Abstract

The use of herbicides is important to eliminate losses of weed interference on crops. However, excessive and inappropriate employment of these substances can cause serious consequences to the environment. In this way, the release system is very attractive for the weed control in the agriculture area. The aim of this work was to study a new delivery system for sulfentrazone herbicide encapsulated into the calcium alginate (Ca-ALG) microparticles for the weed control. The alginate microparticles were prepared via ionotropic gelation method and characterized by using optical microscopy, scanning electron microscopy, and thermogravimetric and differential thermal analysis. The controlled release (M t /M ∞ vs. time) of the sulfentrazone herbicide was also analyzed using UV–Vis spectroscopy where we proposed different mathematical models to understand the mechanisms of controlled release of the herbicide. Furthermore, the release tests in field trial weed control were conducted using bioindicator species (Cucumis Sativus—Cucumber) to study the phytotoxicity evaluation caused by the Ca-ALG microparticles at different concentrations and their relationship with leaching depth. The results showed that the Ca-ALG microparticles exhibited good encapsulation efficiency (%EE): 76.11, 78.62, and 80.42% for the 4, 5 and 6 g L−1 concentration of herbicide. The release rates in the region I were 39.2, 46.5, and 35.5 mg s−1 for the 4, 5, and 6 g L−1 of herbicide concentration, respectively. The Ca-ALG microparticles containing sulfentrazone herbicide demonstrated potential application in controlled release platforms in agricultural as well as for controlling of weeds and minimization of leaching processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Day by day, the advent of agrochemicals has increased the production of food in the world. Herbicides are chemicals applied to eliminate losses of weed interference on crops and can be used in agriculture, recreation areas, transport routes and industrial areas, leading to substantial agronomic and economic benefits [1]. Thus, the non-judicious use of this product can causes serious problems, including water contamination, neighboring crops, leaching, and volatilization [2, 3]. The use of pre-emergence herbicide causes sorption processes, leaching, and degradation. In order to promote effective solutions for waste herbicides and reduce pollution of the environment, it is important to develop systems that permit the controlled release of these substances [4–7].

The sulfentrazone (N-[2,4-dichlro-5-[4-difluoromethyl)-4-5-dihydro-3methyl-5-oxo-1H-1,2,4-triazol-1-il] methanesulfonamide) [8] herbicide can be applied in the conventional cultivation as in no-tillage system and is a member of the phenyl triazolinone herbicide group [9] and is stable in soil (half-life = 9 months) used for the control of broadleaf weeds and some grasses in crops such as soybeans [10], chickpeas, sugarcane [11], and rice [12]. This herbicide exhibits low affinity for organic matter and mobility only in soils with high sand content and requires moisture to activate and move it into the soil. Due to its intensive use, herbicides are often detected in studies of quality of surface and groundwater [13]. Figure 1 represents the molecular structure for the sulfentrazone herbicide.

Controlled release systems have also been applied extensively in the food and pharmaceutical industries for the release of active substances such as nutrients, drugs and aromas [14, 15]. The employment of natural polymeric microparticles from polysaccharides [3] has been attractive for the development of release system in the agriculture. In particular, the use of alginate is a feasible alternative to obtain stable and well-shaped microparticles by using green routes and with adequate properties as non-toxicity, biocompatibility, and biodegrability.

In this present work, we employed a modern research approach to obtain a controlled release of sulfentrazone herbicide-encapsulated into Ca-ALG microparticles. To understand the mechanisms of controlled release, different mathematical models were investigated. A detailed study of the release tests in field trial weed control was also performed to study the phytotoxicity evaluation caused by the Ca-ALG microparticles in different concentrations and the relationship with the leaching depth. To the best of our knowledge, this is first study concerning an effective controlled release system using the sulfentrazone herbicide encapsulated into a biodegradable polymer fashion with high prospects in agriculture area.

Experimental

Materials

All chemicals used were of analytical grade. The biopolymer sodium alginate (Na-ALG) were purchased from Sigma-Aldrich (Brazil) with molecular weight (M/W) of 100.000 g mol−1, viscosity of 15–20 cP, 61% of mannuronic acid and 39% of guluronic acid. The calcium alginate microparticles (Ca-ALG) were prepared by using calcium chloride, CaCl2 (Sigma-Aldrich), sodium chloride, NaCl (Sigma-Aldrich), and deionized water [Milli-Q system (Millipore)].

Preparation of bare and sulfentrazone-loaded alginate microparticles

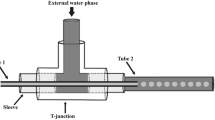

The apparatus used in this work was built based on the studies presented by Dias et al. [16], Shi et al. [17] and Faria [18]. Previously, solutions of sodium alginate (3% m/v) and concentrations of 0.1 mol L−1 of CaCl2 were prepared. In sequence, Na-ALG solution was dropped in CaCl2 solution, resulting in a total of 100 microparticles. According to Faria [18], in order to improve the texture and roundness of the microparticles, the alginate solution was adjusted to by adding 0.1 mol L−1 of sodium chloride (NaCl) to form batches of microparticles. The Ca-ALG microparticles was stored in deionized water and passed through a process of water exchange during 3 days. The 3-day-long washing process was performed on bare Ca-alginate microparticles only in order for purification of this material to be used in the posterior characterization techniques. For sulfentrazone-loaded Ca-alginate, the microparticles were washed right after the obtainment to minimize the possible loss of herbicide. After wards, the Ca-Alg microparticles were dried in an oven at 35 °C for 24 h.

