to 5 mL s− 1. The flow rate during EMF measurements was maintained at 3 mL s− 1. Temperature cycling did not significantly affect the EMF. At the end of each experiment, the cell was dismantled after cooling and the electrodes were examined by optical microscopy, XRD and SEM equipped with EDS. The phase compositions of all the electrodes of cells 1 and 2 were found to be unaltered by the high-temperature exposure. A summary of the characterization results is given in the supplementary file.

Results and discussion

The reversible EMF of the two cells was measured as a function of temperature in the range from 1000 to 1300 K. The results are summarized in Table 1 and displayed in Fig. 3.

The EMF of both cells vary linearly with temperature. The least-mean square regression analysis gives,

where E 1 and E 2 refer to the EMF of cell 1 and cell 2, respectively. The uncertainties in Eqs. (3) and (4) are expanded uncertainties U (0.95 level of confidence) obtained by regression analysis. The EMF of the cells responds to the difference in the chemical potential of fluorine at the electrodes. In the range of fluorine potentials encountered in this study, SrF2 is an ionic conductor with transport number of fluoride ions greater than 0.99.

The electrochemical reaction at the working electrode of cell 1 can be written as:

Corresponding reaction at the reference electrode of cell 1 is:

For cell 1, virtual net reaction is:

From reversible EMF of cell 1, the standard Gibbs energy of formation of SrAl12O19 from its constituent binary oxides can be computed using the Nernst equation:

where n = 2 is the number of electrons involved in electrode reactions and F = 96485.33289 C/mol is the Faraday constant and E/V is the EMF. The first term on the right-hand side of Eq. (8) is the enthalpy of formation of SrAl12O19 from its constituent binary oxides (−83.4 (± 0.95) kJ mol−1) at the average experimental temperature of 1150 K. The second temperature-dependent term on the right-hand side of Eq. (8) with sign reversed gives the corresponding entropy change (25.74 (± 0.82) J K−1 mol−1) for the reaction. The high entropy of SrAl12O19 relative to its component binary oxides may be related to statistical disorder of Al in AlO5 polyhedra. Aluminium atoms in the trigonal bipyramid are axially displaced from the centre. The large number of binary oxide molecules (7) per formula unit of SrAl12O19 is another reason for the relatively large entropy value.

Assuming the applicability of Neumann–Kopp rule for the solid-state reaction (7), the standard enthalpy of formation of SrAl12O19 from its elements at 298.15 K can be estimated as \( \Delta H_{f}^{o} \) (298.15 K) = −10,729.6 (± 30) kJ mol−1 by using the values of enthalpy of formation of Al2O3 (−1675.69 (± 5) kJ mol−1) and SrO (−592.036 (± 3.8) kJ mol−1) from thermodynamic data compilation of Knacke et al. [9]. Similarly, the standard entropy of SrAl12O19 at 298.15 K can be estimated as S o (298.15 K) = 387 (± 2.7) J K−1 mol−1 by using the values of \( S_{{{\text{Al}}2{\text{O}}3}}^{o} \) (50.949 (± 0.42) J K−1 mol−1) and \( S_{\text{SrO}}^{o} \) (55.522 (± 0.4) J K−1 mol−1) from thermodynamic data compilation of Knacke et al. [9]. However, because of the complicated crystal structure of SrAl12O19 with Al in three different coordination states, the application of Neumann–Kopp rule needs verification. Measurement of both high- and low-temperature heat capacity of SrAl12O19 is required to confirm and refine the data obtained in this study.

Gibbs energy of formation of SrAl12O19 from its constituent compounds obtained in this study is compared with values reported in the literature in Fig. 2. There is excellent agreement with the data of Akolis et al. [14] in the overlapping range of temperature, with a significant difference in the temperature dependence of Gibbs energy. Ye et al. [11] assume that entropy of formation from component binary oxides is zero. Although entropy change for solid-state reactions is generally small, they make a significant contribution to the stability of ternary oxides at high temperatures and should not be ignored. The result of Ueda et al. [15] at 1723 K is ~ 82 kJ mol−1 more positive than the extrapolated result of this study. In the successive experiments, Ueda et al. [15] equilibrated liquid Cu of unspecified purity with SrO, Al2O3 + SrAl12O19 and SrAl12O19 + SrAl4O7 in a graphite crucible (99.9% pure) under flowing CO gas. The oxygen potential was assumed to be established by the equilibrium between graphite crucible and CO gas. From the equilibrium concentration of Sr in liquid Cu, they computed the Gibbs energy of formation of two strontium aluminates. The measured Sr concentrations in Cu were extremely low: 75.7 at. (atom) ppm when equilibrated with SrO, 3.14 at. ppm when equilibrated with Al2O3 + SrAl12O19 and 1.82 at. ppm when equilibrated with SrAl12O19 + SrAl4O7. The results of this study suggest Sr concentrations in Cu more than 100 times lower than those reported by Ueda et al. [15], which are beyond the limit of quantitative measurement with ICP-AES. The higher Sr concentrations reported by Ueda et al. [15] probably result from residual Sr impurities in Cu and Sr pickup from their graphite crucible.