Sunfentrazone release experiments

Prior to encapsulating the sulfentrazone herbicide in the alginate microparticles, the ultraviolet–visible spectroscopy (UV–Vis) technique was used to verify the interaction between the sulfentrazone herbicide and the alginate matrix. For this, a spectrophotometer PerkinElmer Lambda 750 in the range 200–800 nm wavelength was used.

The sulfentrazone analytical curve was obtained by preparing aqueous solutions of sulfentrazone (Boral®) varying the herbicide concentration from 0.3984 to 4.7619 mg L−1 which was described by the equation y = 542.1073x with R 2 = 0.9975 as shown in Fig. 2. The absorbance versus concentration data was adjusted using a minimum-square method to obtainment of the best fit.

For the encapsulation of the herbicide into the Ca-ALG microparticles, desired amounts of sulfentrazone (4, 5 and 6 g L−1) were added to a freshly prepared 3% (m/v) alginate solution. The sulfentrazone-loaded microparticles were obtained by dropping this solution in 0.1 mol L−1 CaCl2 and isolated using the same procedure. After obtaining the microparticles, they were filtered and washed with deionized water to remove the remaining NaCl, then dried in an oven at 35 °C until the mass remains constant. The encapsulation efficiency (%EE) of sulfentrazone herbicide was measured by the amount of herbicide remaining in the supernatant as described in Faria et al. [18]. The (% EE) was evaluated by the difference of the amount of herbicide added in the alginate + sulfentrazone solution and the unentrapped amount of sulfentrazone remaining in the supernatant after the removal of the formed microparticles, following the equation:

The controlled release experiments were performed by mixing 400 mg of dried sulfentrazone-loaded Ca-ALG microparticles in 50 mL of deionized water. Aliquots were withdrawn from the system at different time intervals and taken to the spectrophotometer for the absorbance measurements. Figure 3 shows a representative scheme used on the controlled release assays.

Characterization of the Ca-ALG microparticles

The shape and external size of the dried Ca-ALG microparticles were examined under an optical microscopy (OM) using a microscopy Olympus with 10× magnification. The surface and microstructure of the Ca-ALG microparticles were also studied with scanning electron microscopy (SEM) (JEOL JSM-6601LV). The samples were mounted to the specimen holder with a double-sided adhesive tape and vacuum coated with gold. The sizes of the dried Ca-ALG microparticles were obtained by digital image analysis. The polydispersity distribution curve was performed using ImageJ software.

Thermogravimetric and differential thermal analysis (TG/DTA) measurements were recorded on a DTG and 60H Shimadzu equipment model. Samples were heated from room temperature to 1000 °C at a heating rate of 10 °C min−1 under oxygen (100 mL min−1) flow. Alumina crucibles were used for the TG–DTA curves.

Mathematical modeling

Different mathematical models, including first-order, Hixson–Crowell, Higuchi, Korsmeyer–Peppas and Baker–Lonsdale were used to associate mechanisms to the controlled release of sulfentrazone herbicide using Ca-ALG microparticles.

Release tests in field trial and leaching

The microparticles were distributed in PVC columns with 50 cm in height and 15 cm in diameter. The PVC columns were filled with soil (Red Latosol) and demarcated externally every 10 cm. The soil used to fill the PVC columns consisted of 56.5% clay, 6.5% silt, and 37% of sand. Subsequently, they were conducted and maintained in a greenhouse. Figure 4 represents the apparatus used in this work for the release tests in field trial weed control.

The experimental design was completely randomized in factorial scheme 5 × 5, five treatments with and without herbicide (pre-emergence) and five depths. The treatments were constituted by the conventional application and microparticles containing the herbicide: [0.0 (control), 1.2 L ha−1 (conventional), 4, 5 and 6 g L−1] and five evaluated depths in the soil profile (0–10, 10–20, 20–30, 30–40 and 40–50 cm) with three replicates.

The herbicide conventionally applied was Boral 500 SC®, sprayed into PVC columns using a CO2 pressurized costly sprayer, equipped with four spray nozzles of the fan type Teejet 11.04 spaced 50 cm from each other at a working pressure of 30 psi. The machine was set to provide a solution output of 250 L ha−1. At the time of application, the climatic conditions were favorable to operation, with air temperature around 27.7 °C, air humidity of 45.4%, and wind speed of 4.9 km h−1.

The concentration of herbicide in each microparticle (4, 5 and 6 g L−1) was performed according to the manufacturer’s recommendation of the herbicide Boral 500 SC®, resulting in 9 mg of microparticles for 4 g L−1, 8 mg of microparticles for 5 g L−1, and 6 mg of microparticles for 6 g L−1.

The microparticles were distributed on the surface of the PVC columns manually, and the amount of microparticles distributed was calculated based on the upper area of the PVC columns. Subsequently, the soil was artificially irrigated until accumulate 100 mm of water and then separated into two halves. Immediately, sowing of the bioindicator species (Cucumis sativus—cucumber). This species was chosen because of its high sensitivity to the herbicide of interest. Eight cucumber seeds were distributed to each 10 cm demarcation in the PVC column.

The phytotoxicity evaluations in the bioindicator plants sown in the columns were performed at 17, 24, 31 and 38 days after sowing (DAS). As a criterion for the evaluation of plant phytotoxicity (injuries), the scale of grades from 0 to 100% [19] was adopted, where 0 corresponds to no injury and 100% is equivalent to plant death. In this work the data were discussed associating the results of phytointoxication observed in the cucumber plants with the leaching depth, that is, the higher the percentage of phytotoxification, the greater the leaching of the herbicide.

The results were submitted to the means of the treatments compared by the Tukey test at 5% of probability [20]. The percentage data (%) of phytointoxication were transformed into arcsin √x/100. The Tukey test used in this study is based on the minimum significant difference (MSD). Since the absolute value of the difference between two means is equal to or greater than the MSD, the means are considered statistically different at the established significance level and their values are followed by letters (a, b or c for example). Initially, the means are ordered in ascending or descending order to facilitate comparisons. A letter of the alphabet is placed in the first mean (usually the letter ‘a’), and then the difference with the following means is compared. If the difference is greater than or equal to the MSD value, the difference between two averages shall be considered significant. The difference between two means is represented by the presence of different letters. Therefore, averages of plant poisoning percentage, followed by equal letters, do not differ significantly from each other, by the Tukey test at the 5% probability level.

Results and discussion

Preparation, characterization, and mathematical modeling

The UV–Vis molecular absorption spectra of Boral® (500 g L−1 of Sulfentrazone) (Fig. 5) aqueous solution exhibit a band with maximum absorbance at 207 nm and two broad shouldered peaks at 232 and 245 nm attributed to the transitions π → π* of herbicide, which is in agreement with data in the literature [21]. These bands are a function of substitution groups on benzene ring, and they are expected occur relatively at lower wavelength, due to the consequence of the extended aromaticity of the benzene ring. These values may be slightly shifted by solvent effects [21]. The same procedure was applied for the alginate, which exhibited no absorption in the UV–Vis region. For the sake of clarity, the interference between the bands (interaction between these two compounds) was demonstrated by dialysis procedure (not shown).

Figure 6 shows the polydispersity curve of dried Ca-ALG microparticles with NaCl for different concentration of sulfentrazone herbicide. The average radius of the Ca-ALG microparticles were 495.1 ± 40.7, 568.4 ± 35.3 and 586.4 ± 24.3 µm for the 4, 5 and 6 g L−1 herbicide concentration, respectively. It is not surprising that increased herbicide concentration the radius of microparticle also increase once the guest causes the swelling of alginate host. As described by Villafranca-Sánches et al. [22], the increasing of concentration of the herbicide was directly related to the radius of microparticle size, standard deviation, and better roundness. According to Tsirigotis-Maniecka et al. [23], the spherical degree shape of the Ca-ALG microparticles for the 4 and 6 g L−1 herbicide concentration can be associated to the high degree of cross-linked polymer. As reported by Lacerda et al. [24], spherical structure with rough surfaces is a typical characteristic of microparticles consisting of sodium alginate.

Figure 7 presents the OM images of Ca-ALG microparticles at different concentrations of herbicide. The difference between the figures is the concentration of herbicide used in the encapsulation process. The 5 g L−1 concentration of herbicide produced more irregular microparticles. Thus, the controlled release curve for the concentration of 5 g L−1 behaves differently from the others as will be discussed later. The SEM micrographs were also used to determine and compare the size distribution profiles of the different Ca-ALG microparticles.

Figure 8 displays SEM images of the Ca-ALG with sulfentrazone herbicide. The morphology of sulfentrazone Ca-ALG microparticles exhibited some cracks on the microparticle surface as can be seen the zooned area for each micrography. Through the morphology of the microparticles we can use a mathematical model that best describes the diffusion mechanisms involved in the controlled release process of the sulfentrazone herbicide. As observed the 4 and 6 g L−1 herbicide concentrations present shape more regular compared to the 5 g L−1 sample. The size difference is associated with the variation of the mean size obtained between the microparticles for the three concentrations studied which was around 13%. The incorporation of NaCl in alginate matrix promotes a more spherical particle. Morphological analysis of the microparticle’s surface is very important since knowledge of the surface characteristics can help to understand the release mechanism of the herbicide associated with them [15, 25]. The mean radius of the Ca-ALG microparticles were 495.1 ± 40.7, 568.4 ± 35.3, and 586.4 ± 24.3 µm for the 4, 5, and 6 g L−1 herbicide concentration, respectively.

Thermal behavior of the samples was also investigated by TG/DTA analysis. Figure 9a shows the TG curves under air atmosphere of the alginate pure and herbicide alginate. The TG curve was characterized by three mass loss regions. The first mass loss (20%) displayed on heating the complex up to 210 °C corresponds to the evolution of adsorbed water molecules. The second decomposition step, starting above 200 °C and extending to about 315 °C, involves a mass loss of about 32.5% for all samples. This value may correspond to the degradation of alginate by rupture of the bonds to form an intermediate compound. Figure 9b depicts that any peak was observed on the DTA curve, indicating that the alginate does not follow the second mass loss. This behavior suggests that the formation of the intermediate occurs smoothly, i.e., without gain or loss of heat. On increasing the temperature until 495 °C, the TG curve presents that the third decomposition stage is associated with a 30% mass loss. This value corresponds to the decomposition of the intermediate to the final product, sodium, or calcium oxide. For the materials based on herbicide and alginate composites, this last decomposition step occurs at higher temperatures 510, 517, and 527 °C for the samples 4, 5, and 6 g L−1, respectively, associated to the degradation/oxidation of organic herbicide present in alginate matrix. Moreover, in the composites herbicide alginate a lower amount of residue can also be observed (31.4 and 27.4% for the alginate and alginate/herbicide, respectively). So, one can be demonstrated that the decomposition of alginate proceeds in three stages and the herbicide–alginate composites has slightly high thermal stability of alginate matrix.