The electrochemical reaction at the working electrode of cell 2 can be written as:

Corresponding reaction at the reference electrode of cell 2 is:

For cell 2, virtual net reaction is:

From the reversible emf of the cell, ΔG o for reaction (11) can be computed using the Nernst equation:

The value of n is 4 for this reaction. By combining Eqs. (7) and (11), the standard Gibbs energy of formation of SrAl4O7 from its constituent binary oxides is obtained:

The extrapolated result of this study is compared with the data of Ueda et al. [15] for SrAl4O7 at 1723 K in Fig. 4. The result from Ueda et al. [15] is ~ 94 kJ mol−1 more positive. The reason for the discrepancy in the data of Ueda et al. [15] has already been outlined in the discussion on SrAl12O19. According to Capron and Douy [21] SrAl12O19 is unstable above 1373 K; it decomposes to a mixture of Sr4Al14O25 and SrAl12O19. The modified phase diagram suggested by Capron and Douy [21] is in violation of phase rule since four compounds are shown to coexist along a reaction isotherm at ~ 1335 K in the pseudo-binary SrO–Al2O3. Capron and Douy [21] suggest reappearance of SrAl4O7 as a stable phase above 1973 K. If the modified phase diagram Capron and Douy [21] is correct, Ueda et al. [15] should not have encountered SrAl4O7 at 1723 K. Further research is required to resolve this issue.

The second-law enthalpy of formation of SrAl4O7 from its constituent binary oxides is (−80.2 (± 1.1) kJ mol−1) at the average experimental temperature of 1150 K. Corresponding second-law entropy change for this reaction is (25.38 (± 0.93) JK−1 mol−1). The high entropy of SrAl4O7 is probably related to rattling Sr in sevenfold coordination. Invoking Neumann–Kopp rule for reaction (13), the standard enthalpy of formation of SrAl4O7 from its elements at 298.15 K can be estimated as \( \Delta H_{f}^{o} \) (298.15 K) = −4023.6 (± 11) kJ mol−1 using enthalpy of formation values for Al2O3 and SrO from Knacke et al. [9]. Similarly, using values of standard entropy of Al2O3 and SrO from Knacke et al. [9], the standard entropy of SrAl12O19 at 298.15 K can be estimated: S o (298.15 K) = 182.8 (± 1.3) J K−1 mol−1. The high entropies of formation of SrAl12O19 and SrAl4O7 mirror similar properties of analogous calcium compounds CaAl12O19 and CaAl4O7 [22]. Calorimetric determination of enthalpy of formation and heat capacity as a function of temperature is required to confirm and refine the results of this study.

The enthalpy of mixing for the system SrO–Al2O3 is displayed in Fig. 5. The data for SrAl12O19 and SrAl4O7 are from this study, and data for SrAl2O4, Sr3Al2O6 and Sr4Al2O7 are taken from Brisi et al. [12]. It is seen that the data obtained in the study integrate well with the calorimetric data of Brisi et al. [12] for strontium aluminates having higher concentration of SrO. Minimum enthalpy of mixing occurs at the equimolar composition. This is the reason for the appearance of SrAl2O4 as the first phase when reacting SrO and Al2O3 or crystallizing from the amorphous state, irrespective of composition. It is seen that the enthalpy of mixing for SrAl4O7 lies on a line connecting values for SrAl12O19 and SrAl2O4. This explains the difficulty in synthesizing phase pure SrAl4O7 by direct solid-state reaction between SrO and Al2O3. The instability of Sr4Al2O7 at low temperatures (below 1403 K) is also revealed in Fig. 5. The compound is entropy stabilized.

The enthalpy of mixing for the system SrO–Al2O3: this study (red filled circle); Brisi et al. [12] (black filled square)

Conclusion

In this study, the thermodynamic data for the compounds SrAl12O19 and SrAl4O7 have been determined by a potentiometric method. The standard Gibbs energies of formation for SrAl12O19 and SrAl4O7 in the temperature range 1000 to 1300 K are:

The apparent high entropy value of SrAl12O19 relative to its constituent binary oxides is caused by the large number of binary oxide molecules (7) per formula unit of SrAl12O19 and statistical disorder of Al in AlO5 polyhedra. The high entropy of SrAl4O7 is probably related to rattling Sr atom having sevenfold coordination inside the pentagonal bipyramid. The standard enthalpies of formation of SrAl12O19 and SrAl4O7 from elements at 298.15 K, obtained by applying Neumann–Kopp rule, are −10,729.6 (± 30) kJ mol−1 and −4023.6 (± 11) kJ mol−1, respectively. Similarly, the standard or absolute entropies of SrAl12O19 and SrAl4O7 at 298.15 K are 387 (± 2.7) J K−1 mol−1 and 183 (± 1.3) J K−1 mol−1, respectively. These results can be confirmed and refined by calorimetric determination of enthalpy of formation and measurement of heat capacity as a function of temperature, starting at the lowest possible temperature. The minimum value of enthalpy of mixing at equiatomic composition explains the occurrence of SrAl2O4 as the first ternary oxide to form when SrO and Al2O3 are reacted at high temperatures irrespective of their relative concentrations.