In this study, the encapsulation efficiency (%EE) was 76.11, 78.62, and 80.42% for 4, 5, and 6 g L−1 herbicide concentrations, respectively. The values of encapsulation are related to the solubility of the herbicide in water, in which the water solubility sulfentrazone features 490 mg L−1 [26]. Despite its low solubility, the mobility of sulfentrazone in the soil is strongly driven though its partition in water. So, it was necessary establish a previous understanding of the interactions of sulfentrazone-loaded Ca-ALG with water as simplified release medium to serve as a base of comparison with the release behavior in the soil solution.

Figure 10 presents the controlled release assays for the sulfentrazone herbicide encapsulated on the Ca-ALG microparticles at different concentrations of herbicide. As can be seen, the release curve presents distinct regions. According to Siepmann and Siepmann [27], when the release of the active compound from the polymer microparticles is controlled by matrix erosion mechanism, the release kinetics shows a triphasic profile. In the first region, immediately after placement of the polymer matrix in contact with the media release, a large amount of herbicide is released. This phenomenon is commonly known as Burst effect [28]. The Burst effect leads to an initial accelerated release of the active compound.

The release rates (M t /M infinite vs. t) in the region I were 39.2, 46.5 and 35.5 mg s−1 for the 4, 5 and 6 g L−1 of herbicide concentration, respectively. The 4 and 6 g L−1 herbicide concentration presented a very similar behavior after 2400 min. One can note that the herbicide was faster released to the 5 g L−1 concentration (50% release during the first 2400 min). Such effect probably may be explained by the amount of the sulfentrazone a top the microparticles surface, featuring a diffusion phenomenon as the main release process in the region I. The second region is associated with the diffusion of the compound, which may be caused by cleavage of the polymeric bonds and the formation of pores that is related to a certain amount of herbicide within the polymer matrix [28]. According to Siepmann et al. [29] the region III is associated with the active compound that is still present within the microparticle at the moment the polymer structure begins to disintegrate. In this work, all data related to the controlled release curves were checked, and it was possible to verify the absence of a region III.

Figure 11a–c shows a mathematical model used to explain the herbicide sulfentrazone release mechanisms encapsulated in the Ca-ALG microparticles and the schematic drawing for region I and II of the controlled release curve. The model that most closely matches the experimental data, for the three concentrations was proposed by Korsmeyer–Peppas [30]. Such model was the one that showed the best correlation coefficient, R 2, for the 60% release of the herbicide [31, 32]. The parameters obtained were correlation coefficient (R 2), kinetic constant release of the active ingredient (k), and diffusion parameter (n) according to Eq. (2).

where M t /M ∞ is the proportion of compound released in the time t, K is the kinetic constant, and n is the exponent which reflects the type of release mechanism.

The values of diffusion parameter found were 0.2928, 0.3288, and 0.2866 for 4, 5, and 6 g L−1 concentration of herbicide, respectively. According to Korsmeyer–Peppas model, the value of n describes the release mechanism of the active ingredient. The Korsmeyer–Peppas proposed that values of n ≤ 0.43 are indicative of release mechanisms that follow Fick’s law, while n > 0.85 indicates that the mechanism are governed by relaxation processes of the polymeric matrix, defined as case II type transport. Intermediate values 0.43 ≤ n ≤ 0.85 suggest anomalous behavior with non-Fickian release (combination of diffusion and relaxation of the polymeric matrix) [18, 25, 33]. Fickian diffusion refers to the solute transport process in which the polymer relaxation time (t r) is much greater than the characteristic solvent diffusion time (t d) [34]. In general, diffusion, erosion, and degradation are the most important mechanisms for solute transport from polymeric matrices [34]. The release of active ingredients in alginate particles containing Ca2+ ions has a diffusive release of the active ingredient for n < 0.43 according to Fick’s law [35]. The values of R 2 for the 4, 5, and 6 g L−1 are 0.97, 0.98, and 0.96, respectively. It is worth mentioning that other mathematical models were evaluated to investigate the release mechanism as shown in the support information (SI).

Release tests in field trial weed control

As described in “Release tests in field trial and leaching” section the samples were distributed in PVC columns with the purpose of studying the phytointoxication observed in the bioindicators species (Cucumis sativus—cucumber) with the leaching depth. Thus, in this section, we will discuss phytointoxication observed in the cucumber plants with the leaching depth. It is worth mentioning that the bioindicator species was chosen because of its high sensitivity to the sulfentrazone herbicide. As previously mentioned the phytotoxicity was evaluated at 17, 24, 31, and 38 days after sowing (DAS) according to criterion for the evaluation of plant phytotoxicity (injuries). In weed control studies using herbicides, the percentage of control is evaluated from a visual scale and percentage of grades ranging from zero to 100. In this case, zero consists of no control and 100% of total control of treated plants (plant death). The evaluations are performed weekly until the disappearance of the phytotoxication symptoms or until the death of the plants (SBCPD, 1995) [19] and are also correlated with the Latin American Association of Weeds (ALAM) [36] scale which ranges from 1 (the poor) to 6 (excellent control).

Figure 12 shows the first symptoms presented by the herbicide sulfentrazone released from the Ca-ALG microparticles. The first symptoms presented by the sulfentrazone herbicide are initiated by the ribbed leaf chlorosis, followed by dark green spots showing aspect of waterlogging due to the disruption of the cell membrane and cytoplasmic fluid spill in cell intervals, becoming whitish and subsequently necrosis of the plant (see Fig. 12a). The dark and white spots on their leaves correspond to the accumulation of protoporphyrinogen IX in chloroplasts and subsequent translocation extravasation in the cytosol and accumulation of reactive forms of oxygen lead to necrosis, paralyzing the growth and leading to death of the plant (Fig. 12b).

The inhibition of protoporphyrinogen oxidation to protoporphyrin IX causes an intriguing accumulation of this pigment in the plants treated with the herbicides of this group. In plants, protoporphyrin IX also shows great reactivity, producing in the presence of light singlet oxygen. This substance is produced in chloroplasts by the action of PROTOX, which has protoporphyrinogen IX as a substrate. As route, regulation depends primarily on the concentration of protoporphyrin IX and its derivatives within the chloroplasts. The paralysis of the activity of this enzyme generates a large accumulation of protoporphyrinogen IX, which exits into the cytosol. The protoporphyrinogen IX is converted, non-enzymatically, into protoporphyrin IX, which is accumulated in large concentrations and is toxic to sensitive plants [37]. These features are in agreement to the symptoms visually observed by Ferreira et al. [38] and Roman [39] for 17 DAS.

It is important to note that the rate in which these symptoms were observed in pre-emergence applications to all treatments does not match those reported in the literature for the herbicides Protox inhibitors, which arise from 3 to 7 days after spraying [40, 41] once this work the perception of visual symptoms occurred to the 17 DAS. The herbicide sulfentrazone is an enzyme protoporphyrinogen oxidase inhibitor (PPO or PROTOX), which is a herbicide whose mechanism of action inhibits the activity of PROTOX in plants. The inhibition of the enzyme activity PROTOX prevents the oxidation of protoporphyrinogen to protoporphyrin IX (precursors of chlorophyll) as described in Fig. 13. The non-oxidation of protoporphyrinogen to protoporphyrin IX causes the protoporphyrinogen spreading out of the reactive center producing a protoporphyrin IX with different structural conformation that produced under normal conditions (no herbicide). This abnormal condition leads to an interaction between oxygen and light, generating singlet oxygen, responsible in last instance by the peroxidation of lipids in cell membranes. These later results in the loss of chlorophyll and carotenoids and the rupture of the membranes, which makes the dehydrated organelles disintegrate quickly, leading to plant death [42]. The differences in this behavior may be related to the herbicide molecule sorption to soil colloids, becoming unavailable for an effective control. In this way, the knowledge of the soil–herbicide relationship is important since there are processes such as leaching and sorption that interfere in the action of this herbicide when applied in pre-emergence. Sulfentrazone herbicide presents high adsorptive capacity; thus, the organic matter content is generally the most important factor to be considered once the high organic matter content in the soil promotes a lower leaching process [42–46].

Additionally, we considered the time of action of sulfentrazone herbicide in the bioindicator plants. According to Freitas et al. [47], the pH of the soil interferes directly on the herbicide dissociation. The sulfentrazone herbicide is a weak acid (pKa = 6.56) and tends to not interact with the soil solution, causing it to increase its latency time for activity in low pH soils as used in this study (pH ≈ 5.4). The maximum release time for the 5 g L−1 concentration of herbicide (25 min) corresponds to approximately 17 days. Studies involving the sorption of herbicides in Brazilian soils are essential for two reasons: to assess the effectiveness of weed control of the site, because the high sorption may compromise the effectiveness of herbicides used in pre-emergence, and when little sorption can have high risk of leaching and contaminating groundwater [48, 49].

When we analyzed the relationship of depth with the phytotoxicity, a significant difference in the visual symptoms among the treatments (4, 5 and 6 g L−1 concentration of herbicide) for the 17 and 24 DAS in the 0–10 cm depth was not observed. With regard to the 31 DAS, the microparticles containing 6 g L−1 of sulfentrazone resulted in 40% of phytotoxicity symptoms followed by conventional and 4 g L−1 treatment. For the conventional treatment and the concentration of 4 g L−1 of herbicide observed at 38 DAS, a homogeneous leaching process and a high phytotoxicity rate in cucumber plants. The other two treatments at this depth were observed less leaching, while the percentage of control has been unsatisfactory according to ALAM [36].

The phytotoxicity percentage of Cucumis sativus plants submitted to treatments in the 0–10 cm deep is shown in Table 1. Means followed by different letters (a, b and/or c) in the column are statistically different according to Tukey’s test (p ≤ 0.05). The sulfentrazone leaching applied in conventional form using PVC columns for different pluviometric indices (30, 60 and 90 mm) under greenhouse conditions using Red Latosol and Chernosol were reported by Rossi et al. [51]. According to Faustino et al. [52], in the latter, there was uniformity of the distribution of the product along the column, proportional to the precipitation, and in the Red Latosol, the sulfentrazone was not very mobile, remaining in the superficial layer, independently of the precipitation.