References

Gantis F, Chemekova TY, Udalof YP (1979) The system SrO–Al2O3. Russ J Inorg Chem 24:260–263

Yamaguchi O, Narai A, Shimizu K (1986) New compound in the system SrO–Al2O3. J Am Ceram Soc 69:C36–C37

Wang M, Wang D, Lu G (1998) Research on fluorescence spectra and structure of single-phase 4SrO·7Al2O3:Eu2+ phosphor prepared by solid-state reaction method. Mater Sci Eng, B 57:18–23

Lin Y, Tang Z, Zhang Z (2001) Preparation of long-afterglow Sr4Al14O25-based luminescent material and its optical properties. Mater Lett 51:14–18

Xu C, Yamada H, Wang X, Zheng X (2004) Strong elasticoluminescence from monoclinic-structure SrAl2O4. Appl Phys Lett 84(16):3040

Katsumata T, Sasajima K, Nabae T, Komuro S, Morikawa T (1998) Characteristics of strontium aluminate crystals used for long-duration phosphors. J Am Ceram Soc 81(2):413–416

Guo Y, Huang YM (2010) Green aluminate phosphors used for information display. Key Eng Mater 428–429:421–425

Srivastava AM, Beers WW (1997) Luminescence of Pr3+ in SrAl120: observation of two photon luminescence in oxide lattice. J Lumin 71:285–290

Knacke O, Kubaschewski O, Hesselmann K (1991) Thermochemical properties of inorg. substances, 2nd edn. Springer, Berlin

Barin I (1995) Thermochemical data of pure substances, 3rd edn. VCH, Weinheim

Ye X, Zhuang W, Wang J, Yuan W, Qiao Z (2007) Thermodynamic description of SrO–Al2O3 system and comparison with other systems. J Phase Equilb Diffus 28:362–368

Brisi C, Abbattista F (1960) Searches on the heats of formation of the strontium aluminated one. Ann Chimica 50:165–169 in Italian

Levitski VA, Scolis YY (1974) Thermodynamics of double oxides I. Galvanic-cell study of strontium tungstates and aluminates. J Chem Thermodyn 6:1181–1190

Akolis YY, Vintonyak VM, Levitskii VA, Yanishevskii VM (1983) Investigation of the thermodynamic properties of SrAl12O19 at the elevated temperatures by the emf method. Inorg Mater 19:228

Ueda S, Utagawa K, Yamaguchi K (2008) Activity coefficient of strontium in liquid copper and the standard free energy of formation for SrO·6Al2O3 and SrO·2Al2O3. Mater Trans 49(6):1338–1341

Lindop AJ, Matthews C, Goodwin DW, Haan JW, Ven JM, Kentgens APM, Nachtegaal GH (1975) The refined structure of SrO·6Al2O3. Acta Cryst B 31:2940

Jansen SR, Hintzen HT, Metselaar R (1998) Multiple quantum 27Al magic-angle-spinning nuclear magnetic resonance spectroscopic study of SrAl12O19: identification of a 27Al resonance from a well-defined AlO5 site. J Phys Chem B 102:5969–5976

Lindop AJ, Goodwin DW (1972) The refined structure of SrO·2A12O3. Acta Cryst B 28:2625

Jacob KT, Hajra JP (1987) Measurements of Gibbs energies of formation of CoF2 and MnF2 using a new composite dispersed solid electrolyte. Bull Mater Sci 9:37–46

Jacob KT, Abraham KP, Ramachandran S (1990) Gibbs energies of formation of intermetallic phases in the systems Pt–Mg, Pt–Ca, and Pt–Ba and some applications. Metall Trans B 21B:521–527

Capron M, Douy A (2002) Strontium dialuminate SrAl4O7: synthesis and stability. J Am Ceram Soc 85:3036–3040

Allibert M, Chatillon C, Jacob KT, Lourtau R (1981) Mass-spectroscopic and electrochemical studies of thermodynamic properties of liquid and solid phases in the system CaO–A12O3. J Am Ceram Soc 64:307–314

Acknowledgements

One of the authors (KTJ) is grateful to the National Academy of Sciences, India (NASI), for the award of Platinum Jubilee Senior Scientist Fellowship. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jacob, K.T., Shreyas, V. Thermodynamic properties of SrAl12O19 and SrAl4O7 . J Mater Sci 53, 1723–1730 (2018). https://doi.org/10.1007/s10853-017-1634-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1634-0