Table 2 presents the phytotoxicity percentage of Cucumis sativus plants submitted to treatments in the 10–20 cm deep. At 17 DAS, the highest leaching observed was for conventional treatments and 5 g L−1 concentration of herbicide and no significant difference between these treatments was observed. With 24 and 31 DAS, there was no difference between the treatments. A high leaching was noticed for conventional treatments and 4 g L−1 concentration of sulfentrazone at 38 DAS; these treatments had more than 90% phytotoxification. These results are in agreement with the controlled release for the 5 g L−1 condition that presented the highest rate of release in relation to the others concentrations, which explains its greater effectiveness in the 10–20 cm. As reported by Rodrigues et al. [50] the sulfentrazone herbicide may be leached to layers with a depth greater than 10 cm in the soil profile when submitted to 20 mm irrigation during 24 h after spraying. Rossi et al. [51] evaluated the mobility of sulfentrazone in PVC columns and found a small mobility of the herbicide in Red Nitosol (up to 7.5 cm) and Quartzarenic Neosol (up to 12.5 cm) even when submitted to 90 mm of rainfall. These authors also cited that one of the factors that influenced the action of the herbicide was the soil saturation, since the higher the rainfall index, greater the intensity of injury at the plants.

As far as depths of 20–30 cm are concerned, at 17 DAS, a significant difference between the treatments was verified, and the leaching of the herbicide at this depth caused slight injuries at the plants treated with the herbicide in the conventional way, followed by the 5 g L−1 treatment. It is important to note that the other treatments (4 and 6 g L−1 concentration) did not differ. With 24 and 31 DAS, there was no differentiation between the treatments. At the end of the evaluations, at 38 DAS, it was observed that the leaching at this depth resulted in injuries in the order of 91.67% of phytointoxication in the conventional treatment, followed by the treatment of 4 g L−1 with 73.33% of phytotoxification. Table 3 presents the phytotoxicity percentage of Cucumis sativus plants submitted to treatments in the 20–30 cm deep. Faustino et al. [52] observed the mobility of sulfentrazone herbicide in 60 mm of simulated rainfall when they used Red–Yellow Latosol. The authors used sorghum as indicator plant, and the leaching process occurs at about 25 cm of depth.

At depth of 30–40 cm, at 17 and 24 DAS, there was no significant difference between the treatments. At 31 DAS, the highest phytointoxication was observed for the 4 g L−1 concentration of herbicide. At the end of the evaluations, at 38 DAS, it was verified that the conventional treatment and the 4 g L−1 were statistically equal, obtaining a phytotoxification of 91 and 78.33%, respectively. The 5 and 6 g L−1 presented lower control efficiency and consequently, lower leaching. The phytotoxicity percentage of Cucumis sativus plants submitted to treatments in the 30–40 cm deep can be observed in Table 4. According to Braga and Melo [53], the leaching is higher in Red Latosol (up to 35 cm) in depth when compared to Acrisolo, Cambisolo, and Gleisolo soils.

The evaluations referring to the last depths (40–50 cm) did not present a significant difference to the 17 DAS. With regard to the 24 DAS, the control results were 20, 18.33, and 12.67% for the 4, 5 g L−1 and conventional treatments, respectively. At 31 DAS the highest percentage of injury was caused by the 4 g L−1 concentration of herbicide. The last assessment occurred at 38 DAS, and it was observed that the conventional treatment resulted in 94.67% of phytotoxification. Table 5 shows the phytotoxicity percentage of Cucumis sativus plants submitted to treatments in the 40–50 cm.

Comparing all data one can verify that the best results were exhibited for the 4 g L−1 concentration of herbicide and conventional form in accordance with the scale of ALAM [36] at 38 DAS. It is stressed to mention that when we compared the leaching process of the conventional herbicide with the Ca-ALG microparticles containing different concentrations of sulfentrazone from the visual symptoms of intoxication the encapsulated design reduced the injuries throughout the soil profile, denoting their elution much lower. The results of leaching presented by the treatments using Ca-ALG microparticles, will allow the implementation of the technique in a large scale, enabling, correct and safe recommendations of the sulfentrazone that allows the efficiency in the control of weeds in the different soils with low environmental impact. It is worth mentioning that the encapsulation technique of herbicide on ALG microparticles is quite innovative and that there are still gaps in the literature about its behavior in soil and the environment and its efficiency in the control of weeds. Nevertheless, the Ca-ALG microparticles containing sulfentrazone herbicide are potential candidates for controlled release platforms in agricultural applications and can be effective for controlling weeds.

Conclusions

In this present work, we employed a novel green process to obtain a controlled release of sulfentrazone herbicide-encapsulated into Ca-ALG microparticles. To the best our knowledge, this is the first study concerning an effective controlled release system using the sulfentrazone herbicide encapsulated into a biodegradable polymer fashion with high prospects in agriculture area. The controlled release assays for the sulfentrazone herbicide encapsulated on the Ca-ALG microparticles in different concentrations of herbicide (4, 5 and 6 g L−1) demonstrated distinct regions and the model that most closely matches the experimental data, for the three concentrations of herbicide, was proposed by Korsmeyer–Peppas. The distinct regions presented in the release curves agree to the TG/DTA analyses that also showed the decomposition of alginate proceeds in three stages and the herbicide slightly high the thermal stability of alginate matrix. The results of leaching presented by the treatments using Ca-ALG microparticles, will allow the implementation of the technique in a large scale, enabling, correct and safe recommendations of the sulfentrazone that allows the efficiency in the control of weeds in the different soils with low environmental impact. Thus, Ca-ALG microparticles containing sulfentrazone herbicide are potential composites for controlled release platforms in agricultural applications and can be effective for controlling weeds.

References

Katz H, Mishael YG (2014) Reduced herbicide leaching by in situ adsorption of herbicide micelle formulations to soil. J Agric Food Chem 52:50–57

Singh B, Sharma DK, Kumar R et al (2009) Controlled release of the fungicide thiram from starch–alginate–clay based formulation. Appl Clay Sci 45:76–82

Nayak AK, Pal D, Santra K (2016) Swelling and drug release behavior of metformin HCl-loaded tamarind seed polysaccharide—alginate beads. Int J Biol Macromol 82:1023–1027

Nir S, Nahhal EL, Undabeytia T et al (2006) Clays and pesticides. Handb Clay Sci 1:677–691

Carter AD (2000) Herbicide movement in soils: principles, pathways and processes. Weed Res 40:113–122

Rice PJ, Anderson TA, Coats JR (2002) Degradation and persistence of metolachlor in soil: effects of concentration, soil moisture, soil depth, and sterilization. Environ Toxicol Chem 21:2640–2648

Gevao B, Semple KT, Jones KC (2000) Bound pesticide residues in soils: a review. Environ Pollut 108:3–14

Martinez CO, Souza Filho CMM, Fay EF et al (2008) The effects of moisture and temperature on the degradation sulfentrazone. Geoderma 147:56–62

Theodoridis G, Baum JS, Hotzman FW (1992) Synthesis and herbicidal properties of aryltriazolinones. A new class of pre and pos-emergence herbicide. In: Baker DR, Fenyes JG and Steffens JJ (eds) Synthesis and chemistry of agrochemicals III, ACS symposium series, pp 13115–13146

Belfry KD, Mcnaughton KE, Sikkema PH (2015) Weed control in soybean using pyroxasulfone and sulfentrazone. Can J Plant Sci 95:1199–1204

Carbonari CA, Gomes GLGC, Trindade MLB et al (2016) Dynamics of sulfentrazone applied to sugarcane crop residues. Weed Sci 64:201–206

Duart VM, Duart AM, Tramontin MT, Spannemberg R et al (2013) Controle pré-emergente de plantas daninhas em sistema de sameadura de arroz em solo seco. 2º Simpósio de Integração Científica e Tecnológica do Sul Catarinense—SICT—Sul, pp 49–54

Tanabe A, Mitobe H, Kawata K et al (2001) Seasonal and special studies on pesticides residues in surface eaters of the Shinano River in Japan. J Agric Food Chem 49:3847–3852

El BahrI Z, TaverdeT J-L (2007) Elaboration and characterisation of microparticles loaded by pesticide model. Powder Technol 172:30–40

Grillo R, Pereira AES, de Melo NFS et al (2011) Controlled release system for ametryn using polymer microspheres: preparation, characterization and release kinetics in water. J Hazard Mater 186:1645–1651

Dias FS, Queiroz DC, Nascimento RF, Lima MB (2008) Um sistema simples para preparação de microesferas de quitosana. Quim Nova 31:160–163

Shi LES, Chen M, Xinf LY, Guo XF, Zhao LM (2011) Chitosan nanoparticles as drug delivery carriers for biomedical engineering. J Chem Soc Pak 33:929–934

Faria DM (2016) Obtenção de micropartículas de alginato para liberação controlada do herbicida Tebuthiuron. Disssertação (Mestrado em Agroquímica), Instituto Federal de Educação, Ciência e Tecnologia Goiano, IF Goiano, GO, Brazil

Sociedade Brasileira da Ciência das Plantas Daninhas (1995) Procedimentos para instalação, avaliação e análise de experimentos com herbicidas. SBCPD, Londrina

Pimentel-Gomes F (1976) Curso de estatística experimental, 6th edn. Gráfica Binetti, Piracicaba, p 430

Rajamani T, Muthu S, Karabacak M (2013) Electronic absorption, vibrational spectra, nonlinear optical properties, NBO analysis and thermodynamic properties of N-(4-nitro-2-phenoxyphenyl) methanesulfonamide molecule by ab initio HF and density functional methods. Spectrochim Acta A Mol Biomol Spectrosc 108:186–196

Villafranca-Sánches M, Flores-céspedes F, Daza-Fernández et al (2011) Prevention of herbicides pollution using sorbents in controlled release formulations. In: Andreas Kortekamp (ed) Herbicides and environment, p 157–172, https://www.intechopen.com/books/herbicides-and-environment/prevention-of-herbicides-pollution-using-sorbents-in-controlled-release-formulations

Tsirigotis-Maniecka M, Roman G, Wilk KA (2016) Preparation and characterization of sodium alginate/chitosan microparticles containing esculin. Colloids Surf A Physicochem Eng Asp 510:22–32

Lacerda L, Parize AL, Fávere V et al (2014) Development of pH-sensitive sodium alginate/chitosan microparticles containing the antituberculosis drug refampicin. Mater Sci Eng C 39:161–167

Faria DM, Dourado Júnior SM, Nascimento JPL et al (2016) Development and evaluation of a controlled release system of TBH herbicide using alginate microparticles. Mat Res 20(1):225–235

Rodrigues BN, Almeida FS (2005) Guia de herbicidas, 5th edn. Londrina, Edição dos Autores, p 592

Siepmann J, Siepmann F (2006) Microparticles used as drug delivery systems. Smart Colloidal Mater 133:15–21

Huang X, Brazel CS (2001) On the importance and mechanisms of burst release in matrix-controlled drug delivery systems. J Controll Release 73:121–136

Siepmann J, Faisant N, Benoit JP (2002) A new mathematical model quantifying drug release from bio erodible microparticles using Monte Carlo simulations. Pharm Res 19:1885–1893

Siepmann J, Peppas NA (2001) Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv Drug Deliv Rev 48:139–157

Carbinatto FM, Castro AD, Evangelista RC et al (2014) Insights into the swelling process and drug release mechanisms from cross-linked pectin/high amylose starch matrices. Asian J Pharm Sci 9:27–34

Cojocaru V, Ranetti AE, Hinescu LG et al (2015) Formulation and evaluation of in vitro release kinetics of Na3CaDTPA decorporation agent embedded in microemulsion-based gel formulation for topical delivery. Farmacia 63:656–664

Suvakanta D, Padala NM, Lilakanta N et al (2010) Kinetic modeling on drug release from controlled drug delivery systems. Acta Pol Pharm Drug Res 67:217–223

Yao F, Weiyuan JK (2010) Drug release kinetics and transport mechanisms of non-degradable and degradable polymeric delivery systems. Expert Opin Drug Deliv 7:429–444

Wilson A, Blenner M, Guiseppi-Elie A (2014) Polyplex formation influences release mechanism of mono- and di-valent ions from phosphorylcholine group bearing hydrogels. Polymers 6:2451–2472

ASOCIACIÓN LATINOAMERICANA DE MALEZAS—ALAM (1974) Recomendaciones sobre unificación de los sistemas de evaluación en ensayos de control de malezas. ALAM 1(1):35–38

Barberis LRM, Trindade MLB, Velini ED (2009) Seleção de genótipos de cana-de-açúcar para acúmulo de protoporfirina IX com uso de herbicidas inibidores da protox. Planta Daninha 27:809–814

Ferreira FA, Silva AA, Ferreira LR (2005). Mecanismos de ação de herbicidas. In: Congresso Brasileiro do Algodão, p 5, Salvador. Algodão, uma fibra natural: Anais... Campina Grande: Embrapa Algodão, 2005. 1 CD-ROM

Roman ES, Beckie H, Vargas L, Hall L et al (2007) Berthier: Como funcionam os herbicidas: Da biologia à aplicação, Passo Fundo, p 159

Takahashi EM, Alves LCA, Salgado TP et al (2009) Consequências da deriva de clomazone e sulfentrazone em clones de E. Grandis × E. Urophylla. Rev Árvore 33:675–683

Oliveira Júnior RS, Constantin J, Inou MH (2011) Biologia e manejo de plantas daninhas, Omnipax, pp 263–304

Sprankle P, Meggitt WF, Penner D (1975) Adsorption, mobility, and microbial degradation of glyphosate in the soil. Weed Sci 23:229–234

Mandhun YA, Young JL, Freed VH (1986) Binding of herbicides by water-soluble organic materials from soil. J Environ Qual 15:64–68

Senesi N, Brunetti G, La Cava P (1994) Adsorption of alachlor by humic acids from sewage and amended and nonamended soils. Soil Sci 157:176–184

Nicholls PH (1988) Factors influencing entry of pesticides into soil water. Pest Sci 22:123–137

Monqueiro PA, Silva AC, Binha DP et al (2008) Mobilidade e persistência de herbicidas aplicados em pré-emergência em diferentes solos. Planta Daninha 26:411–417

Freitas MAM, Passos ABRJ, Torres LG et al (2014) Sulfentrazone sorption in different types of soil by bioassays. Planta Daninha 32:385–392

Oliveira RS, Koskinen WC, Ferreira FA (2002) Sorption and leachig potential of herbicides on Brazilian soils. Weed Res 41:97–110

Silva MRA, Trovó AG, Nogueira RFP (2007) Degradation of the herbicide tebuthiuron using solar photo-Fenton process and ferric citrate complex at circumneutral pH. J Photochem Photobiol A 191:187–192

Rodrigues BN, Lima J, Yada IFU et al (1999) Influência da cobertura morta no comportamento do herbicida sulfentrazone. Planta Daninha 17:445–458

Rossi CVS, Alves PLCA, Marques Júnior J (2005) Mobilidade do sulfentrazone em Latossolo Vermelho e em Chernossolo. Planta Daninha 23:701–710

Faustino LA, Freitas MAM, Passos ABRJ et al (2016) Mobility of sulfentrazone in soils with different physical and chemical characteristics. Planta Daninha 33:795–802

Braga DF, Melo VC (2016) Leaching of sulfentrazone in soils from the sugarcane region in the northeast region of Brazil. Planta Daninha 34:161–169

Acknowledgements

The authors gratefully acknowledge Laboratory of Plasma Technology/LaPTec—State University of São Paulo—UNESP, Federal University of Mato Grosso—UFMT for providing the laboratories facilities, FAPEG and FAPEMIG. The research was financially supported by CAPES and CNPq.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dourado Junior, S.M., Nunes, E.S., Marques, R.P. et al. Controlled release behavior of sulfentrazone herbicide encapsulated in Ca-ALG microparticles: preparation, characterization, mathematical modeling and release tests in field trial weed control. J Mater Sci 52, 9491–9507 (2017). https://doi.org/10.1007/s10853-017-1103-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1103-9